MAINTENANCE and MECHANICAL Information- Don't Post Questions Here! (UPDATED)

#1

Mod her. Ate her.

Thread Starter

iTrader: (19)

Join Date: May 2002

Location: Martinsburg, WV

Posts: 9,827

MAINTENANCE and MECHANICAL Information- Don't Post Questions Here! (UPDATED)

Do Not Post Questions In This Thread!

Note:

To search this thread use the "search this thread" box in the upper right corner.

Fault Indicator Light Diagnosis (If "trouble" lights are on, read here first!!!)

LINK to 4th Gen How-To Summary!

LINK to Exhaust Information Thread (With Sound Clips)!

Repair Manual Online The autozone "manual" has many general how to's. Check and see if the how to is in here before making random threads.

60k Service

I know some of the links do not work, check the NEW how to link posted above for more information/new links!!!!!

Links to get started:

Credit: SXN

Engine

How to replace a Water Pump

http://www.vqpower.com/v2/readarticle.php?article_id=68

How to Analyize/Reset a Check Engine Light http://forums.maxima.org/oldthread.php?t=104931

How to Change Knock Sensor http://www.motorvate.ca/mvp.php/507

How to Change Engine Oil http://www.motorvate.ca/mvp.php/511

How to Change Engine Coolant http://www.motorvate.ca/mvp.php/502

How to Replace Power Steering Fluid http://www.motorvate.ca/mvp.php/702

How to Replace Fuel Pump

http://www.vqpower.com/v2/readarticle.php?article_id=96

How to Install a Basic UDP http://www.greghome.com/Greg's%20Garage/1999%20Nissan%20Maxima%20SE/Underdrive%20Pulley.htm

How to replace drive belts

http://www.greghome.com/images/Maxim...DriveBelts.jpg

How to Change Your Spark Plugs http://www.vqpower.com/v2/readarticle.php?article_id=45

How to Install a Mevi (Middle Eastern Variable Intake)http://www.vqpower.com/v2/readarticle.php?article_id=50

How to Change Clutch Slave Cylinder Hose http://www.vqpower.com/v2/readarticle.php?article_id=62

How to Remove/ Replace Your Power Steering http://www.motorvate.ca/mvp.php/702

How to Examine/Change Your Fuel Filter

http://www.vqpower.com/v2/readarticle.php?article_id=97

How to Trouble Shoot TPS (Throttle Position Sensor) Problems

http://www.vqpower.com/v2/readarticle.php?article_id=95

How to Re-Grease Starter http://www.motorvate.ca/mvp.php/516

How to Wire Your Cooling Fans For Manual Use http://jime.f-sw.com/fan.html

How to Install a Pathfinder Throttle Body

http://www.vqpower.com/v2/readarticl...article_id=147

How to install a stillen SC - http://www.vqpower.com/v2/readarticle.php?article_id=73

How to change fuel injectors http://www.vqpower.com/v2/readarticl...article_id=153

How to change Thermostat - http://www.vqpower.com/v2/readarticl...article_id=150

How to change timing chain tensioner

http://forums.maxima.org/showthread.php?t=134338

http://forums.maxima.org/oldthread.php?t=527500 - update

Drivetrain/ Transmission

How To change Motor Mounts http://www.vqpower.com/v2/readarticl...article_id=151

How to cheaply improve manual shifter feeling http://forums.maxima.org/oldthread.php?t=331517

How to Fix CV Joints http://www.motorvate.ca/mvp.php/401

How to Change/Replace Your Clutch http://www.motorvate.ca/mvp.php/801

How to Remove/Rebuild Your Tranny (5 Speed) http://www.motorvate.ca/mvp.php/805

How to Install a Short Throw Shifter http://www.vbxmaxima.8m.com/shifter.html

How to Convert Your Auto to 5 Speed (pretty serious and involved) http://www.vqpower.com/v2/readarticle.php?article_id=44

How to Install a Valve Body http://www.vqpower.com/v2/readarticle.php?article_id=60

Electrical

How to activate the Low Washer Fluid light (for cars without cold/deluxe packages) http://www.vqpower.com/v2/readarticl...article_id=113

How to change alternator http://www.motorvate.ca/mvp.php/500

How to Fix Starter Noise http://www.motorvate.ca/mvp.php/516

How to make your cruise control always ready http://www.vqpower.com/v2/readarticle.php?article_id=28

How to Remove Your Top Speed Limiter

http://www.vqpower.com/v2/readarticle.php?article_id=38

How to Make Your Sun Roof One Touch Open http://www.vqpower.com/v2/readarticle.php?article_id=40

How to Make Your Wipers Variable Intermittent http://www.vqpower.com/v2/readarticle.php?article_id=42

Note:

To search this thread use the "search this thread" box in the upper right corner.

Fault Indicator Light Diagnosis (If "trouble" lights are on, read here first!!!)

LINK to 4th Gen How-To Summary!

LINK to Exhaust Information Thread (With Sound Clips)!

Repair Manual Online The autozone "manual" has many general how to's. Check and see if the how to is in here before making random threads.

60k Service

I know some of the links do not work, check the NEW how to link posted above for more information/new links!!!!!

Links to get started:

Credit: SXN

Engine

How to replace a Water Pump

http://www.vqpower.com/v2/readarticle.php?article_id=68

How to Analyize/Reset a Check Engine Light http://forums.maxima.org/oldthread.php?t=104931

How to Change Knock Sensor http://www.motorvate.ca/mvp.php/507

How to Change Engine Oil http://www.motorvate.ca/mvp.php/511

How to Change Engine Coolant http://www.motorvate.ca/mvp.php/502

How to Replace Power Steering Fluid http://www.motorvate.ca/mvp.php/702

How to Replace Fuel Pump

http://www.vqpower.com/v2/readarticle.php?article_id=96

How to Install a Basic UDP http://www.greghome.com/Greg's%20Garage/1999%20Nissan%20Maxima%20SE/Underdrive%20Pulley.htm

How to replace drive belts

http://www.greghome.com/images/Maxim...DriveBelts.jpg

How to Change Your Spark Plugs http://www.vqpower.com/v2/readarticle.php?article_id=45

How to Install a Mevi (Middle Eastern Variable Intake)http://www.vqpower.com/v2/readarticle.php?article_id=50

How to Change Clutch Slave Cylinder Hose http://www.vqpower.com/v2/readarticle.php?article_id=62

How to Remove/ Replace Your Power Steering http://www.motorvate.ca/mvp.php/702

How to Examine/Change Your Fuel Filter

http://www.vqpower.com/v2/readarticle.php?article_id=97

How to Trouble Shoot TPS (Throttle Position Sensor) Problems

http://www.vqpower.com/v2/readarticle.php?article_id=95

How to Re-Grease Starter http://www.motorvate.ca/mvp.php/516

How to Wire Your Cooling Fans For Manual Use http://jime.f-sw.com/fan.html

How to Install a Pathfinder Throttle Body

http://www.vqpower.com/v2/readarticl...article_id=147

How to install a stillen SC - http://www.vqpower.com/v2/readarticle.php?article_id=73

How to change fuel injectors http://www.vqpower.com/v2/readarticl...article_id=153

How to change Thermostat - http://www.vqpower.com/v2/readarticl...article_id=150

How to change timing chain tensioner

http://forums.maxima.org/showthread.php?t=134338

http://forums.maxima.org/oldthread.php?t=527500 - update

Drivetrain/ Transmission

How To change Motor Mounts http://www.vqpower.com/v2/readarticl...article_id=151

How to cheaply improve manual shifter feeling http://forums.maxima.org/oldthread.php?t=331517

How to Fix CV Joints http://www.motorvate.ca/mvp.php/401

How to Change/Replace Your Clutch http://www.motorvate.ca/mvp.php/801

How to Remove/Rebuild Your Tranny (5 Speed) http://www.motorvate.ca/mvp.php/805

How to Install a Short Throw Shifter http://www.vbxmaxima.8m.com/shifter.html

How to Convert Your Auto to 5 Speed (pretty serious and involved) http://www.vqpower.com/v2/readarticle.php?article_id=44

How to Install a Valve Body http://www.vqpower.com/v2/readarticle.php?article_id=60

Electrical

How to activate the Low Washer Fluid light (for cars without cold/deluxe packages) http://www.vqpower.com/v2/readarticl...article_id=113

How to change alternator http://www.motorvate.ca/mvp.php/500

How to Fix Starter Noise http://www.motorvate.ca/mvp.php/516

How to make your cruise control always ready http://www.vqpower.com/v2/readarticle.php?article_id=28

How to Remove Your Top Speed Limiter

http://www.vqpower.com/v2/readarticle.php?article_id=38

How to Make Your Sun Roof One Touch Open http://www.vqpower.com/v2/readarticle.php?article_id=40

How to Make Your Wipers Variable Intermittent http://www.vqpower.com/v2/readarticle.php?article_id=42

Last edited by Kevlo911; 06-23-2009 at 09:40 AM.

#2

Can I add ABS to my car?

#3

Can I put a Fifth Gen (2000-2001/3.0) engine in my fourth Gen?

Yes. The fifth Gen engine is the same basic design as the fourth gen engine. It is rated at 222 HP compared with the fourth gens 190, but makes basically the same power until after 5000 RPM. Some of this increase comes from slightly improved exhaust, if you put an aftermarket exhaust on your car it will be much better than the fifth gen exhaust. The Majority of the gains come from the intake manifold. The fifth Gen intake manifold is a dual runner design, it switches to shorter runners above 5000 Rpm for improved high RPM power. In the fourth Gen power drops off quickly after about 5500 RPM due to the long intake runners. Any engine swap on a Nissan is going to be a huge undertaking and very expensive. If you are not up to the task, it may more cost effective to bolt-on or boost your 4th Gen. There are about 2.5 Bazillion threads on this, so try the Google Search.

How about a fifth Gen intake manifold?

Yes. Also consider that there is a fourth gen Variable intake Manifold available, if you can find one. It is not a true dual runner design like the fifth gen and will not give your engine the same increase over 5000 RPM that a fifth gen has, but it still is a great improvement over the stock intake manifold. Putting a fifth gen intake manifold on a fourth gen involves replacing pretty much everything from the top of the head up, a huge undertaking. There are many threads on this. Use the Google Search for more info.

Can I put the fifth Gen 3.5 engine in my fourth Gen?

Yes- but this is a huge and very expensive undertaking for many reasons. It may be cheaper to turbocharge or supercharge your 3.0 engine. There are many threads on this- Google Search is your friend.

http://forums.maxima.org/all-motor/4...swap-info.html

Look at that for more information.

Can I use the turbocharged engine or turbo parts from a 300zx?

No.

http://forums.maxima.org/oldthread.php?threadid=66787

http://forums.maxima.org/oldthread.php?threadid=43306

http://forums.maxima.org/oldthread.php?threadid=3010

http://forums.maxima.org/oldthread.php?threadid=61393

Can I put 300zx headers on a Maxima?

No.

http://forums.maxima.org/oldthread.php?threadid=75492

How about port and polish then?

This is a waste of time and energy.

http://forums.maxima.org/oldthread.php?threadid=33112

http://forums.maxima.org/oldthread.php?threadid=89247

Should I buy the Tornado Air fuel saver?

NO!

http://forums.maxima.org/oldthread.php?threadid=36255

How about the Electrice Supercharger?

NO!

http://forums.maxima.org/oldthread.php?threadid=100321

http://forums.maxima.org/oldthread.php?threadid=28016

http://forums.maxima.org/oldthread.php?threadid=1939

Theres a Throttle Body Bypass Coolant Mod on Ebay...should I?

This is the most ridiculous mod known to man, right along with the Tornado Fuel Saver.

1) Prepare to have a sticky throttle, that high idles at 1500 RPM alot. This is due to no coolant being passed through the TB and the high idle will kick in constantly.

"The Fast Idle Cam is operated by a Thermo-element mounted on the bottom of the Throttle Body. When you do the TB bypass mod, you are disabling the FIC. This is a silly mod except for a true race car, a car which is used only for racing." -Daniel B. Martin (http://forums.maxima.org/showpost.ph...9&postcount=43)

2) I felt zero difference in performance when I did it before. Whoever claims it adds 6 HP or whatever figure is FOS.

3) When I did it before, it cost me about $2.00 worth of materials. If you are going to do this, you buy a 2 foot section of 3/8" hose, you can reuse the hose clamps, or buy new ones, and (optional) buy 3/8" rubber cappers to cap the throttle body coolant. To pay more then $5 without shipping is completely highway robbery.

http://forums.maxima.org/oldthread.p...ghlight=bypass

What are all these 20+ HP chips I see on ebay?

They are timing advance resistors. Basically, it tells your ecu that your intake is recieving colder air.

----Do they work?

NO. The ECU only uses the air temp sensor as a reference to ensure that all it's primary readings are within range. Changing this resistance will not get any HP gains.

Don't even bother with them.[/QUOTE]

[QUOTE=ericdwong;662886]There seems to be a problem with the 5 speed 4 gen. Maxima's transmissions. Namely 95-97ish models with around 60,000 miles on them. A common problem is the differential bearings have failed. Seems to be that Nissan/whoever built the tranny did not bother to properly shim the preload of the differential bearings. Tell tale signs of differential bearing failure include:

-leaking seals

-metal shavings in transmission fluid

-play in the CV axle where it enters the transmission

-grinding/whining noises when the car is in motion

You may also have the problem and not show any signs of it. My car did not show any of the above signs, until I opened my transmission for a different project and discovered it. Simply changing the seals is not the answer either, as they will just get stretched again.

The repair bill of this item is very expensive due to labor. Probabaly $800 to well over $1000 for labor charges, to change the $35 bearing(s). The transmission must be taken off the car and disassembled to service. If having somebody else do the service, BE SURE THEY PROPERLY SHIM THE NEW BEARINGS OR ELSE THE PROBLEM WILL CROP UP AGAIN!!! Many times the repair shop will just say "screw it" and not shim the new bearings. This is a great way to put a patch on the wound that will just break again.

"Can I do it myself?" Sure. Just prepared to remove and diassemble the transmission from the car. You will also need a precision dial gauge indicator to properly shim the bearings, a factory service manual, and you will need probably a week to wait for parts to come in. Definately not a job for the amature mechanic.

There is nothing you can do short of crossing your fingers to prevent this from happening, it is a manufacturing defect. Hopefully you will catch it before the 60,000 mile powertrain warranty is up.

references:

http://forums.maxima.org/4th-generat...w.motorvate.ca

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread.php?t=66782

http://forums.maxima.org/showthread.php?t=54048

http://forums.maxima.org/showthread.php?t=31530

http://forums.maxima.org/showthread.php?t=29857

Yes. The fifth Gen engine is the same basic design as the fourth gen engine. It is rated at 222 HP compared with the fourth gens 190, but makes basically the same power until after 5000 RPM. Some of this increase comes from slightly improved exhaust, if you put an aftermarket exhaust on your car it will be much better than the fifth gen exhaust. The Majority of the gains come from the intake manifold. The fifth Gen intake manifold is a dual runner design, it switches to shorter runners above 5000 Rpm for improved high RPM power. In the fourth Gen power drops off quickly after about 5500 RPM due to the long intake runners. Any engine swap on a Nissan is going to be a huge undertaking and very expensive. If you are not up to the task, it may more cost effective to bolt-on or boost your 4th Gen. There are about 2.5 Bazillion threads on this, so try the Google Search.

How about a fifth Gen intake manifold?

Yes. Also consider that there is a fourth gen Variable intake Manifold available, if you can find one. It is not a true dual runner design like the fifth gen and will not give your engine the same increase over 5000 RPM that a fifth gen has, but it still is a great improvement over the stock intake manifold. Putting a fifth gen intake manifold on a fourth gen involves replacing pretty much everything from the top of the head up, a huge undertaking. There are many threads on this. Use the Google Search for more info.

Can I put the fifth Gen 3.5 engine in my fourth Gen?

Yes- but this is a huge and very expensive undertaking for many reasons. It may be cheaper to turbocharge or supercharge your 3.0 engine. There are many threads on this- Google Search is your friend.

http://forums.maxima.org/all-motor/4...swap-info.html

Look at that for more information.

Can I use the turbocharged engine or turbo parts from a 300zx?

No.

http://forums.maxima.org/oldthread.php?threadid=66787

http://forums.maxima.org/oldthread.php?threadid=43306

http://forums.maxima.org/oldthread.php?threadid=3010

http://forums.maxima.org/oldthread.php?threadid=61393

Can I put 300zx headers on a Maxima?

No.

http://forums.maxima.org/oldthread.php?threadid=75492

How about port and polish then?

This is a waste of time and energy.

http://forums.maxima.org/oldthread.php?threadid=33112

http://forums.maxima.org/oldthread.php?threadid=89247

Should I buy the Tornado Air fuel saver?

NO!

http://forums.maxima.org/oldthread.php?threadid=36255

How about the Electrice Supercharger?

NO!

http://forums.maxima.org/oldthread.php?threadid=100321

http://forums.maxima.org/oldthread.php?threadid=28016

http://forums.maxima.org/oldthread.php?threadid=1939

Theres a Throttle Body Bypass Coolant Mod on Ebay...should I?

This is the most ridiculous mod known to man, right along with the Tornado Fuel Saver.

1) Prepare to have a sticky throttle, that high idles at 1500 RPM alot. This is due to no coolant being passed through the TB and the high idle will kick in constantly.

"The Fast Idle Cam is operated by a Thermo-element mounted on the bottom of the Throttle Body. When you do the TB bypass mod, you are disabling the FIC. This is a silly mod except for a true race car, a car which is used only for racing." -Daniel B. Martin (http://forums.maxima.org/showpost.ph...9&postcount=43)

2) I felt zero difference in performance when I did it before. Whoever claims it adds 6 HP or whatever figure is FOS.

3) When I did it before, it cost me about $2.00 worth of materials. If you are going to do this, you buy a 2 foot section of 3/8" hose, you can reuse the hose clamps, or buy new ones, and (optional) buy 3/8" rubber cappers to cap the throttle body coolant. To pay more then $5 without shipping is completely highway robbery.

http://forums.maxima.org/oldthread.p...ghlight=bypass

What are all these 20+ HP chips I see on ebay?

They are timing advance resistors. Basically, it tells your ecu that your intake is recieving colder air.

----Do they work?

NO. The ECU only uses the air temp sensor as a reference to ensure that all it's primary readings are within range. Changing this resistance will not get any HP gains.

Don't even bother with them.[/QUOTE]

[QUOTE=ericdwong;662886]There seems to be a problem with the 5 speed 4 gen. Maxima's transmissions. Namely 95-97ish models with around 60,000 miles on them. A common problem is the differential bearings have failed. Seems to be that Nissan/whoever built the tranny did not bother to properly shim the preload of the differential bearings. Tell tale signs of differential bearing failure include:

-leaking seals

-metal shavings in transmission fluid

-play in the CV axle where it enters the transmission

-grinding/whining noises when the car is in motion

You may also have the problem and not show any signs of it. My car did not show any of the above signs, until I opened my transmission for a different project and discovered it. Simply changing the seals is not the answer either, as they will just get stretched again.

The repair bill of this item is very expensive due to labor. Probabaly $800 to well over $1000 for labor charges, to change the $35 bearing(s). The transmission must be taken off the car and disassembled to service. If having somebody else do the service, BE SURE THEY PROPERLY SHIM THE NEW BEARINGS OR ELSE THE PROBLEM WILL CROP UP AGAIN!!! Many times the repair shop will just say "screw it" and not shim the new bearings. This is a great way to put a patch on the wound that will just break again.

"Can I do it myself?" Sure. Just prepared to remove and diassemble the transmission from the car. You will also need a precision dial gauge indicator to properly shim the bearings, a factory service manual, and you will need probably a week to wait for parts to come in. Definately not a job for the amature mechanic.

There is nothing you can do short of crossing your fingers to prevent this from happening, it is a manufacturing defect. Hopefully you will catch it before the 60,000 mile powertrain warranty is up.

references:

http://forums.maxima.org/4th-generat...w.motorvate.ca

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread.php?t=66782

http://forums.maxima.org/showthread.php?t=54048

http://forums.maxima.org/showthread.php?t=31530

http://forums.maxima.org/showthread.php?t=29857

Last edited by Kevlo911; 06-23-2009 at 09:41 AM.

#4

Stock Flywheel weight and upgrading

For those interested in objective flywheel data I put together some of my old posts: Number one, the 4 gen flywheel is NOT lightenable like the 3 gens are. The reason for this is because, our flywheel is a 2 piece set. The secondary ring gear is what the crankshaft position sensor reads. I got a call back from my machine shop who was gonna lighten my flywheel and they told me this. They unbolted the secondary ring gear from the main ring gear and they tell me that there really isnt any place to lighten the OE flywheel, and even if there was, there wouldnt be enough meat to remove to yield a siginificant difference. Now that I think about it, I dont think anybody in the 4th or 5th gen's have had their OE flywheel chopped. Only 3rd gen's including Jeff92se and Matt93gxe because their designs are different.

The formula according to Phuong for calculating flywheel weight reduction is:

1/2 FW weight * [(flywheel radius x gear x final drive)/(tire radius)]^2

On my 4th generaion, I am running 225 50 16s. I did the conversions and plugged in the formula. BTW, the 4th gen's M/T gearing is like this according to my FSM on page MT40. Ratios: 1st (3.285), 2nd (1.850), 3rd (1.272), 4th (0.954), 5th(0.795), Reverse (3.428) and Final gear is (3.823). For those of you who want to plug the formula in easier in 1st gear it will be 1/2 flywheel weight * [(120mm*3.285x3.823)/314.96mm]^2.

I got my OE flywheel weighed at the local post office, and they confirmed it was calibrated to spec, etc. The stock flywheel WITHOUT the secondary ring gear or bolts weighs 18 pounds, 7 ounces. I used my own postal scale and found the bolts and secondary ring gear to be 1 pound, 10.7 ounces. Add these two together and the total rotating mass (not including pressure plate) is 20 pounds, 1.7 ounce. Since the secondary has to be used with either flywheel the difference in weight is roughly 13 pounds, 7 ounces or 13.4375 pounds. from the Unorthodox Racing flywheel which claims a net weight of 5 pounds. Plug this number into our favorite equation up above and the weight reduction in first gear is equivalent of removing 153.8 pounds of static weight.

The other two options are the Mueller/Stillen Flywheel and the fidanza. The fidanza or stillen wheels shouldnt suffer any sorta drivabilty problem like the U/R at 5 pounds unit might. One thing about a lighter flywheel is that although it reduces rotating mass, it may produce a bog effect at the drag strip off the line.

The formula according to Phuong for calculating flywheel weight reduction is:

1/2 FW weight * [(flywheel radius x gear x final drive)/(tire radius)]^2

On my 4th generaion, I am running 225 50 16s. I did the conversions and plugged in the formula. BTW, the 4th gen's M/T gearing is like this according to my FSM on page MT40. Ratios: 1st (3.285), 2nd (1.850), 3rd (1.272), 4th (0.954), 5th(0.795), Reverse (3.428) and Final gear is (3.823). For those of you who want to plug the formula in easier in 1st gear it will be 1/2 flywheel weight * [(120mm*3.285x3.823)/314.96mm]^2.

I got my OE flywheel weighed at the local post office, and they confirmed it was calibrated to spec, etc. The stock flywheel WITHOUT the secondary ring gear or bolts weighs 18 pounds, 7 ounces. I used my own postal scale and found the bolts and secondary ring gear to be 1 pound, 10.7 ounces. Add these two together and the total rotating mass (not including pressure plate) is 20 pounds, 1.7 ounce. Since the secondary has to be used with either flywheel the difference in weight is roughly 13 pounds, 7 ounces or 13.4375 pounds. from the Unorthodox Racing flywheel which claims a net weight of 5 pounds. Plug this number into our favorite equation up above and the weight reduction in first gear is equivalent of removing 153.8 pounds of static weight.

The other two options are the Mueller/Stillen Flywheel and the fidanza. The fidanza or stillen wheels shouldnt suffer any sorta drivabilty problem like the U/R at 5 pounds unit might. One thing about a lighter flywheel is that although it reduces rotating mass, it may produce a bog effect at the drag strip off the line.

#5

Whats this oil leak near my oil pan?

Chances are it is the Oil Pressure Sender unit, which is a 1" in diameter funky looking switch that has an electrical connector on it. The OEM ones are notorious for failing and/or leaking, even as low as 20K miles. Anyway to change it out is very easy. You have to use a 1 1/16" DEEP WELL socket. 6 or 12 point should work, but I used 6 point. Unclip the electrical connector, and simply remove the switch using the wrench stated above, while having the new switch ready. Draining the oil is not necessary, but a few drops will come out. Prepare to catch the spill using shop towels/rags. Put in the new switch and snug it up. After, I cleaned my entire area up using brake cleaner. Check it periodically to make sure it isnt leaking again and make sure your OIL light does not come on in the dash. So far, mine has been OK.

Daniel B Martin suggest NOT to use the OEM switch. I got a Wells PS159 switch for about $6 from a local auto parts store.

Daniel B Martin suggest NOT to use the OEM switch. I got a Wells PS159 switch for about $6 from a local auto parts store.

#6

Can I install an Optima Battery in my car? What are the benefits?

You can install an Optima battery in your car with very little modification. I have a Yellow top in my car. The OEM cables are long enough to reach the top terminals of an Optima Battery. The only modification you must do, is find some sort of spacer to put beneath the battery in the battery tray. I used scraps of 1/4" MDF. This is because the Optima Battery is shorter in height then the OEM battery. That plastic box that the OE battery comes with is not used. The OEM battery tie down and battery clamps will work. If your new Optima's battery has side terminals, I suggest double grounding the negative side by going to your local car parts store and buying a 24" 4 gauge side terminal battery clamp, and a side terminal for the battery. I put my second ground from the Optima's side terminal to the transmission mount's through bolt, although I had to slightly enlarge the battery cable's connector with a dremel.

The advantages of using a Yellow top are its deep cycle properties, mainly for high powered car stereo use.

For more info go to:

www.optimabatteries.com

The advantages of using a Yellow top are its deep cycle properties, mainly for high powered car stereo use.

For more info go to:

www.optimabatteries.com

#7

My 5 speed transmission is leaking near the CV inputs

There seems to be a problem with the 5 speed 4 gen. Maxima's transmissions. Namely 95-97ish models with around 60,000 miles on them. A common problem is the differential bearings have failed. Seems to be that Nissan/whoever built the tranny did not bother to properly shim the preload of the differential bearings. Tell tale signs of differential bearing failure include:

-leaking seals

-metal shavings in transmission fluid

-play in the CV axle where it enters the transmission

-grinding/whining noises when the car is in motion

You may also have the problem and not show any signs of it. My car did not show any of the above signs, until I opened my transmission for a different project and discovered it. Simply changing the seals is not the answer either, as they will just get stretched again.

The repair bill of this item is very expensive due to labor. Probabaly $800 to well over $1000 for labor charges, to change the $35 bearing(s). The transmission must be taken off the car and disassembled to service. If having somebody else do the service, BE SURE THEY PROPERLY SHIM THE NEW BEARINGS OR ELSE THE PROBLEM WILL CROP UP AGAIN!!! Many times the repair shop will just say "screw it" and not shim the new bearings. This is a great way to put a patch on the wound that will just break again.

"Can I do it myself?" Sure. Just prepared to remove and diassemble the transmission from the car. You will also need a precision dial gauge indicator to properly shim the bearings, a factory service manual, and you will need probably a week to wait for parts to come in. Definately not a job for the amature mechanic.

There is nothing you can do short of crossing your fingers to prevent this from happening, it is a manufacturing defect. Hopefully you will catch it before the 60,000 mile powertrain warranty is up.

references:

www.motorvate.ca

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....ission+bearing

http://forums.maxima.org/showthread....ission+bearing

-leaking seals

-metal shavings in transmission fluid

-play in the CV axle where it enters the transmission

-grinding/whining noises when the car is in motion

You may also have the problem and not show any signs of it. My car did not show any of the above signs, until I opened my transmission for a different project and discovered it. Simply changing the seals is not the answer either, as they will just get stretched again.

The repair bill of this item is very expensive due to labor. Probabaly $800 to well over $1000 for labor charges, to change the $35 bearing(s). The transmission must be taken off the car and disassembled to service. If having somebody else do the service, BE SURE THEY PROPERLY SHIM THE NEW BEARINGS OR ELSE THE PROBLEM WILL CROP UP AGAIN!!! Many times the repair shop will just say "screw it" and not shim the new bearings. This is a great way to put a patch on the wound that will just break again.

"Can I do it myself?" Sure. Just prepared to remove and diassemble the transmission from the car. You will also need a precision dial gauge indicator to properly shim the bearings, a factory service manual, and you will need probably a week to wait for parts to come in. Definately not a job for the amature mechanic.

There is nothing you can do short of crossing your fingers to prevent this from happening, it is a manufacturing defect. Hopefully you will catch it before the 60,000 mile powertrain warranty is up.

references:

www.motorvate.ca

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....t=transmission

http://forums.maxima.org/showthread....ission+bearing

http://forums.maxima.org/showthread....ission+bearing

#8

How do I get rid of my top speed limiter?

Only some 4th gen GXEs are limited. If you have an SE or GLE, you have no limiter. The only way to tell if your GXE has one is to hit the road and see how fast you can go. If you have a limiter, your fuel will be cut off and the engine will drop to idle speed at about 115mph.

original thread

Credit: mzmtg & SprintMax

Write up with pics: http://www.sprintmax.com/tails/bensecumod.htm

EDIT:There is no doubt when you have hit the speed limiter. It is not subtle. In the following link, listen to the sound. The accelerator is floored for the entire duration of this clip. The engine cuts of suddenly and the RPMs drop. Actually, at the last second of the clip, you can see the fuel come back on and the RPM start to climb. If your car just eases up to a speed and stops accelerating, you dont have a limiter, your car is just topped out.

Right click, save as:

http://www.vqpower.com/vids/DSCN0336.avi

Disclaimer: The driving in this clip was conducted on a closed course by a professional driver. Do not attempt. And no comments on my slow azz car.

original thread

Credit: mzmtg & SprintMax

Write up with pics: http://www.sprintmax.com/tails/bensecumod.htm

EDIT:There is no doubt when you have hit the speed limiter. It is not subtle. In the following link, listen to the sound. The accelerator is floored for the entire duration of this clip. The engine cuts of suddenly and the RPMs drop. Actually, at the last second of the clip, you can see the fuel come back on and the RPM start to climb. If your car just eases up to a speed and stops accelerating, you dont have a limiter, your car is just topped out.

Right click, save as:

http://www.vqpower.com/vids/DSCN0336.avi

Disclaimer: The driving in this clip was conducted on a closed course by a professional driver. Do not attempt. And no comments on my slow azz car.

Last edited by Kevlo911; 02-09-2008 at 07:23 AM.

#9

I want to install a Quaife differential- what are its benefits, can I do it myself?

NOTE: This part is no longer available in the United States!

Quaife differential is a automatic torque biasing differential, similar to a limited slip.

http://www.quaifeamerica.com

"The Quaife unit is not only the first aftermarket differential available for the Maxima and I30, it is arguably the best design in production for any car. Its all-gear design does what a typical limited slip differential is supposed to do, just a lot better, under any circumstances and for more miles. The Quaife differential makes your car accelerate quicker and corner faster by simply getting more power to the ground.

The Quaife Differential powers both drive wheels under nearly all conditions, instead of just one. With the Maxima's open differential, a lot of precious power is wasted during wheelspin (of one wheel) under acceleration. This happens because the open differential shifts power to the wheel with less grip. The Quaife does the opposite by sensing which wheel has the better grip, and biasing power to that wheel. This happens smoothly and constantly, without ever completely removing power from the other wheel.

The Quaife provides a significant advantage in any racing situation:

· In straight-line drag racing, torque is biased in a close to ideal 50/50 power split to both drive wheels, resulting in essentially twice the grip of an ordinary differential.

· In autocross or road racing, the Quaife biases power to the outside wheel while accelerating out of a turn, reducing inside-wheel spin. This allows the driver to begin accelerating earlier, exiting the corner at a higher speed.

The Quaife also controls loss of traction when the front wheels are on slippery surfaces like ice or mud, providing the appropriate constant and infinitely variable drive. Power is transferred automatically without the use of normal friction pads or plates seen in other limited-slip designs. The Quaife is extremely strong and durable and since it is gear operated, there are no plates or clutches that can wear out and need costly replacement.

Every Quaife ATB Differential comes with something else others don't have: a Limited Lifetime Warranty. This warranty applies even when raced! "

User's reactions:

http://forums.maxima.org/showthread.php?t=60646

http://forums.maxima.org/showthread.php?t=59267

http://forums.maxima.org/showthread.php?t=57425

http://forums.maxima.org/showthread.php?t=57068

Great so what does it look like?

OK, so how do I install it?

You'll need the minimum of these parts.

1. bearings you need 2 of them, 38440-96E00

2. Nissan part #32701-03E01 (speedometer drive gear)

3. differential seals #s are 38342-81X01 and 38342-81x00. Yes they are different, not sure what the input or gear selector seals are.

4. shims

You'll also need a Factory Service Manual, and a precision dial gauge that can read into the 1/1000 of an inch.

Instructions for canadian maxima 5speed rebuild can be found at: www.motorvate.ca The extra step is just to transfer the ring gear from the included differential to the quaife

also the pics are a tad different- the canadian maxima's had LSD already, where ours had open differentials. You can either use the existing speedeometer gear, by cutting/pressing the existing bearing, or buy a new one. I just bought a new one.

Make sure they set the bearing preload and use the gear fluid. Make sure there.s no silver, milky, or dark stuff in there. Use a magnet to see if there are any shavings. Oh yea, and make sure its 75-w90 GL4 gear oil. I used Amsoil synthetic 75w90 with excellent results in all temperatures.

Regarding the shims, what happens is you have to reassemble the transmission without the shims in place. then make the differential assembly move by pushing on it, and measure this movement using a dial gauge precision meter then, using the FSM's table reference, you will know what size of shim to order. You then must take apart the tranny again and put in the shims.

While you're at it, I think it is a good idea to check the shims of the input shaft as well, since I recently discovered that some of the transmissions have the exact same shims in them and were improperly shimmed. To do this, remove the shims of the input shaft and do the same process as the differential. Then using the FSM table and a micrometer, see if the shims in there are the correct ones. If not, order the correct ones. This step is real easy.

When you put the seals in, grease around the outside lip and dont drive them in too far. Also do it while the (the shop will most likely know all of this, this is more towards the DIYer) tranny is out of the car, and DON'T drive the seales in too far like I did, or otherwise you'll get nothing but a humongous leak.

Lets see, a few things to look out for while reassembling that I screwed up, to make sure you won't screw up. Make sure the cleaner magnet is in place, make sure the shifter rods point the right way with their detents so the shifter will have a "click" action, make sure the reverse gear is in between the reverse engagement fork and not ontop of it. Also make sure a torque wrench is always used and I recommend loctite on every threaded bolt in and outside the transmission. Be sure to TEST the tranny by giving it a spin test in every gear to make sure that it works the way its supposed to. Other then that, reassembling the manual tranny isn't too bad.

Expect this project to take several days, many of it will be waiting for parts to arrive. While you're at it, its a great time to polyurethaneize your motor mounts, steam clean the inside, change the flywheel/clutch or any other project that may take several days.

EDIT- I've recently found out you can do this project very easily. You DO NOT have to take apart all the transmission internals to get to the differential. Open the case, remove the speedometer sensor, and then pull the main and input shaft up about 1/4" or so. Then the differential will slide right out!

Quaife differential is a automatic torque biasing differential, similar to a limited slip.

http://www.quaifeamerica.com

"The Quaife unit is not only the first aftermarket differential available for the Maxima and I30, it is arguably the best design in production for any car. Its all-gear design does what a typical limited slip differential is supposed to do, just a lot better, under any circumstances and for more miles. The Quaife differential makes your car accelerate quicker and corner faster by simply getting more power to the ground.

The Quaife Differential powers both drive wheels under nearly all conditions, instead of just one. With the Maxima's open differential, a lot of precious power is wasted during wheelspin (of one wheel) under acceleration. This happens because the open differential shifts power to the wheel with less grip. The Quaife does the opposite by sensing which wheel has the better grip, and biasing power to that wheel. This happens smoothly and constantly, without ever completely removing power from the other wheel.

The Quaife provides a significant advantage in any racing situation:

· In straight-line drag racing, torque is biased in a close to ideal 50/50 power split to both drive wheels, resulting in essentially twice the grip of an ordinary differential.

· In autocross or road racing, the Quaife biases power to the outside wheel while accelerating out of a turn, reducing inside-wheel spin. This allows the driver to begin accelerating earlier, exiting the corner at a higher speed.

The Quaife also controls loss of traction when the front wheels are on slippery surfaces like ice or mud, providing the appropriate constant and infinitely variable drive. Power is transferred automatically without the use of normal friction pads or plates seen in other limited-slip designs. The Quaife is extremely strong and durable and since it is gear operated, there are no plates or clutches that can wear out and need costly replacement.

Every Quaife ATB Differential comes with something else others don't have: a Limited Lifetime Warranty. This warranty applies even when raced! "

User's reactions:

http://forums.maxima.org/showthread.php?t=60646

http://forums.maxima.org/showthread.php?t=59267

http://forums.maxima.org/showthread.php?t=57425

http://forums.maxima.org/showthread.php?t=57068

Great so what does it look like?

OK, so how do I install it?

You'll need the minimum of these parts.

1. bearings you need 2 of them, 38440-96E00

2. Nissan part #32701-03E01 (speedometer drive gear)

3. differential seals #s are 38342-81X01 and 38342-81x00. Yes they are different, not sure what the input or gear selector seals are.

4. shims

You'll also need a Factory Service Manual, and a precision dial gauge that can read into the 1/1000 of an inch.

Instructions for canadian maxima 5speed rebuild can be found at: www.motorvate.ca The extra step is just to transfer the ring gear from the included differential to the quaife

also the pics are a tad different- the canadian maxima's had LSD already, where ours had open differentials. You can either use the existing speedeometer gear, by cutting/pressing the existing bearing, or buy a new one. I just bought a new one.

Make sure they set the bearing preload and use the gear fluid. Make sure there.s no silver, milky, or dark stuff in there. Use a magnet to see if there are any shavings. Oh yea, and make sure its 75-w90 GL4 gear oil. I used Amsoil synthetic 75w90 with excellent results in all temperatures.

Regarding the shims, what happens is you have to reassemble the transmission without the shims in place. then make the differential assembly move by pushing on it, and measure this movement using a dial gauge precision meter then, using the FSM's table reference, you will know what size of shim to order. You then must take apart the tranny again and put in the shims.

While you're at it, I think it is a good idea to check the shims of the input shaft as well, since I recently discovered that some of the transmissions have the exact same shims in them and were improperly shimmed. To do this, remove the shims of the input shaft and do the same process as the differential. Then using the FSM table and a micrometer, see if the shims in there are the correct ones. If not, order the correct ones. This step is real easy.

When you put the seals in, grease around the outside lip and dont drive them in too far. Also do it while the (the shop will most likely know all of this, this is more towards the DIYer) tranny is out of the car, and DON'T drive the seales in too far like I did, or otherwise you'll get nothing but a humongous leak.

Lets see, a few things to look out for while reassembling that I screwed up, to make sure you won't screw up. Make sure the cleaner magnet is in place, make sure the shifter rods point the right way with their detents so the shifter will have a "click" action, make sure the reverse gear is in between the reverse engagement fork and not ontop of it. Also make sure a torque wrench is always used and I recommend loctite on every threaded bolt in and outside the transmission. Be sure to TEST the tranny by giving it a spin test in every gear to make sure that it works the way its supposed to. Other then that, reassembling the manual tranny isn't too bad.

Expect this project to take several days, many of it will be waiting for parts to arrive. While you're at it, its a great time to polyurethaneize your motor mounts, steam clean the inside, change the flywheel/clutch or any other project that may take several days.

EDIT- I've recently found out you can do this project very easily. You DO NOT have to take apart all the transmission internals to get to the differential. Open the case, remove the speedometer sensor, and then pull the main and input shaft up about 1/4" or so. Then the differential will slide right out!

Last edited by Kevlo911; 02-09-2008 at 07:23 AM.

#10

Does this hose connect to anything?

...I was under the hood the other day and noticed a hose that is connected to nothing. Is this normal?

Yes this is normal. This hose is a breather hose that points down and is not connected to anything. Have no fear.

The hose is located near the large breather hose on the front valve cover. It appears to connected to the transmission at the bottom. It is a hard rubber hose that has it's open, upper end molded to face downward.

Yes this is normal. This hose is a breather hose that points down and is not connected to anything. Have no fear.

The hose is located near the large breather hose on the front valve cover. It appears to connected to the transmission at the bottom. It is a hard rubber hose that has it's open, upper end molded to face downward.

#11

My clutch pedal is too high/too low/wants to adjust itself...what can I do?

Get a flashlight and move back your seat. Get a 12 mm open ended wrench. Look above the clutch pedal and there is a threaded rod that also has ridges that run up and down the rod that goes into the fire wall and moves with the pedal. Find the 12 mm lock nut and loosen it. Adjust the clutch pedal release point and height by turning this rod. Do it slowly as it doesnt take much movement to change the positioning at all. DO NOT PRELOAD the slave operating cylinder, otherwise (if your clutch pedal wants to adjust itself, this is why it does it) the automatic clutch adjustment will be constantly adjusting the clutch pedal on you and it is VERY annoying and almost impossible to consistently race like that.

After you find a sweet spot, tighten down the lock nut.

Great, I did that, now my cruise control doesnt work... why?

While you're down there, you have to make sure you adjust the switch that senses the clutch is all the way "out" or engaged. Look infront of the clutch pedal and you'll see a switch with an electrical connector on it. Unplug the electrical connector, and simply screw the switch to adjust its height. The correct adjustment is that the switch will be engaged when the clutch pedal is all the way out.

After you find a sweet spot, tighten down the lock nut.

Great, I did that, now my cruise control doesnt work... why?

While you're down there, you have to make sure you adjust the switch that senses the clutch is all the way "out" or engaged. Look infront of the clutch pedal and you'll see a switch with an electrical connector on it. Unplug the electrical connector, and simply screw the switch to adjust its height. The correct adjustment is that the switch will be engaged when the clutch pedal is all the way out.

#12

Home Made Poly Engine Mounts

For those of you who have the P/R motor mounts, you know how much vibration those things caused. Being as I am semi luxo and semi performance oriented, I wanted to stiffen the motor mounts to reduce some of the slop and flop. I had these in for about a week exchanged them for new ones and then decided to get rid of them. They didn't fit on the car and were almost impossible to get on and off. The vibration, noise and harshness was just too great. I was prompted to get the P/R mounts because I broke my stock rear mount on the crossmember.

I had this idea before, but just could not think of an appropriate material to "fill" the motor mount with. Then I came across this site (maybe it was somebody here) http://importnut.net/motormount.htm (cut n paste it). I got the 80 Durometer Shore A polyurethane resin which is a 2 part mix from http://www.mcmaster.com part number 8644K11. It is about $20 for enough to do many motor mounts. Very interesting stuff indeed. The base and activater are both liquid by themselves, but when you mix it, it turns hard. For those of you who don't know what Durometer is its a hardness measuring scale.

In the mean time, I had tried to fill the existing lower 2 mounts on my car with polyurethane roof flashing sealant from home depot for $2 a tube. My attempt was also to fix my busted mount. This stuff proved to be no good at all. It didn't adhere to the rubber and a few weeks later I find my rear mount leaking casue the inside never dried despite curing for nearly a month. WHen I drive around, theres so much flop on the on and off of the throttle. And, there is alot of clutch chatter making the car uncomfortable, and it sounded like somethin was banging around in the engine bay.

I bought a brand new rear motor mount from Nissan and prepped it for $70 from the local dealer (NOT the one who gave me a $#!t fit before). When I got the mount, I noticed that there was a pocket of something that was jelly like beneath the rubber above the "open" area that I was going to fill. This would not be good for what I wanted it to do, so I took a knife and gashed it open thinking it was an air bubble. Boy was I wrong as a ton of liquid came gashing out. I cleaned it all out with brake cleaner. I dried the entire unit and then ductaped sealed one side of the mount. Then, I took the polyurethane, and mixed it 2 parts base to 1 part activater by weight using my parent's postal scale (accurate to .01 of an oz). I waited maybe 15 minutes or so until the polyurethane had the right thick consistency that was pourable (like thick syrup), but would not leak out of the duct tape. I poured it all in, making sure to get rid of any air bubbles I could by ramming a screw driver into the loose rubber. I let it cure for 3 days under artificial heat. The results looked really good. The polyurethane was black, smooth, consistent, and hard.

So today, I removed my old mounts by dropping the entire crossmember, and the rear one was toast indeed. It wasnt doing a thing at all, it was so bad I could move the bushing sleeve with my finger. I put the new motor mount on and then put everything back together.

Word of advice when doing motor mount projects-do not tighten down any of the mounting bolts or nuts until AFTER everything is situated in the right place cause you'll need the few mm's of play. Also- support the motor with a jack and be sure to use jackstands. To get to the rear motor mount's rear bolt, unbolt the driver's wheel and get together about 2-3 feet of extensions for a socket. Then stick a 17mm socket in there to undo the thru bolt. If its stuck, get some kind of pivot point. Also, take off the front splash gaurds to save you from alot of swearing.

So, once I put the motor mount in, I started the car. There was a tiny bit of a shock, but nothing like the P/R mounts would do when the motor kicks over (if you got P/R's, you know what I'm talkin about). I put the car in reverse to back the car out of the garage, as I slowly let off the clutch, I immediately noticed that there was NO clutch chatter!! It was smooth! The car was still at high idle, so I didnt know if the car was gonna vibrate or not. After some driving around, warming up the car, there isnt as much flop in the drivetrain. THe car chirps 3rd gear pretty consistently now. Sitting at a stoplight produced something unexpected. The car actually felt QUIETER then it did before at idle!! This is probably now because the motor has all the support it needs, instead of with that busted mount putting a strain on all the others. But the best part was that it had zero vibration. That was my biggest concern. Car felt almost like a new car.

I still can get wheel hop if I hit it just right. This is probably cause I only toughened up one of the mounts, and I'm still on a stock SE suspension.

I'm going to the drags strip tomorrow night. I hope I wont break anything, but it should be interesting. That rear mount should definately not break now, as there is no room for the rubber to move to. As for the other mounts, I definately plan to do them, but only one at a time to see what happens with vibration. My next candidate will be the front torque strap mount near the radiator. Fortunately the "caulk" i put in that one didnt adhere to the rubber well at all and I'll be able to clean it out.

Overall, I consider this project to be a complete success. I'm really happy with the result.

--Credit: ericdwong

I had this idea before, but just could not think of an appropriate material to "fill" the motor mount with. Then I came across this site (maybe it was somebody here) http://importnut.net/motormount.htm (cut n paste it). I got the 80 Durometer Shore A polyurethane resin which is a 2 part mix from http://www.mcmaster.com part number 8644K11. It is about $20 for enough to do many motor mounts. Very interesting stuff indeed. The base and activater are both liquid by themselves, but when you mix it, it turns hard. For those of you who don't know what Durometer is its a hardness measuring scale.

In the mean time, I had tried to fill the existing lower 2 mounts on my car with polyurethane roof flashing sealant from home depot for $2 a tube. My attempt was also to fix my busted mount. This stuff proved to be no good at all. It didn't adhere to the rubber and a few weeks later I find my rear mount leaking casue the inside never dried despite curing for nearly a month. WHen I drive around, theres so much flop on the on and off of the throttle. And, there is alot of clutch chatter making the car uncomfortable, and it sounded like somethin was banging around in the engine bay.

I bought a brand new rear motor mount from Nissan and prepped it for $70 from the local dealer (NOT the one who gave me a $#!t fit before). When I got the mount, I noticed that there was a pocket of something that was jelly like beneath the rubber above the "open" area that I was going to fill. This would not be good for what I wanted it to do, so I took a knife and gashed it open thinking it was an air bubble. Boy was I wrong as a ton of liquid came gashing out. I cleaned it all out with brake cleaner. I dried the entire unit and then ductaped sealed one side of the mount. Then, I took the polyurethane, and mixed it 2 parts base to 1 part activater by weight using my parent's postal scale (accurate to .01 of an oz). I waited maybe 15 minutes or so until the polyurethane had the right thick consistency that was pourable (like thick syrup), but would not leak out of the duct tape. I poured it all in, making sure to get rid of any air bubbles I could by ramming a screw driver into the loose rubber. I let it cure for 3 days under artificial heat. The results looked really good. The polyurethane was black, smooth, consistent, and hard.

So today, I removed my old mounts by dropping the entire crossmember, and the rear one was toast indeed. It wasnt doing a thing at all, it was so bad I could move the bushing sleeve with my finger. I put the new motor mount on and then put everything back together.

Word of advice when doing motor mount projects-do not tighten down any of the mounting bolts or nuts until AFTER everything is situated in the right place cause you'll need the few mm's of play. Also- support the motor with a jack and be sure to use jackstands. To get to the rear motor mount's rear bolt, unbolt the driver's wheel and get together about 2-3 feet of extensions for a socket. Then stick a 17mm socket in there to undo the thru bolt. If its stuck, get some kind of pivot point. Also, take off the front splash gaurds to save you from alot of swearing.

So, once I put the motor mount in, I started the car. There was a tiny bit of a shock, but nothing like the P/R mounts would do when the motor kicks over (if you got P/R's, you know what I'm talkin about). I put the car in reverse to back the car out of the garage, as I slowly let off the clutch, I immediately noticed that there was NO clutch chatter!! It was smooth! The car was still at high idle, so I didnt know if the car was gonna vibrate or not. After some driving around, warming up the car, there isnt as much flop in the drivetrain. THe car chirps 3rd gear pretty consistently now. Sitting at a stoplight produced something unexpected. The car actually felt QUIETER then it did before at idle!! This is probably now because the motor has all the support it needs, instead of with that busted mount putting a strain on all the others. But the best part was that it had zero vibration. That was my biggest concern. Car felt almost like a new car.

I still can get wheel hop if I hit it just right. This is probably cause I only toughened up one of the mounts, and I'm still on a stock SE suspension.

I'm going to the drags strip tomorrow night. I hope I wont break anything, but it should be interesting. That rear mount should definately not break now, as there is no room for the rubber to move to. As for the other mounts, I definately plan to do them, but only one at a time to see what happens with vibration. My next candidate will be the front torque strap mount near the radiator. Fortunately the "caulk" i put in that one didnt adhere to the rubber well at all and I'll be able to clean it out.

Overall, I consider this project to be a complete success. I'm really happy with the result.

--Credit: ericdwong

#13

I connected an airhorn compressor directly to the horn, now no horn works....

I connected an airhorn compressor directly to the horn, now no horn works...

If you wired airhorns to the car and were too lazy to use a relay, chances are you ran it directly off the horn that is next to the engine block. It probably worked for a few honks but it was weak. Now none of the horn works, and chances are your OEM alarm is not working either. Now your first instinct is to check the "horn" fuse but it is still intact. Well, chances are you blew the "theft deterrant" fuse that is under the hood next to the battery. Replace this fuse and your horns and alarm should return to normal. Next time use a relay.

P.S. I do not know if it is the same fuse if your car does not have an OEM alarm.

If you wired airhorns to the car and were too lazy to use a relay, chances are you ran it directly off the horn that is next to the engine block. It probably worked for a few honks but it was weak. Now none of the horn works, and chances are your OEM alarm is not working either. Now your first instinct is to check the "horn" fuse but it is still intact. Well, chances are you blew the "theft deterrant" fuse that is under the hood next to the battery. Replace this fuse and your horns and alarm should return to normal. Next time use a relay.

P.S. I do not know if it is the same fuse if your car does not have an OEM alarm.

#14

Member who somehow became The President of The SE-L Club

iTrader: (19)

Join Date: Jun 2001

Posts: 16,033

Spark Plug Boot Stuck on the Plug

While changing your spark plugs there is a chance when you pull one of the coil packs that the boot will stay on the plug, making it impossible to get your spark plug wrench on to take the plug out.

Don't panic! Go get some crazy glue and apply it to the end of the shaft of the part of the coil pack that came out. Insert it back into the stuck boot. Wait 5 minutes and pull up again. The boot will come up this time.

Now is a good time to check all your coil packs to make sure the spark plug boots are securely glued on.

Don't panic! Go get some crazy glue and apply it to the end of the shaft of the part of the coil pack that came out. Insert it back into the stuck boot. Wait 5 minutes and pull up again. The boot will come up this time.

Now is a good time to check all your coil packs to make sure the spark plug boots are securely glued on.

#15

How do I manually control my cooling fans at the track?

I wanted to have manual control over the radiator fan so that I could run the fan manually, without the car or the ignition switch being on. I have always liked the way the VW's fan runs after you shut the car off to cool the engine down, but wanted to be able to control it myself so that when racing I could manually turn the fan on and leave it on while waiting in the lineup for the next pass.

This switch allows just that, manual control while the car is off in one position and normal operation in the other position.

You have to a DPDT (double pole, double throw) switch. DO NOT get one with center off.

The relay is located just in front of the battery. You will see them labelled Cooling Fan Relay 1, 2 & 3. We are only going to connect into Cooling Fan Relay 1, it is located in the lower right corner.

Remove the two screws holding the relay, remove the top cover and then the bottom cover so you have access to the wires beneath the relays. Turn it over and look for the wires under Cooling Fan Relay 1. You will see two small gauge wires (these are the control for the relay) and two larger wires. (these are connected directly to the fan motors)

The only two wires we are interested in are the G/Y (Green with yellow stripe) and the LG/R (Light green with red stripe). Cut both of these wire leaving enough wire on each end to strip and connect into. (Indicated by the white X on the picture)

Connect four lengths of wire (for each of the cut ends) approximately 6' in length (to reach inside the car). I soldered mine but you can just strip and wrap the wires together or use a connector. Make sure you label them so you can tell them apart when they are inside the cockpit. I used 18 gauge wire, this is only signal wire for the relay it does not power the fans. Probably could be even smaller but I like to err on the side of caution.

I used red wire for the G/Y connections and green wire for the LG/R connections. I put black tape around the two wires that came from the relay for identification (they connect to the center terminals of the switch). I used the grommet just above the fuel filter to get into the car.

Once inside the car just hook them up to the switch as shown in the picture.

The other two connections on the switch go to a +12 hot wire and the other to ground. I used the +12 wire going to the hazard switch and tapped into it.

I have my switch so that down is normal operation and up turns on the fans manually.

It sounds a lot more difficult than it is, the whole operation should take a maximum of one hour most of which is deciding where to come through the firewall and where to mount the switch.

It could also be wired for high speed operation but I decided that the normal speed was sufficient for my needs.

Original thread.

Credit: Jime

This switch allows just that, manual control while the car is off in one position and normal operation in the other position.

You have to a DPDT (double pole, double throw) switch. DO NOT get one with center off.

The relay is located just in front of the battery. You will see them labelled Cooling Fan Relay 1, 2 & 3. We are only going to connect into Cooling Fan Relay 1, it is located in the lower right corner.

Remove the two screws holding the relay, remove the top cover and then the bottom cover so you have access to the wires beneath the relays. Turn it over and look for the wires under Cooling Fan Relay 1. You will see two small gauge wires (these are the control for the relay) and two larger wires. (these are connected directly to the fan motors)

The only two wires we are interested in are the G/Y (Green with yellow stripe) and the LG/R (Light green with red stripe). Cut both of these wire leaving enough wire on each end to strip and connect into. (Indicated by the white X on the picture)

Connect four lengths of wire (for each of the cut ends) approximately 6' in length (to reach inside the car). I soldered mine but you can just strip and wrap the wires together or use a connector. Make sure you label them so you can tell them apart when they are inside the cockpit. I used 18 gauge wire, this is only signal wire for the relay it does not power the fans. Probably could be even smaller but I like to err on the side of caution.

I used red wire for the G/Y connections and green wire for the LG/R connections. I put black tape around the two wires that came from the relay for identification (they connect to the center terminals of the switch). I used the grommet just above the fuel filter to get into the car.

Once inside the car just hook them up to the switch as shown in the picture.

The other two connections on the switch go to a +12 hot wire and the other to ground. I used the +12 wire going to the hazard switch and tapped into it.

I have my switch so that down is normal operation and up turns on the fans manually.

It sounds a lot more difficult than it is, the whole operation should take a maximum of one hour most of which is deciding where to come through the firewall and where to mount the switch.

It could also be wired for high speed operation but I decided that the normal speed was sufficient for my needs.

Original thread.

Credit: Jime

Last edited by Kevlo911; 02-09-2008 at 07:24 AM.

#16

Member who somehow became The President of The SE-L Club

iTrader: (19)

Join Date: Jun 2001

Posts: 16,033

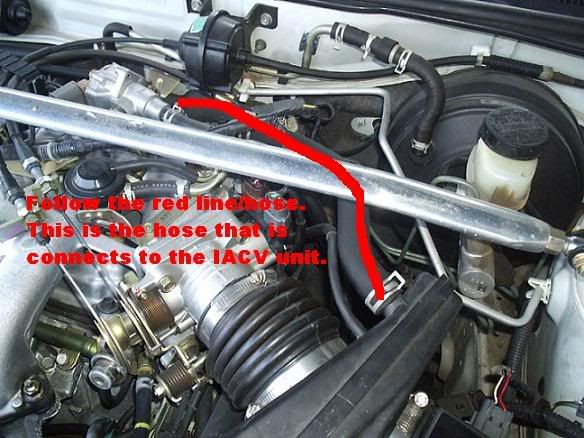

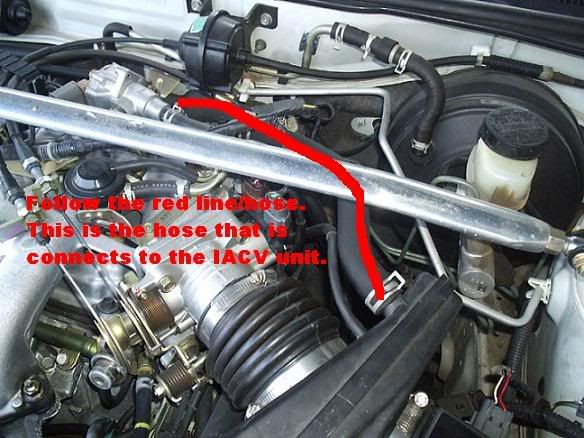

How to clean IAC valve

The credit goes to Mango95SE for this procedure.

Tools needed:

10 and 12 mm sockets

3 inch socket extension

universal joint (swivel pivot socket thing)

12-inch rachet (a short rachet may not work - need something to apply a lot of torque to loosen the bolts

Philip's screwdriver

rag

throttle body cleaner

1. Unplug the 4 connectors from the IAC assembly. Undo the hose that connects teh IAC to the intake assembly.

2. The metal bracket holding up the gray-colored connector is blocking one of the IAC mounting bolts. Using a 10mm socket, remove the bolt that holds the metal bracket. The bolt is just below the purple connector - you have to twist your head and crane your neck around to see the bolt.

3. Remove the 3 mounting bolts using the 12mm socket. The lowest bolt may require the Universal joint.

4. Pull out your IAC valve and clean it w/throttle body cleaner, rag, and old toothbrush.

You may even want to separate the plastic valve to clean it more thoroughly. Use a philip's head screwdriver, but make sure it is a snug fight. It's on there tight and if you don't have a good fitting screwdriver, you could ruin the screw head.

Reinstallation is just the reverse of these steps. It may be easier access to the IAC if you remove the whole air intake assembly, but it's not necessary.

Tools needed:

10 and 12 mm sockets

3 inch socket extension

universal joint (swivel pivot socket thing)

12-inch rachet (a short rachet may not work - need something to apply a lot of torque to loosen the bolts

Philip's screwdriver

rag

throttle body cleaner

1. Unplug the 4 connectors from the IAC assembly. Undo the hose that connects teh IAC to the intake assembly.

2. The metal bracket holding up the gray-colored connector is blocking one of the IAC mounting bolts. Using a 10mm socket, remove the bolt that holds the metal bracket. The bolt is just below the purple connector - you have to twist your head and crane your neck around to see the bolt.

3. Remove the 3 mounting bolts using the 12mm socket. The lowest bolt may require the Universal joint.

4. Pull out your IAC valve and clean it w/throttle body cleaner, rag, and old toothbrush.

You may even want to separate the plastic valve to clean it more thoroughly. Use a philip's head screwdriver, but make sure it is a snug fight. It's on there tight and if you don't have a good fitting screwdriver, you could ruin the screw head.

Reinstallation is just the reverse of these steps. It may be easier access to the IAC if you remove the whole air intake assembly, but it's not necessary.

#17

Does my 4th gen need a timing belt replacement?

No.

All VQ equiped Maximas (1995 - on) use a dual stage timing chain. This needs no periodic maintenace or replacement. It is designed to last the life of the engine. This is a very good thing.

All VQ equiped Maximas (1995 - on) use a dual stage timing chain. This needs no periodic maintenace or replacement. It is designed to last the life of the engine. This is a very good thing.

#18

What is the 60K service, can I do it myself, and HOW?

Your owner's manual details which checks and changes need to be done at which intervals.

The major service interval is 60000 miles. This website details what is needed and how to do each of them:

http://integra.vtec.net/geeser/megamax/60k_service.html OR HERE : http://web.archive.org/web/200201081...k_service.html *

As you will see, this service can be performed by just about anybody. Some dealers charge over $500 for this service, don't let them rip you off.

http://www.vqpower.com/v2/infusions/...?article_id=76

* if the link doesn't work click another one from here http://web.archive.org/web/*/http://...k_service.html

The major service interval is 60000 miles. This website details what is needed and how to do each of them:

http://integra.vtec.net/geeser/megamax/60k_service.html OR HERE : http://web.archive.org/web/200201081...k_service.html *

As you will see, this service can be performed by just about anybody. Some dealers charge over $500 for this service, don't let them rip you off.

http://www.vqpower.com/v2/infusions/...?article_id=76

* if the link doesn't work click another one from here http://web.archive.org/web/*/http://...k_service.html

Last edited by Kevlo911; 05-15-2008 at 06:06 AM.

#19

Why does my A/C only work on fan speed 4?

There is a resistor assembly mounted on the air duct close to the blower motor. That part has failed. It is used to control fan speeds 1, 2, and 3. Speed 4 is the maximum blower motor speed, so no resistors are involved. Replacing the resistor assembly is something the home mechanic can do. The only tool needed is a Phillips screwdriver. The replacement part costs about US$25.

The blower motor is located just above the passenger's feet. Look at the wires leading away from the blower motor. Just inches away from the blower motor there is an electrical connector located on the air duct. That's the resistor assembly. It is easy to remove and replace.

Replacement is the usual remedy. However, if a spot of localized damage is seen it may be repaired with a soldering gun.

There is a good photo of the blower motor and resistor assembly in the Haynes repair manual, page 3-8. If you don't already have a copy of this book, please get one. It will be money well spent.

a) Move the front pass seat all the way back (for convenience)

b) Remove a harness connector (with 4 wires I think) running into the bottom of the blower motor.

c) Remove the 2 philips screws that hold the blower motor resistor in place.

d) Put new one in, reverse install.

Blower Motor Resistor Part Number: 27150-1E405

You can get it here:

http://www.nissanparts.cc/cart/?pn=27150-1E405

Should be $28 at your local dealer. It's $28 delivered from discount Nissan parts sites.

Edit: If you are handy with a soldering iron, you can try to fix it yourself. See this thread.

The blower motor is located just above the passenger's feet. Look at the wires leading away from the blower motor. Just inches away from the blower motor there is an electrical connector located on the air duct. That's the resistor assembly. It is easy to remove and replace.

Replacement is the usual remedy. However, if a spot of localized damage is seen it may be repaired with a soldering gun.

There is a good photo of the blower motor and resistor assembly in the Haynes repair manual, page 3-8. If you don't already have a copy of this book, please get one. It will be money well spent.

a) Move the front pass seat all the way back (for convenience)

b) Remove a harness connector (with 4 wires I think) running into the bottom of the blower motor.

c) Remove the 2 philips screws that hold the blower motor resistor in place.

d) Put new one in, reverse install.

Blower Motor Resistor Part Number: 27150-1E405

You can get it here:

http://www.nissanparts.cc/cart/?pn=27150-1E405

Should be $28 at your local dealer. It's $28 delivered from discount Nissan parts sites.

Edit: If you are handy with a soldering iron, you can try to fix it yourself. See this thread.

#20

What is the MEVI ?

The MEVI, Middle East Variable Intake (Don't know the official name) is a 4th Gen thing...

The Infiniti I30 is sold in the Middle East (Bahrian, Saudi etc) under the name Maxima, and it has a specially-designed intake.

It's not a true Dual-Plane intake (like the Taurus SHO, or the 3.8 SPI from the later model Windstar/Mustang) which has two distinct air paths from the air filter to each cylinder (one long, for low revs - one short for high revs). Instead, it's a Dual-Plenum design that has a second plenum directly above the lower intake, providing a shorter path for the Dynamic Supercharging effect (described below). The second plenum is 'activated' by opening a set of butterfly valves. These valves are opened by a vacuum actuator at the appropriate engine speed.

Dynamic Supercharging is the concept that when the intake valve closes it causes a pressure wave to travel from the outside of the intake valve back towards the air filter. When the pressure wave reaches the plenum (the common part of the intake track between the throttle body and the individual runners) it bounces back towards the intake valve. If the intake valve opens just as the pressure waves gets back, then more air is forced into the cylinders and it increases the volumetric efficiency. There is a specific engine speed at which this Dynamic Supercharging effect happens, and the length of the runners changes this engine speed, because of the time it takes the wave to travel.

Intake spacers change this effect to a lower engine speed (because the wave takes longer) giving the engine more bottom-end grunt (marginally, and at the cost of mid-range grunt)

The dual-plenum design gives the engine TWO speeds at which dynamic supercharging happens - at high speed the upper plenum valves open and the shorter path to the upper plenum gives the dynamic superchargin effect at higher engine speeds, increasing breathing and prolonging the powerband.

That's it, in a nutshell.

Credit: Scruit

.

MEVI FAQ

The Infiniti I30 is sold in the Middle East (Bahrian, Saudi etc) under the name Maxima, and it has a specially-designed intake.

It's not a true Dual-Plane intake (like the Taurus SHO, or the 3.8 SPI from the later model Windstar/Mustang) which has two distinct air paths from the air filter to each cylinder (one long, for low revs - one short for high revs). Instead, it's a Dual-Plenum design that has a second plenum directly above the lower intake, providing a shorter path for the Dynamic Supercharging effect (described below). The second plenum is 'activated' by opening a set of butterfly valves. These valves are opened by a vacuum actuator at the appropriate engine speed.

Dynamic Supercharging is the concept that when the intake valve closes it causes a pressure wave to travel from the outside of the intake valve back towards the air filter. When the pressure wave reaches the plenum (the common part of the intake track between the throttle body and the individual runners) it bounces back towards the intake valve. If the intake valve opens just as the pressure waves gets back, then more air is forced into the cylinders and it increases the volumetric efficiency. There is a specific engine speed at which this Dynamic Supercharging effect happens, and the length of the runners changes this engine speed, because of the time it takes the wave to travel.

Intake spacers change this effect to a lower engine speed (because the wave takes longer) giving the engine more bottom-end grunt (marginally, and at the cost of mid-range grunt)