3rd gen VQ35DE Full ECU Swap Progress Thread

#401

I am glad to see it done...

I decided to hop back on the forums because I have milked my original engine (over 227k miles) for all it will give me, and now need to rebuild or replace. This has always been the best place to find information to make the job easier, so here I am, and your pictures are one of the first things I see. I am so glad to see this done, I have been talking about wanting to do it for a few years in my 89 max. I love the car, and would love the power. I never have the time or money (mix of military and family) so it has been nothing but a pipe dream. Mix that with all the nay sayers talking about how it will never fit, and it can get very frustrating.

All I can say is congrats for having the ability and the drive to get this done. I may use your experience to help with mine if I ever get the opportunity. Thank you for the great pics man.

All I can say is congrats for having the ability and the drive to get this done. I may use your experience to help with mine if I ever get the opportunity. Thank you for the great pics man.

#402

yea you're probably right. unfortunately i HAD to have my car back on the road, without the luxury of having spare mounts to install in the meantime, so i could make it to class.

#404

#405

KK so slightly off topic, but my plan on my car was always to convert it to a 6 speed tranni in the gen 6 (has the stock auto now). Thing is I always wondered what I would have to change for the spacing and connections of the transaxles. Figured spacing would be pretty close, and if I were to have to do anything I would replace the hubs if the connections were different, but to be honest just not sure.

#406

KK so slightly off topic, but my plan on my car was always to convert it to a 6 speed tranni in the gen 6 (has the stock auto now). Thing is I always wondered what I would have to change for the spacing and connections of the transaxles. Figured spacing would be pretty close, and if I were to have to do anything I would replace the hubs if the connections were different, but to be honest just not sure.

You would need an adapter plate to bolt the RS6F51 up to the VG, as well as a flywheel spacer most likely. Axles would probably have to be custom as well. Long story short, just swap out to a VG 5 speed. Much easier, less expensive, and you'll probably get about the same MPG as you would with the 6MT.

Other than that, everything's going to be one-off.

Not slightly off topic, very off topic. Try making your own thread in the J30 subforum.

#407

6 speed manual? Asking because before you edited, it said 6 speed auto.

You would need an adapter plate to bolt the RS6F51 up to the VG, as well as a flywheel spacer most likely. Axles would probably have to be custom as well. Long story short, just swap out to a VG 5 speed. Much easier, less expensive, and you'll probably get about the same MPG as you would with the 6MT.

Other than that, everything's going to be one-off.

Not slightly off topic, very off topic. Try making your own thread in the J30 subforum.

You would need an adapter plate to bolt the RS6F51 up to the VG, as well as a flywheel spacer most likely. Axles would probably have to be custom as well. Long story short, just swap out to a VG 5 speed. Much easier, less expensive, and you'll probably get about the same MPG as you would with the 6MT.

Other than that, everything's going to be one-off.

Not slightly off topic, very off topic. Try making your own thread in the J30 subforum.

#408

I decided to hop back on the forums because I have milked my original engine (over 227k miles) for all it will give me, and now need to rebuild or replace. This has always been the best place to find information to make the job easier, so here I am, and your pictures are one of the first things I see. I am so glad to see this done, I have been talking about wanting to do it for a few years in my 89 max. I love the car, and would love the power. I never have the time or money (mix of military and family) so it has been nothing but a pipe dream. Mix that with all the nay sayers talking about how it will never fit, and it can get very frustrating.

All I can say is congrats for having the ability and the drive to get this done. I may use your experience to help with mine if I ever get the opportunity. Thank you for the great pics man.

All I can say is congrats for having the ability and the drive to get this done. I may use your experience to help with mine if I ever get the opportunity. Thank you for the great pics man.

You would have to find a way to adapt your 3rd gen 5spd tranny to the VQ35. Or you can just swap the 6spd tranny, which is probably what I'd do if I wanted to be slower.

KK so slightly off topic, but my plan on my car was always to convert it to a 6 speed tranni in the gen 6 (has the stock auto now). Thing is I always wondered what I would have to change for the spacing and connections of the transaxles. Figured spacing would be pretty close, and if I were to have to do anything I would replace the hubs if the connections were different, but to be honest just not sure.

#411

For someone to do the basic swap and get the engine running like it should, you could do it for under $1500. But I would calculate $2000 just to be safe. There is no telling how many times I had to suddenly buy a part that I forgot about, like MAF, PS pump, alternator, starter, front engine mount, etc.

But once my swap is done, I will compile a basic list of parts that I needed in order to do this swap. I try to update my original post every now and then for new people coming into this thread.

#412

Aaron, do you have a plan on how to open up those two water ports leaving the block - you know, the ones that need to be ground down another 1/2" or so for increased water flow through the HR gaskets...

Grinding out the metal is simple - keeping the grindings out of the block - not so simple.. Wet cloths, packing in the block, vacuum cleaner running, doing the job upside down ???

Grinding out the metal is simple - keeping the grindings out of the block - not so simple.. Wet cloths, packing in the block, vacuum cleaner running, doing the job upside down ???

#413

Aaron, do you have a plan on how to open up those two water ports leaving the block - you know, the ones that need to be ground down another 1/2" or so for increased water flow through the HR gaskets...

Grinding out the metal is simple - keeping the grindings out of the block - not so simple.. Wet cloths, packing in the block, vacuum cleaner running, doing the job upside down ???

Grinding out the metal is simple - keeping the grindings out of the block - not so simple.. Wet cloths, packing in the block, vacuum cleaner running, doing the job upside down ???

I am going to tape off every orifice I can think of. I was planning on using my carbide bur for porting on my 1/4" variable electric die grinder. That sends tiny chucks of aluminum flying EVERYWHERE! So I'll cover the engine really carefully, stuff rags all in the block, maybe little wads of duct tape to help catch the shavings, and shop vac running right ON the section I'm grinding. And I was definitely planning on flipping the block upside down and sit on the floor while I do it.

I have to be careful cause my short block is all installed and ready to go. I'll be sure to take pics when I get around to doing it within the next 2 weeks.

What tool were you going to use to grind out the coolant passages?

I am desperately waiting on my HR valve spring retainers to arrive! I can't believe I forgot to order them! And they are on backorder from Japan and no dealership in the country has them in stock. Dave B is working on it for me though. So I am concentrating on pruning my dash harness right now. I have lots more work to do on my actual Maxima as well. Remove dash pieces, EC harness, radiator, fill 4th gen motor mounts with PU, install 3.5 dash harness and solder into the car, etc.

#414

I was thinking about one or two of my Dremel rotary cutter wheels - more like barrels - one is rounded, the other is straight - but they cut good, just have to clean out the grooves with a wire brush. You know, modeling clay might work - or Play Dough - stuff it into every crevice, tape over everything else with Gorilla Tape and plastic, then grind away - while upside down. The things we do.....

#415

Yeah, I have a nice 1/8" rotary with a cutting disc. I will see if I can somehow use that. It should minimize the metal shavings compared to the 1/4" shank die grinder with carbide cutting bur, which just flings little pieces of metal everywhere!

Edit: I just tried to test fit a VERY small and worn out cutting disc on the 1/8" rotary tool. I can't find a good way to get it in there. If you can think of a different bit, please let me know. but this carbide bur cuts on the top of it pretty easily.

I have the one on the right (1/4" shank):

Edit: I just tried to test fit a VERY small and worn out cutting disc on the 1/8" rotary tool. I can't find a good way to get it in there. If you can think of a different bit, please let me know. but this carbide bur cuts on the top of it pretty easily.

I have the one on the right (1/4" shank):

Last edited by Aaron92SE; 03-27-2009 at 08:17 AM.

#416

Yeah, I have a nice 1/8" rotary with a cutting disc. I will see if I can somehow use that. It should minimize the metal shavings compared to the 1/4" shank die grinder with carbide cutting bur, which just flings little pieces of metal everywhere!

Edit: I just tried to test fit a VERY small and worn out cutting disc on the 1/8" rotary tool. I can't find a good way to get it in there. If you can think of a different bit, please let me know. but this carbide bur cuts on the top of it pretty easily.

I have the one on the right (1/4" shank):

Edit: I just tried to test fit a VERY small and worn out cutting disc on the 1/8" rotary tool. I can't find a good way to get it in there. If you can think of a different bit, please let me know. but this carbide bur cuts on the top of it pretty easily.

I have the one on the right (1/4" shank):

#418

You can do it the unpleasant way...drill actual holes in the metal...as close to each other as you can without touching. Requires a very steady hand and good bits. Then bust out a hand file and work it by hand. Kind of sucks but i've done it a few times with excellent results. You should be able to tilt the engine 45+ degrees while drilling instead of doing it upside down

#419

#420

Aaron you are the freakin man if you pull this off!!! This would be a true testament that with enough money, time and skill, you make things work in a 3rd Gen. Well I guess that means I could really get a VE in my car. Dam i just want a little more power and you just went for the whole bank....Go 'head wit yo bad ***!!!

#421

You can do it the unpleasant way...drill actual holes in the metal...as close to each other as you can without touching. Requires a very steady hand and good bits. Then bust out a hand file and work it by hand. Kind of sucks but i've done it a few times with excellent results. You should be able to tilt the engine 45+ degrees while drilling instead of doing it upside down

Here are two Dremel cutting bits, good for soft metals like aluminum.

http://i48.photobucket.com/albums/f2...9/DSCN0788.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0788.jpg

Also, I got a call from Dave B today! He was able to get the HR valve spring retainers for me! I can't believe it! The entire country is on backorder and is waiting on Japan to send more out. And somehow, he was able to get them for me in less than 5 days!

Aaron you are the freakin man if you pull this off!!! This would be a true testament that with enough money, time and skill, you make things work in a 3rd Gen. Well I guess that means I could really get a VE in my car. Dam i just want a little more power and you just went for the whole bank....Go 'head wit yo bad ***!!!

#423

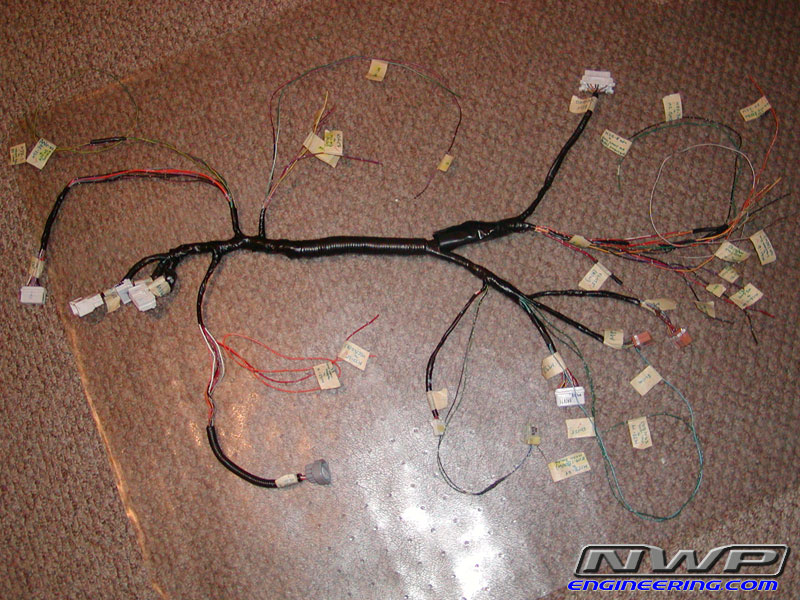

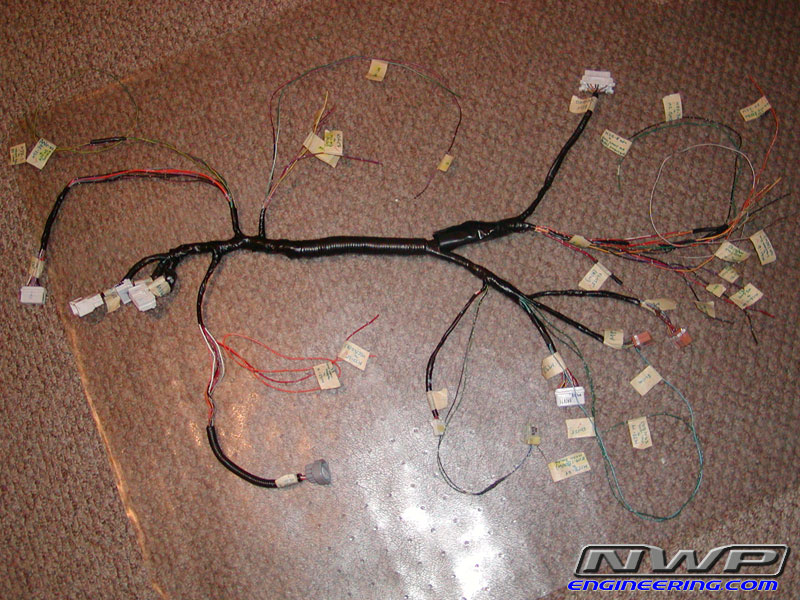

Thanks a lot. This project is NOT for everybody! I can tell you that. Here is what my office floor looks like when I'm reading over the hundreds of pages of schematics for the main dash harness. I am labeling and cutting all the wires I will need in order to solder them into my 3rd gen. I will probably go ahead and wire up my car before the engine is even back together. That way, all my wiring notes are still fresh in my mind.

Last edited by Shadow_Fire; 03-30-2009 at 01:24 PM.

#424

Thanks a lot. This project is NOT for everybody! I can tell you that. Here is what my office floor looks like when I'm reading over the hundreds of pages of schematics for the main dash harness. I am labeling and cutting all the wires I will need in order to solder them into my 3rd gen. I will probably go ahead and wire up my car before the engine is even back together. That way, all my wiring notes are still fresh in my mind.

Isn't it amazing what you can talk yourself into doing?

And just when 4th-gen cars are getting cheaper and cheaper.....

And just when 4th-gen cars are getting cheaper and cheaper.....

Persistence, perseverance, and patience will prevail. Probably.

Aaron and AA are this year's finalists for the most complex projects - the winner will be decided by the one who first has a running car at the end... Say, are you guys related?

.

#425

Thanks.  This is the dash harness which I got from an 02 Maxima at the junkyard. In fact, it was the same car I got my engine, cluster, ECU, NATS, and egas from.

This is the dash harness which I got from an 02 Maxima at the junkyard. In fact, it was the same car I got my engine, cluster, ECU, NATS, and egas from.

The engine control harness hasn't been touched yet. There is just a little wiring I'll have to do to that one though.

Thanks. But, I got a 92 Maxima VE Auto parts car in the backyard right now that I can use if I need anything. I don't mind hacking up my VE's dash harness. I don't have to make anything plug in. It's much easier just to solder particular wires together one at a time instead of making some type of plug and play harness. Plus, the entire dash is coming out along with both seats. It shouldn't be too hard to reach everything once it's all apart.

Yeah. At the start of this project, I kept asking myself, "what have I gotten myself into?" But, the more I study the schematics on the 5.5 gen and the 3rd gen, the more I realize how easy it is. Well, it's easy for me just cause I understand exactly where every wire is going to go. That's only after studying the FSMs every single day for several months straight.

I had to chat a little bit with eng92 and Jime to get a general idea of what wires are needed. After that, nobody can spoon feed you. Everything you need to know is in the FSMs. What sucks is that I quickly realized that the 5.5 gen FSM doesn't have a full schematic foldout page like the 3rd gen FSM has. Instead, I had to print out over 150 pages of schematics in the EC and EL section of the 5.5 gen FSM and flip through every single one until I find a particular harness referenced. Then make a note of it.

Right now, I'm at the point that I am tracing every single wire for all the connectors I plan to keep. Then if it connects to a connector that I'm not keeping, then I have to decide which wire I am going to solder it to in my 3rd gen. There are several things that don't directly cross reference between the 3.5 and the VE. So I have to solder more wires into existing fuses that aren't meant for it without overloading them.

Once I finish pruning and labeling the dash harness, I have to start doing the same thing on the EC harness! But, that will be much less work.

Oh and it took me a while to find out who AA is. You mean doublea? BTW, I hope to have my car running by the first week in May!

This is the dash harness which I got from an 02 Maxima at the junkyard. In fact, it was the same car I got my engine, cluster, ECU, NATS, and egas from.

This is the dash harness which I got from an 02 Maxima at the junkyard. In fact, it was the same car I got my engine, cluster, ECU, NATS, and egas from.The engine control harness hasn't been touched yet. There is just a little wiring I'll have to do to that one though.

Thought on the wiring harness. You should be able to pick up an old harness from a ve somewhere in a junkyard that you can use to cannibalize plugs off of. Would give you more room for working on the soldering, and/or repairing mistakes. Usually what I do when wiring anything. That way if something is messed up I did not break the original, and I always have a spare... just in case...

Isn't it amazing what you can talk yourself into doing?  And just when 4th-gen cars are getting cheaper and cheaper.....

And just when 4th-gen cars are getting cheaper and cheaper.....

Persistence, perseverance, and patience will prevail. Probably.

Aaron and AA are this year's finalists for the most complex projects - the winner will be decided by the one who first has a running car at the end... Say, are you guys related?

.

And just when 4th-gen cars are getting cheaper and cheaper.....

And just when 4th-gen cars are getting cheaper and cheaper.....

Persistence, perseverance, and patience will prevail. Probably.

Aaron and AA are this year's finalists for the most complex projects - the winner will be decided by the one who first has a running car at the end... Say, are you guys related?

.

I had to chat a little bit with eng92 and Jime to get a general idea of what wires are needed. After that, nobody can spoon feed you. Everything you need to know is in the FSMs. What sucks is that I quickly realized that the 5.5 gen FSM doesn't have a full schematic foldout page like the 3rd gen FSM has. Instead, I had to print out over 150 pages of schematics in the EC and EL section of the 5.5 gen FSM and flip through every single one until I find a particular harness referenced. Then make a note of it.

Right now, I'm at the point that I am tracing every single wire for all the connectors I plan to keep. Then if it connects to a connector that I'm not keeping, then I have to decide which wire I am going to solder it to in my 3rd gen. There are several things that don't directly cross reference between the 3.5 and the VE. So I have to solder more wires into existing fuses that aren't meant for it without overloading them.

Once I finish pruning and labeling the dash harness, I have to start doing the same thing on the EC harness! But, that will be much less work.

Oh and it took me a while to find out who AA is. You mean doublea? BTW, I hope to have my car running by the first week in May!

#426

It gives me a headache just thinking about your wiring project - I won't work that hard on anything. But when you're done and driving around in it, you can be proud. (but you're still nuts for doing it).

.

#427

I should have realized you had access to it all cause I had read that you had a parts car.

I see what you mean about the ease with the dash out. Have fun with it though. I can rewire the communications system on an aircraft without batting an eye, but working with automotive wiring makes me cringe everytime I even look at it. lol have fun, and will be glad to see the progress.

I see what you mean about the ease with the dash out. Have fun with it though. I can rewire the communications system on an aircraft without batting an eye, but working with automotive wiring makes me cringe everytime I even look at it. lol have fun, and will be glad to see the progress.

#428

Yup , you and doublea are both Car Crazies.... so you think you'll win the Most Complex Car Project for this year, hummm ?? He's busy reinventing his car from bare metal up, and you're reinventing your car from the wiring up.

It gives me a headache just thinking about your wiring project - I won't work that hard on anything. But when you're done and driving around in it, you can be proud. (but you're still nuts for doing it).

.

It gives me a headache just thinking about your wiring project - I won't work that hard on anything. But when you're done and driving around in it, you can be proud. (but you're still nuts for doing it).

.

His project involves a LOT more physical work than mine though. My project is mostly reading schematics.

#429

I just realized that I don't have the two oxygen sensors for the downstream #2 spot for both banks. I have the ones that go in the stock exhaust manifolds and I will just put those in my headers.

But, do I need the ones that go in the Ypipe/Precat area if inspection or emissions aren't a problem for me? Will not having these 2 o2 sensors plugged in cause me to go into a safety fuel map? I don't care about codes if they don't affect my 1/4 mile times.

But, do I need the ones that go in the Ypipe/Precat area if inspection or emissions aren't a problem for me? Will not having these 2 o2 sensors plugged in cause me to go into a safety fuel map? I don't care about codes if they don't affect my 1/4 mile times.

#430

I just realized that I don't have the two oxygen sensors for the downstream #2 spot for both banks. I have the ones that go in the stock exhaust manifolds and I will just put those in my headers.

But, do I need the ones that go in the Ypipe/Precat area if inspection or emissions aren't a problem for me? Will not having these 2 o2 sensors plugged in cause me to go into a safety fuel map? I don't care about codes if they don't affect my 1/4 mile times.

But, do I need the ones that go in the Ypipe/Precat area if inspection or emissions aren't a problem for me? Will not having these 2 o2 sensors plugged in cause me to go into a safety fuel map? I don't care about codes if they don't affect my 1/4 mile times.

I have only had 2 o2 sensors for 3 years now.

#432

It's been a VERY busy day working on this project, but at least I got a lot done.

I recently got my VQ35HR valve spring retainers since I forgot the order them. Dave B really came through for me! They were on backorder with every dealership in the country. But somehow Dave was able to come up with a set for me in a timely manner.

Comparison between the VQ35DE non-rev up retainer and the revup/HR retainer (same part number):

Also, after a LOT of testing, I was able to find a way to use the 02 Maxima steering wheel with the cruise control switch. The trick was finding a way to still use my 3rd gen combination and wiper switches and have the turn signal auto-off still function properly when you straighten the wheel back up. I first tried to put my 3rd gen comb/wiper switches on the 5.5 gen spiral cable assembly. After a lot of dremeling and custom work, I was able to get them mounted. But the auto-off turn signals won't work with this setup.

But, I found that the slip ring assembly from a non-airbag 3rd gen worked GREAT on the 5.5 gen steering wheel after a little modifying! Thanks Jared! Then, I did a little custom wiring to make it all work.

3rd gen non-airbag slip ring assembly and comb./wiper switch mounting bracket on the 5.5 gen steering wheel:

Airbag was already blow from the salvage yard. So I trimmed it up a tad.

I pieced together the airbag cover pieces and stuck it in place. Doesn't look bad, huh?

I recently got my VQ35HR valve spring retainers since I forgot the order them. Dave B really came through for me! They were on backorder with every dealership in the country. But somehow Dave was able to come up with a set for me in a timely manner.

Comparison between the VQ35DE non-rev up retainer and the revup/HR retainer (same part number):

Also, after a LOT of testing, I was able to find a way to use the 02 Maxima steering wheel with the cruise control switch. The trick was finding a way to still use my 3rd gen combination and wiper switches and have the turn signal auto-off still function properly when you straighten the wheel back up. I first tried to put my 3rd gen comb/wiper switches on the 5.5 gen spiral cable assembly. After a lot of dremeling and custom work, I was able to get them mounted. But the auto-off turn signals won't work with this setup.

But, I found that the slip ring assembly from a non-airbag 3rd gen worked GREAT on the 5.5 gen steering wheel after a little modifying! Thanks Jared! Then, I did a little custom wiring to make it all work.

3rd gen non-airbag slip ring assembly and comb./wiper switch mounting bracket on the 5.5 gen steering wheel:

Airbag was already blow from the salvage yard. So I trimmed it up a tad.

I pieced together the airbag cover pieces and stuck it in place. Doesn't look bad, huh?

Last edited by Aaron92SE; 04-04-2009 at 08:46 PM.

#433

After several weeks of hard work, I was finally able to finish pruning the dash harness. Let me tell you, it was NOT a simple task! Anybody who undertakes this task has my respect! And thank you eng92 and Jime for your help with this.

Studying the schematics and taking notes is a VERY tedious process. It's easy if you understand wiring. It just takes forever!

Pruned 5.5 gen dash harness all labeled and ready to be soldered in my 3rd gen:

All the wires I removed from the harness:

I will probably go ahead and start wiring up my 3rd gen even before the engine is assembled. I want to do it while all the wiring information is fresh in my head.

Studying the schematics and taking notes is a VERY tedious process. It's easy if you understand wiring. It just takes forever!

Pruned 5.5 gen dash harness all labeled and ready to be soldered in my 3rd gen:

All the wires I removed from the harness:

I will probably go ahead and start wiring up my 3rd gen even before the engine is assembled. I want to do it while all the wiring information is fresh in my head.

#436

Jim, have you ever made some WOT pulls without any kind of Ypipe, just open headers? Do you know if the #1 o2 sensors get some kind of weird reading caused by the open headers and cause the ECU to affect performance?

I just want to make sure I will be able to do that just to test my car out when the engine is initially installed.

I just want to make sure I will be able to do that just to test my car out when the engine is initially installed.

#439

But would you happen to know if they still function properly at partial throttle or at idle with open headers? I've never tested this myself and want to get an idea if they may be a problem for me when I first crank up the car and let it idle.

Thanks.

Last edited by Aaron92SE; 04-06-2009 at 10:49 AM.

#440

Why do you need that particular connector for a universal dash fan? I need one of those too since I don't have AC. Let me know what your idea is.