Oil Drain Pan Screws

#3

IF YOU MEAN oil drain plug its 22-29 foot lbs(my 92 fsm)same for ve

IF YOU MEAN OIL PAN SCREWS

5.1 to 5.8 foot lbs from my 92 factory service manual pg em-39

for the ve its 4.6-6.1 foot lbs

i dont even have a micro torque wrench ,"I was raised in the woods"

IF YOU MEAN OIL PAN SCREWS

5.1 to 5.8 foot lbs from my 92 factory service manual pg em-39

for the ve its 4.6-6.1 foot lbs

i dont even have a micro torque wrench ,"I was raised in the woods"

Last edited by maximagician; 06-23-2009 at 04:06 AM.

#5

Thanks guys - I actually meant the length of bolt, head, and thread pitch. There's 18 in total and they should all be the same length. Just don't want to pay the dealer.

Were these those self sealing kind of bolts that are use once and throw away?

Were these those self sealing kind of bolts that are use once and throw away?

#6

i believe it takes 10mm socket.

not self sealing (no loctite or anything)...but keep in mind there's no gasket on the oil pan from factory so it's all RTV.

#7

#9

Thanks dudes. Sure D. if you have one lying around - otherwise I'm going to the JY and I can pull one off, as I need to pull out some other items to get the thread pitch.. Good to know they aren't dealer only (self sealing). Nitrous - oil pan isn't rotted, but I'm overhauling the VG engine, so I'm replacing like 100 fasteners while I'm doing it. Here's some other fasteners I need the spec on if anyone on the ORG has them stored on your hard drive:

THROTTLE CHAMBER BOLT (2)

THROTTLE CHAMBER BOLT (1)

IACV-AAC VALVE-->UIM (4)

ROCKER SHAFT BOLT (24)

INTAKE MANIFOLD BOLT (4)

INTAKE MANIFOLD NUT (4)

INTAKE MANIFOLD STUD (4)

STEERING RACK BRACKET CAP SCREW (5)

FRONT COVER WASHER (16) [Timing Belt Cover]

FRONT COVER BOLT (15)

BACK COVER BOLT (2)

THERMOSTAT HOUSING FRONT BOLT (4)

THERMOSTAT HOUSING REAR BOLT (2)

WATER OUTLET PIPE BOLT (2)

MAIN BEARING CAP BOLTS ?

THROTTLE CHAMBER BOLT (2)

THROTTLE CHAMBER BOLT (1)

IACV-AAC VALVE-->UIM (4)

ROCKER SHAFT BOLT (24)

INTAKE MANIFOLD BOLT (4)

INTAKE MANIFOLD NUT (4)

INTAKE MANIFOLD STUD (4)

STEERING RACK BRACKET CAP SCREW (5)

FRONT COVER WASHER (16) [Timing Belt Cover]

FRONT COVER BOLT (15)

BACK COVER BOLT (2)

THERMOSTAT HOUSING FRONT BOLT (4)

THERMOSTAT HOUSING REAR BOLT (2)

WATER OUTLET PIPE BOLT (2)

MAIN BEARING CAP BOLTS ?

#10

Thanks dudes. Sure D. if you have one lying around - otherwise I'm going to the JY and I can pull one off, as I need to pull out some other items to get the thread pitch.. Good to know they aren't dealer only (self sealing). Nitrous - oil pan isn't rotted, but I'm overhauling the VG engine, so I'm replacing like 100 fasteners while I'm doing it. Here's some other fasteners I need the spec on if anyone on the ORG has them stored on your hard drive:

THROTTLE CHAMBER BOLT (2)

THROTTLE CHAMBER BOLT (1)

IACV-AAC VALVE-->UIM (4)

ROCKER SHAFT BOLT (24)

INTAKE MANIFOLD BOLT (4)

INTAKE MANIFOLD NUT (4)

INTAKE MANIFOLD STUD (4)

STEERING RACK BRACKET CAP SCREW (5)

FRONT COVER WASHER (16) [Timing Belt Cover]

FRONT COVER BOLT (15)

BACK COVER BOLT (2)

THERMOSTAT HOUSING FRONT BOLT (4)

THERMOSTAT HOUSING REAR BOLT (2)

WATER OUTLET PIPE BOLT (2)

MAIN BEARING CAP BOLTS ?

THROTTLE CHAMBER BOLT (2)

THROTTLE CHAMBER BOLT (1)

IACV-AAC VALVE-->UIM (4)

ROCKER SHAFT BOLT (24)

INTAKE MANIFOLD BOLT (4)

INTAKE MANIFOLD NUT (4)

INTAKE MANIFOLD STUD (4)

STEERING RACK BRACKET CAP SCREW (5)

FRONT COVER WASHER (16) [Timing Belt Cover]

FRONT COVER BOLT (15)

BACK COVER BOLT (2)

THERMOSTAT HOUSING FRONT BOLT (4)

THERMOSTAT HOUSING REAR BOLT (2)

WATER OUTLET PIPE BOLT (2)

MAIN BEARING CAP BOLTS ?

whatever you get make sure you have some cad or nickel plating on them.

#11

Yes Guy!

That helps alot. It's scorching hot outside now, and I really don't look forward to going to the JY. I've sourced almost all the parts and I won't be doing this until AUG so you can get around to it when you get a chance.

Dan I'm concerned about the flatness of the driveway. These cheap import engine hoists and engine stands, if the driveway has cracks in it or isn't perfectly level, do you find theres a big risk of breaking the welds in the equipment? Driveway is pretty flat but it's not exactly flat like a concrete floor in an industrial unit.

Think it's necessary to buy a huge sheet of particle board that may flatten the driveway out a bit? It's not that it's on a slope - it's just eneven a bit.

That helps alot. It's scorching hot outside now, and I really don't look forward to going to the JY. I've sourced almost all the parts and I won't be doing this until AUG so you can get around to it when you get a chance.

Dan I'm concerned about the flatness of the driveway. These cheap import engine hoists and engine stands, if the driveway has cracks in it or isn't perfectly level, do you find theres a big risk of breaking the welds in the equipment? Driveway is pretty flat but it's not exactly flat like a concrete floor in an industrial unit.

Think it's necessary to buy a huge sheet of particle board that may flatten the driveway out a bit? It's not that it's on a slope - it's just eneven a bit.

#12

Yes Guy!

That helps alot. It's scorching hot outside now, and I really don't look forward to going to the JY. I've sourced almost all the parts and I won't be doing this until AUG so you can get around to it when you get a chance.

Dan I'm concerned about the flatness of the driveway. These cheap import engine hoists and engine stands, if the driveway has cracks in it or isn't perfectly level, do you find theres a big risk of breaking the welds in the equipment? Driveway is pretty flat but it's not exactly flat like a concrete floor in an industrial unit.

Think it's necessary to buy a huge sheet of particle board that may flatten the driveway out a bit? It's not that it's on a slope - it's just eneven a bit.

That helps alot. It's scorching hot outside now, and I really don't look forward to going to the JY. I've sourced almost all the parts and I won't be doing this until AUG so you can get around to it when you get a chance.

Dan I'm concerned about the flatness of the driveway. These cheap import engine hoists and engine stands, if the driveway has cracks in it or isn't perfectly level, do you find theres a big risk of breaking the welds in the equipment? Driveway is pretty flat but it's not exactly flat like a concrete floor in an industrial unit.

Think it's necessary to buy a huge sheet of particle board that may flatten the driveway out a bit? It's not that it's on a slope - it's just eneven a bit.

i'm not going to get into concrete repairs...so it's your call if you want to fix it.

particle board won't stand a chance...it'll just crack or crumble under the weight. if it's REALLY that uneven...maybe try a concrete skim coat over it or hardwood boards with the edges beveled....but don't use particle board.

it won't break the equipment but it might break your back (pushing and pulling). these things are set up to hold big block V8s and etc...so our small V6 is a joke to them. you make the call...if it looks unsafe it probably is.

#13

The problem with any pavement in the heat is the weight put on the hoists small wheels causes it to sink and it makes it real hard to roll. On hot days I put pieces of plywood under my jack and jack stands. I only use 1/2, it works good but the jack stands dig in which is actually good for my purposes. I think if you got the thickest plywood you can, like 3/4 or bigger, you should be able to roll on it without it caving in too much. Depending on how bad the driveway is though. Don't bother with particle board it's garbage.

#15

The problem with any pavement in the heat is the weight put on the hoists small wheels causes it to sink and it makes it real hard to roll. On hot days I put pieces of plywood under my jack and jack stands. I only use 1/2, it works good but the jack stands dig in which is actually good for my purposes. I think if you got the thickest plywood you can, like 3/4 or bigger, you should be able to roll on it without it caving in too much. Depending on how bad the driveway is though. Don't bother with particle board it's garbage.

concrete won't do that.

so i guess it depends on what he has.

#16

I went to the junkyard today in 100 degree heat with absolutely no clouds or shade. Thought I was gonna keel over from a heat stroke after just a few minutes

#17

Wicked - thanks guy. I'll order up those bolts, now I won't have to go under it at the JY. Nitrous it's asphalt - and it really isn't that bad. It's actually pretty level in the covered area...theres a roof over it (car port). The exposed part of the asphalt driveway though is really bumpy and rough, I can just avoid wheeling it around on that part.

It's bad here though James - it's kind of humid, it makes it worse.

It's bad here though James - it's kind of humid, it makes it worse.

#18

The problem with any pavement in the heat is the weight put on the hoists small wheels causes it to sink and it makes it real hard to roll. On hot days I put pieces of plywood under my jack and jack stands. I only use 1/2, it works good but the jack stands dig in which is actually good for my purposes. I think if you got the thickest plywood you can, like 3/4 or bigger, you should be able to roll on it without it caving in too much. Depending on how bad the driveway is though. Don't bother with particle board it's garbage.

I'll take a picture sometime for safety issues how I got around it. I put those small pieces of plywood under at all times, even in the fall, just in case. If it was concrete - I probably wouldn't care.

#19

Dan - did you remove the entire oil pan? If you do get a chance - see if you can get the spec on the bearing cap bolts.

#21

No big deal though, the wrong ones only cost me a few bucks for 30, i'll just re-order the slightly bigger ones.

#22

Fixed

Last edited by 300zmax; 08-19-2009 at 09:53 AM.

#24

dont remember having an issue

#25

300, your right on those internal ones though - i checked the bearing cap bolts and they are OEM I'm pretty sure. They don't look like ordinary bolts. The rocker shaft bolts too have a slight bulge in the shaft near the head, similar to those intake manifold studs - OEM.

The oil pan bolts are definately 12mm length but 10mm likely gives enough thread to hold the pan on fine. If one measures below the washer it does show 10mm.

#26

And all those internal bolts that are covered in varnish, like the Bearing Cap Bolts, Rocker Shaft Bolts, would you bother replacing those? They 'look' preserved in time in perfect condition, my only concern was that all that heat over time might weaken them by now.

300, your right on those internal ones though - i checked the bearing cap bolts and they are OEM I'm pretty sure. They don't look like ordinary bolts. The rocker shaft bolts too have a slight bulge in the shaft near the head, similar to those intake manifold studs - OEM.

The oil pan bolts are definately 12mm length but 10mm likely gives enough thread to hold the pan on fine. If one measures below the washer it does show 10mm.

300, your right on those internal ones though - i checked the bearing cap bolts and they are OEM I'm pretty sure. They don't look like ordinary bolts. The rocker shaft bolts too have a slight bulge in the shaft near the head, similar to those intake manifold studs - OEM.

The oil pan bolts are definately 12mm length but 10mm likely gives enough thread to hold the pan on fine. If one measures below the washer it does show 10mm.

#28

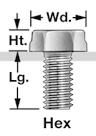

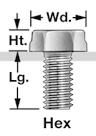

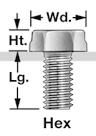

THREAD LENGTH...below the washer is the start and the end of the threaded part (tip) is the end.

when you measure a bolt you measure THREAD LENGTH. you don't measure the head of the bolt.

measure the "LG" on your bolt....is it 10mm?

stop trying to prove me wrong...it's not going to work. go back to torching your motor.

#30

THREAD LENGTH...10mm.

THREAD LENGTH...below the washer is the start and the end of the threaded part (tip) is the end.

when you measure a bolt you measure THREAD LENGTH. you don't measure the head of the bolt.

measure the "LG" on your bolt....is it 10mm?

stop trying to prove me wrong...it's not going to work. go back to torching your motor.

THREAD LENGTH...below the washer is the start and the end of the threaded part (tip) is the end.

when you measure a bolt you measure THREAD LENGTH. you don't measure the head of the bolt.

measure the "LG" on your bolt....is it 10mm?

stop trying to prove me wrong...it's not going to work. go back to torching your motor.

#31

Sorry Dan - I didn't mean to agitate you again. But yes, your LG length is wrong, it's 12mm, but it's not a big deal - they cost me like 3 bucks.

A little tip - when you measure the bolt, you always EXCLUDE the washer, regardless if it's full thread or partial thread. I suspected you just mixed it up because you measured below the washer. No big deal though.

A little tip - when you measure the bolt, you always EXCLUDE the washer, regardless if it's full thread or partial thread. I suspected you just mixed it up because you measured below the washer. No big deal though.

#32

Sorry Dan - I didn't mean to agitate you again. But yes, your LG length is wrong, it's 12mm, but it's not a big deal - they cost me like 3 bucks.

A little tip - when you measure the bolt, you always EXCLUDE the washer, regardless if it's full thread or partial thread. I suspected you just mixed it up because you measured below the washer. No big deal though.

A little tip - when you measure the bolt, you always EXCLUDE the washer, regardless if it's full thread or partial thread. I suspected you just mixed it up because you measured below the washer. No big deal though.

can someone else confirm? 300 said that it's 10mm.

you can stop the little tips because you're not helping anyone...please keep your tips to yourself.

I KNOW YOU DON'T INCLUDE THE WASHER!!! you think i just picked up a wrench for the first time today?!? there's no way that washer is 2mm thick. it's a mini split washer which is at max 1mm thick.

you know what...take a pic of your bolt and how you measured it.

but like matt said it's pointless...but you wanted to show me off and prove me wrong (which you didn't)...so go ahead and shove your 12mm bolt in there if it makes you happy.

Last edited by DanNY; 08-19-2009 at 12:41 PM.

#33

No problem Dan. I'll keep those little tips to myself if you want me to. Unfortunately I can't take a photo of the bolt. Those tiny cap screws were the OEM ones that came off the oil pan.

Please calm down a bit, you sound really hostile. How old are you by the way? I'm 30.

Please calm down a bit, you sound really hostile. How old are you by the way? I'm 30.

#34

No problem Dan. I'll keep those little tips to myself if you want me to. Unfortunately I can't take a photo of the bolt. Those tiny cap screws were the OEM ones that came off the oil pan.

Please calm down a bit, you sound really hostile. How old are you by the way? I'm 30.

Please calm down a bit, you sound really hostile. How old are you by the way? I'm 30.

you see another member in this thread that gave up that information? another member that went out of their way to help a total stranger?

i measured the bolt that came off the oil pan. if you have a different bolt then i don't know what to tell you. i can say that this motor is the orig motor with the orig hardware and i am the orig owner. this bolt will hold the oil pan since the pan is sealed with RTV also. of course you want to play these childish games and try and prove me wrong. i can take the pics of the cad plated OEM bolt with the caliper that i used to measure it with (yes the washer was pulled out to measure thread length) but that would be more effort to prove something that i don't even want to waste my time on since i'm sure you'll come up with another excuse why your bolt is 2mm longer.

you bit the hand that fed you so that's it...i'm done with you...you're a waste of my time like this thread now.

#35

No problem bud. I don't need to see your photo, as I just re-ordered the correct size. Who knows, maybe the Maxima's in Canada had different screws.

No worries, I don't want to waste any of your time, I forgot that your not responding anymore to my questions, so don't worry I won't ask you another question. A little tid bit of advice, it's OK to be wrong sometimes, nobody is perfect.

Thanks Bud.

No worries, I don't want to waste any of your time, I forgot that your not responding anymore to my questions, so don't worry I won't ask you another question. A little tid bit of advice, it's OK to be wrong sometimes, nobody is perfect.

Thanks Bud.

#36

No problem bud. I don't need to see your photo, as I just re-ordered the correct size. Who knows, maybe the Maxima's in Canada had different screws.

No worries, I don't want to waste any of your time, I forgot that your not responding anymore to my questions, so don't worry I won't ask you another question. A little tid bit of advice, it's OK to be wrong sometimes, nobody is perfect.

Thanks Bud.

No worries, I don't want to waste any of your time, I forgot that your not responding anymore to my questions, so don't worry I won't ask you another question. A little tid bit of advice, it's OK to be wrong sometimes, nobody is perfect.

Thanks Bud.

like what i said in a different thread that i responded back to you...when i'm wrong i'll admit that i'm wrong. do you?

in this case i stand firm that i'm NOT wrong here. so for you to call me out and tell me that i'm wrong you better come back to me with facts and picture and not just some BS accusation with nothing to back it up.

so stop the BS...ok?

#37

i thought you would stop giving me advice? you can't even take your own advice.

like what i said in a different thread that i responded back to you...when i'm wrong i'll admit that i'm wrong. do you?

in this case i stand firm that i'm NOT wrong here. so for you to call me out and tell me that i'm wrong you better come back to me with facts and picture and not just some BS accusation with nothing to back it up.

so stop the BS...ok?

like what i said in a different thread that i responded back to you...when i'm wrong i'll admit that i'm wrong. do you?

in this case i stand firm that i'm NOT wrong here. so for you to call me out and tell me that i'm wrong you better come back to me with facts and picture and not just some BS accusation with nothing to back it up.

so stop the BS...ok?

Ok that is a second on dan, can we now quit.

by the way 1993 are you the first owner of the car. i ask because you said the bolt was a cap head ((see link) our bolts are hex head (hex head link). it is possible your pan was pull before and fixed for what ever reason

#38

I found something very strange in the casting near the camshaft locate plate on the head that was making the rattling noise. It seems there is a crack but nothing spins where the crack is, I don't know if it was just a defect from the original casting, and I can't see the huge chunk of aluminum that would have came out when I removed that rear cover plate covering the locate plate. I'll take a photo during the week. Not sure if I should replace this head during re-assembly because of this open hole. Note - when I install the new rear cover gasket and rear cover there would be no oil leakage, and the hole is on the outside of the locate plate & washer. The inside of this engine looks new and the inspections so far are showing not a lot of wear. Watch this, I bet you after I re-assemble it, that noise will still be there. Wondering if the crack near the locate plate could trigger the noise at the distributor end...that's where the noise was coming from.

Timing belt showed no sign of wear and the tension inspection showed 22 lbs exactly. Using the bore gauge tommorow so i'll check the main bearings, rod bearings, camshaft journals, and camshaft runout, lifter guide holes, spring pressure, rocker arm holes (I.D.), bores, and i'll hope for the best.

300, those were the original screws on my oil pan. Your measurements are correct, 10mm MINUS washer. Washer is 2mm thick. When you measure a cap screw you remove all the washers, and you'll find it's 12mm when you remove it. Regardless of what the washer is it doesn't matter since it measures just like the diagram above (Lg) above and when you go to order the bolt you say M6X12 Coarse Full and then washers are up to you. Honestly though it's not a big deal. I already ordered the replacements, and yes, we can stop talking about these tiny screws.

Timing belt showed no sign of wear and the tension inspection showed 22 lbs exactly. Using the bore gauge tommorow so i'll check the main bearings, rod bearings, camshaft journals, and camshaft runout, lifter guide holes, spring pressure, rocker arm holes (I.D.), bores, and i'll hope for the best.

300, those were the original screws on my oil pan. Your measurements are correct, 10mm MINUS washer. Washer is 2mm thick. When you measure a cap screw you remove all the washers, and you'll find it's 12mm when you remove it. Regardless of what the washer is it doesn't matter since it measures just like the diagram above (Lg) above and when you go to order the bolt you say M6X12 Coarse Full and then washers are up to you. Honestly though it's not a big deal. I already ordered the replacements, and yes, we can stop talking about these tiny screws.

#39

i thought you would stop giving me advice? you can't even take your own advice.

like what i said in a different thread that i responded back to you...when i'm wrong i'll admit that i'm wrong. do you?

in this case i stand firm that i'm NOT wrong here. so for you to call me out and tell me that i'm wrong you better come back to me with facts and picture and not just some BS accusation with nothing to back it up.

so stop the BS...ok?

like what i said in a different thread that i responded back to you...when i'm wrong i'll admit that i'm wrong. do you?

in this case i stand firm that i'm NOT wrong here. so for you to call me out and tell me that i'm wrong you better come back to me with facts and picture and not just some BS accusation with nothing to back it up.

so stop the BS...ok?

.

.

#40

300, those were the original screws on my oil pan. Your measurements are correct, 10mm MINUS washer. Washer is 2mm thick. When you measure a cap screw you remove all the washers, and you'll find it's 12mm when you remove it. Regardless of what the washer is it doesn't matter since it measures just like the diagram above (Lg) above and when you go to order the bolt you say M6X12 Coarse Full and then washers are up to you. Honestly though it's not a big deal. I already ordered the replacements, and yes, we can stop talking about these tiny screws.

TAKE A PIC OF THE PAN BOLT WITH YOUR MEASUREMENTS!!!

otherwise stop posting in this thread.