Beefing up/rebuilding the VE 5 speed RS5F50V

#41

nice job man...i was asking neal what size solder to use and he was telling me something massive to use..like 2mm...i'm like woah.

i like yours a little better maybe instead of laying it out like a "X" like the other posts asks for i'll do the little snips like how you did there.

right now i'm stuck with ordering snap ring and parts that came from the input shaft. The little springs around the syncros seems a little worn (one had a tiny piece broken off). it appears it's all dealer only parts...so let's see how that goes.

james did you end up swapping the snap rings off the main shaft since they have different thickness on them.

neal recommended i look at mcmaster for shims or talk to a bearing supplier...did you talk to nissan about getting shims?

i like yours a little better maybe instead of laying it out like a "X" like the other posts asks for i'll do the little snips like how you did there.

right now i'm stuck with ordering snap ring and parts that came from the input shaft. The little springs around the syncros seems a little worn (one had a tiny piece broken off). it appears it's all dealer only parts...so let's see how that goes.

james did you end up swapping the snap rings off the main shaft since they have different thickness on them.

neal recommended i look at mcmaster for shims or talk to a bearing supplier...did you talk to nissan about getting shims?

#42

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

nice job man...i was asking neal what size solder to use and he was telling me something massive to use..like 2mm...i'm like woah.

i like yours a little better maybe instead of laying it out like a "X" like the other posts asks for i'll do the little snips like how you did there.

right now i'm stuck with ordering snap ring and parts that came from the input shaft. The little springs around the syncros seems a little worn (one had a tiny piece broken off). it appears it's all dealer only parts...so let's see how that goes.

james did you end up swapping the snap rings off the main shaft since they have different thickness on them.

neal recommended i look at mcmaster for shims or talk to a bearing supplier...did you talk to nissan about getting shims?

i like yours a little better maybe instead of laying it out like a "X" like the other posts asks for i'll do the little snips like how you did there.

right now i'm stuck with ordering snap ring and parts that came from the input shaft. The little springs around the syncros seems a little worn (one had a tiny piece broken off). it appears it's all dealer only parts...so let's see how that goes.

james did you end up swapping the snap rings off the main shaft since they have different thickness on them.

neal recommended i look at mcmaster for shims or talk to a bearing supplier...did you talk to nissan about getting shims?

And yeah, the little snipped sections worked real well, and it held in place very well with the wheel bearing grease. I was a little worried on the mainshaft bearing that when tapping it into the transmission case that the snips might fall off even with the grease but they stuck on there like glue.

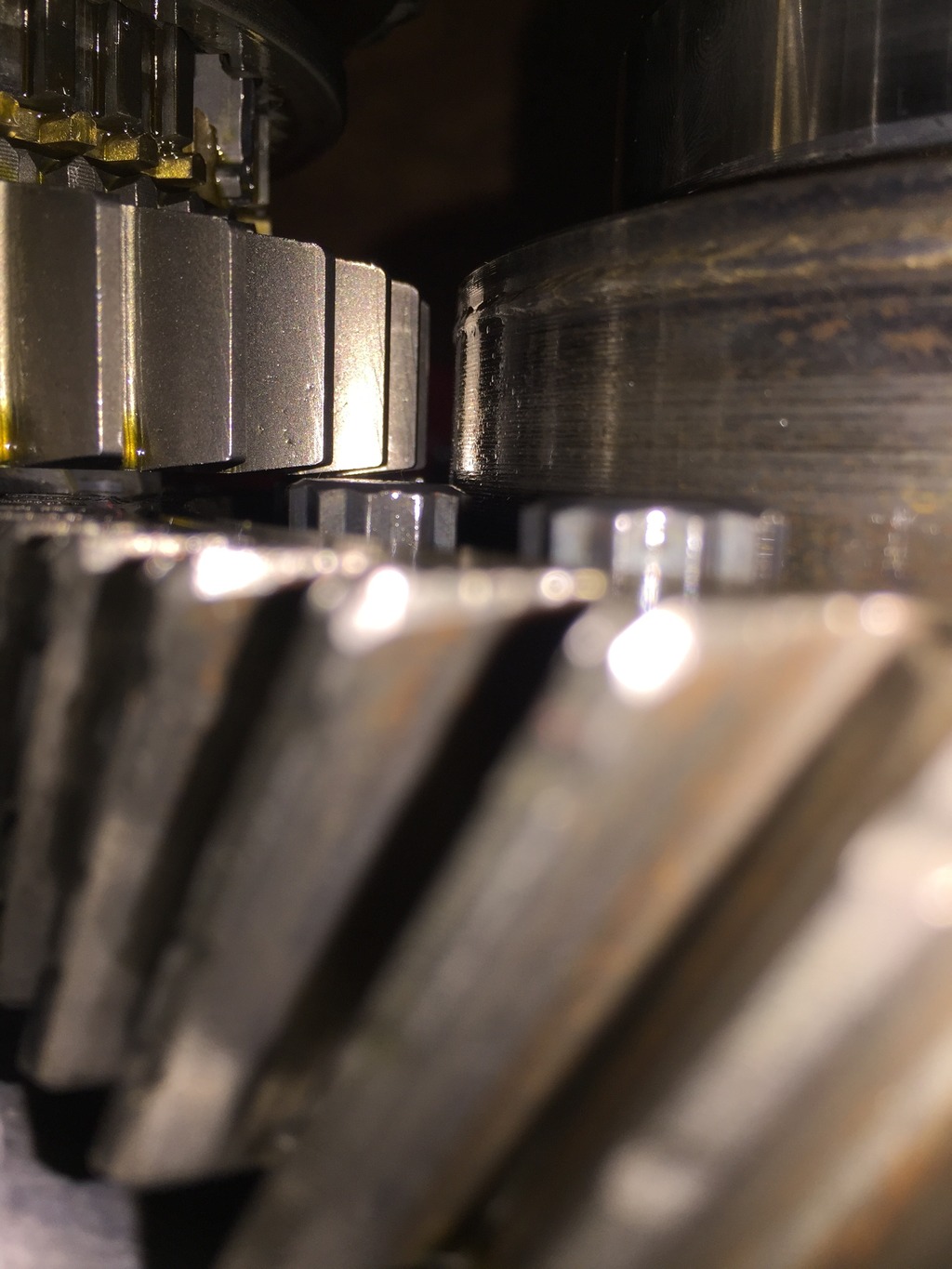

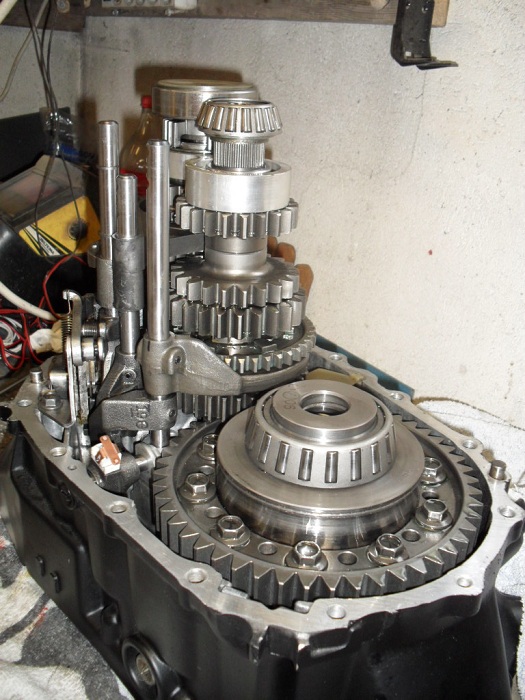

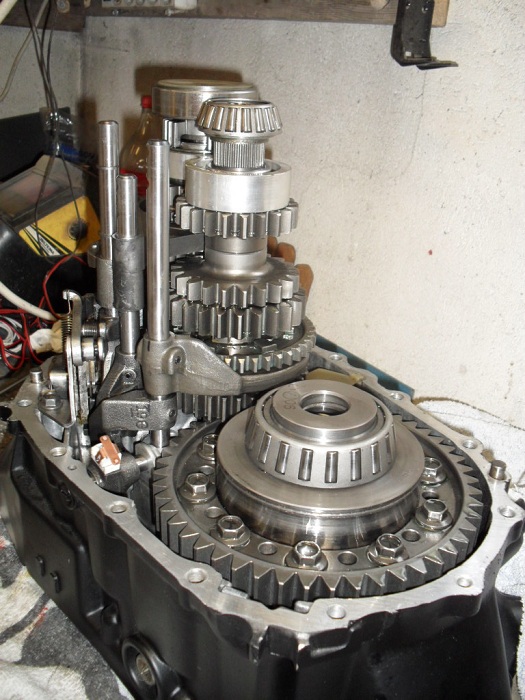

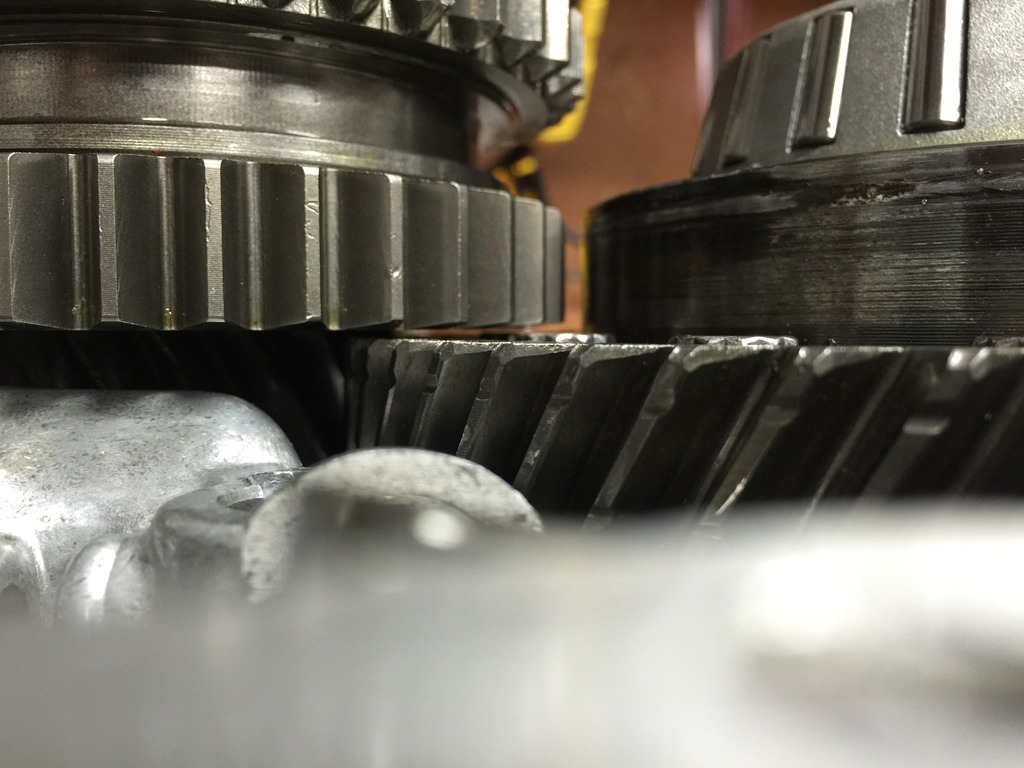

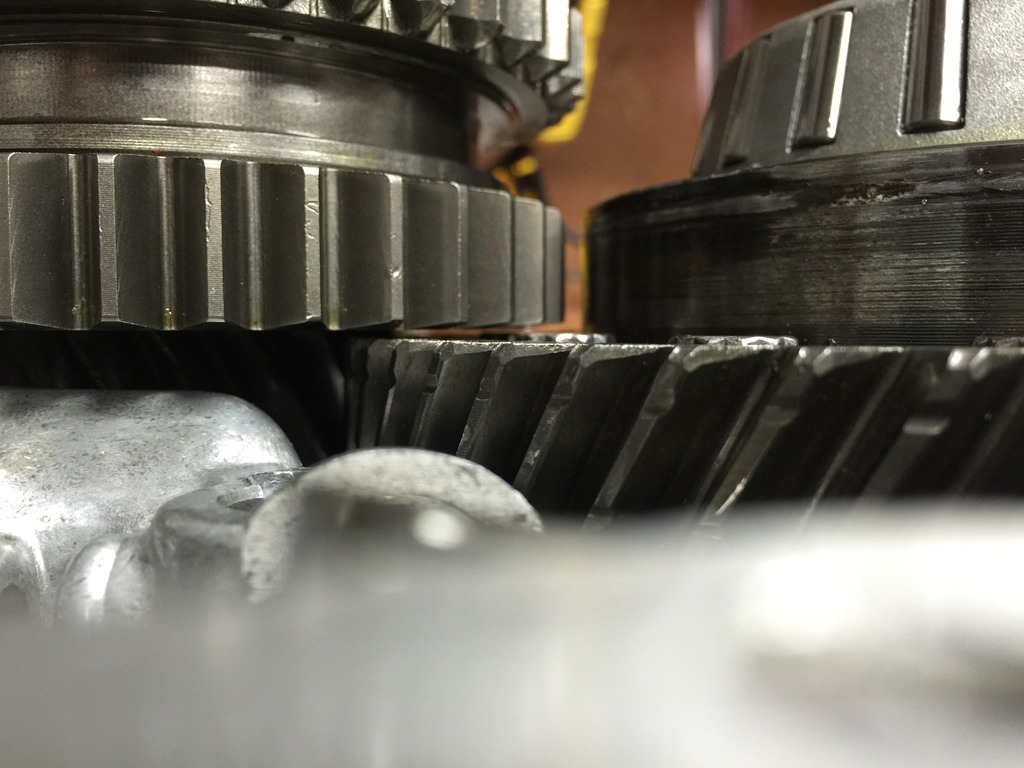

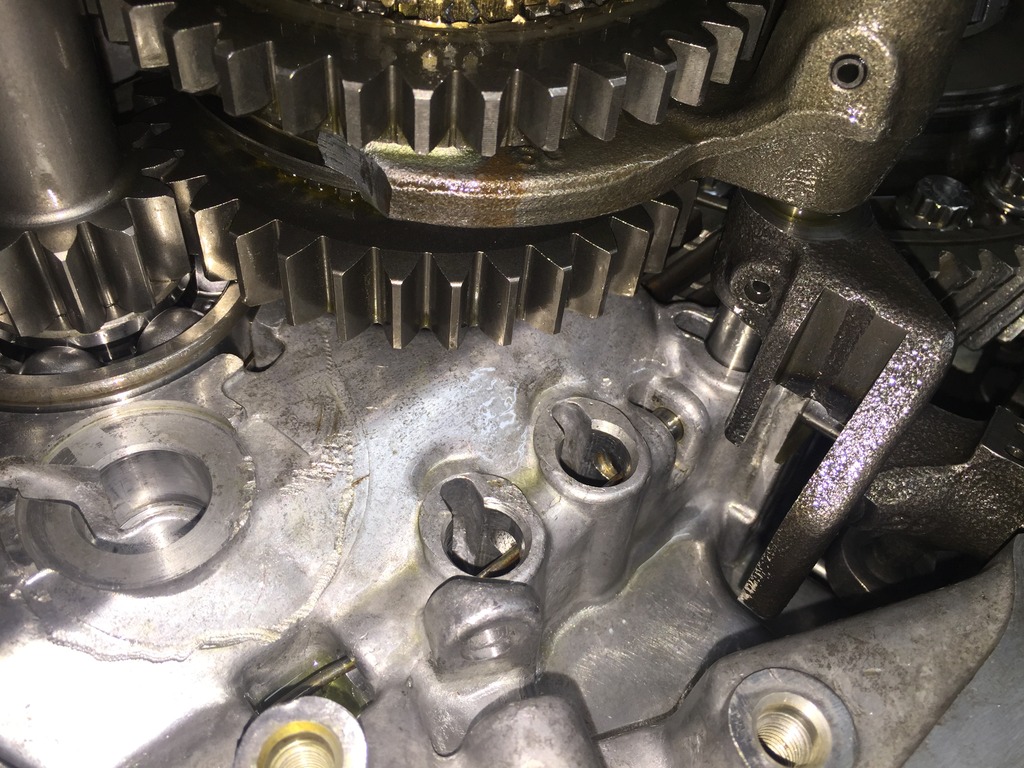

I just re-used the same snap rings and thrust washer stuff that was on the old shaft(s). I realize they come in different thicknesses based on clearances, but after being assembled, everything measured out within factory spec (or very close) - well, everything except for the 4th gear end play (measured between 4th and 5th). The FSM calls for .25mm to .55mm, mine measured 1.142mm. I don't know if I'm misinterpreting the FSM or what, but I studied the pictures of the old shafts I took prior to disassembly and it appears to be about the same gap according to the ol' eye test. The old gap was DEFINITELY much larger than .25mm to .55mm at the very least. Also, when setting in both the input and mainshafts, both 5th gears line up dead even - so I guess that's the most important thing? I'm not really sure. Here's both shafts installed and the 5th gear line up:

3rd gear end play on the input shaft - measured between 2nd and 3rd as per the FSM (I had .254mm, factory range is .23mm to .43mm):

I didn't take any pictures of the input 4th gear end play - measured between 4th and 5th per the the FSM (this is the larger-than-FSM-spec I mentioned above).

Here's my input 5th gear end play rig:

And the measured 5th gear deflection (.019", right on the outside edge of the FSM acceptable range of .0091" to .0189"):

1st gear end play on the mainshaft (I had .229mm, factory range is .23mm to .43mm):

2nd gear end play on the mainshaft (I had .533mm, factory range is .23mm to .58mm):

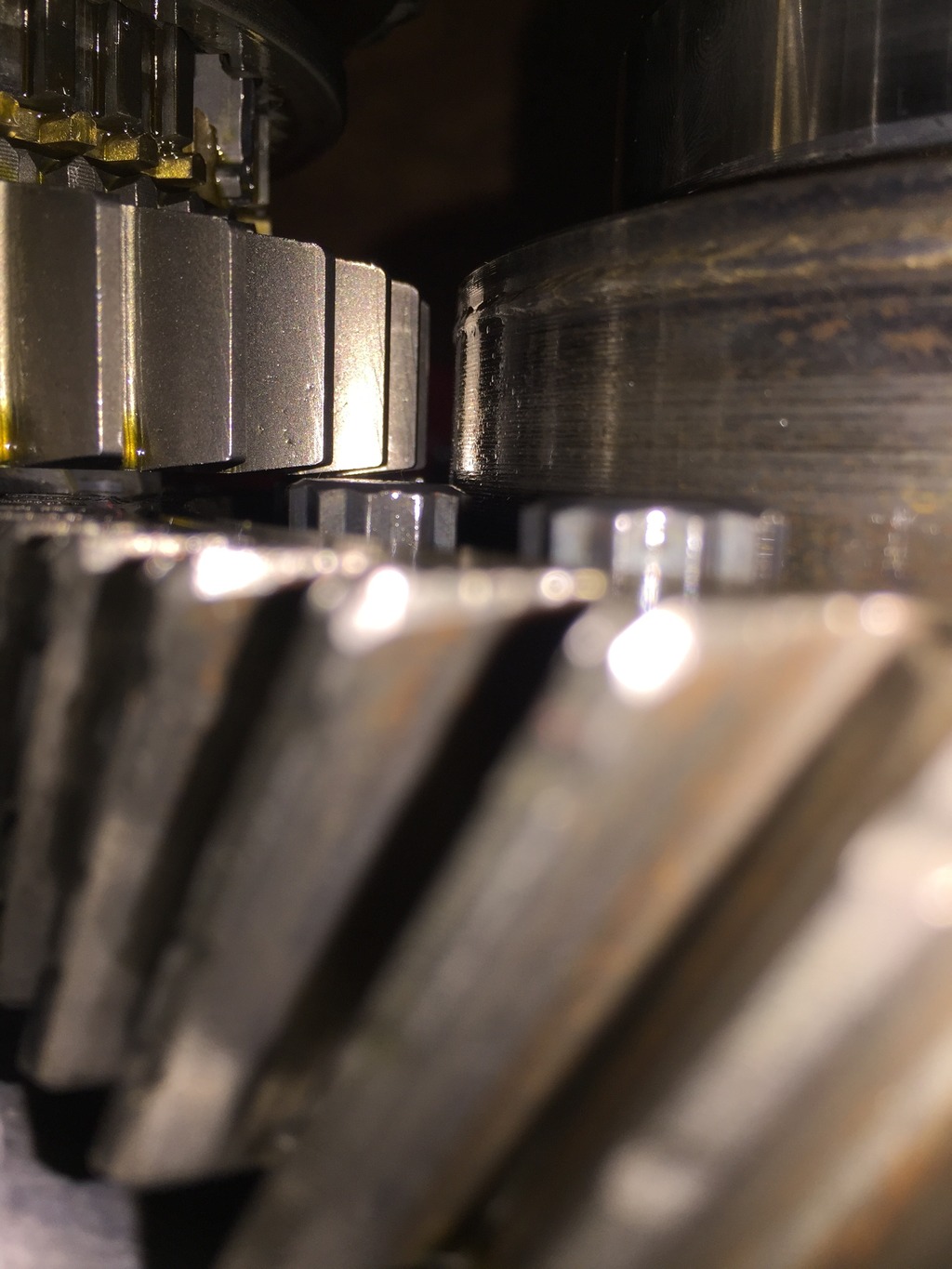

Soooooo, my takeaway here is that everything seems decently well enough in spec, thankfully. I did notice tonight that when I set the differential and both shafts in place on the bellhousing that the bolt heads on the differential are very, very close to the underside of 1st gear on the mainshaft. I should have thought to measure the actual clearance tonight with my feeler gauges but didn't think about it. I'm not sure what the clearance should be either way though, but I sure hope it's not too close. I'm not sure what I could do about it anyway.

How far out of spec are your measurements between the gears? Wayyyyy out of whack or fairly close? What all are you having to order, all new snap rings AND thrust washer or just one type of thing?

I haven't ordered my shims yet. I did very briefly look on McMaster but didn't really find anything. I think you said you had found some there?

I really need to sit down and figure out exactly what combinations of shims I can use to get X total thicknesses. I want to be able to check about availability from Nissan on a large assortment of combinations that will yield what I'm looking for, that way if Y shim is backordered but I can still achieve the same result with two Z shims for example and those aren't backordered, then obviously I want to order two Z shims. But it will take me some time to figure out my total range of combos so that I can then check for what's actually available. I was hoping to have some time to do that today at work but I was busy non-stop today.

#43

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Okay so makes total sense why first gear is so close to the differential bolts.

PAR 1st gear teeth are really just that much thicker than the OEM (in hindsight, duh).

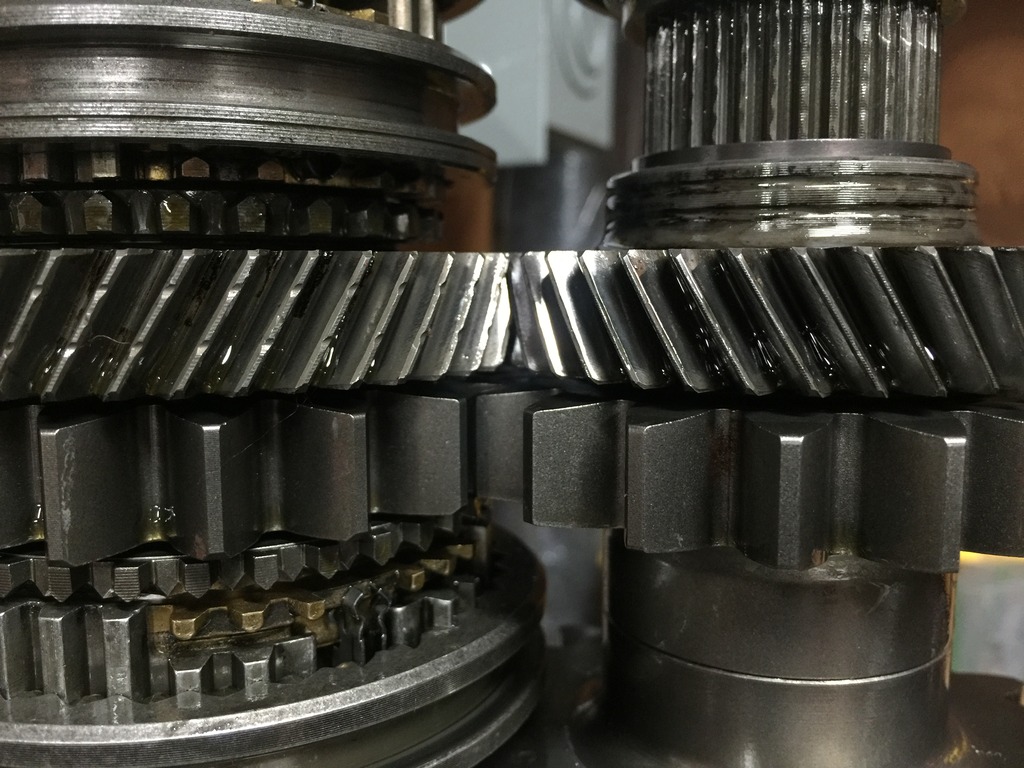

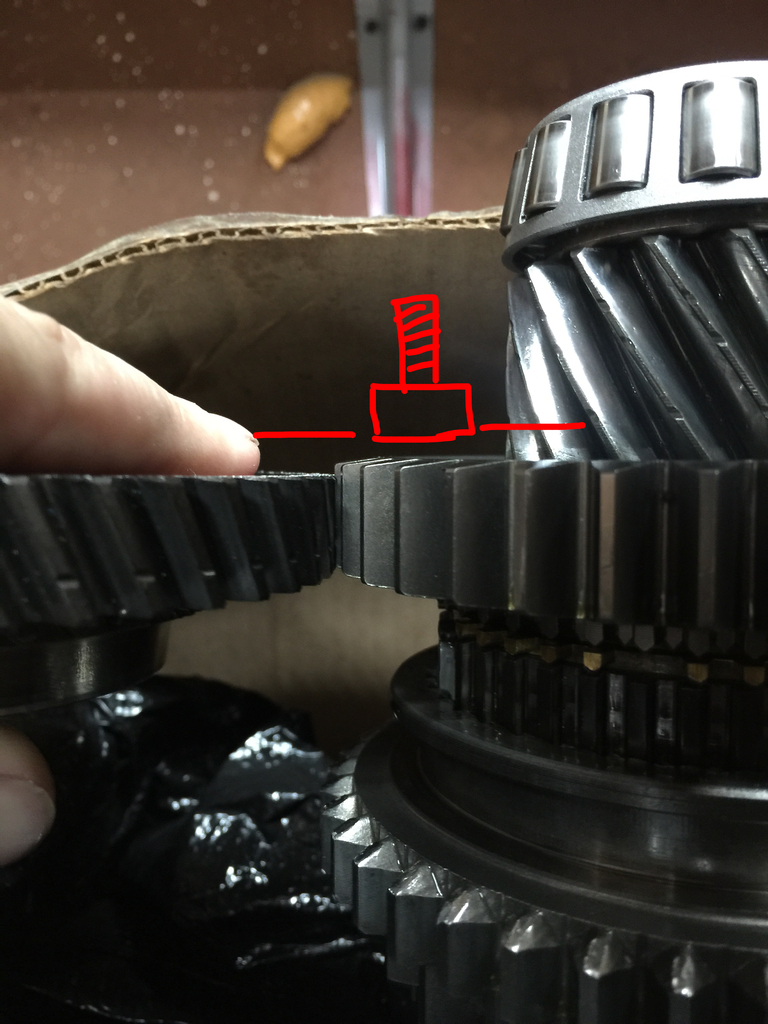

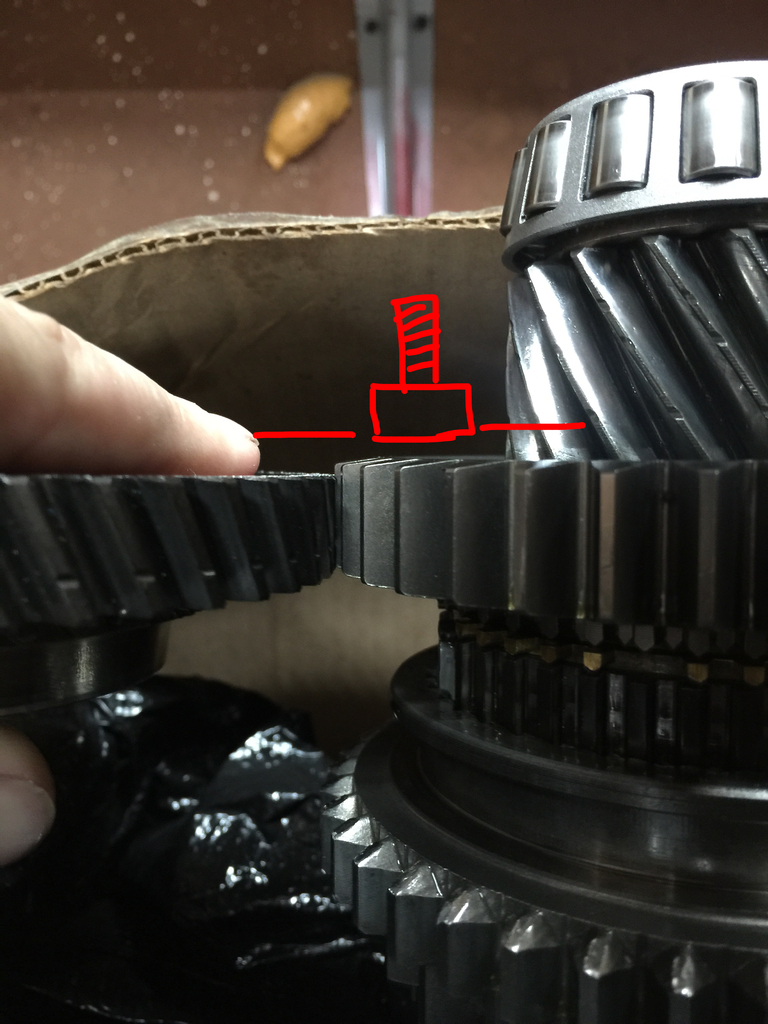

PAR 1st gear:

OEM:

PAR and OEM lined up:

Differential bolts would be here (you can see how OEM has a lot more clearance between gear and differential bolts due to being thinner):

I may have to ask PAR about this, because the underside of the gear is really, really close to the differential bolts. I wonder if I could just replace these bolts with ones that have slightly shorter heads? Anyway, pic of clearance (or lack thereof):

Also got a chance this morning to figure up what shim combos I can use and have collected my total range of Nissan shim part numbers. We shall see what, if any, are actually available from Nissan.

PAR 1st gear teeth are really just that much thicker than the OEM (in hindsight, duh).

PAR 1st gear:

OEM:

PAR and OEM lined up:

Differential bolts would be here (you can see how OEM has a lot more clearance between gear and differential bolts due to being thinner):

I may have to ask PAR about this, because the underside of the gear is really, really close to the differential bolts. I wonder if I could just replace these bolts with ones that have slightly shorter heads? Anyway, pic of clearance (or lack thereof):

Also got a chance this morning to figure up what shim combos I can use and have collected my total range of Nissan shim part numbers. We shall see what, if any, are actually available from Nissan.

#44

between the gears are within spec prior to pulling it apart. i think i mangled the snap ring on the input shaft a little too much where i can't feel good about reusing it again. the FSM shows it as "X"...replace..so i'm swapping to play it safe. i didn't pull apart the main shaft yet but i will once the input shaft is back together.

i did order some snap rings off the input shaft and some small springs off the syncro pieces. the little springs are pretty d@mn expensive for what they are.

i did order some snap rings off the input shaft and some small springs off the syncro pieces. the little springs are pretty d@mn expensive for what they are.

#46

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

For the input shaft and mainshaft I was able to find two shims that are actually confirmed available from Nissan.

For the mainshaft I ordered (confirmed available) 32139-03E06 (.0283") which by itself will end up smack in the middle of my necessary shim range of .0268" to .0292"

For the input shaft I ordered (confirmed available) 32225-08E03 (.0205") which combined with an existing .021 shim I have this will give me a total shim thickness of .0415" which is pretty darn close to spec. Nissan only has ONE 32225-08E03 with any extra backordered, so thankfully that one will work for me.

Unfortunately a lot of the differential shims are discontinued and obsolete.

38753-56E00, 38763-56E01, 38763-56E03, and 38763-56E13 are all confirmed discontinued and unavailable. 38753-56E02 is on back order. Between all of that and leaving me no combination to reach my needed shim size I'm really SOL on the differential shims and will have to try to find something aftermarket/universal or something.

Differential shim OD is 98mm and ID is 91mm. I have two existing shims sized .023" and .018", and what I need is .0346" total shim. Were you able to find any non-Nissan sources Dan?

For the mainshaft I ordered (confirmed available) 32139-03E06 (.0283") which by itself will end up smack in the middle of my necessary shim range of .0268" to .0292"

For the input shaft I ordered (confirmed available) 32225-08E03 (.0205") which combined with an existing .021 shim I have this will give me a total shim thickness of .0415" which is pretty darn close to spec. Nissan only has ONE 32225-08E03 with any extra backordered, so thankfully that one will work for me.

Unfortunately a lot of the differential shims are discontinued and obsolete.

38753-56E00, 38763-56E01, 38763-56E03, and 38763-56E13 are all confirmed discontinued and unavailable. 38753-56E02 is on back order. Between all of that and leaving me no combination to reach my needed shim size I'm really SOL on the differential shims and will have to try to find something aftermarket/universal or something.

Differential shim OD is 98mm and ID is 91mm. I have two existing shims sized .023" and .018", and what I need is .0346" total shim. Were you able to find any non-Nissan sources Dan?

#47

It's interesting that this transmission I'm rebuilding now has no shims on it whatsoever anywhere other than the input shaft rear bearing. None anywhere else. I'm really starting to think that most likely even "professionals" don't bother shimming the mainshaft stuff or much of anything really. Not that that makes it the right thing to do. I mean a shop only needs it to last long enough to not fail during the 6 or 12 month warranty period.

When researching this, it appears that the 4th gen guys especially for some reason seem to blow through bearings. They consider it a massive weak point of the transmission. I don't seem to recall ever seeing/hearing as much complaint from the 3rd gen guys about it though. I've never had one "fail" on me and I've rocked four separate 5 speed transmissions over the past decade plus. Is that what you're saying too is that the front (clutch side) input shaft bearing is the weak link?

I mean this transmission I'm messing with now lasted something like 160k miles before the rebuild, and at that point the rebuild wasn't so much necessary as it was just me wanting a fresh transmission. And that was with flyry110 (I think that was his username) beating the absolute **** out of it (full slicks at drag strip routinely) for 100k miles.

The SKF is German: This is the only bearing in my rebuild set that isn't Japanese.

When researching this, it appears that the 4th gen guys especially for some reason seem to blow through bearings. They consider it a massive weak point of the transmission. I don't seem to recall ever seeing/hearing as much complaint from the 3rd gen guys about it though. I've never had one "fail" on me and I've rocked four separate 5 speed transmissions over the past decade plus. Is that what you're saying too is that the front (clutch side) input shaft bearing is the weak link?

I mean this transmission I'm messing with now lasted something like 160k miles before the rebuild, and at that point the rebuild wasn't so much necessary as it was just me wanting a fresh transmission. And that was with flyry110 (I think that was his username) beating the absolute **** out of it (full slicks at drag strip routinely) for 100k miles.

The SKF is German: This is the only bearing in my rebuild set that isn't Japanese.

The ISB is definitely a concern, and a common problem. I have replaced 6 of them, five of them were from 3rd gens, and another from the 4th gen. I started with mine, which was at 92k miles IIRC, and has held up for 10 years now. The others were all trade ins or cores, and the only problem any of them had, was a blown input shaft bearing. One of them actually did have a cracked bellhousing thanks to the bearing, so I tore a trans down in the junkyard, and bought a replacement for $7 on a 50% off day. I also had a VE that had a busted bearing, but I sold it without repairing it. It still drove, it was just noisy at the time, and I did inform the buyer. There are plenty of threads regarding ISB's, and the reason you might not see many now, are because most have been replaced already, or the cars haven't been driven hard enough to destroy it. Mine blew out when I went through a few gears against a guy in an SE-R with 2 fat chicks in it. I've driven it just as hard since the replacement, and it has been fine. I remember 505Max (Shawn?) who was boosted, talking about how he got so used to replacing the ISB, he would do the teardown with the bellhousing bolted up. Could be that the reason you've used four different transmissions is because of busted ISB's? I don't know the circumstances.

I guess I was mistaking whatever Korean brand I used. I usually the NSK, which is OEM, just stamped "Nissan". The last one I did however, I cheaped out and went with some random brand advertised for motorcycle engines or gear boxes. It's a pretty common bearing if you search by dimensions instead of brand or application. There used to be a thread about the possibility of machining the bellhousing to accept a larger diameter bearing. But I'm not sure how plausible that actually is. You don't have much material to work with.

Last edited by Hectic; 10-07-2015 at 04:05 AM.

#48

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Those two shims are the only ones that should be there in a factory transmission, so that is normal. The shimming and tolerance check procedures in the FSM are specifically for rebuilds. It's good you're doing it by the book however, but it seems like you might be focusing a little too much on things that aren't going to make a ton of difference in the end because...

The ISB is definitely a concern, and a common problem. I have replaced 6 of them, five of them were from 3rd gens, and another from the 4th gen. I started with mine, which was at 92k miles IIRC, and has held up for 10 years now. The others were all trade ins or cores, and the only problem any of them had, was a blown input shaft bearing. One of them actually did have a cracked bellhousing thanks to the bearing, so I tore a trans down in the junkyard, and bought a replacement for $7 on a 50% off day. I also had a VE that had a busted bearing, but I sold it without repairing it. It still drove, it was just noisy at the time, and I did inform the buyer. There are plenty of threads regarding ISB's, and the reason you might not see many now, are because most have been replaced already, or the cars haven't been driven hard enough to destroy it. Mine blew out when I went through a few gears against a guy in an SE-R with 2 fat chicks in it. I've driven it just as hard since the replacement, and it has been fine. I remember 505Max (Shawn?) who was boosted, talking about how he got so used to replacing the ISB, he would do the teardown with the bellhousing bolted up. Could be that the reason you've used four different transmissions is because of busted ISB's? I don't know the circumstances.

The ISB is definitely a concern, and a common problem. I have replaced 6 of them, five of them were from 3rd gens, and another from the 4th gen. I started with mine, which was at 92k miles IIRC, and has held up for 10 years now. The others were all trade ins or cores, and the only problem any of them had, was a blown input shaft bearing. One of them actually did have a cracked bellhousing thanks to the bearing, so I tore a trans down in the junkyard, and bought a replacement for $7 on a 50% off day. I also had a VE that had a busted bearing, but I sold it without repairing it. It still drove, it was just noisy at the time, and I did inform the buyer. There are plenty of threads regarding ISB's, and the reason you might not see many now, are because most have been replaced already, or the cars haven't been driven hard enough to destroy it. Mine blew out when I went through a few gears against a guy in an SE-R with 2 fat chicks in it. I've driven it just as hard since the replacement, and it has been fine. I remember 505Max (Shawn?) who was boosted, talking about how he got so used to replacing the ISB, he would do the teardown with the bellhousing bolted up. Could be that the reason you've used four different transmissions is because of busted ISB's? I don't know the circumstances.

But the basic point of what you're saying - are you saying all this in the sense of it's almost pointless to attempt to shim it textbook? Because it will fail regardless? And in that sense you're saying I should just re-use the existing shims type of deal?

#49

i say definitely follow the FSM and shim the input shaft.

It's a personal call on shimming the other bearings (diff and main) but if you're going to do the job then do it right..it's your car..don't be a hack. most transmission shops build transmissions to last past their warranty...that's it. after that they want to charge you another few grand to redo the work since you're out of warranty.

the guy who keeps throwing ISBs...i doubt he shims and that's why he's chewing up ISBs or there might even be an issue with the case. there's definitely some wear on the case when you drive on a busted ISB...maybe very slight but i do see some wear grooves on the alum bellhousing in my case.

It's a personal call on shimming the other bearings (diff and main) but if you're going to do the job then do it right..it's your car..don't be a hack. most transmission shops build transmissions to last past their warranty...that's it. after that they want to charge you another few grand to redo the work since you're out of warranty.

the guy who keeps throwing ISBs...i doubt he shims and that's why he's chewing up ISBs or there might even be an issue with the case. there's definitely some wear on the case when you drive on a busted ISB...maybe very slight but i do see some wear grooves on the alum bellhousing in my case.

#50

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Oh I'm definitely going to follow the FSM and shim everything as close as I possibly can - I'm in no extreme rush here and want this to last hopefully the life of the car at this point. I was just wanting to understand his point exactly.

I think potentially a bigger issue at this point is the clearance (lack thereof actually) at the differential bolts and 1st gear. It's soooooo close that it seems that just a little bit of play or even simple expansion from heat will quickly cause contact there. I've sent an e-mail with pics off to PAR and will see what they say.

I think potentially a bigger issue at this point is the clearance (lack thereof actually) at the differential bolts and 1st gear. It's soooooo close that it seems that just a little bit of play or even simple expansion from heat will quickly cause contact there. I've sent an e-mail with pics off to PAR and will see what they say.

#52

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

No chance they'll do that  well, not unless I pay them to do so and I'm definitely not gonna spend several hundred more bucks and waiting several months longer at this point.

well, not unless I pay them to do so and I'm definitely not gonna spend several hundred more bucks and waiting several months longer at this point.

I'm thinking now the thing to do is just find/buy different bolts with smaller bolt heads. I've been looking at some other PAR setups, like this one in a Canadian GTiR (this one has the Nismo LSD unit):

Notice how the bolts have different/smaller bolt heads that are actually shorter than the final gear itself (whereas mine stick higher than the final gear) I'll have to pull one of mine and find something similar with the correct length and thread pitch etc.

well, not unless I pay them to do so and I'm definitely not gonna spend several hundred more bucks and waiting several months longer at this point.

well, not unless I pay them to do so and I'm definitely not gonna spend several hundred more bucks and waiting several months longer at this point.I'm thinking now the thing to do is just find/buy different bolts with smaller bolt heads. I've been looking at some other PAR setups, like this one in a Canadian GTiR (this one has the Nismo LSD unit):

Notice how the bolts have different/smaller bolt heads that are actually shorter than the final gear itself (whereas mine stick higher than the final gear) I'll have to pull one of mine and find something similar with the correct length and thread pitch etc.

#53

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

I've found a couple of readily available shims for these cars.

For the input shaft shims I've found that Sonnax actually makes a shim intended for the GM 4T60/4T60-E/4T65-E that should fit our input shafts. Stock is 3.0" OD and 2.835" ID. The Sonnax shims are 2.950" OD and 2.835" ID. Unfortunately I've only found them in .010" and .020" thicknesses. If you could get them in .005" as well that would be totally perfect! The part numbers are 84733-10 for the .010" and 84733-20 for the .020".

Also managed to find something that could at least be SOME help on the mainshaft. Stock mainshaft shims are 2.32" OD and 2.05 ID. Sonnax makes a shim meant for the Ford C3 transmission with an OD of 2.30" and an ID of 2.053". Part number FD-WS-16. Unfortunately it's only available in a thickness of .020" as best I can tell so far. Again would be totally ideal if it were available in .010" and especially .005".

For the input shaft shims I've found that Sonnax actually makes a shim intended for the GM 4T60/4T60-E/4T65-E that should fit our input shafts. Stock is 3.0" OD and 2.835" ID. The Sonnax shims are 2.950" OD and 2.835" ID. Unfortunately I've only found them in .010" and .020" thicknesses. If you could get them in .005" as well that would be totally perfect! The part numbers are 84733-10 for the .010" and 84733-20 for the .020".

Also managed to find something that could at least be SOME help on the mainshaft. Stock mainshaft shims are 2.32" OD and 2.05 ID. Sonnax makes a shim meant for the Ford C3 transmission with an OD of 2.30" and an ID of 2.053". Part number FD-WS-16. Unfortunately it's only available in a thickness of .020" as best I can tell so far. Again would be totally ideal if it were available in .010" and especially .005".

#55

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

So where I'm going with this is that I wouldn't know where to snag one even I were going to try that (which I'm not).

I don't think I'll have any problem finding bolts with shorter heads on them

#56

awesome of you to document this. i wish i had taken more pictures when i did my "A" rebuild. I also wish i had done as thorough a job as you are. i kind of want to start looking into parts interchange now because your "V" trans looks identical internally to my "A" trans. the only thing that looks different is the LSD and clutch case. itd sure be awesome if i could upgrade my diff... do you know the gear ratios or final drive of that trans?

#57

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

awesome of you to document this. i wish i had taken more pictures when i did my "A" rebuild. I also wish i had done as thorough a job as you are. i kind of want to start looking into parts interchange now because your "V" trans looks identical internally to my "A" trans. the only thing that looks different is the LSD and clutch case. itd sure be awesome if i could upgrade my diff... do you know the gear ratios or final drive of that trans?

When you ask the gear ratios on "that" trans which one are you referring to? The GTiR? Or the third gen? If the 3rd gen, 1st gear is 3.295, 2nd is 1.850, 3rd is 1.272, 4th is .0954, and 5th is .0795. Final drive is 3.266. According to my manual it appears the RS5F50A and V both have identical ratios and final drive.

#59

I didn't say to omit shims. Just that from the factory, there should only be the two.

What I meant is that what you are focusing on, isn't necessarily addressing the ISB concern. Of course there's nothing wrong with upgrading the internals and essentially rebuilding the entire transmission. Just saying that you wouldn't want it all to be for naught, if you end up blowing front bearings. That's all speculation though, don't worry too much about it. The only way you'll find out is by driving the boosted car the way it should be driven. I would make sure to change your gear oil religiously, every 15k or so.

Replacing or milling down those final drive bolts is probably the way to go.

What I meant is that what you are focusing on, isn't necessarily addressing the ISB concern. Of course there's nothing wrong with upgrading the internals and essentially rebuilding the entire transmission. Just saying that you wouldn't want it all to be for naught, if you end up blowing front bearings. That's all speculation though, don't worry too much about it. The only way you'll find out is by driving the boosted car the way it should be driven. I would make sure to change your gear oil religiously, every 15k or so.

Replacing or milling down those final drive bolts is probably the way to go.

#61

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

I didn't say to omit shims. Just that from the factory, there should only be the two.

What I meant is that what you are focusing on, isn't necessarily addressing the ISB concern. Of course there's nothing wrong with upgrading the internals and essentially rebuilding the entire transmission. Just saying that you wouldn't want it all to be for naught, if you end up blowing front bearings. That's all speculation though, don't worry too much about it. The only way you'll find out is by driving the boosted car the way it should be driven. I would make sure to change your gear oil religiously, every 15k or so.

Replacing or milling down those final drive bolts is probably the way to go.

What I meant is that what you are focusing on, isn't necessarily addressing the ISB concern. Of course there's nothing wrong with upgrading the internals and essentially rebuilding the entire transmission. Just saying that you wouldn't want it all to be for naught, if you end up blowing front bearings. That's all speculation though, don't worry too much about it. The only way you'll find out is by driving the boosted car the way it should be driven. I would make sure to change your gear oil religiously, every 15k or so.

Replacing or milling down those final drive bolts is probably the way to go.

Speaking of that, earlier this summer during a bunch of my research I found some old posts by Matt - not on here but on some random general Nissan forum. He was stating that he had found the "tech sheet" (for lack of a better word) on those exact bearings our cars use. He stated the bearings are only rated to something like 6K RPM. So he theorized that over time, anybody who even somewhat regularly drives their car in a "spirited" fashion is routinely spinning that bearing faster than it was designed for, obviously contributing to its early demise. Couple that with in some cases endplay that is big time out of whack and I'm sure you have a recipe for repeated failures. It is very odd indeed that Nissan would choose a bearing that isn't even rated to its own factory redline on the car(s) they used them in.

#62

Speaking of that, earlier this summer during a bunch of my research I found some old posts by Matt - not on here but on some random general Nissan forum. He was stating that he had found the "tech sheet" (for lack of a better word) on those exact bearings our cars use. He stated the bearings are only rated to something like 6K RPM. So he theorized that over time, anybody who even somewhat regularly drives their car in a "spirited" fashion is routinely spinning that bearing faster than it was designed for, obviously contributing to its early demise. Couple that with in some cases endplay that is big time out of whack and I'm sure you have a recipe for repeated failures. It is very odd indeed that Nissan would choose a bearing that isn't even rated to its own factory redline on the car(s) they used them in.

http://www.ntnamericas.com/en/produc...id=RBSRD&ctc=B

#63

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

in oil the max speed is 13,000 RPM. not that i'm doubting matt...but that's the ISB that's closest to the clutch and this is direct from NTN.

http://www.ntnamericas.com/en/produc...id=RBSRD&ctc=B

http://www.ntnamericas.com/en/produc...id=RBSRD&ctc=B

#65

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

If anybody remembers, my textbook desired differential shim thickness is .0346" (according to my calculations from my epiphany post dated 10/4).

Nissan actually has (had) a single shim in this EXACT thickness and I tried to order it a few days ago, and was told it was no longer available and obsolete from Nissan. Then I started looking for other options but haven't been able to find anything. I figured that some random dealer SOMEWHERE surely had it in their warehouse still.

~V~max (who works in Nissan parts) was actually able to find a dealer in South Carolina who had the shim, part number 38353-56E13 and I just called them, confirmed actual availability and bought it.

Nissan actually has (had) a single shim in this EXACT thickness and I tried to order it a few days ago, and was told it was no longer available and obsolete from Nissan. Then I started looking for other options but haven't been able to find anything. I figured that some random dealer SOMEWHERE surely had it in their warehouse still.

~V~max (who works in Nissan parts) was actually able to find a dealer in South Carolina who had the shim, part number 38353-56E13 and I just called them, confirmed actual availability and bought it.

#66

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

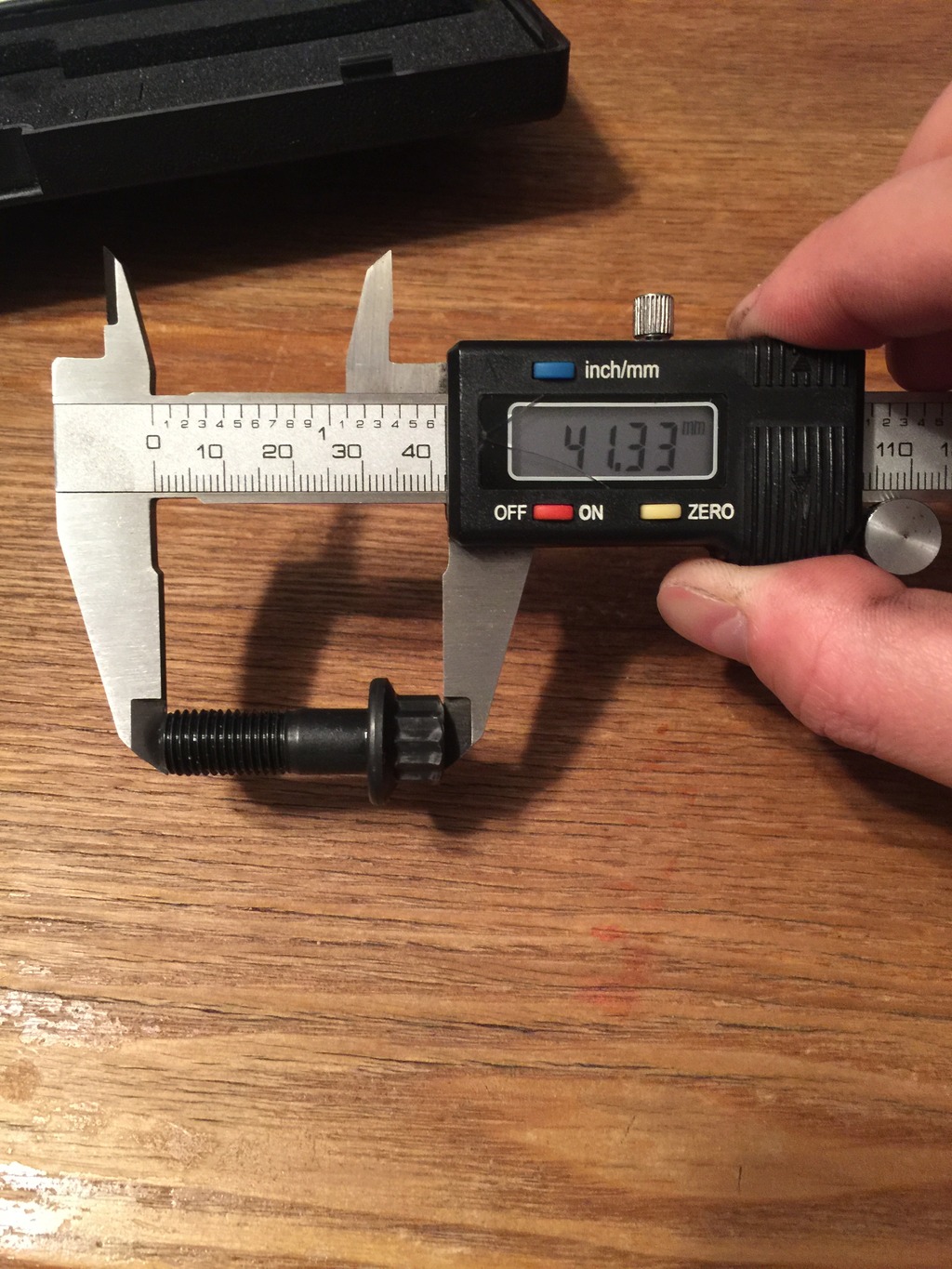

So my quest for replacement differential bolts has been more difficult than I imagined it would be. The stock differential bolts are kind of unique in that they are an M10 x 1.25 with a 30mm length under the head, but only about 20mm of it is threaded.

For my replacement bolts I was hoping to keep the same threaded/unthreaded ratio. I've been communicating with a nice sales lady at Kimball Midwest who filled me in on a lot of this bolt lingo and industry standards. She actually stated they could make some custom bolts to my specifications but it would require a minimum purchase of 50 units at $20 per bolt! No thanks on that one. In terms of off-the-shelf bolts, ALL M10 x 1.25 30mm bolts are fully threaded - it's apparently just standardized that way. The shortest non-fully threaded length is 40mm.

So I had to abandon my OEM style partially threaded hopes. Kimball Midwest produces some M10 x 1.25 30mm bolts that are grade 10.9 (equivalent to SAE grade 8 that you're probably used to hearing) that I planned to buy from them this next Tuesday.

Today I found some bolts at Lowe's that match the Kimball Midwest bolts in basically every dimension - although the Lowe's bolts are only grade 8.8 (equivalent to SAE grade 5). So I bought one in order to test fit the Kimball Midwest bolts I planned to purchase. Of course I wanted to go with the stronger 10.9 Kimball Midwest's vs. the 8.8 Lowe's hence only using the Lowe's unit for the test fit.

Here's how that turned out:

As you can see, I quickly realized that these aren't going to work because I have no room to get a socket in there to tighten them down! So that sucks, because these bolts only have a head height of 7mm which would have given me a lot of clearance vs the 11mm head height of the OEM units. But good thing I decided to do this test before buying the Kimball Midwest bolts.

After some more searching today, I decided to go with some ARP's, part # 773-1003. A little pricey, but I can't find any other options. The good thing is that the ARP's are much stronger than what I would have gotten from Kimball Midwest, and especially stronger than the Lowe's units. The ARP's are 12 points just like OEM but the head height is only 9mm - so this will give me 2mm of clearance, which may not sound like a lot but it really is quite a bit of clearance over the stock units.

All of this trouble and in the back of my mind I keep thinking I should just grind the stockers down. Just want to avoid hack job stuff like that if I can

For my replacement bolts I was hoping to keep the same threaded/unthreaded ratio. I've been communicating with a nice sales lady at Kimball Midwest who filled me in on a lot of this bolt lingo and industry standards. She actually stated they could make some custom bolts to my specifications but it would require a minimum purchase of 50 units at $20 per bolt! No thanks on that one. In terms of off-the-shelf bolts, ALL M10 x 1.25 30mm bolts are fully threaded - it's apparently just standardized that way. The shortest non-fully threaded length is 40mm.

So I had to abandon my OEM style partially threaded hopes. Kimball Midwest produces some M10 x 1.25 30mm bolts that are grade 10.9 (equivalent to SAE grade 8 that you're probably used to hearing) that I planned to buy from them this next Tuesday.

Today I found some bolts at Lowe's that match the Kimball Midwest bolts in basically every dimension - although the Lowe's bolts are only grade 8.8 (equivalent to SAE grade 5). So I bought one in order to test fit the Kimball Midwest bolts I planned to purchase. Of course I wanted to go with the stronger 10.9 Kimball Midwest's vs. the 8.8 Lowe's hence only using the Lowe's unit for the test fit.

Here's how that turned out:

As you can see, I quickly realized that these aren't going to work because I have no room to get a socket in there to tighten them down! So that sucks, because these bolts only have a head height of 7mm which would have given me a lot of clearance vs the 11mm head height of the OEM units. But good thing I decided to do this test before buying the Kimball Midwest bolts.

After some more searching today, I decided to go with some ARP's, part # 773-1003. A little pricey, but I can't find any other options. The good thing is that the ARP's are much stronger than what I would have gotten from Kimball Midwest, and especially stronger than the Lowe's units. The ARP's are 12 points just like OEM but the head height is only 9mm - so this will give me 2mm of clearance, which may not sound like a lot but it really is quite a bit of clearance over the stock units.

All of this trouble and in the back of my mind I keep thinking I should just grind the stockers down. Just want to avoid hack job stuff like that if I can

#67

Do it right man..lol

Finally got the input shaft together. That reverse /5th gear syncros set is a total pain in the rear..omg.

Now to pull the main shaft out and swap those syncros.

Also grinding them down...wouldn't that cause a bit of imbalance in the diff?

Finally got the input shaft together. That reverse /5th gear syncros set is a total pain in the rear..omg.

Now to pull the main shaft out and swap those syncros.

Also grinding them down...wouldn't that cause a bit of imbalance in the diff?

#68

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

I did notice removing the old differential bolts that there was definitely loctite on them. I don't see any mention of that in the FSM but I guess I'll add some loctite to the ARP's.

I don't remember the 5th synchro stuff being a pain at all. Some of those synchro clip deals were fairly fiddly though. Makes me wonder now if I missed something

What specifically was a pain about it?

What specifically was a pain about it?

#69

That's what I was thinking, that in theory surely it would be imbalanced if I unscientifically ground stuff off the bolts. That's part of why I just went with the ARP's.

I did notice removing the old differential bolts that there was definitely loctite on them. I don't see any mention of that in the FSM but I guess I'll add some loctite to the ARP's.

I don't remember the 5th synchro stuff being a pain at all. Some of those synchro clip deals were fairly fiddly though. Makes me wonder now if I missed something What specifically was a pain about it?

What specifically was a pain about it?

I did notice removing the old differential bolts that there was definitely loctite on them. I don't see any mention of that in the FSM but I guess I'll add some loctite to the ARP's.

I don't remember the 5th synchro stuff being a pain at all. Some of those synchro clip deals were fairly fiddly though. Makes me wonder now if I missed something

What specifically was a pain about it?

What specifically was a pain about it?i think i messed up the sequence originally and the 2nd bronze ring was on top of the retainer ring (the ring with the 2 tabs) so it never press down and i was scratching my head trying to figure out the sequence.

i guess it doesn't help i was doing this at like midnight...by 2am i was able to assemble the entire mess back together....hopefully correctly.

#70

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Ahh, this bad boy. After you got it assembled did you make sure that outside ring deal is able to click into both synchro deals? That's basically what I've been using as my "test". Of course some of the synchro rings/gears need to spin a little bit to line up/click into place but I assume if they all do so then all is well.

#71

Ahh, this bad boy. After you got it assembled did you make sure that outside ring deal is able to click into both synchro deals? That's basically what I've been using as my "test". Of course some of the synchro rings/gears need to spin a little bit to line up/click into place but I assume if they all do so then all is well.

yeah i did that...i was like ok if i can slide this that means that's good right...well i pulled it too hard and the sleeve pops all the way out...ugh..gotta reset the springs again and line it up again.

#73

yup...courtesy nissan found me a very overpriced snap ring for the input shaft. the main shaft i'm trying to do it and not mess any snap rings up.

also had to get new springs since i had 2 broken ones..there was a small nub missing on them so figure i would replace it....also crazy expensive for curled spring steel that's so small.

also had to get new springs since i had 2 broken ones..there was a small nub missing on them so figure i would replace it....also crazy expensive for curled spring steel that's so small.

#74

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

My differential shim came in

The shims I need for the mainshaft and input shaft are scheduled to be here this week along with a bunch of other stuff I ordered - new o-ring for the speedo sensor, as well as o-rings for the two arm deals that pass through the case/bell housing - not sure of the technical terms for them. Also got a new strike rod boot deal and shift fork rubber surround. So basically this will be an entirely new unit for all intents and purposes. And the ARP bolts for the differential are scheduled to arrive this week too. So hopefully I'll get this entire sucker back together this weekend!

The shims I need for the mainshaft and input shaft are scheduled to be here this week along with a bunch of other stuff I ordered - new o-ring for the speedo sensor, as well as o-rings for the two arm deals that pass through the case/bell housing - not sure of the technical terms for them. Also got a new strike rod boot deal and shift fork rubber surround. So basically this will be an entirely new unit for all intents and purposes. And the ARP bolts for the differential are scheduled to arrive this week too. So hopefully I'll get this entire sucker back together this weekend!

#76

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

The input and mainshaft shims I got from Ray Kelly at Tri-Cities Nissan (www.nissanpartsasap.com) - which has actually been my go-to place for some years now. I can't remember how exactly, but Chris Gregg is affiliated with them somehow.

Anyway, they're cheaper than Courtesy and way more helpful IMO. Even after shipping, Tri-Cities is usually cheaper for me even if I were to pick the stuff up in person at Courtesy.

Get this - I ordered the rest of the transmission stuff from Ray about a week and a half ago, and then later on e-mailed him about the shim availability. After figuring out which ones he could actually get from Nissan (and determining that those combined with my existing shims would get me in spec), I went ahead and asked him to just hold the original order and add the shims to it and ship it all at once. I asked him to just let me know the difference and I'd pay them. Dude added in the shims FOR FREE. Now that's "ony" about ~$10 worth of parts, but still! Great guy.

The differential shim I got from Quality Nissan in Greenwood, South Carolina. I tried ordering it first from Tri-Cities first but Ray said it's discontinued/obsolete and he wasn't even able to order it. ~V~max was able to find out for me that Quality Nissan had this shim in their dealer stock (only one in the country).

Anyway, they're cheaper than Courtesy and way more helpful IMO. Even after shipping, Tri-Cities is usually cheaper for me even if I were to pick the stuff up in person at Courtesy.

Get this - I ordered the rest of the transmission stuff from Ray about a week and a half ago, and then later on e-mailed him about the shim availability. After figuring out which ones he could actually get from Nissan (and determining that those combined with my existing shims would get me in spec), I went ahead and asked him to just hold the original order and add the shims to it and ship it all at once. I asked him to just let me know the difference and I'd pay them. Dude added in the shims FOR FREE. Now that's "ony" about ~$10 worth of parts, but still! Great guy.

The differential shim I got from Quality Nissan in Greenwood, South Carolina. I tried ordering it first from Tri-Cities first but Ray said it's discontinued/obsolete and he wasn't even able to order it. ~V~max was able to find out for me that Quality Nissan had this shim in their dealer stock (only one in the country).

#77

Wow...I always forget about tricities... courtesy is a real rip off now. Got the main shaft together..it was a walk in the park compared to first time on the input shaft. So time to clean the case and start crushing some solder. The diff bearings looked brand new so I'm going to keep them there and after seeing what a total pain to pull the big one I'm just going to let them stay.

Is there an easy way to get the bearing races out? Is it clearer once I pull the seals off?

Is there an easy way to get the bearing races out? Is it clearer once I pull the seals off?

#78

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Wow...I always forget about tricities... courtesy is a real rip off now. Got the main shaft together..it was a walk in the park compared to first time on the input shaft. So time to clean the case and start crushing some solder. The diff bearings looked brand new so I'm going to keep them there and after seeing what a total pain to pull the big one I'm just going to let them stay.

Is there an easy way to get the bearing races out? Is it clearer once I pull the seals off?

Is there an easy way to get the bearing races out? Is it clearer once I pull the seals off?

The mainshaft bearing outer race in the bellhousing side just sits in there and can be removed by hand. The mainshaft race in the outer case I had a hard time with. I tried several different jaw pullers and couldn't ever get any to work. You need some really skinny "teeth" to get under there with an actual puller and I didn't want to grind up any of my pullers just to potentially have them break.

I think I mentioned it earlier, but I found that the Harbor Freight small pry bar works PERFECT for pulling the mainshaft outer race. It's almost like they were made for eachother.

Just hook the "head" under the race and pry it up (rotating in a couple of spots of course). You have to buy it as a 3 piece set but the set is only $8 (item # 68339):

Just hook the "head" under the race and pry it up (rotating in a couple of spots of course). You have to buy it as a 3 piece set but the set is only $8 (item # 68339):http://www.harborfreight.com/3-pc-pr...set-68339.html

So to sum it all up - all you need is a flat head and that little pry bar (or something similar) to remove/replace all the races.

Last edited by James92SE; 10-14-2015 at 07:22 AM.

#79

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

Argh I'm an idiot. I'm one bolt short on the differential, there's 16 but I somehow only counted 15. Had to buy another set of the ARP's tonight and pay $20 extra for shipping to make sure it gets here this week

#80

2 VE's are better than one!

Thread Starter

iTrader: (31)

Join Date: Sep 2000

Location: Dallas

Posts: 7,358

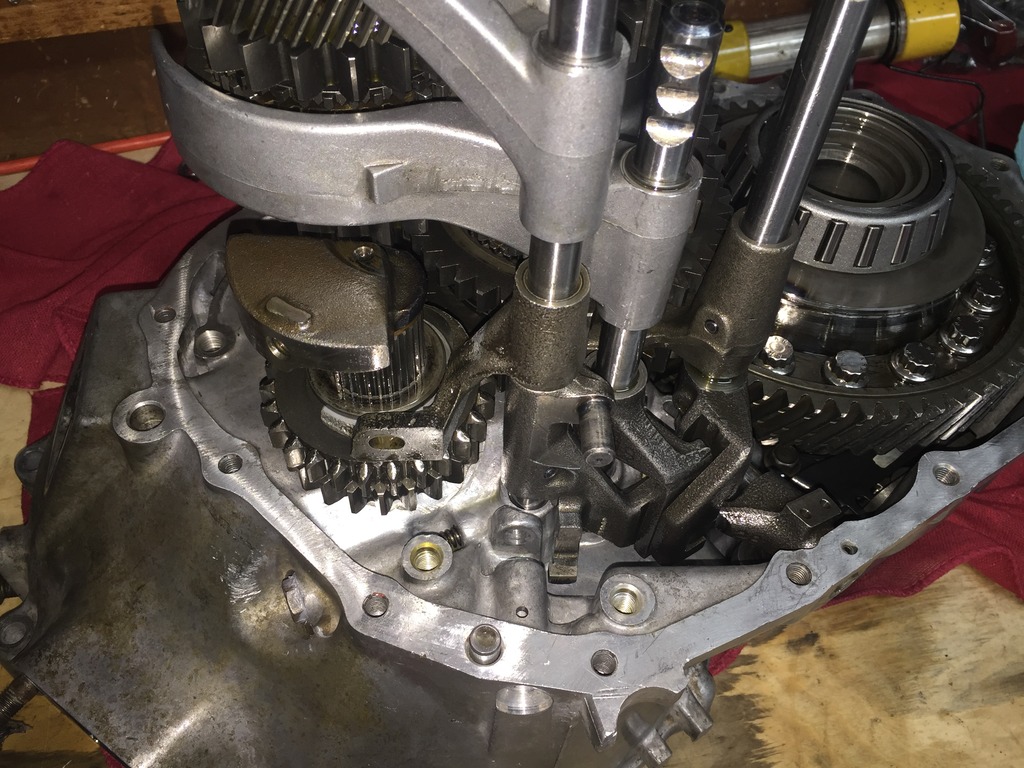

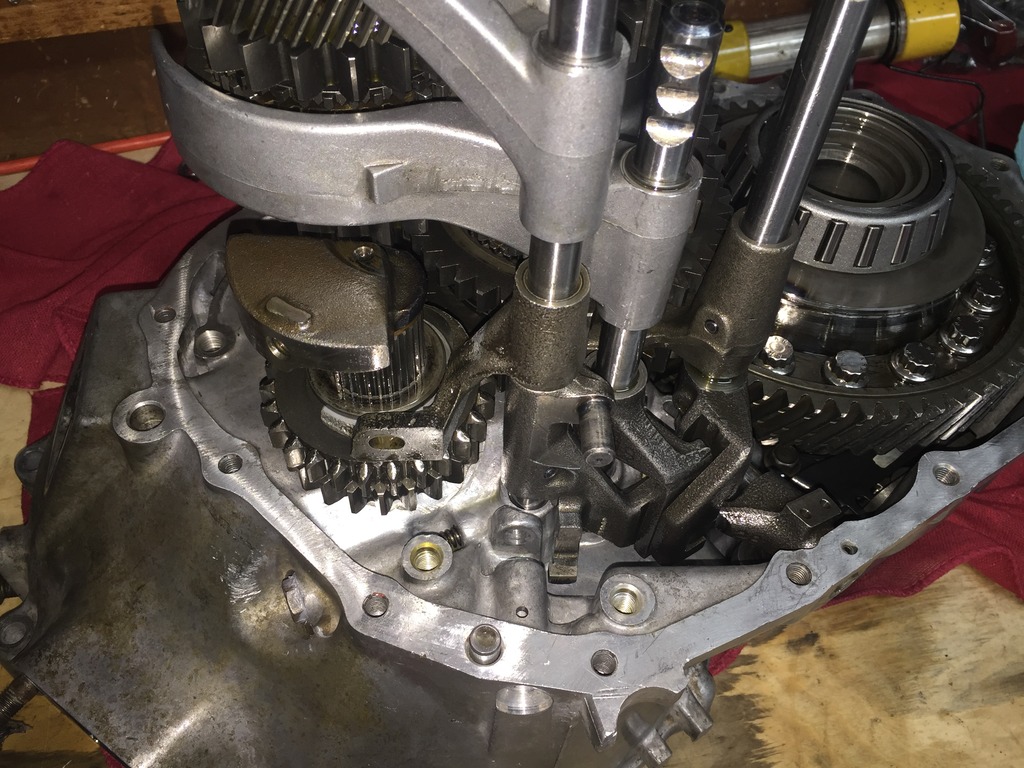

So I got the other ARP set in and with the help of a buddy was able to get the differential bolts torqued down. Thankfully he was able to help because it was virtually impossible to do by myself. It took the both of us and also the vice to get everything held down and torqued down.

Decent clearance now with the ARP's instead of the stock differential bolts:

I also have better clearance than I thought I did at the mainshaft 1st gear at the input shaft bearing:

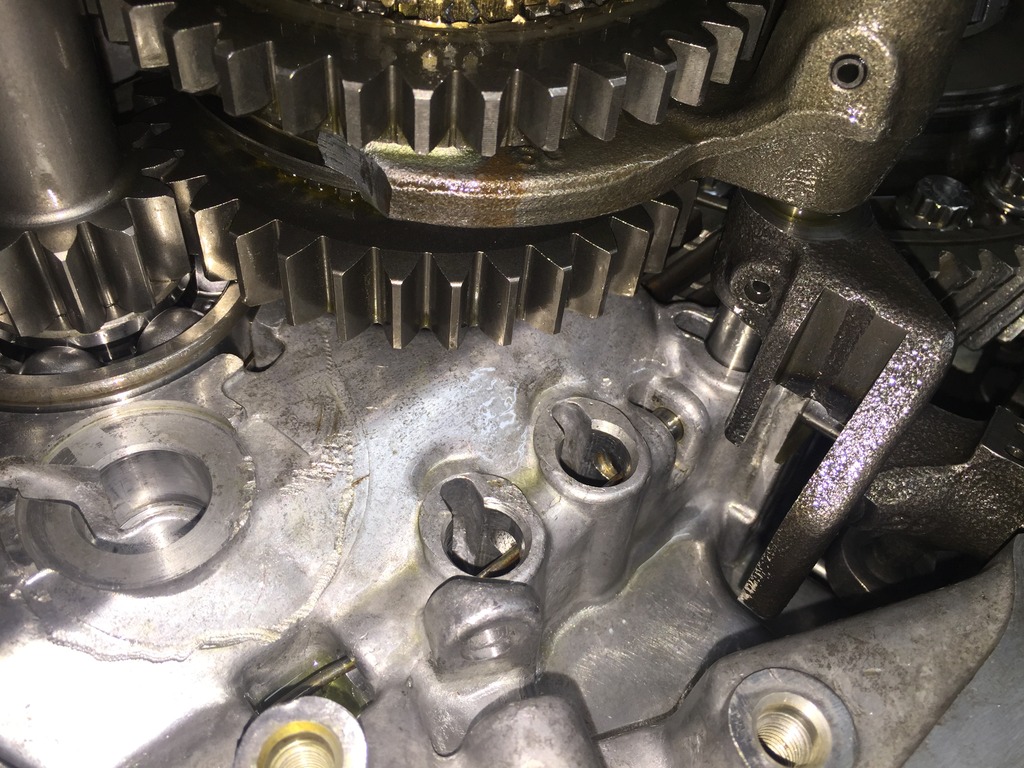

Putting everything back together:

Notice my clothes hanger to keep those stupid check ***** from falling back out constantly:

Used some grease to hold this check ball in. This one would really suck if you dropped it down in the case somewhere not accessible:

New strike rod seal and boot:

Ready for the case:

Done!

Hopefully within the next few weeks I can get it installed in the car

Decent clearance now with the ARP's instead of the stock differential bolts:

I also have better clearance than I thought I did at the mainshaft 1st gear at the input shaft bearing:

Putting everything back together:

Notice my clothes hanger to keep those stupid check ***** from falling back out constantly:

Used some grease to hold this check ball in. This one would really suck if you dropped it down in the case somewhere not accessible:

New strike rod seal and boot:

Ready for the case:

Done!

Hopefully within the next few weeks I can get it installed in the car