Rev-up cams+3.0=oil leaks?

#1

Rev-up cams+3.0=oil leaks?

Here is the issue, i have rev-ups in a 3.0 and im continually having oil leaks on both banks of the motor. i have my motor torn down right now to fix an oil leak again and im wondering whats going on here, because this is the second time i have had to pull it apart because of leaking oil. Im starting suspect the cams are the problem.

What im wondering is which side of the heads is the oil being feed through? when i pulled out my cam bolts oil bank 1s intake cam had no oil pour out of it which has a cam bracket from a 3.5. What seems to be happening is the oil is being forced out through the bracket's bolts.

If i can figure out which way the oil is flowing through the cams because i figure i can just add some relieve groves to the either the bracket on the timing cover side of the cam or the brackets on the rear on the cams to stop the oil from forcing its way out and instead letting it fall back into timing cover or valve cover.

Is it that or do the rev-ups required hollowed cam bolts which is another can of worms.

What im wondering is which side of the heads is the oil being feed through? when i pulled out my cam bolts oil bank 1s intake cam had no oil pour out of it which has a cam bracket from a 3.5. What seems to be happening is the oil is being forced out through the bracket's bolts.

If i can figure out which way the oil is flowing through the cams because i figure i can just add some relieve groves to the either the bracket on the timing cover side of the cam or the brackets on the rear on the cams to stop the oil from forcing its way out and instead letting it fall back into timing cover or valve cover.

Is it that or do the rev-ups required hollowed cam bolts which is another can of worms.

#2

#4

also take a look at this page

http://forums.maxima.org/members-rid...ml#post8286047

and this

http://forums.maxima.org/supercharge...ercharged.html

http://forums.maxima.org/members-rid...ml#post8286047

and this

http://forums.maxima.org/supercharge...ercharged.html

#5

I'm glad I stumbled on this thread. I was searching to confirm I needed longer bolts on the exhaust side for the Rev Up cams in the 3.0 head and found it.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

#6

I'm glad I stumbled on this thread. I was searching to confirm I needed longer bolts on the exhaust side for the Rev Up cams in the 3.0 head and found it.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

Ever thought about making small channels in the threads running the length of the bolt?

#7

I'm glad I stumbled on this thread. I was searching to confirm I needed longer bolts on the exhaust side for the Rev Up cams in the 3.0 head and found it.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

I think I am going to get two new 3.0 intake cam bolts and drill holes in them. I tried it out on an old exhaust cam bolt, and the drilling was easy except when I was trying to drill though the threads. The bolts appear to be case hardened either by the thread forming process or by heat treatment. The steel on the inside is relatively soft, however.

I didn't bother to clean up the threads because I won't actually be using this bolt. The radial hole will be on the un-threaded part of the intake cam bolt, about 30mm from the washer. That's approximately where the oil feed hole is through the cam. It will go completely though the bolt.

that is what i was thinking the cam bolt has to be hollowed out, KRZ350 said he got his car together with the cams and normal bolts with out modification. unless the direction through the cams alone can be changed.

#8

I think KRZ350 put the Rev Up came in a 3.5, didn't he? If so, the #2 journal on the exhaust side has an oil feed hole and this modification should not be necessary.

Crusher, what was your solution?

#9

The holes don't have to line up. There is enough clearance inside the cam around the bolt that oil will flow to the holes.

I think KRZ350 put the Rev Up came in a 3.5, didn't he? If so, the #2 journal on the exhaust side has an oil feed hole and this modification should not be necessary.

Crusher, what was your solution?

I think KRZ350 put the Rev Up came in a 3.5, didn't he? If so, the #2 journal on the exhaust side has an oil feed hole and this modification should not be necessary.

Crusher, what was your solution?

#11

That's what I was referring to when I posted the thread links.

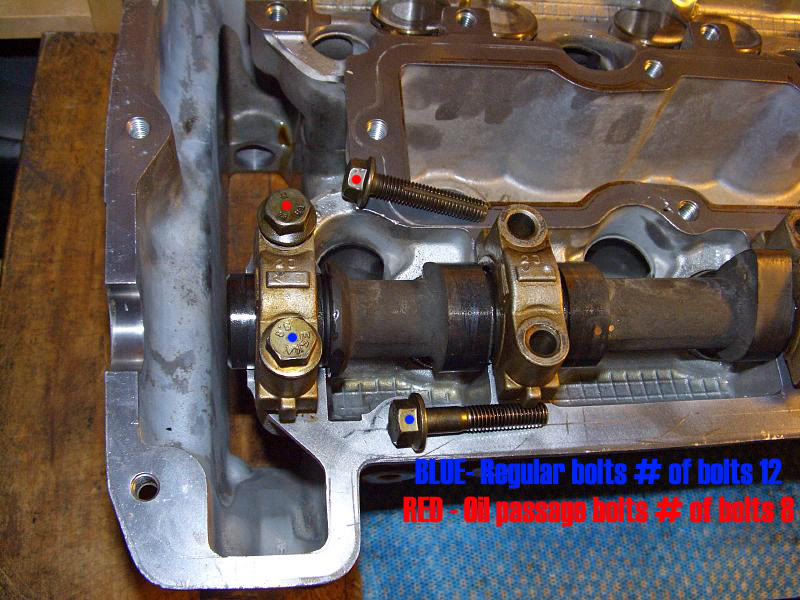

I would pay a machine shop to put 3 oil channels like in the red bolt into those DEK bolts.

They are still hollow cams and won't solve the lubrication problem.. So you would still need this. Sure is a nice advantage not having to worry about this by swappin in a 3.5

#12

You know, I did fund your project in part by buying your Rev Up cams, so I feel a bit more encouragement is in order.

I considered putting oil channels in the bolt lengthwise as shown in McSteve's picture, but figured the threads would get less screwed up (I would have used a Dremel) if I drilled a hole through the bolt. I plan on using the mill we have at work and as long as I make sure everything is aligned when I drill, there should be no problems. I used a POS Cummings Tool drill press and vise to drill the holes in the 3.0 DE exhaust cam bolt and things turned out fine.

Crusher, I still don't understand how your #2, 3 and 4 exhaust camshaft journals are going to get oil.

I considered putting oil channels in the bolt lengthwise as shown in McSteve's picture, but figured the threads would get less screwed up (I would have used a Dremel) if I drilled a hole through the bolt. I plan on using the mill we have at work and as long as I make sure everything is aligned when I drill, there should be no problems. I used a POS Cummings Tool drill press and vise to drill the holes in the 3.0 DE exhaust cam bolt and things turned out fine.

Crusher, I still don't understand how your #2, 3 and 4 exhaust camshaft journals are going to get oil.

#13

If you could use the stock 3.0 DE exhaust camshaft sprocket bolts with the HKS 272 cams in the 3.0 DE heads, then there would be no problem as the #1 camshaft journal oil passage would not be blocked. I think that is what Moncef is saying.

#14

#16

In a normal 3.5 I suspect the threads are cut into the cam before the feed hole. If this were not the case, everyone using 3.5 cams in a 3.0 engine would not be able to reuse the 3.0 exhaust cam sprocket bolt and would be starving journals 2-4 on thier exhaust cams.

See how the stock 3.5 exhaust cam bolts are short?

#21

#23

You know, I did fund your project in part by buying your Rev Up cams, so I feel a bit more encouragement is in order.

I considered putting oil channels in the bolt lengthwise as shown in McSteve's picture, but figured the threads would get less screwed up (I would have used a Dremel) if I drilled a hole through the bolt. I plan on using the mill we have at work and as long as I make sure everything is aligned when I drill, there should be no problems. I used a POS Cummings Tool drill press and vise to drill the holes in the 3.0 DE exhaust cam bolt and things turned out fine.

Crusher, I still don't understand how your #2, 3 and 4 exhaust camshaft journals are going to get oil.

I considered putting oil channels in the bolt lengthwise as shown in McSteve's picture, but figured the threads would get less screwed up (I would have used a Dremel) if I drilled a hole through the bolt. I plan on using the mill we have at work and as long as I make sure everything is aligned when I drill, there should be no problems. I used a POS Cummings Tool drill press and vise to drill the holes in the 3.0 DE exhaust cam bolt and things turned out fine.

Crusher, I still don't understand how your #2, 3 and 4 exhaust camshaft journals are going to get oil.

#24

I don't remember. Maybe like 35 or so. I just picked a random one since it was just a test.

For the bolts I will actually use, I'll measure the diameter of the two holes in the cam that feed the inside of the cam from journal 1. From this measurement, I will calculate the combined area. The hole that I drill lengthwise in the cam should have an area no less than that. This will ensure the holes I drill are not an oil flow bottleneck. I'll assume that as long as these holes do not decrease flow, cam journals 2-4 will have sufficient oil.

The formula should be something like

2 * sqrt (((pi * r ^ 2)2)/pi) = d

where r is the radius of the holes in cam journal 1, and d is the diameter of the hole to be drilled.

For the bolts I will actually use, I'll measure the diameter of the two holes in the cam that feed the inside of the cam from journal 1. From this measurement, I will calculate the combined area. The hole that I drill lengthwise in the cam should have an area no less than that. This will ensure the holes I drill are not an oil flow bottleneck. I'll assume that as long as these holes do not decrease flow, cam journals 2-4 will have sufficient oil.

The formula should be something like

2 * sqrt (((pi * r ^ 2)2)/pi) = d

where r is the radius of the holes in cam journal 1, and d is the diameter of the hole to be drilled.

#26

do you think hollowing out the bolt and adding the hole on top of it will not change the structural integrity / balance? Those bolts are torqued down with 95ft/lb and on top of that the bolt would be turning with up to 3500rpm... I'd imagine changing the integral mass of the bolt could change the behavior due to centrifugal forces a lot.

On the other hand, the metal will be replaced by oil flowing through, changing things up even more. so I guess you would need to make super sure that you hit the center when drilling.

On the other hand, the metal will be replaced by oil flowing through, changing things up even more. so I guess you would need to make super sure that you hit the center when drilling.

#27

do you think hollowing out the bolt and adding the hole on top of it will not change the structural integrity / balance? Those bolts are torqued down with 95ft/lb and on top of that the bolt would be turning with up to 3500rpm... I'd imagine changing the integral mass of the bolt could change the behavior due to centrifugal forces a lot.

On the other hand, the metal will be replaced by oil flowing through, changing things up even more. so I guess you would need to make super sure that you hit the center when drilling.

On the other hand, the metal will be replaced by oil flowing through, changing things up even more. so I guess you would need to make super sure that you hit the center when drilling.

The holes in the cam at the #1 journal are 2mm. So that means the hole through the bolt axially should be 112 thousandths. The radial holes through the bolt can be 79 thousands (~ 2 mm) because there are two of them.

Using this calculator, the clamping force of the bolt is half a ton. The proof load of a grade five bolt (I think these bolts are stronger than grade 5) is 85,000 psi. The cross sectional area of the bolt is 0.175 in^2. Because the bolt is an M12, it's diameter is 0.472 in. Multiply this by 0.079 inch (the radial hole diameter) to get the area of the material being removed by drilling at the bolt's narrowest point in terms of cross sectional area. (I know it's an estimation as the area of the material removed is not rectangular), and subtract the result from 0.175 in^2.

At its narrowest, the drilled bolt will have a cross sectional area of 0.138 in^2. That's a reduction of 21% from a bolt that has not been drilled. This equates to a proof load of 11,700 pounds, about 12 times higher than the clamping force required of an M12 bolts at 95 ft. lbs.

Please let me know if my reasoning is sound. I would hate to make a mistake and find out later.

#28

I mean your calculation works of the premise that a hollow bolt will have the same properties as a solid one. By calculating the removed metal out, you for practicability purposes made a calculation for a smaller SOLID bolt, instead of a hollow one.

I don't know, because it's not my metier, but I would imagine a hollow body to react to pressure/ clampforce differently than a solid one. I mean logically thinking, if you have a solid bolt and bolt it really tightly, the pressure on the threads is resisted by the solid mass inside. I would imagine that by removing the inner material on a regular bolt, you might run the risk that there is nothing to push back against the compression from the threads.

However, i'm in the process of becoming a lawyer, not an engineer. We have a couple of those around here, so maybe one of them could chime in.

I don't know, because it's not my metier, but I would imagine a hollow body to react to pressure/ clampforce differently than a solid one. I mean logically thinking, if you have a solid bolt and bolt it really tightly, the pressure on the threads is resisted by the solid mass inside. I would imagine that by removing the inner material on a regular bolt, you might run the risk that there is nothing to push back against the compression from the threads.

However, i'm in the process of becoming a lawyer, not an engineer. We have a couple of those around here, so maybe one of them could chime in.

#29

I'm not worried about the strength of the bolt, I think it can withstand the clamping force. My concern would be fatigue. There are going to be a lot of heat cycles on this bolt. Vibration will also be present.

Any holes in the outside, the harder, more brittle part, are going to be perfectly round, a good shape for resisting fatigue. There will be some sharp corners on the inside, however. Specifically where the axial hole meets the radial hole. The inside of the bolt seems to be more ductile though.

#31

I spoke with the lead mechanical engineer at work, and he thinks drilling the bolts should work. Drilling shall begin Tuesday, as long as the bolts come in on Monday, like UPS says they should.

#32

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

I don't think I ever ordered RU exhaust bolts to see what they looked like. It sounds like the 3.0 doesn't have the oil passage on the #2, that would make sense why the 3.5 fsm was wrong, they love to just steal pics from older fsm's.

Last edited by KRRZ350; 06-29-2012 at 07:45 AM.

#35

To answer the OP's answer my motor does not leak oil. It did initially but that was because I muffed up the compression fitting I used.

Its better now!

Thread

Thread Starter

Forum

Replies

Last Post

litch

4th Generation Maxima (1995-1999)

123

01-04-2024 07:01 PM

My Coffee

New Member Introductions

15

06-06-2017 02:01 PM

For you that will be $500+shipping.

For you that will be $500+shipping.