maximelt's all time build NA VQ35DE/HR hybrid

#121

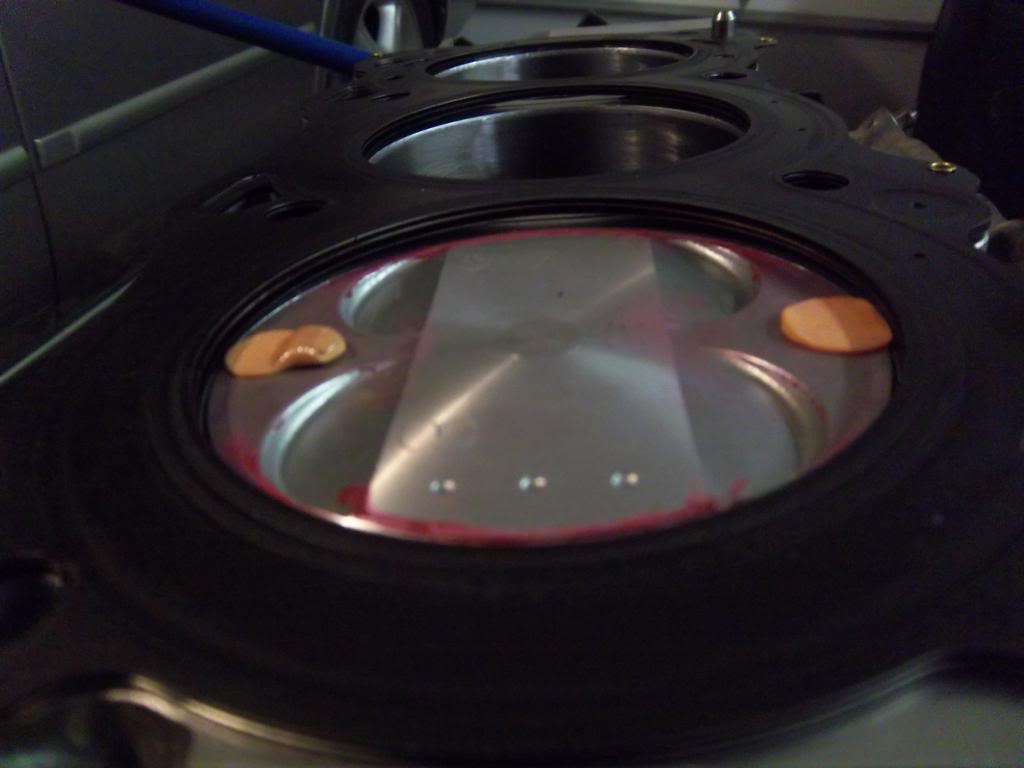

OK, I got ALL my stuff back! He took .006" off the block and another .006" off the heads, so I'm down about 0.012" then. He also polished the crankshaft journals, and balanced all the rods/pistons. Not for free of course. I used permatex ultra slick on the mains, and i accidentally misplaced two main bearings, on #2 and #4, but it spins smooth, although it takes a bit to spin the crank. I'm wondering of this is accounting for the ultra slick bcause its very tacky. Anyways, I'm in the garage and will try to get some pics.

#122

I put the first piston in lastnight. What a pain. Anyway, the honing job that he did is so much better than the original honing job that I did. I'm just trying to measure the rod journals because I am thinking of replacing the rod bearings. I will report later, at work right now. Happy New year guys.

#124

Well this kinda stinks, I have a stripped head bolt hole. I'm looking for inserts to fix it.

Nevermind that ish, I guess it was playing trix on me because it wasn't stripped!

I have the heads on so next is timing cover I believe. I;m using a 0.045" hg.

Nevermind that ish, I guess it was playing trix on me because it wasn't stripped!

I have the heads on so next is timing cover I believe. I;m using a 0.045" hg.

Last edited by Maximeltman; 01-27-2013 at 02:03 PM.

#125

I just fired it up and once again-white smoke. I cant figure out wahts wrong here because I had the heads presure checked, and the block decked, and got new head gaskets. This is real annoying.

#127

#130

I kinda want my money back lol they sold me a BUM engine. But now, I'm debating on whether getting the block fixed like if someone can weld it, or just getting a new block, but that would mean that I'd need to size up the Main bearings again=pita. But I am very relieved that I found the culprit, it's been there the whole time, I even posted a pic of it in this thread without even knowing exactly what it is, but then I looked up cracked cylinder pics and some look like the pic I posted on here.

#131

Taking this into account are you planning on re-timing the intake cams? From my swap I saw that the dowel pin on the intake cam may look close but it's far from where you want it with static timing.

#132

#133

I used stock 07+ Alti cams that came with the engine. I would have to assume the dowel locations are similar to yours since the head castings are the same and you said the HR cams just bolted up.

The dowel pin on the intake cam looked like it was in the right location for 3.0 timing equipment but when I compared it to a 3.0 intake it was 28 crank (14 cam) degrees off.

Details are in my swap thread.

The dowel pin on the intake cam looked like it was in the right location for 3.0 timing equipment but when I compared it to a 3.0 intake it was 28 crank (14 cam) degrees off.

Details are in my swap thread.

#134

I used stock 07+ Alti cams that came with the engine. I would have to assume the dowel locations are similar to yours since the head castings are the same and you said the HR cams just bolted up.

The dowel pin on the intake cam looked like it was in the right location for 3.0 timing equipment but when I compared it to a 3.0 intake it was 28 crank (14 cam) degrees off.

Details are in my swap thread.

The dowel pin on the intake cam looked like it was in the right location for 3.0 timing equipment but when I compared it to a 3.0 intake it was 28 crank (14 cam) degrees off.

Details are in my swap thread.

I'm out of steam at this point, I have the engine torn down for the third time on the engine stand, cylinder three has a burn/pitting mark on the cylinder wall, but I can't see any cracks. Now I'm debating whether to get block pressure checked or use Spotcheck to look for cracks. I cannot understand what the deal is and why the coolant keeps mixing with oil!

Are you suggesting that my timing is too advanced and somehow blowing the head gasket, causing the white smoke due to preignition or something?

BTW, I torque the headbolts per FSM instructions, but I never used a thread chaser for the bolts, maybe that's the problem? I am getting a good seal, there is an indentation around each cylinder where the HG gets crushed, and I can't imagine anything getting past the headgasket! I'm using cometic 0.045" head gaskets. On the good side, I can pull the engine out and tear it down in about 10 hours time now

but that doesn't make me feel much better I just want it running!

but that doesn't make me feel much better I just want it running!

#135

The 07 Alti cams seem to have a dowel hole in the intake can in a similar position as your HR cams. This makes sense since the 07 Alti came with HR heads.

If your cams stock dowel hole is in the same spot as mine, it will be too far advanced for decent powerband with static timing.

I was just suggesting you check the timing like I did and redrill (also like I did) if necessary since you've got it all apart.

I'm definitely not saying this is why your mixing oil and coolant.

I do know that Cometic MLS gaskets have sealing issues on other platforms though and you may want to go with some version of OEM.

If your cams stock dowel hole is in the same spot as mine, it will be too far advanced for decent powerband with static timing.

I was just suggesting you check the timing like I did and redrill (also like I did) if necessary since you've got it all apart.

I'm definitely not saying this is why your mixing oil and coolant.

I do know that Cometic MLS gaskets have sealing issues on other platforms though and you may want to go with some version of OEM.

#137

Here you go:

https://www.flatoutgroup.com/SearchC...Head%20Gaskets

Thicknesses from .021-.120 can be cut to your bore specs.

https://www.flatoutgroup.com/factstips.aspx

Andy

https://www.flatoutgroup.com/SearchC...Head%20Gaskets

Thicknesses from .021-.120 can be cut to your bore specs.

https://www.flatoutgroup.com/factstips.aspx

Andy

Last edited by ABIGBRAIN; 03-08-2013 at 02:57 PM.

#138

Here you go:

https://www.flatoutgroup.com/SearchC...Head%20Gaskets

Thicknesses from .021-.120 can be cut to your bore specs.

https://www.flatoutgroup.com/factstips.aspx

Andy

https://www.flatoutgroup.com/SearchC...Head%20Gaskets

Thicknesses from .021-.120 can be cut to your bore specs.

https://www.flatoutgroup.com/factstips.aspx

Andy

But I can't figure out how I messed up. I torqued the HR headbolts down to 78ft/lb, lossened all of them, then torqued again to 30ft/lb, then two additional 90* turns. That's what the FSM calls for. BTW, there was one HR bolt that was about 3mm longer than all the rest. And I know that they were all HR bolts because they all had those two dots on the top!!

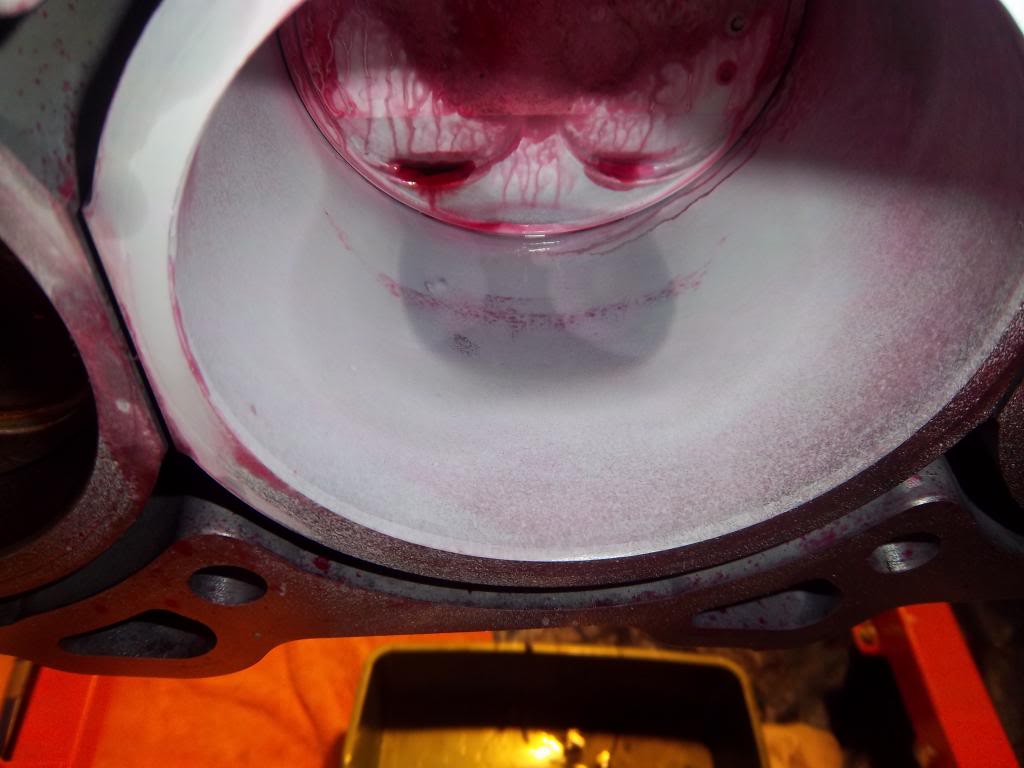

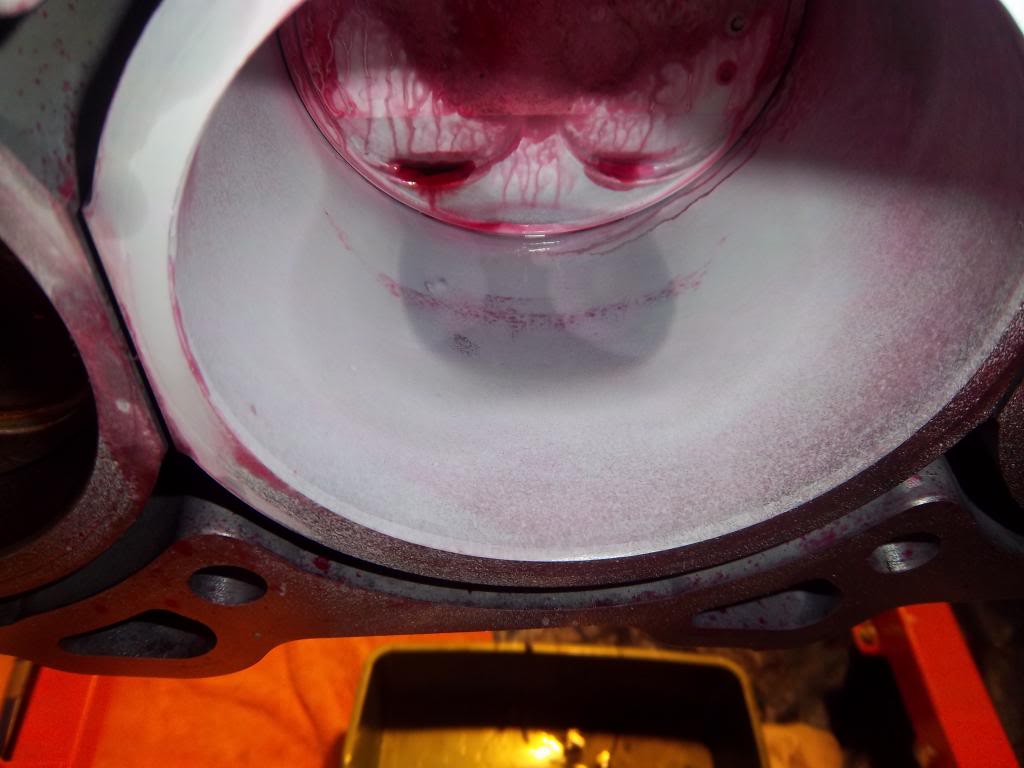

The machinest said that the finish is roughly 40RA, so I don't think that's the problem. I'm going to use spotcheck on the block pretty soon here. I want to see if the theory of a cracked cylinder wall is valid.

Last edited by Maximeltman; 03-08-2013 at 06:21 PM.

#140

I cut my hand pretty bad...it was bleeding profusely

but heres a shot what spotcheck found, just a lot of pitting, but from what I dont know it came like that. So Im sure this isnt the problem. Anybody know what the stock pistons sit inside of the block or at zero deck? because these ones I have sit above and Id like to get them flycut so I can use a stock head gasket because I am not having luck with cometics at all..I also read fel pro gaskets are great. 0.7mm is about 0.027 and I'm at 0.045 so almost double thickness. But I didnt chase the headbolt threads so maybe that (and that one bolt being 3mm longer than the rest threw the torque off.

Also 95Nasta, I compared the intake cams and they are looking a bit more advanced than stock 3.0 DE cams, but they also have their duration that's about 16* more that the 3.0. so I have no idea, I have read that preignition can blow the head gaskets.

I only had the thing running like 1 -2 min before the white smoke comes like a sea monster getting a pirate ship or something

but heres a shot what spotcheck found, just a lot of pitting, but from what I dont know it came like that. So Im sure this isnt the problem. Anybody know what the stock pistons sit inside of the block or at zero deck? because these ones I have sit above and Id like to get them flycut so I can use a stock head gasket because I am not having luck with cometics at all..I also read fel pro gaskets are great. 0.7mm is about 0.027 and I'm at 0.045 so almost double thickness. But I didnt chase the headbolt threads so maybe that (and that one bolt being 3mm longer than the rest threw the torque off.

Also 95Nasta, I compared the intake cams and they are looking a bit more advanced than stock 3.0 DE cams, but they also have their duration that's about 16* more that the 3.0. so I have no idea, I have read that preignition can blow the head gaskets.

I only had the thing running like 1 -2 min before the white smoke comes like a sea monster getting a pirate ship or something

#141

Pistons should be sitting in the hole .6 mm (or .024") Gasket thickness should be .024" as well... giving a quench of .048" (this allows for proper flame travel and valve to piston clearance at thermal expansion. NA motor should almost NEVER have a piston above the deck.

You also should get your cams checked by a professional to ensure they are properly setup.

Andy

You also should get your cams checked by a professional to ensure they are properly setup.

Andy

#142

Pistons should be sitting in the hole .6 mm (or .024") Gasket thickness should be .024" as well... giving a quench of .048" (this allows for proper flame travel and valve to piston clearance at thermal expansion. NA motor should almost NEVER have a piston above the deck.

You also should get your cams checked by a professional to ensure they are properly setup.

Andy

You also should get your cams checked by a professional to ensure they are properly setup.

Andy

I don't think there are any 'proffesional' nissan vq30de-to vq35de/hr hybrid cam swapped people near where I live, though. I saw that 95NAsta made a cam jig so maybe that's what I can do.

#143

i didnt get a chance to finish reading this thread but how did the oil lines to the seconday tensioners work out. they still holding up. im doing a 3.5 swap with 3.0 timing and i was thinking about doing those oil lines if anyone else thinks a good idea. i have read alot about the tensioners loosing pressure and timing skips. let me no asap.

good job with the build +1

good job with the build +1

#144

i didnt get a chance to finish reading this thread but how did the oil lines to the seconday tensioners work out. they still holding up. im doing a 3.5 swap with 3.0 timing and i was thinking about doing those oil lines if anyone else thinks a good idea. i have read alot about the tensioners loosing pressure and timing skips. let me no asap.

good job with the build +1

good job with the build +1

Abigbrain, thanks for all the help man.

I found this http://www.motoiq.com/magazine_artic...-r-part-8.aspx and author says that the factory piston sits in the deck 0.016? But then you say 0.024? I guess anywhere in between is ok as long as I have around 0.045 of cold squish clearance? If I decided to fly cut these pistons would I take material off the edges where the lines are drawn? So if my pistons are average 0.012" above the deck, then I would remove 0.028-0.036 to make the aformentioned in-deck specs?

Last edited by Maximeltman; 03-10-2013 at 03:29 PM.

#145

OK change o' plans

I just got some HR head gaskets, in hopes they will seal better with those extra preloaded fire rings around each cylinder. I had the pistons shaved for clearance. I really hope this proves successful.

I just got some HR head gaskets, in hopes they will seal better with those extra preloaded fire rings around each cylinder. I had the pistons shaved for clearance. I really hope this proves successful.

#146

Thread

Thread Starter

Forum

Replies

Last Post

kjlouis

4th Generation Maxima (1995-1999)

12

10-03-2015 05:29 AM

trungg86

4th Generation Maxima (1995-1999)

7

09-04-2015 04:58 AM