Work to mate RWD VQ with FWD drivetrain

#1

Work to mate RWD VQ with FWD drivetrain

Greetings. First post here, but I've been in the Nissan fold for a while - currently have an SR20VET powered S13 track car. Appreciate any insight that you guys have, as I know RWD Nissans much better than I know FWD ones.

Short story - what are the pitfalls of using a RWD VQ with a FWD VQ 6 speed manual? I'm thinking of putting a RWD VQ in a mid-engine kit car that looks like this:

Long story: The car is designed around using a common FWD drivetrain, swapped into the middle of a lightweight kit car that's designed around the idea of a Lotus Seven/Locost. The engine would be kept NA ideally, and it'd either be a VQ37VHR or VQ35HR if I went with the RWD block obviously.

I'd honestly want somewhere in the 360-380 rwhp range, which will be a huge stretch and a lot of work on either of the above, and probably impossible to hit with a 7g Maxima engine due to the bottom end stability at higher revs. The VQ37VHR honestly sounds like the best bet, and I could offset grind the crank with narrowed 1UZFE rods and get 4L of displacement, which would make that power figure much more attainable. The 35HR could get pushed to 3.7L with the stock crank, or find a VQ37 crank. The 7G Maxima VQ could get pushed out to 3.7 with 2JZGTE rods and offset grinding the crank (did you guys know this? didn't see it mentioned with searching). But I still don't think it'd like over 7500 RPM much, so it won't get me to that power figure. A stroked VQ37VHR would likely be 30-40 rwhp up on the FWD VQ due to easily turning 8k RPM and having ~8% more displacement.

Preface before telling me to reach the RWD vs. FWD sticky :

:

I know the mounts are very different on a RWD vs. FWD VQ, but that wouldn't matter to me since I'd be building the chassis from scratch and putting the mounts where ever they need to go. Same with transmission bellhousing (would have to make an adapter, which is a pain, but not entirely possible - just money).

Known issues that I could work around:

1. Need to use RWD VQ headers (easy enough, probably better than trying to go under the oil pan obviously, I could go over the transmission on the front side).

2. Adapter plate for transmission to bolt to RWD VQ HR block

3. Looks like there's no provisions for a mount on the timing chain cover, but I'm sure I can build something that would pick up off one side of the engine and going forward to stabilize the engine in that direction.

Potential problems that I'm not 100% sure on:

4. Starter mounting? Does this bolt to the 6 speed FWD 6 speed, or do the bolts go from the bellhousing into the starter?

5. Will the starter on the RWD VQ HR block be in the right location to pick up on a flywheel that fits in the FWD 6 speed bellhousing? Would I be looking at using an HR flywheel (most likely to work, might not fit?), or a flywheel from a FWD VQ? I know Nissan likes to go with smaller flywheels on FWD stuff, so that's why I'm worried about it, but I can't find any real info on starter ring gear diameters.

6. Passenger/long axle mounting to the block. I'm sure I can fab something up if the mounting bosses aren't on the block (unlikely), but if there aren't mounting bosses in that general location, it could be a pain, not too worried about this, but it's hard to know what the deal is.

Short story - what are the pitfalls of using a RWD VQ with a FWD VQ 6 speed manual? I'm thinking of putting a RWD VQ in a mid-engine kit car that looks like this:

Long story: The car is designed around using a common FWD drivetrain, swapped into the middle of a lightweight kit car that's designed around the idea of a Lotus Seven/Locost. The engine would be kept NA ideally, and it'd either be a VQ37VHR or VQ35HR if I went with the RWD block obviously.

I'd honestly want somewhere in the 360-380 rwhp range, which will be a huge stretch and a lot of work on either of the above, and probably impossible to hit with a 7g Maxima engine due to the bottom end stability at higher revs. The VQ37VHR honestly sounds like the best bet, and I could offset grind the crank with narrowed 1UZFE rods and get 4L of displacement, which would make that power figure much more attainable. The 35HR could get pushed to 3.7L with the stock crank, or find a VQ37 crank. The 7G Maxima VQ could get pushed out to 3.7 with 2JZGTE rods and offset grinding the crank (did you guys know this? didn't see it mentioned with searching). But I still don't think it'd like over 7500 RPM much, so it won't get me to that power figure. A stroked VQ37VHR would likely be 30-40 rwhp up on the FWD VQ due to easily turning 8k RPM and having ~8% more displacement.

Preface before telling me to reach the RWD vs. FWD sticky

:

:I know the mounts are very different on a RWD vs. FWD VQ, but that wouldn't matter to me since I'd be building the chassis from scratch and putting the mounts where ever they need to go. Same with transmission bellhousing (would have to make an adapter, which is a pain, but not entirely possible - just money).

Known issues that I could work around:

1. Need to use RWD VQ headers (easy enough, probably better than trying to go under the oil pan obviously, I could go over the transmission on the front side).

2. Adapter plate for transmission to bolt to RWD VQ HR block

3. Looks like there's no provisions for a mount on the timing chain cover, but I'm sure I can build something that would pick up off one side of the engine and going forward to stabilize the engine in that direction.

Potential problems that I'm not 100% sure on:

4. Starter mounting? Does this bolt to the 6 speed FWD 6 speed, or do the bolts go from the bellhousing into the starter?

5. Will the starter on the RWD VQ HR block be in the right location to pick up on a flywheel that fits in the FWD 6 speed bellhousing? Would I be looking at using an HR flywheel (most likely to work, might not fit?), or a flywheel from a FWD VQ? I know Nissan likes to go with smaller flywheels on FWD stuff, so that's why I'm worried about it, but I can't find any real info on starter ring gear diameters.

6. Passenger/long axle mounting to the block. I'm sure I can fab something up if the mounting bosses aren't on the block (unlikely), but if there aren't mounting bosses in that general location, it could be a pain, not too worried about this, but it's hard to know what the deal is.

#2

I've been totaling up how much work I think it'll be to build this, and the thought of spending a couple hundred hours messing around with a bunch of custom crap to make the engine work doesn't sound very appealing.

So I'm more leaning towards the 7g Maxima engine.

Since revs are somewhat limited on this engine, I'm still thinking of offset grinding the crank to stroke it to 3.7L. It'd have 142 mm rods, and a rod/stroke ratio of 1.65 vs. 1.77 stock. That shouldn't really impact things too much up top since it's still not a "bad" ratio. Compression should bump up to roughly 11.1-11.2 with stock pistons.

Getting to the simple question - with some aftermarket rods and stock pistons, what sort of "safe" rev limiter do you think the 7G Maxima engine could stand up to for track driving? I'm hoping 7600-7800 RPM, which could probably be enough with 3.7L to get me in the 330-340 whp range with some work.

It'd have cams and valve springs, so the head should be fine. I can't find any info on the oil pump, but it's much cheaper than the VQ35DE rev up pump, so I'm thinking it'd have to have a rev up pump.

Anything sound off with this plan?

So I'm more leaning towards the 7g Maxima engine.

Since revs are somewhat limited on this engine, I'm still thinking of offset grinding the crank to stroke it to 3.7L. It'd have 142 mm rods, and a rod/stroke ratio of 1.65 vs. 1.77 stock. That shouldn't really impact things too much up top since it's still not a "bad" ratio. Compression should bump up to roughly 11.1-11.2 with stock pistons.

Getting to the simple question - with some aftermarket rods and stock pistons, what sort of "safe" rev limiter do you think the 7G Maxima engine could stand up to for track driving? I'm hoping 7600-7800 RPM, which could probably be enough with 3.7L to get me in the 330-340 whp range with some work.

It'd have cams and valve springs, so the head should be fine. I can't find any info on the oil pump, but it's much cheaper than the VQ35DE rev up pump, so I'm thinking it'd have to have a rev up pump.

Anything sound off with this plan?

#3

I think it will be much easier to mate the 7G engine to the FWD 6mt, than the HR, even if it wont make quite as much power as the worked 3.7. I can't quite speak for your engine build plans but I've 'heard' that the 7G oil pump only good to 7200 rpm like the previous DE, but never seen any data to back up that claim.

One thread I'd suggest checking out is this one: https://maxima.org/forums/nitrous/61...out-doing.html

Probably about half way through, the thread goes from direct port nitrous to monster 7G 3.5 build.

One thread I'd suggest checking out is this one: https://maxima.org/forums/nitrous/61...out-doing.html

Probably about half way through, the thread goes from direct port nitrous to monster 7G 3.5 build.

#4

Thanks for the reply... was beginning to think I was just going to hear crickets.

I assume I can just pop in a DE rev up oil pump to get the revs up to the 7500-7600 RPM range.

I agree with you that the 7G Maxima engine will take a ton of work off my plate. It won't make as much power as a worked over VQ37VHR, but ya can't have it all and do it all yourself.

I can offset grind the VQ35DE crank to make it a 3.7, which will be needed if I'm only spinning it to 7500-7600 RPM. Plus then I'll have aftermarket rods so I won't be worried about the stock DE rods letting loose.

You guys are into budget builds (which I'm all about), has anybody ever replaced rods and reused the factory piston and rings in the same bore? I assume any 7G engine I get will be pretty low miles, so I can't see any reason why the same piston and rings in the same bore would have an issue. They move all around in operation, so as long as I index them to the factory alignment, should work just fine since they won't have to really "reseat?" I could dingleball hone it really quickly and toss in a new set of rings, but I'll admit I've never used a dingleball hone before.

Any other bits to replace inside a 7G for higher revs besides the oil pump and rods?

I was looking at some dynos, and I think if I can get enough intake flow and the right header primary length, I could reasonably make 330 to maybe 340 rwhp with careful tuning. That'll be enough for me in a 1600-1700 lb car I think.

I assume I can just pop in a DE rev up oil pump to get the revs up to the 7500-7600 RPM range.

I agree with you that the 7G Maxima engine will take a ton of work off my plate. It won't make as much power as a worked over VQ37VHR, but ya can't have it all and do it all yourself.

I can offset grind the VQ35DE crank to make it a 3.7, which will be needed if I'm only spinning it to 7500-7600 RPM. Plus then I'll have aftermarket rods so I won't be worried about the stock DE rods letting loose.

You guys are into budget builds (which I'm all about), has anybody ever replaced rods and reused the factory piston and rings in the same bore? I assume any 7G engine I get will be pretty low miles, so I can't see any reason why the same piston and rings in the same bore would have an issue. They move all around in operation, so as long as I index them to the factory alignment, should work just fine since they won't have to really "reseat?" I could dingleball hone it really quickly and toss in a new set of rings, but I'll admit I've never used a dingleball hone before.

Any other bits to replace inside a 7G for higher revs besides the oil pump and rods?

I was looking at some dynos, and I think if I can get enough intake flow and the right header primary length, I could reasonably make 330 to maybe 340 rwhp with careful tuning. That'll be enough for me in a 1600-1700 lb car I think.

#6

Yup, a DE Rev up pump will bolt right in.

Again, I haven't seen any data on the 7G rod bolts, but it might be a good idea to go with some aftermarket rod bolts while you're in there. I'd like to see what you come up with for the headers. I've been kicking around the idea of a mid engine VQ lately.

Well, which ECU will you be using?

Since there is no official FWD HR, I refer to the 7G engine as Gen II, and the earlier counterparts Gen I.

2009+ Maxima 290hp (VTC Intake & Exhaust, Larger plenum and 75mmTB)= Gen II

2007+ Altima 270hp (VTC Intake, Smaller plenum and 70mmTB)= Gen II

The 270hp Gen II was also used in later Murano and Quest, but I'm not sure of the years it was implemented in those vehicles.

All other older FWD 3.5 are Gen I.

RWD DE is Gen I.

The Gen I and Gen II use different style signal plates for the crank sensor.

A Gen I 6MT flywheel can be used on a Gen II engine.

Gen I FWD and RWD flywheels are interchangeable, BUT the crank sensor will need to be shifted 7.5mm towards the transmission, and the two flywheels are clocked differently on the crank.

Long story short - which ECU will you be using?

Again, I haven't seen any data on the 7G rod bolts, but it might be a good idea to go with some aftermarket rod bolts while you're in there. I'd like to see what you come up with for the headers. I've been kicking around the idea of a mid engine VQ lately.

Well, which ECU will you be using?

Since there is no official FWD HR, I refer to the 7G engine as Gen II, and the earlier counterparts Gen I.

2009+ Maxima 290hp (VTC Intake & Exhaust, Larger plenum and 75mmTB)= Gen II

2007+ Altima 270hp (VTC Intake, Smaller plenum and 70mmTB)= Gen II

The 270hp Gen II was also used in later Murano and Quest, but I'm not sure of the years it was implemented in those vehicles.

All other older FWD 3.5 are Gen I.

RWD DE is Gen I.

The Gen I and Gen II use different style signal plates for the crank sensor.

A Gen I 6MT flywheel can be used on a Gen II engine.

Gen I FWD and RWD flywheels are interchangeable, BUT the crank sensor will need to be shifted 7.5mm towards the transmission, and the two flywheels are clocked differently on the crank.

Long story short - which ECU will you be using?

#7

Nice thread here. I was just getting ready to come in and start flaming lol.

So what you want is possible and very easy to reach your goal the real question becomes what does your wallet think about all this. You have a ~380whp goal, and want to use a VQ how much money can you sacrifice to this goal.

VQs are like legos most parts mix and match so anything you can really think of will likely work. The only worry i would have is once those power numbers start climbing how much HP will our little gearbox hold. They have been generally reliable up to around 450hp but your pushing it. See what VQ swapped S13/14s were doing about starters for the people using the FWD blocks. I dont think anything changed really just mount it in the oem transmission location. The flywheel will be the determining factor there so as long as your flywheel/transmission/start all match should not be a problem.

Do not bother trying to mate old OEM toyota parts to a nissan engine just go get the parts fresh especially for a build of this caliber. there are already kits available that will reliably make the power. USE THEM. If you want a 2JZ, 1UZ or what have you rods piston cranks just use that entire engine. The philosophy behind the VQ is low down grunt and a punchy mid range, that required a flat torque curve. Its a torquey engine. In order to get the motor to rev freely and fluidly Nissan made the rotating assembly lightweight, as light as the could possibly make them, and unfortunately the strength to handle the stresses of boost were sacrificed. That's the reality.

However getting back to what you are looking for. What kind of power band do you want? Do you want a high revving peaky engine like a BMW M motor something of that nature(if you do stop here find another engine lol) or a motor with power everywhere in the power band like an LS1/2/3 etc? Just saying 380whp yea that's nice but peak power is not everything. So specify a little more what you actually want, such as is the goal of this car just to be fun on the street or are you going to compete in it?

In the FWD blocks the weak points in them as far as high RPM is concerned is the Oil pump and valve springs, replacing them with the rev-up pump and either 350Z HR valve springs or aftermarket address this weakness. This will get you up to 7500rpm safely. Anything higher and then you will have to start looking at more expensive oil pumps and rotating assembly parts. Most of us do not bother doing that, too much money and not enough gain over going with some form of boost.

In your case this is what i would do if keeping NA is a must. Start with an VQ35HR block. Look into the 4.1 stroker kit for the 3.5L, with the 11.0:1 or 11.5:1 compression, get a set of high lift cams. As long as your Duration is +260* your all set just where do you want your powerband is the question you have to answer. the intake manifold i would either go with a ITB setup or use the R35 GTR manifold. With a solid standalone tuner like a haltech. regardless if you have a FWD or RWD block that should be a 380-400whp capable motor NA.

A cheaper option would be to buy a standard 3.5L out of the 350Z leave it completely stock, just add some bigger injectors and slap a supercharger on it. That will easily get you to 380whp with out much of any fuss and totally reliably.

So what you want is possible and very easy to reach your goal the real question becomes what does your wallet think about all this. You have a ~380whp goal, and want to use a VQ how much money can you sacrifice to this goal.

VQs are like legos most parts mix and match so anything you can really think of will likely work. The only worry i would have is once those power numbers start climbing how much HP will our little gearbox hold. They have been generally reliable up to around 450hp but your pushing it. See what VQ swapped S13/14s were doing about starters for the people using the FWD blocks. I dont think anything changed really just mount it in the oem transmission location. The flywheel will be the determining factor there so as long as your flywheel/transmission/start all match should not be a problem.

Do not bother trying to mate old OEM toyota parts to a nissan engine just go get the parts fresh especially for a build of this caliber. there are already kits available that will reliably make the power. USE THEM. If you want a 2JZ, 1UZ or what have you rods piston cranks just use that entire engine. The philosophy behind the VQ is low down grunt and a punchy mid range, that required a flat torque curve. Its a torquey engine. In order to get the motor to rev freely and fluidly Nissan made the rotating assembly lightweight, as light as the could possibly make them, and unfortunately the strength to handle the stresses of boost were sacrificed. That's the reality.

However getting back to what you are looking for. What kind of power band do you want? Do you want a high revving peaky engine like a BMW M motor something of that nature(if you do stop here find another engine lol) or a motor with power everywhere in the power band like an LS1/2/3 etc? Just saying 380whp yea that's nice but peak power is not everything. So specify a little more what you actually want, such as is the goal of this car just to be fun on the street or are you going to compete in it?

In the FWD blocks the weak points in them as far as high RPM is concerned is the Oil pump and valve springs, replacing them with the rev-up pump and either 350Z HR valve springs or aftermarket address this weakness. This will get you up to 7500rpm safely. Anything higher and then you will have to start looking at more expensive oil pumps and rotating assembly parts. Most of us do not bother doing that, too much money and not enough gain over going with some form of boost.

In your case this is what i would do if keeping NA is a must. Start with an VQ35HR block. Look into the 4.1 stroker kit for the 3.5L, with the 11.0:1 or 11.5:1 compression, get a set of high lift cams. As long as your Duration is +260* your all set just where do you want your powerband is the question you have to answer. the intake manifold i would either go with a ITB setup or use the R35 GTR manifold. With a solid standalone tuner like a haltech. regardless if you have a FWD or RWD block that should be a 380-400whp capable motor NA.

A cheaper option would be to buy a standard 3.5L out of the 350Z leave it completely stock, just add some bigger injectors and slap a supercharger on it. That will easily get you to 380whp with out much of any fuss and totally reliably.

#8

Yup, a DE Rev up pump will bolt right in.

Again, I haven't seen any data on the 7G rod bolts, but it might be a good idea to go with some aftermarket rod bolts while you're in there. I'd like to see what you come up with for the headers. I've been kicking around the idea of a mid engine VQ lately.

Well, which ECU will you be using?

Since there is no official FWD HR, I refer to the 7G engine as Gen II, and the earlier counterparts Gen I.

2009+ Maxima 290hp (VTC Intake & Exhaust, Larger plenum and 75mmTB)= Gen II

2007+ Altima 270hp (VTC Intake, Smaller plenum and 70mmTB)= Gen II

The 270hp Gen II was also used in later Murano and Quest, but I'm not sure of the years it was implemented in those vehicles.

All other older FWD 3.5 are Gen I.

RWD DE is Gen I.

The Gen I and Gen II use different style signal plates for the crank sensor.

A Gen I 6MT flywheel can be used on a Gen II engine.

Gen I FWD and RWD flywheels are interchangeable, BUT the crank sensor will need to be shifted 7.5mm towards the transmission, and the two flywheels are clocked differently on the crank.

Long story short - which ECU will you be using?

Again, I haven't seen any data on the 7G rod bolts, but it might be a good idea to go with some aftermarket rod bolts while you're in there. I'd like to see what you come up with for the headers. I've been kicking around the idea of a mid engine VQ lately.

Well, which ECU will you be using?

Since there is no official FWD HR, I refer to the 7G engine as Gen II, and the earlier counterparts Gen I.

2009+ Maxima 290hp (VTC Intake & Exhaust, Larger plenum and 75mmTB)= Gen II

2007+ Altima 270hp (VTC Intake, Smaller plenum and 70mmTB)= Gen II

The 270hp Gen II was also used in later Murano and Quest, but I'm not sure of the years it was implemented in those vehicles.

All other older FWD 3.5 are Gen I.

RWD DE is Gen I.

The Gen I and Gen II use different style signal plates for the crank sensor.

A Gen I 6MT flywheel can be used on a Gen II engine.

Gen I FWD and RWD flywheels are interchangeable, BUT the crank sensor will need to be shifted 7.5mm towards the transmission, and the two flywheels are clocked differently on the crank.

Long story short - which ECU will you be using?

Nice thread here. I was just getting ready to come in and start flaming lol.

So what you want is possible and very easy to reach your goal the real question becomes what does your wallet think about all this. You have a ~380whp goal, and want to use a VQ how much money can you sacrifice to this goal.

VQs are like legos most parts mix and match so anything you can really think of will likely work. The only worry i would have is once those power numbers start climbing how much HP will our little gearbox hold. They have been generally reliable up to around 450hp but your pushing it. See what VQ swapped S13/14s were doing about starters for the people using the FWD blocks. I dont think anything changed really just mount it in the oem transmission location. The flywheel will be the determining factor there so as long as your flywheel/transmission/start all match should not be a problem.

Do not bother trying to mate old OEM toyota parts to a nissan engine just go get the parts fresh especially for a build of this caliber. there are already kits available that will reliably make the power. USE THEM. If you want a 2JZ, 1UZ or what have you rods piston cranks just use that entire engine. The philosophy behind the VQ is low down grunt and a punchy mid range, that required a flat torque curve. Its a torquey engine. In order to get the motor to rev freely and fluidly Nissan made the rotating assembly lightweight, as light as the could possibly make them, and unfortunately the strength to handle the stresses of boost were sacrificed. That's the reality.

However getting back to what you are looking for. What kind of power band do you want? Do you want a high revving peaky engine like a BMW M motor something of that nature(if you do stop here find another engine lol) or a motor with power everywhere in the power band like an LS1/2/3 etc? Just saying 380whp yea that's nice but peak power is not everything. So specify a little more what you actually want, such as is the goal of this car just to be fun on the street or are you going to compete in it?

In the FWD blocks the weak points in them as far as high RPM is concerned is the Oil pump and valve springs, replacing them with the rev-up pump and either 350Z HR valve springs or aftermarket address this weakness. This will get you up to 7500rpm safely. Anything higher and then you will have to start looking at more expensive oil pumps and rotating assembly parts. Most of us do not bother doing that, too much money and not enough gain over going with some form of boost.

In your case this is what i would do if keeping NA is a must. Start with an VQ35HR block. Look into the 4.1 stroker kit for the 3.5L, with the 11.0:1 or 11.5:1 compression, get a set of high lift cams. As long as your Duration is +260* your all set just where do you want your powerband is the question you have to answer. the intake manifold i would either go with a ITB setup or use the R35 GTR manifold. With a solid standalone tuner like a haltech. regardless if you have a FWD or RWD block that should be a 380-400whp capable motor NA.

A cheaper option would be to buy a standard 3.5L out of the 350Z leave it completely stock, just add some bigger injectors and slap a supercharger on it. That will easily get you to 380whp with out much of any fuss and totally reliably.

So what you want is possible and very easy to reach your goal the real question becomes what does your wallet think about all this. You have a ~380whp goal, and want to use a VQ how much money can you sacrifice to this goal.

VQs are like legos most parts mix and match so anything you can really think of will likely work. The only worry i would have is once those power numbers start climbing how much HP will our little gearbox hold. They have been generally reliable up to around 450hp but your pushing it. See what VQ swapped S13/14s were doing about starters for the people using the FWD blocks. I dont think anything changed really just mount it in the oem transmission location. The flywheel will be the determining factor there so as long as your flywheel/transmission/start all match should not be a problem.

Do not bother trying to mate old OEM toyota parts to a nissan engine just go get the parts fresh especially for a build of this caliber. there are already kits available that will reliably make the power. USE THEM. If you want a 2JZ, 1UZ or what have you rods piston cranks just use that entire engine. The philosophy behind the VQ is low down grunt and a punchy mid range, that required a flat torque curve. Its a torquey engine. In order to get the motor to rev freely and fluidly Nissan made the rotating assembly lightweight, as light as the could possibly make them, and unfortunately the strength to handle the stresses of boost were sacrificed. That's the reality.

However getting back to what you are looking for. What kind of power band do you want? Do you want a high revving peaky engine like a BMW M motor something of that nature(if you do stop here find another engine lol) or a motor with power everywhere in the power band like an LS1/2/3 etc? Just saying 380whp yea that's nice but peak power is not everything. So specify a little more what you actually want, such as is the goal of this car just to be fun on the street or are you going to compete in it?

In the FWD blocks the weak points in them as far as high RPM is concerned is the Oil pump and valve springs, replacing them with the rev-up pump and either 350Z HR valve springs or aftermarket address this weakness. This will get you up to 7500rpm safely. Anything higher and then you will have to start looking at more expensive oil pumps and rotating assembly parts. Most of us do not bother doing that, too much money and not enough gain over going with some form of boost.

In your case this is what i would do if keeping NA is a must. Start with an VQ35HR block. Look into the 4.1 stroker kit for the 3.5L, with the 11.0:1 or 11.5:1 compression, get a set of high lift cams. As long as your Duration is +260* your all set just where do you want your powerband is the question you have to answer. the intake manifold i would either go with a ITB setup or use the R35 GTR manifold. With a solid standalone tuner like a haltech. regardless if you have a FWD or RWD block that should be a 380-400whp capable motor NA.

A cheaper option would be to buy a standard 3.5L out of the 350Z leave it completely stock, just add some bigger injectors and slap a supercharger on it. That will easily get you to 380whp with out much of any fuss and totally reliably.

I'm familiar with the VQ, I owned a G35 Coupe with a VQ35DE Rev up in it. The main advantage is a fairly compact 6 cylinder that can make over 300 rwhp (to some level), and has a readily available manual trans with an LSD that's ok for track usage stock.

Thinking it over, I know an HR block can make more power, but it just isn't worth all the headache on the build at this point to integrate it into the vehicle. Too much scope creep for maybe 30-40 rwhp more capability all things being equal.

What I want out of the engine - a broad powerband is good, and I like'd to make around 4.5 lbs/rwhp, or about 4 lbs/BHP. That should make it properly crazy on track, and I want to keep it NA. Low end power won't mean much to me, as the car will weigh <1700 lbs wet, so I figure I want a reasonable 4-7.5k RPM powerband preferably.

I already have a near 500 rwhp turbo SR20 with a VE head, SR16VE N1 cams, Full-Race twin scroll manifold, Borg Warner EFR 7163, twin disk Tilton 7.25" clutch yada yada. I've already done the turbo thing, so I do want to do the NA build thing. If the engine meets my desire to scare myself on track without a ton of work, all the better. But I like to fiddle, so I see myself wanting an honest 350-360 rwhp someday. Not sure a FWD DE block of any gen can really do that NA, but I'll probably fiddle enough to try it.

I could do ARP rod bolts on stock rods, but at that point, I'm pretty damn close to a set of Eagles. Then it's not too much cash to offset grind the crank and just use 2JZ Eagles. That does require opening up the engine, but it shouldn't be too bad to just pull the engine apart and put all new gaskets and whatnot in it, then at least I'm not gambling with finishing a track weekend with a rev limiter around 7500-7600 RPM (would probably shift around 7200-7400 RPM). The engine will be out, so it's just a matter of a few extra hours of wrenching.

I'm pretty sure I can reuse the rings in existing bores since it's a low mileage engine, but it's hard to find much real info on it since most people are opening up an engine that's beat to crap and they're obviously rebuilding it and needing a hone (at the very minimum) with new rings.

#9

BTW - the creator of that specific build of Locost (DIY version of 1960ish Lotus Seven) chose a turbo Honda K24. I see why he chose it, as he's never had a turbo engine before (I did the same thing choosing my S13), but I don't think an NA K24 would meet my needs, and I'm pretty sure a K24 drivetrain is only about 30-40 lbs lighter than the VQ35 drivetrain. Don't get me wrong, that's pretty huge in a <1700 lb car (could be as light as 1500-1600 lbs, hard to tell until you build it and pay the piper on the scales), but I think the VQ35 is a much more flexible package and is not going to be near as stressed at a probable 320-340 rwhp vs. a 300 rwhp 9k RPM screamer of a K24 with greater than F1 piston speeds. Those Honda "drag race builds" never seem to hold up at the track for obvious reasons. Either start using a ton of oil due to bore wear, or just blow the F up!

So that's why I'm really drawn to the VQ35 package. Plus I'm an older Nissan kinda guy if I have my choices.

So that's why I'm really drawn to the VQ35 package. Plus I'm an older Nissan kinda guy if I have my choices.

#10

I see the 8G Maxima is rated at 300 HP, but still looks to have about the same upper intake manifold as the 7G.

Any ideas on what really changed between the two? I just see vague marketing talk of "60% new" with no real talk of what changed. The compression ratio is the same, and the only obvious difference is it seems they threw a bit more duration on the intake cam (256/240). So probably not worth thinking about right?

Any ideas on what really changed between the two? I just see vague marketing talk of "60% new" with no real talk of what changed. The compression ratio is the same, and the only obvious difference is it seems they threw a bit more duration on the intake cam (256/240). So probably not worth thinking about right?

#11

Money. How much are you looking to spend on an engine? Because this VQ route is going to get expensive. It might be cheaper and more suited to your needs to start with a bigger more powerful motor. V8s are available if you like the VQ then the VK is right up your ally as its a VQ with 2 extra cylinders. That will make the 380whp your looking for pretty much unopened.

I honestly do not get what is difficult about using the HR block if you are starting from scratch. It will be just as difficult as any other VQ engine. In the end you will wish you would have started with it in the first place.

But the using 2JZ rods, that's really just making things more difficult than it has to be. It is honestly completely unnecessary. You can bolt the VQ40 rods and crank into the 3.5L block, IIRC that makes a 3.8L or you can just start with a VQ40 if you want more displacement. The heads are the same as the VQ35 so plenty of options to play with. Thats why I'm saying forget about using toyota parts just no point of doing that. You will go through all that trouble trying to mate the parts to a Nissan crank when there are already parts available for the motor in the first place.

The thing about the rod bolts is i have never heard of a Rod bolt failure. of course we look at them and say "ZOMG THEY ARE SO SMALL!!!" However they do not fail, its just we as people who tune the motors see them and become uncomfortable with how small they are vs other motors. i can understand they discomfort but its just something you do to make you feel better.

And the K series is a very stout motor. The drag builds are pushing the limits of the motor period however street built NA K24s on pump gas will make +300whp for days. Strength is not a problem with those motors. It might be the better choice over the VQ in this application with the car in question being so light. You should do some more research on them before saying they do not hold up.

I honestly do not get what is difficult about using the HR block if you are starting from scratch. It will be just as difficult as any other VQ engine. In the end you will wish you would have started with it in the first place.

But the using 2JZ rods, that's really just making things more difficult than it has to be. It is honestly completely unnecessary. You can bolt the VQ40 rods and crank into the 3.5L block, IIRC that makes a 3.8L or you can just start with a VQ40 if you want more displacement. The heads are the same as the VQ35 so plenty of options to play with. Thats why I'm saying forget about using toyota parts just no point of doing that. You will go through all that trouble trying to mate the parts to a Nissan crank when there are already parts available for the motor in the first place.

The thing about the rod bolts is i have never heard of a Rod bolt failure. of course we look at them and say "ZOMG THEY ARE SO SMALL!!!" However they do not fail, its just we as people who tune the motors see them and become uncomfortable with how small they are vs other motors. i can understand they discomfort but its just something you do to make you feel better.

And the K series is a very stout motor. The drag builds are pushing the limits of the motor period however street built NA K24s on pump gas will make +300whp for days. Strength is not a problem with those motors. It might be the better choice over the VQ in this application with the car in question being so light. You should do some more research on them before saying they do not hold up.

#12

as far as no 3.5L doing close to 380whp, this is a 372whp DE block:

they also made +370whp

But the money it took to get to that level is quite enormous. That's serious head work, cams, rods&pistons, nismo oil pump, ITBs, tuning its money. And lots of it. Im quite sure this is what you are after however will your wallet support it? Otherwise all of this is just pipe dreams. Something like a set of ITBs can be upwards of $3,000 for a VQ so im really curious to how serious you are with wanting a VQ to make that kind of power NA given your not in a race class that is limiting the displacement you can run or something of that nature.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

they also made +370whp

But the money it took to get to that level is quite enormous. That's serious head work, cams, rods&pistons, nismo oil pump, ITBs, tuning its money. And lots of it. Im quite sure this is what you are after however will your wallet support it? Otherwise all of this is just pipe dreams. Something like a set of ITBs can be upwards of $3,000 for a VQ so im really curious to how serious you are with wanting a VQ to make that kind of power NA given your not in a race class that is limiting the displacement you can run or something of that nature.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

Last edited by Crusher103; 01-08-2017 at 05:43 AM.

#13

Money. How much are you looking to spend on an engine? Because this VQ route is going to get expensive. It might be cheaper and more suited to your needs to start with a bigger more powerful motor. V8s are available if you like the VQ then the VK is right up your ally as its a VQ with 2 extra cylinders. That will make the 380whp your looking for pretty much unopened.

I honestly do not get what is difficult about using the HR block if you are starting from scratch. It will be just as difficult as any other VQ engine. In the end you will wish you would have started with it in the first place.

But the using 2JZ rods, that's really just making things more difficult than it has to be. It is honestly completely unnecessary. You can bolt the VQ40 rods and crank into the 3.5L block, IIRC that makes a 3.8L or you can just start with a VQ40 if you want more displacement. The heads are the same as the VQ35 so plenty of options to play with. Thats why I'm saying forget about using toyota parts just no point of doing that. You will go through all that trouble trying to mate the parts to a Nissan crank when there are already parts available for the motor in the first place.

The thing about the rod bolts is i have never heard of a Rod bolt failure. of course we look at them and say "ZOMG THEY ARE SO SMALL!!!" However they do not fail, its just we as people who tune the motors see them and become uncomfortable with how small they are vs other motors. i can understand they discomfort but its just something you do to make you feel better.

And the K series is a very stout motor. The drag builds are pushing the limits of the motor period however street built NA K24s on pump gas will make +300whp for days. Strength is not a problem with those motors. It might be the better choice over the VQ in this application with the car in question being so light. You should do some more research on them before saying they do not hold up.

I honestly do not get what is difficult about using the HR block if you are starting from scratch. It will be just as difficult as any other VQ engine. In the end you will wish you would have started with it in the first place.

But the using 2JZ rods, that's really just making things more difficult than it has to be. It is honestly completely unnecessary. You can bolt the VQ40 rods and crank into the 3.5L block, IIRC that makes a 3.8L or you can just start with a VQ40 if you want more displacement. The heads are the same as the VQ35 so plenty of options to play with. Thats why I'm saying forget about using toyota parts just no point of doing that. You will go through all that trouble trying to mate the parts to a Nissan crank when there are already parts available for the motor in the first place.

The thing about the rod bolts is i have never heard of a Rod bolt failure. of course we look at them and say "ZOMG THEY ARE SO SMALL!!!" However they do not fail, its just we as people who tune the motors see them and become uncomfortable with how small they are vs other motors. i can understand they discomfort but its just something you do to make you feel better.

And the K series is a very stout motor. The drag builds are pushing the limits of the motor period however street built NA K24s on pump gas will make +300whp for days. Strength is not a problem with those motors. It might be the better choice over the VQ in this application with the car in question being so light. You should do some more research on them before saying they do not hold up.

I've also owned a K series before (K20Z1 in an RSX Type S), and I don't really buy the "300 whp is easy for a street engine." It can be done, but it requires really high compression ratio and stupid high piston speeds. It won't last for long on track, probably on the order of 20-40 hrs of run time based on what I've seen from high HP B series builds with the high piston speeds. It just wears the pistons and rings out really quickly. Plus it'll be a fairly peaky powerband compared to a 300 rwhp VQ (which is pretty much as simple as dropping in a 7G Maxima engine and getting it running with the "bolt-ons" I'd need to make it work in the car). A 300 whp K24 would probably cost around $5-8k more than the VQ. The I4 sound is also kinda lame without a turbo to make things more interesting, so I'd much rather have a sweet sounding V6.

Keep in mind this is primarily a track car, so it will hang around the upper 25% of its rev range for 2-3 hrs an outing.

I think you're misunderstanding why I'd be using 2JZ rods. They're not Toyota rods, they're Eagle rods off probably the same forging as the VQ35DE rods. They just have a slightly smaller rod journal diameter, which enables the crank to be offset ground for a longer stroke. Then the big end and small end are narrowed, and the wrist pin diameter is spot on. Think of it as a really cheap stroker kit, with ~$450 of rods and maybe $300-400 of machine work. The extra displacement will really help hit higher numbers and keeping the revs away from "problem areas."

The VQ40 is a tall deck block, the crank won't swap into a DE bottom end at all. It's completely different, and it uses the same HR bellhousing bolt pattern...

As for using the RWD VQ blocks, I don't really care about the different mount locations, that's trivial, but the transmission adapter plate will probably cost me $500-600, and that's assuming I get everything spot on with the first design (it's possible, but not guaranteed when making a prototype). Then there's the question of holding the intermediate axle and making a bracket in the right location for that.

Doable? Yes. Easy? Not at all. It'd be a ton of work, and it's a ton of work just to build a car like this in the first place. Think about having to fabricate almost EVERY bit of a chassis including the suspension. It's a large undertaking, and scope creep frequently kills builds. Some people finish cars in about 2 yrs (my timeline goal), but others can take upwards of 10 years to finish cars if they really start customizing stuff.

But if there's some info out there where someone actually puts a later HR bellhousing block up to a FWD 6 speed, I'd be really interested if you could link that. Without that, I don't think I want to go down that path. Keep in mind the car will only weigh 1500-1700 lbs, so if I "only" make 320-330 rwhp reliably, it'll still be supercar fast. Like sub 3 second 0-60 with no launch control and a 10 second quarter mile time without slicks. I'm all about doing it if it's feasible, but it seemed like too much conjecture on how "easy" it'd be, and full of pitfalls that threaten to derail the whole project.

as far as no 3.5L doing close to 380whp, this is a 372whp DE block:

https://www.youtube.com/watch?v=9X0WMeaZufo

they also made +370whp

https://www.youtube.com/watch?v=9u4hrFG4N70

But the money it took to get to that level is quite enormous. That's serious head work, cams, rods&pistons, nismo oil pump, ITBs, tuning its money. And lots of it. Im quite sure this is what you are after however will your wallet support it? Otherwise all of this is just pipe dreams. Something like a set of ITBs can be upwards of $3,000 for a VQ so im really curious to how serious you are with wanting a VQ to make that kind of power NA given your not in a race class that is limiting the displacement you can run or something of that nature.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

https://www.youtube.com/watch?v=9X0WMeaZufo

they also made +370whp

https://www.youtube.com/watch?v=9u4hrFG4N70

But the money it took to get to that level is quite enormous. That's serious head work, cams, rods&pistons, nismo oil pump, ITBs, tuning its money. And lots of it. Im quite sure this is what you are after however will your wallet support it? Otherwise all of this is just pipe dreams. Something like a set of ITBs can be upwards of $3,000 for a VQ so im really curious to how serious you are with wanting a VQ to make that kind of power NA given your not in a race class that is limiting the displacement you can run or something of that nature.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.

Also for some reason G/Z guys think their motors are internally different from the FWD block. They are not, its only the mount location and the intake manifold. You tell them that they will tell you, "oh its because you want your car to be a Z/G" so you just leave them alone with there house of cards elitism. But at this level you have to understand there is no difference, a VQ35DE is a VQ35DE period.It might seem like a lot of money to do this stuff, but going to the track is not a cheap hobby. If I spend a few grand on the engine every year, that'd be about normal based on how the SR20 has gone...

But off the bat I see myself just getting it in and going with the rods and/or rod bolts, probably rev up oil pump, and a set of cams and valve springs (likely Tomei cams, maybe JWT valve springs?).

But off the bat I see myself just getting it in and going with the rods and/or rod bolts, probably rev up oil pump, and a set of cams and valve springs (likely Tomei cams, maybe JWT valve springs?). Has anybody here actually put a FWD trans on a larger HR bellhousing RWD block? That'd make it a lot easier to assess the risk, but the more I think about it, the more I think going with a FWD 7G Maxima engine is the easiest thing going forward.

#14

I did do some calling around, and at least got some rough pricing of probably ~$750ish for an adapter to be between the two patterns. I'm not sure if they have the Sentra bellhousing bolt pattern, but that could potentially save me the cash for a VQ bellhousing, so total cost increase would be about $400ish. But then add on bellhousing machining at about $60-75, right back up to about $500 to be safe. Then add up the time to do an intermediate axle mount fabrication (this could be a huge PITA depending on what is potentially in the way).

Not horrible... But I wonder how far off the FWD VQ would really be. Maybe 20-30 rwhp and higher revs?

I'm going to think on it... I'm still leaning towards FWD 7G Maxima VQ for the more "bolt-on with factory bits" aspect making that part of the build go faster.

And it seems for clutch/flywheel with the 6 speed out of a Sentra Spec V B15, you need a flywheel for say a 2002 Maxima from Fidanza or Spec (only two I saw), and a 350Z clutch would work? I'd probably just do a stock Exedy clutch from a 350Z, as it should hold an NA build I'd think. I'm kinda tired of crazy clutches really...

Not horrible... But I wonder how far off the FWD VQ would really be. Maybe 20-30 rwhp and higher revs?

I'm going to think on it... I'm still leaning towards FWD 7G Maxima VQ for the more "bolt-on with factory bits" aspect making that part of the build go faster.

And it seems for clutch/flywheel with the 6 speed out of a Sentra Spec V B15, you need a flywheel for say a 2002 Maxima from Fidanza or Spec (only two I saw), and a 350Z clutch would work? I'd probably just do a stock Exedy clutch from a 350Z, as it should hold an NA build I'd think. I'm kinda tired of crazy clutches really...

#15

we Use Z clutches all the time. And the 5 and 6spd on the B13-15 sentras are identical tot he maxima transmission minus the bellhousing. We use especially the SpecV 6spd we just swap belhousings so most of the clutches and flywheels are interchangeable as far as i know. But i have never heard of somebody using the 4 cyl parts on the VQ with the abundance of Clutches available. Due to the G/Z we are well catered for with cluches and flywheels they fit. And with the power you want a stage 1 clutch would likely be needed.

Just so you know. Currently there are no aftermarket cam options for the VQ in the 7G maxima. because they read cam timing a little different from the rest of the VQs out there nobody has tackled making aftermarket cams or adapters for them. So unless you just wanted 300WHP that might not be a good choice right now as Cams will become a bottle neck in your setup.

It will honestly be easier to us the 350Z HR block then have an adapter made at this point and time, but then why stick to the sentra transmission there are hundreds of options if you do that, so really your call.

Just so you know. Currently there are no aftermarket cam options for the VQ in the 7G maxima. because they read cam timing a little different from the rest of the VQs out there nobody has tackled making aftermarket cams or adapters for them. So unless you just wanted 300WHP that might not be a good choice right now as Cams will become a bottle neck in your setup.

It will honestly be easier to us the 350Z HR block then have an adapter made at this point and time, but then why stick to the sentra transmission there are hundreds of options if you do that, so really your call.

#16

Wouldn't HR cams like those from Tomei work? I could modify the cam signal wheel to whatever signal I want really, as I'm narrowing down to using an AEM 708 with the FWD Maxima engine. I could maybe get by with a 506 and save a little money, but the extra I/O is nice to have, and I'd be doing open loop EVT control, and who knows how that would work out. It's probably not a linear duty cycle vs. cam angle vs. RPM relationship.

The Sentra Spec V trans is actually one of the cheapest or the cheapest FWD trans that has reasonable strength and a differential from the factory. Honda options seem weaker, and they're like $1k+ for open diff boxes, and more like $1200-1800 for LSD boxes. Another reason why I want to avoid the Honda route. Looking at the prices of parts is a real turn off, and it'll make my ~$4-5k drivetrain budget balloon to probably $7-10k and even then at that level it probably will make about 260-280 rwhp.

I still think the HR block would be pretty tough to solve all the issues. So far it looks like I could do it at about $500ish more and an unknown difficulty on the intermediate shaft mounting. It's still up in the air now... trying to see if some more shops will respond to me about a custom adapter plate, or just giving me the bolt patterns.

The Sentra Spec V trans is actually one of the cheapest or the cheapest FWD trans that has reasonable strength and a differential from the factory. Honda options seem weaker, and they're like $1k+ for open diff boxes, and more like $1200-1800 for LSD boxes. Another reason why I want to avoid the Honda route. Looking at the prices of parts is a real turn off, and it'll make my ~$4-5k drivetrain budget balloon to probably $7-10k and even then at that level it probably will make about 260-280 rwhp.

I still think the HR block would be pretty tough to solve all the issues. So far it looks like I could do it at about $500ish more and an unknown difficulty on the intermediate shaft mounting. It's still up in the air now... trying to see if some more shops will respond to me about a custom adapter plate, or just giving me the bolt patterns.

#17

Wouldn't HR cams like those from Tomei work? I could modify the cam signal wheel to whatever signal I want really, as I'm narrowing down to using an AEM 708 with the FWD Maxima engine. I could maybe get by with a 506 and save a little money, but the extra I/O is nice to have, and I'd be doing open loop EVT control, and who knows how that would work out. It's probably not a linear duty cycle vs. cam angle vs. RPM relationship.

The Sentra Spec V trans is actually one of the cheapest or the cheapest FWD trans that has reasonable strength and a differential from the factory. Honda options seem weaker, and they're like $1k+ for open diff boxes, and more like $1200-1800 for LSD boxes. Another reason why I want to avoid the Honda route. Looking at the prices of parts is a real turn off, and it'll make my ~$4-5k drivetrain budget balloon to probably $7-10k and even then at that level it probably will make about 260-280 rwhp.

I still think the HR block would be pretty tough to solve all the issues. So far it looks like I could do it at about $500ish more and an unknown difficulty on the intermediate shaft mounting. It's still up in the air now... trying to see if some more shops will respond to me about a custom adapter plate, or just giving me the bolt patterns.

The Sentra Spec V trans is actually one of the cheapest or the cheapest FWD trans that has reasonable strength and a differential from the factory. Honda options seem weaker, and they're like $1k+ for open diff boxes, and more like $1200-1800 for LSD boxes. Another reason why I want to avoid the Honda route. Looking at the prices of parts is a real turn off, and it'll make my ~$4-5k drivetrain budget balloon to probably $7-10k and even then at that level it probably will make about 260-280 rwhp.

I still think the HR block would be pretty tough to solve all the issues. So far it looks like I could do it at about $500ish more and an unknown difficulty on the intermediate shaft mounting. It's still up in the air now... trying to see if some more shops will respond to me about a custom adapter plate, or just giving me the bolt patterns.

The real magic of the HR engines as im sure you know is in the head. So technically you could get a DE and just go to town on it and get similar results to a built HR motor. But if you are looking at HR motors you might aswell just buy the VQ37. I know those 2 share bolt patterns. It seems as if the main issue you are going to have is just the trans bolt pattern and having an adapter plate fabbed up is seriously the least of your problems even if you were going to use a normal Junkyard standard DE engine. Shops have been doing that for ages unless its because you wanted to do it yourself.

#18

Why do the HR cams not work? I've seen that mentioned, but no one says why. Same head... should work.

The transmission adapter isn't something I'm that worried about, although it is $750 and you hope it works for that cost since it's a one off. I could even do it myself if I could find someone with a coordinate measuring machine, so I'm well aware of what it takes, and what they do. I've used one to put a VQ35DE RWD 6 speed on my SR before.

It's all the other things of trying to make a FWD drivetrain work with a block that's probably never had it done before. Who knows what's going to hit and where. Maybe it's no problem... maybe it's a big problem...

But I am warming back up to the VQ37VHR idea or maybe a VQ35HR, as once I added up the costs of VQ 6 speed bellhousing (which seems to possibly be NLA?) + rod bolts + rev up oil pump + valve springs + cams... it's pricey. Even not including springs + cams, it still seems the RWD might be attractive if I can solve the issues on it...

Taking a bone stock VQ35DE out of a 7th Gen Maxima and then beating the crap out of it on track sounds like a bad idea to me though. It'll probably not live a very long life, and bits like the V6 bellhousing are freakin' expensive now (over $380) and potentially NLA.

I've thought about other engines too if it's just going to be too hard getting a VQ to work.

I'll think on it.

It'd be nice if I could get a stock ECU to work with one of the RWD engines, as the dual throttle bodies mean I need a pricey ECU to make it work. I could possibly go to cable throttles and do an external H-bridge driver for the VVEL of a VQ37VHR, but I imagine I'd spend almost as much on the cable throttle bodies as I would a more expensive ECU.

Not a clear cut path to me right now...

The transmission adapter isn't something I'm that worried about, although it is $750 and you hope it works for that cost since it's a one off. I could even do it myself if I could find someone with a coordinate measuring machine, so I'm well aware of what it takes, and what they do. I've used one to put a VQ35DE RWD 6 speed on my SR before.

It's all the other things of trying to make a FWD drivetrain work with a block that's probably never had it done before. Who knows what's going to hit and where. Maybe it's no problem... maybe it's a big problem...

But I am warming back up to the VQ37VHR idea or maybe a VQ35HR, as once I added up the costs of VQ 6 speed bellhousing (which seems to possibly be NLA?) + rod bolts + rev up oil pump + valve springs + cams... it's pricey. Even not including springs + cams, it still seems the RWD might be attractive if I can solve the issues on it...

Taking a bone stock VQ35DE out of a 7th Gen Maxima and then beating the crap out of it on track sounds like a bad idea to me though. It'll probably not live a very long life, and bits like the V6 bellhousing are freakin' expensive now (over $380) and potentially NLA.

I've thought about other engines too if it's just going to be too hard getting a VQ to work.

I'll think on it.

It'd be nice if I could get a stock ECU to work with one of the RWD engines, as the dual throttle bodies mean I need a pricey ECU to make it work. I could possibly go to cable throttles and do an external H-bridge driver for the VVEL of a VQ37VHR, but I imagine I'd spend almost as much on the cable throttle bodies as I would a more expensive ECU.

Not a clear cut path to me right now...

#19

The adapter plate is going to be tough to work out. Only one shop responded, and they want $750 + me to ship (probably all) the parts needed to them. Ugh... Well over $1k.

I've found a QR25DE bellhousing pattern, so if I can get my hands on the HR bellhousing pattern, I can probably do the rest myself and get it locally machined for maybe $250ish. Then there's the intermediate axle holder...

As to why to go down the headache route, I'm thinking a stock VQ37VHR swapped in with obviously some non-stock intake/header/exhaust combo will probably put out 320-330 rwhp in FWD config. I don't think 350-360 rwhp would be that hard, since that's like a 335-345 rwhp RWD power level, which doesn't seem that crazy. A stock VQ37VHR and VQ35HR will do 7.8-8k RPM, so it's tough to overlook a bit more displacement and 15% more revs in stock form...

I still might go RWD HR block, but I am having a hard time finding out why VQ35HR cams won't work on a 7G Maxima engine. Why would they not work?

I've found a QR25DE bellhousing pattern, so if I can get my hands on the HR bellhousing pattern, I can probably do the rest myself and get it locally machined for maybe $250ish. Then there's the intermediate axle holder...

As to why to go down the headache route, I'm thinking a stock VQ37VHR swapped in with obviously some non-stock intake/header/exhaust combo will probably put out 320-330 rwhp in FWD config. I don't think 350-360 rwhp would be that hard, since that's like a 335-345 rwhp RWD power level, which doesn't seem that crazy. A stock VQ37VHR and VQ35HR will do 7.8-8k RPM, so it's tough to overlook a bit more displacement and 15% more revs in stock form...

I still might go RWD HR block, but I am having a hard time finding out why VQ35HR cams won't work on a 7G Maxima engine. Why would they not work?

#20

HR cams

The adapter plate is going to be tough to work out. Only one shop responded, and they want $750 + me to ship (probably all) the parts needed to them. Ugh... Well over $1k.

I've found a QR25DE bellhousing pattern, so if I can get my hands on the HR bellhousing pattern, I can probably do the rest myself and get it locally machined for maybe $250ish. Then there's the intermediate axle holder...

As to why to go down the headache route, I'm thinking a stock VQ37VHR swapped in with obviously some non-stock intake/header/exhaust combo will probably put out 320-330 rwhp in FWD config. I don't think 350-360 rwhp would be that hard, since that's like a 335-345 rwhp RWD power level, which doesn't seem that crazy. A stock VQ37VHR and VQ35HR will do 7.8-8k RPM, so it's tough to overlook a bit more displacement and 15% more revs in stock form...

I still might go RWD HR block, but I am having a hard time finding out why VQ35HR cams won't work on a 7G Maxima engine. Why would they not work?

I've found a QR25DE bellhousing pattern, so if I can get my hands on the HR bellhousing pattern, I can probably do the rest myself and get it locally machined for maybe $250ish. Then there's the intermediate axle holder...

As to why to go down the headache route, I'm thinking a stock VQ37VHR swapped in with obviously some non-stock intake/header/exhaust combo will probably put out 320-330 rwhp in FWD config. I don't think 350-360 rwhp would be that hard, since that's like a 335-345 rwhp RWD power level, which doesn't seem that crazy. A stock VQ37VHR and VQ35HR will do 7.8-8k RPM, so it's tough to overlook a bit more displacement and 15% more revs in stock form...

I still might go RWD HR block, but I am having a hard time finding out why VQ35HR cams won't work on a 7G Maxima engine. Why would they not work?

Check my thread in the nitrous thread - it's the one with 158K+ accesses. JWT can sell you hotter cams drilled for whatever engine format you want - cal and ask for Clark.

PIXs on forum pages 43-46 up are still futzed thanks to Photobucket changing review format around the first of the year - I'm still repairing the damage. Web amateurs, you know.

Good luck with what you're doing -

#21

Interested to see this take shape.

For info on how the intake cam dowel location differs between the 02-08 DE vs. the 07+ Alti or 09+ Max see here: https://maxima.org/forums/all-motor/...-0-timing.html

For info on how the intake cam dowel location differs between the 02-08 DE vs. the 07+ Alti or 09+ Max see here: https://maxima.org/forums/all-motor/...-0-timing.html

#22

Seems like SurraTT found that the HR cams are indexed about 9* different than the VQ35DE cams - I kinda remember. PM him and ask. I'm in the middle of building yet another VQ35 - a BC stroked 3.8 VQ35DE FWD engine with HR heads and JWT C11/RZ1 cams to feed my nitrous habit on the street and track. I've done the 2010 Maxima LIM and UIM with direct-port injection on the last engine - that tears the 'ell out of M/T ET Street radials 275-50R-15s.

Check my thread in the nitrous thread - it's the one with 158K+ accesses. JWT can sell you hotter cams drilled for whatever engine format you want - cal and ask for Clark.

PIXs on forum pages 43-46 up are still futzed thanks to Photobucket changing review format around the first of the year - I'm still repairing the damage. Web amateurs, you know.

Good luck with what you're doing -

Check my thread in the nitrous thread - it's the one with 158K+ accesses. JWT can sell you hotter cams drilled for whatever engine format you want - cal and ask for Clark.

PIXs on forum pages 43-46 up are still futzed thanks to Photobucket changing review format around the first of the year - I'm still repairing the damage. Web amateurs, you know.

Good luck with what you're doing -

To the OP talking to Darren would be your best bet at getting your questions answered. Seriously he is the person to talk to about these motors. He pioneered the swap in the cars and is the one really solving the issues. PM SurraTT, he also owns NISformance. Very nice guy.

#23

Ok, that makes sense if you're trying to run the engine on a fixed timing pattern, but the beauty of a standalone is being able to adjust the sync for whatever cam pattern you've got. As long as it's a tooth pattern supported by the system, or something that can be programmed, you're good.

AEM has a 708 box that can read the VQ35DE cam pattern (including rev up), so I think it should be able to handle an HR head just fine with a sync adjustment and maybe the cam signal inverters that I see on voltagedrop.net (although it might work without them).

I'm still leaning towards the VQ37, as just dropping it in it'll probably be about as strong as I could make a 7G Maxima engine with some work. The extra revs, slightly higher compression, and displacement bump would be tough to beat. With all the work in the project, might as well work on adapting the best engine possible, even if it's a bit more work. Since making power on the DE bottom end seems "tough" because you're always going to be very rev limited, and you honestly need revs on an NA engine. Without more revs, you're talking about small gains as your torque just can't pick up much more at some point. It's all about moving it to the right.

AEM has a 708 box that can read the VQ35DE cam pattern (including rev up), so I think it should be able to handle an HR head just fine with a sync adjustment and maybe the cam signal inverters that I see on voltagedrop.net (although it might work without them).

I'm still leaning towards the VQ37, as just dropping it in it'll probably be about as strong as I could make a 7G Maxima engine with some work. The extra revs, slightly higher compression, and displacement bump would be tough to beat. With all the work in the project, might as well work on adapting the best engine possible, even if it's a bit more work. Since making power on the DE bottom end seems "tough" because you're always going to be very rev limited, and you honestly need revs on an NA engine. Without more revs, you're talking about small gains as your torque just can't pick up much more at some point. It's all about moving it to the right.

#24

Ok, that makes sense if you're trying to run the engine on a fixed timing pattern, but the beauty of a standalone is being able to adjust the sync for whatever cam pattern you've got. As long as it's a tooth pattern supported by the system, or something that can be programmed, you're good.

AEM has a 708 box that can read the VQ35DE cam pattern (including rev up), so I think it should be able to handle an HR head just fine with a sync adjustment and maybe the cam signal inverters that I see on voltagedrop.net (although it might work without them).

I'm still leaning towards the VQ37, as just dropping it in it'll probably be about as strong as I could make a 7G Maxima engine with some work. The extra revs, slightly higher compression, and displacement bump would be tough to beat. With all the work in the project, might as well work on adapting the best engine possible, even if it's a bit more work. Since making power on the DE bottom end seems "tough" because you're always going to be very rev limited, and you honestly need revs on an NA engine. Without more revs, you're talking about small gains as your torque just can't pick up much more at some point. It's all about moving it to the right.

AEM has a 708 box that can read the VQ35DE cam pattern (including rev up), so I think it should be able to handle an HR head just fine with a sync adjustment and maybe the cam signal inverters that I see on voltagedrop.net (although it might work without them).

I'm still leaning towards the VQ37, as just dropping it in it'll probably be about as strong as I could make a 7G Maxima engine with some work. The extra revs, slightly higher compression, and displacement bump would be tough to beat. With all the work in the project, might as well work on adapting the best engine possible, even if it's a bit more work. Since making power on the DE bottom end seems "tough" because you're always going to be very rev limited, and you honestly need revs on an NA engine. Without more revs, you're talking about small gains as your torque just can't pick up much more at some point. It's all about moving it to the right.

The VQ37 RWD is a stout engine, but a FWD 3.5 DE stroked to 3.7 might be enough for the job - with a Brian Crower 8K bottom end and HR heads with C11/RZ1 JWT cams, might be a match for the VQ37.

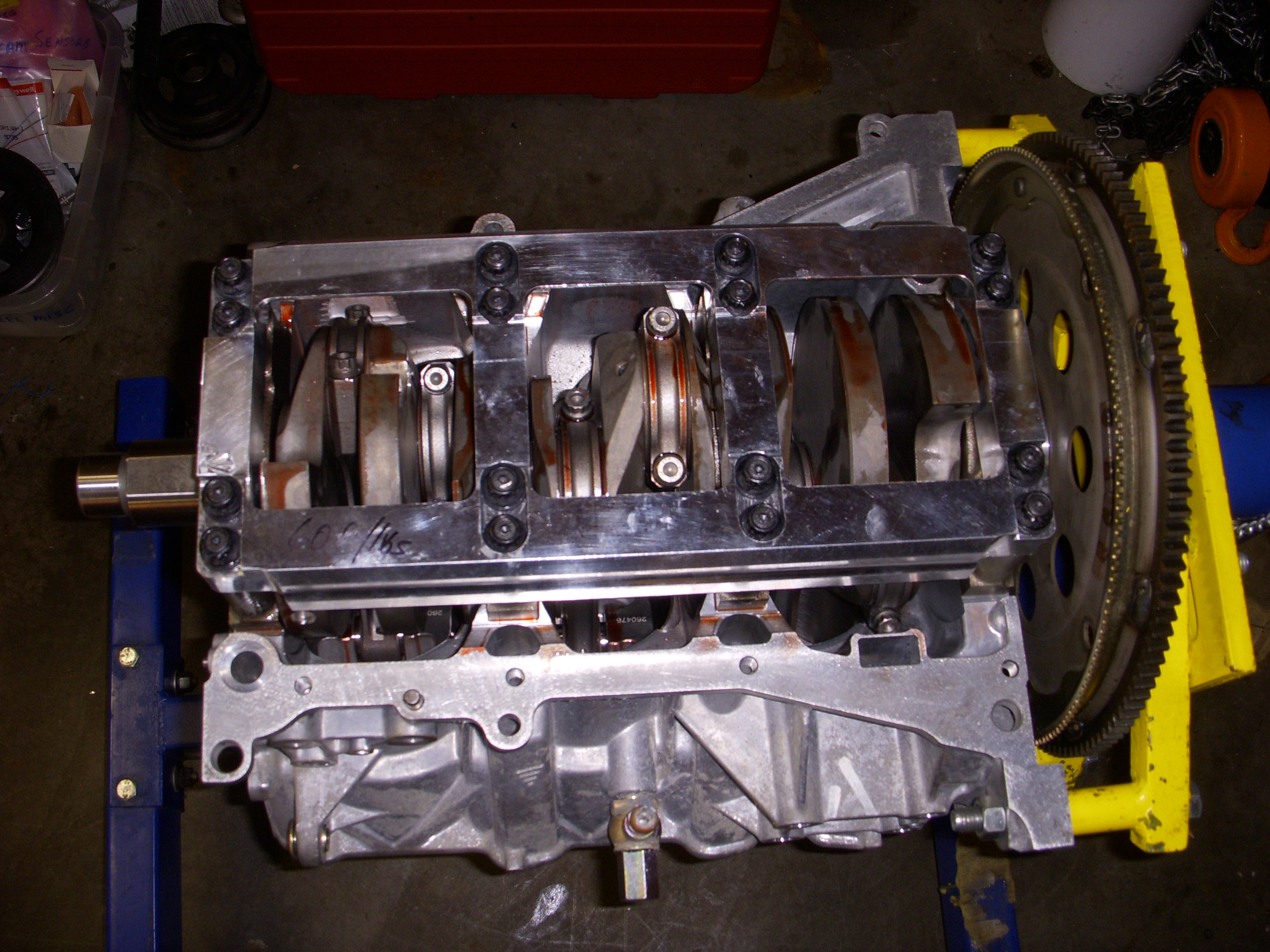

Couple of shots of mine, in progress... (I like what you're doing here - good stuff)

Last edited by grey99max; 01-14-2017 at 02:53 PM.

#25

I've been looking at pics, and one potential issue I see with the VQ37 is that the bed plate seems to extend out pretty far into where the passenger intermediate axle would occupy. It might not be that bad to where some minor grinding fixes it, but on the other hand, it could be pretty nasty.

So far the list of stuff I KNOW is in the way or is a problem is alternator (where intermediate axle lives), bed plate to some degree, adapter plate for trans, intermediate axle holder.

Sooo.... that's looking to blow up into a huge project all in itself. I could do it, but I don't want to while I'm also building a car and getting a standalone up and running on a scratch built electrical system.

Question for you guys - what's the situation with VQ Maxima bellhousings for the 6 speed? They seem to either be NLA or near $400 before shipping. Yuck. Is there any easy used part alternative to this? I really want Sentra SE-R gearing with the 4.1 FD. The Maxima gearing is way too long for what I'm looking to do.

Also, with ARP rod bolts, can do the DE stock rods do 7600-7800 reliably (i.e. hundreds of hours hanging up near there on track), or would they pretty much let go within hours with that kinda usage? I don't mind pushing the limits a bit and trying to see how far a stock engine goes. They're only $1000-1200, so I don't see the point in dropping $2k to maybe stop it from blowing up.

HR headgaskets needed for track work? I'd rather leave the heads on and just replace the bolts to give it a little extra clamping.

My thoughts on the 7G Max engine build would be:

1. Rev up oil pump (seems ridiculously expensive... but added insurance)

2. Juke MR head bolts (seem to be cheap insurance - would leave heads on preferably)

3. ARP rod bolts

4. Tomei 272 10.8 mm HR cams IN/EX

5. JWT HR valvesprings

I'm hoping the above can survive occasional 7.6-7.8k shifts, but I'd probably keep it to more like 7.3-7.4k RPM for 60-70% of usage.

Thoughts?

So far the list of stuff I KNOW is in the way or is a problem is alternator (where intermediate axle lives), bed plate to some degree, adapter plate for trans, intermediate axle holder.

Sooo.... that's looking to blow up into a huge project all in itself. I could do it, but I don't want to while I'm also building a car and getting a standalone up and running on a scratch built electrical system.

Question for you guys - what's the situation with VQ Maxima bellhousings for the 6 speed? They seem to either be NLA or near $400 before shipping. Yuck. Is there any easy used part alternative to this? I really want Sentra SE-R gearing with the 4.1 FD. The Maxima gearing is way too long for what I'm looking to do.

Also, with ARP rod bolts, can do the DE stock rods do 7600-7800 reliably (i.e. hundreds of hours hanging up near there on track), or would they pretty much let go within hours with that kinda usage? I don't mind pushing the limits a bit and trying to see how far a stock engine goes. They're only $1000-1200, so I don't see the point in dropping $2k to maybe stop it from blowing up.

HR headgaskets needed for track work? I'd rather leave the heads on and just replace the bolts to give it a little extra clamping.

My thoughts on the 7G Max engine build would be:

1. Rev up oil pump (seems ridiculously expensive... but added insurance)

2. Juke MR head bolts (seem to be cheap insurance - would leave heads on preferably)

3. ARP rod bolts

4. Tomei 272 10.8 mm HR cams IN/EX

5. JWT HR valvesprings

I'm hoping the above can survive occasional 7.6-7.8k shifts, but I'd probably keep it to more like 7.3-7.4k RPM for 60-70% of usage.

Thoughts?

#26

I've been looking at pics, and one potential issue I see with the VQ37 is that the bed plate seems to extend out pretty far into where the passenger intermediate axle would occupy. It might not be that bad to where some minor grinding fixes it, but on the other hand, it could be pretty nasty.

So far the list of stuff I KNOW is in the way or is a problem is alternator (where intermediate axle lives), bed plate to some degree, adapter plate for trans, intermediate axle holder.

Sooo.... that's looking to blow up into a huge project all in itself. I could do it, but I don't want to while I'm also building a car and getting a standalone up and running on a scratch built electrical system.

Question for you guys - what's the situation with VQ Maxima bellhousings for the 6 speed? They seem to either be NLA or near $400 before shipping. Yuck. Is there any easy used part alternative to this? I really want Sentra SE-R gearing with the 4.1 FD. The Maxima gearing is way too long for what I'm looking to do.

Also, with ARP rod bolts, can do the DE stock rods do 7600-7800 reliably (i.e. hundreds of hours hanging up near there on track), or would they pretty much let go within hours with that kinda usage? I don't mind pushing the limits a bit and trying to see how far a stock engine goes. They're only $1000-1200, so I don't see the point in dropping $2k to maybe stop it from blowing up.

HR headgaskets needed for track work? I'd rather leave the heads on and just replace the bolts to give it a little extra clamping.

My thoughts on the 7G Max engine build would be:

1. Rev up oil pump (seems ridiculously expensive... but added insurance)