The NWP Engineering Engine Torque Link - Interest Thread

#1

Thread Starter

NWP Engineering.com

iTrader: (128)

Joined: Jul 2001

Posts: 14,066

From: Walstonburg, NC

The NWP Engineering Engine Torque Link - Interest Thread

NWP Engineering is currently developing a new modification specifically for the 02-03 Maxima! Want to keep the engine completely locked down while racing your Maxima? Polyurethane engine mounts aren't enough for those serious racers out there.

Introducing the NWP Engineering Engine Torque Link Kit!

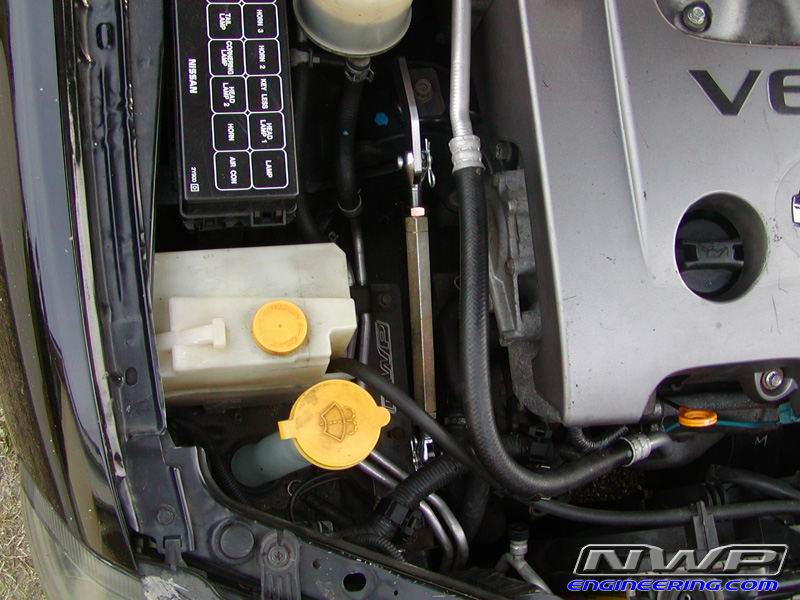

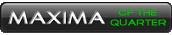

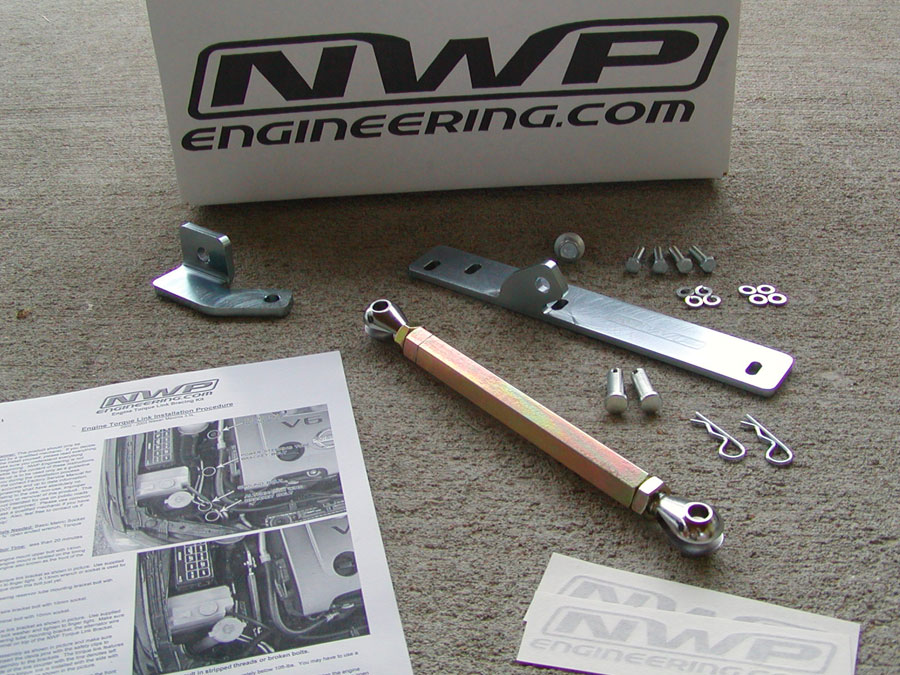

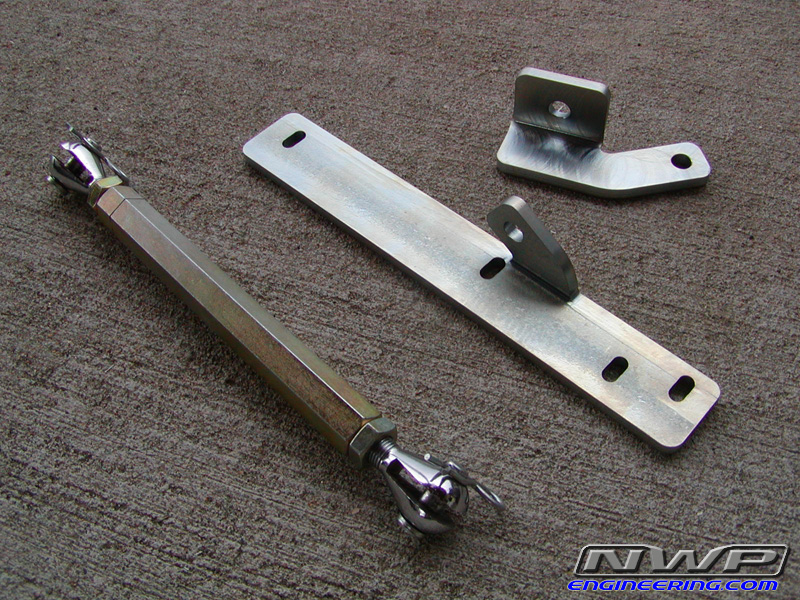

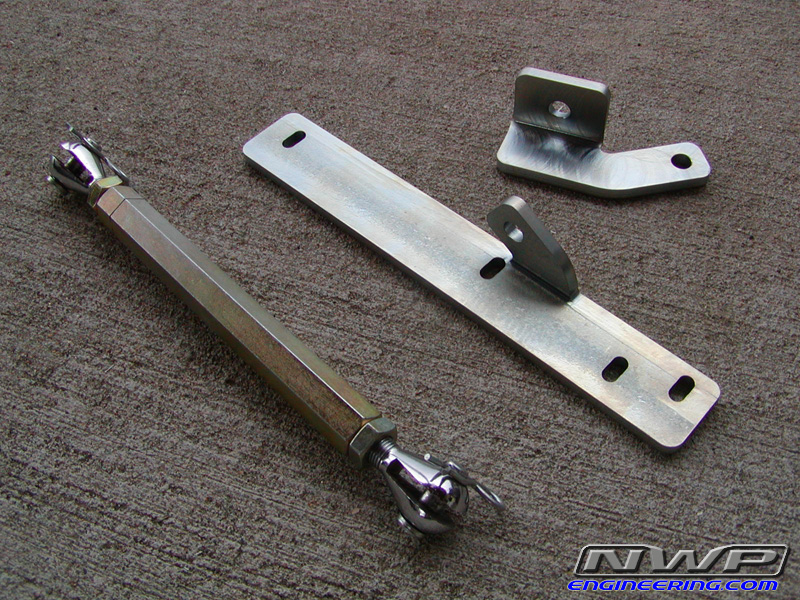

Here are some pictures of our final production run:

This new product will reduce wheel hop, drastically improve shift response and feel, and ultimately lead to faster times and more consistant launches and shifts.

The NWP Engineering Engine Torque Link Kit will come complete with everything needed to install. Included will be two zinc plated CNC machined brackets, an adjustable torque link assembly, all the bolts and washers needed as well as fully detailed installation instructions. And of course, you'll get a pair of NWP Engineering vinyl decals for your car!

The torque link will connect from the front engine mount on the timing cover to the chassis. Once connected, simply rotate the torque link to tighten down the engine to the level of stiffness you prefer. The entire install should only take about 15 minutes and you will be ready for the races! Once you are finished racing, you can disconnect it in a matter of seconds with only one 19mm or 3/4" wrench and leave the brackets in place.

The final price has been set at $160.00. This kit has been released just in time for MAXUS 09 (June 26-28). www.maxus09.com

This thread was started so I can hear everyone's feedback. So, please let me know what you think and if you are interested. Once again, thank you for everyone's support. And I'll see you at MAXUS 09!

Introducing the NWP Engineering Engine Torque Link Kit!

Here are some pictures of our final production run:

This new product will reduce wheel hop, drastically improve shift response and feel, and ultimately lead to faster times and more consistant launches and shifts.

The NWP Engineering Engine Torque Link Kit will come complete with everything needed to install. Included will be two zinc plated CNC machined brackets, an adjustable torque link assembly, all the bolts and washers needed as well as fully detailed installation instructions. And of course, you'll get a pair of NWP Engineering vinyl decals for your car!

The torque link will connect from the front engine mount on the timing cover to the chassis. Once connected, simply rotate the torque link to tighten down the engine to the level of stiffness you prefer. The entire install should only take about 15 minutes and you will be ready for the races! Once you are finished racing, you can disconnect it in a matter of seconds with only one 19mm or 3/4" wrench and leave the brackets in place.

The final price has been set at $160.00. This kit has been released just in time for MAXUS 09 (June 26-28). www.maxus09.com

This thread was started so I can hear everyone's feedback. So, please let me know what you think and if you are interested. Once again, thank you for everyone's support. And I'll see you at MAXUS 09!

Last edited by Aaron92SE; 06-20-2009 at 12:49 PM. Reason: Pictures have been updated

#4

Thread Starter

NWP Engineering.com

iTrader: (128)

Joined: Jul 2001

Posts: 14,066

From: Walstonburg, NC

It definitely works wonders located in this position.

It definitely works wonders located in this position.

#6

this is awsome.. i promise i would be one of the buyers for this...some ?'s for you...

1. you mentioned disconnecting it after the track or whatever,.. would it cause problems if it was left connected all the time ..maybe at a less stiff level..?

2. will this cause more vibration at idle like the MM do?

3. will a write up be included?

4. not a ? but.. installed pics please!!!

5. any slight modifications needed or is it ,.. bolt up and go?

1. you mentioned disconnecting it after the track or whatever,.. would it cause problems if it was left connected all the time ..maybe at a less stiff level..?

2. will this cause more vibration at idle like the MM do?

3. will a write up be included?

4. not a ? but.. installed pics please!!!

5. any slight modifications needed or is it ,.. bolt up and go?

#7

Mmh, I remember there was a similar product for my old car and it was know for ripping the side of the shock tower were it was mounted. I really think a damper strut would be a better idea than a solid rod. $.02

#10

IMO the engine needs to move somewhat. The poly mounts are a good idea because they considerably stiffen the motor yet it still has the ability to flex somewhat. My only question is if the engine can't move anymore thanks to this bar, where does all that energy go? I'm not sure I'd be comfortable putting the extra strain on my chassis.

The idea is definately a step forward, and I'm always diggin' any new mods for 5.5 gens since there's virtually nothing out there for these things. I think it would work better if it was a strut design of some sort, and maybe have it adjustable kinda like a Tokico Illumina lol.

The idea is definately a step forward, and I'm always diggin' any new mods for 5.5 gens since there's virtually nothing out there for these things. I think it would work better if it was a strut design of some sort, and maybe have it adjustable kinda like a Tokico Illumina lol.

#13

my question is, what exactly to you mean by improved shift response and feel? i was talking with a guy recently who mentioned a similar mod where he took a piece of metal, attached it to his motor mount and drilled it down somewhere.. he said that this made his shifts alot smoother, and lessened the need for a perfect clutch/gas relationship for a smooth shift.. is this what your product will do?

#14

when your standing still, you pretty much in neutral as well....this will cause vibration, no matter if auto or stick. its connected to the engine. not the tranny.

#15

#17

#25

Thread Starter

NWP Engineering.com

iTrader: (128)

Joined: Jul 2001

Posts: 14,066

From: Walstonburg, NC

this is awsome.. i promise i would be one of the buyers for this...some ?'s for you...

1. you mentioned disconnecting it after the track or whatever,.. would it cause problems if it was left connected all the time ..maybe at a less stiff level..?

2. will this cause more vibration at idle like the MM do?

3. will a write up be included?

4. not a ? but.. installed pics please!!!

5. any slight modifications needed or is it ,.. bolt up and go?

1. you mentioned disconnecting it after the track or whatever,.. would it cause problems if it was left connected all the time ..maybe at a less stiff level..?

2. will this cause more vibration at idle like the MM do?

3. will a write up be included?

4. not a ? but.. installed pics please!!!

5. any slight modifications needed or is it ,.. bolt up and go?

2) For those people out there that really do not want increased vibrations, then you will probably need to disconnect the torque link on the street. But the test vehicle owner (SurraTT), was barely able to notice increased vibrations even when he really tightened the engine down. This was tested on an 02 Maxima 6spd.

3) Yes, full installation instructions with pictures will be included in every kit.

4) I will see if I can dig up a reference pic of the torque link installed. It will just be a very rough prototype, but it will give you an idea how it bolts up.

5) No modifications needed AT ALL. You simply bolt up and go.

It sounds like the solid rod on your old vehicle was poorly designed and had weak mounting points. We will not mount this engine mount to a part of your car that we feel is weak. It is mounted directly on the actual frame. You won't find a more sturdy place to mount the lower bracket than what we used. But whenever you can, you always want to prevent the engine from moving. A damper strut will not keep the engine from moving 100%. There is a reason that every high horsepower drag racer out there has solid engine mounts and some kind of torque link. When the engine moves on the launch, it will cause more traction issues. The damper struts that you see out there on the market for other cars allow for engine movement, which keeps vibrations to a minimum while driving on the street. But it still has to move for the strut piston to get tight. So the results aren't as good as keeping the engine completely locked down.

IMO the engine needs to move somewhat. The poly mounts are a good idea because they considerably stiffen the motor yet it still has the ability to flex somewhat. My only question is if the engine can't move anymore thanks to this bar, where does all that energy go? I'm not sure I'd be comfortable putting the extra strain on my chassis.

The idea is definately a step forward, and I'm always diggin' any new mods for 5.5 gens since there's virtually nothing out there for these things. I think it would work better if it was a strut design of some sort, and maybe have it adjustable kinda like a Tokico Illumina lol.

The idea is definately a step forward, and I'm always diggin' any new mods for 5.5 gens since there's virtually nothing out there for these things. I think it would work better if it was a strut design of some sort, and maybe have it adjustable kinda like a Tokico Illumina lol.

And since the mounting location on your chassis is plenty strong enough, your car can handle it.

my question is, what exactly to you mean by improved shift response and feel? i was talking with a guy recently who mentioned a similar mod where he took a piece of metal, attached it to his motor mount and drilled it down somewhere.. he said that this made his shifts alot smoother, and lessened the need for a perfect clutch/gas relationship for a smooth shift.. is this what your product will do?

On my VE30DE Auto 92 Maxima, which had a VB mod, I noticed my shift response and feel improved by A LOT. Before, the shifts would feel harsh and sort of bang into place. But afterwards, the shifts felt smoother and much more solid and instant. The quickness of the shifts remained the same, but I was confidently able to downshift into the top of 1st or 2nd gear without the transmission banging too much.

Also, I'd like to state that this torque link should not be treated as a replacement for worn engine mounts. It is simply to reduce engine movement along with functioning engine mounts.

Thank you for all the questions.

#28

NWP Engineering is currently developing a new modification specifically for the 02-03 Maxima! Want to keep the engine completely locked down while racing your Maxima? Polyurethane engine mounts aren't enough for those serious racers out there.

Introducing the NWP Engineering Engine Torque Link Kit!

Please note that the picture below is a prototype. The final kit will be MUCH more beautiful and will have the NWP Engineering logo engraved on the larger bracket.

This new product will reduce wheel hop, drastically improve shift response and feel, and ultimately lead to faster times and more consistant launches and shifts.

The NWP Engineering Engine Torque Link Kit will come complete with everything needed to install. Included will be two zinc plated CNC machined brackets, an adjustable torque link assembly, all the bolts and washers needed as well as fully detailed installation instructions. And of course, you'll get a pair of NWP Engineering vinyl decals for your car!

The torque link will connect from the front engine mount on the timing cover to the chassis. Once connected, simply rotate the torque link to tighten down the engine to the level of stiffness you prefer. The entire install should only take about 15 minutes and you will be ready for the races! Once you are finished racing, you can disconnect it in a matter of seconds with only one 19mm or 3/4" wrench and leave the brackets in place.

The final price has not been set just yet, but right now, it is expected to cost between $115-130 for the kit. This kit is expected to be released before MAXUS 09 (June 26-28). www.maxus09.com

This thread was started so I can hear everyone's feedback. So, please let me know what you think and if you are interested. Once again, thank you for everyone's support. And I'll see you at MAXUS 09!

Introducing the NWP Engineering Engine Torque Link Kit!

Please note that the picture below is a prototype. The final kit will be MUCH more beautiful and will have the NWP Engineering logo engraved on the larger bracket.

This new product will reduce wheel hop, drastically improve shift response and feel, and ultimately lead to faster times and more consistant launches and shifts.

The NWP Engineering Engine Torque Link Kit will come complete with everything needed to install. Included will be two zinc plated CNC machined brackets, an adjustable torque link assembly, all the bolts and washers needed as well as fully detailed installation instructions. And of course, you'll get a pair of NWP Engineering vinyl decals for your car!

The torque link will connect from the front engine mount on the timing cover to the chassis. Once connected, simply rotate the torque link to tighten down the engine to the level of stiffness you prefer. The entire install should only take about 15 minutes and you will be ready for the races! Once you are finished racing, you can disconnect it in a matter of seconds with only one 19mm or 3/4" wrench and leave the brackets in place.

The final price has not been set just yet, but right now, it is expected to cost between $115-130 for the kit. This kit is expected to be released before MAXUS 09 (June 26-28). www.maxus09.com

This thread was started so I can hear everyone's feedback. So, please let me know what you think and if you are interested. Once again, thank you for everyone's support. And I'll see you at MAXUS 09!

WANT ONE!!!! when are they gonna be available... for a 2001???

#31

Thread Starter

NWP Engineering.com

iTrader: (128)

Joined: Jul 2001

Posts: 14,066

From: Walstonburg, NC

If this particular Engine Torque Link Kit fits in the 00-01 Maxima, then it will be released just as soon as it's been tested to work in that Maxima. But if changes to the design need to be made, it will depend on several things such as how severe those design changes will be. So right now, I don't have an estimated timeframe for you on the 00-01 Maxima.

But the 02-03 Maxima Engine Torque Link Kit will be released within the next few weeks and I plan on having several kits at MAXUS 09 as well. Since this kit is so simple to install, I'm sure I will have no problem finding an 00-01 Maxima test vehicle at MAXUS.

Yeah. I have been using his vehicle for several NWP prototype designs. Some of the products were never made after doing extensive testing. But the ones that pass my perfectionist standards, are the ones that actually get produced.

But the 02-03 Maxima Engine Torque Link Kit will be released within the next few weeks and I plan on having several kits at MAXUS 09 as well. Since this kit is so simple to install, I'm sure I will have no problem finding an 00-01 Maxima test vehicle at MAXUS.

Yeah. I have been using his vehicle for several NWP prototype designs. Some of the products were never made after doing extensive testing. But the ones that pass my perfectionist standards, are the ones that actually get produced.

#32

what is preventing this from being used on a 5th gen with a 3.0?

It looks like it may work on a 3.0, we all know when that boost hits the motor wants to jump out of the engine bay. Probably fit 4th gens as well.

Are you using steel? I wouldn't mind welding the bracket to the frame for a firmer hold instead of using the bolts.

I will take one also. Looks like I should be able to fit it on a 3.0 with zero issues, if all fails one of my 5.5 gen buddies can buy it from me.

It looks like it may work on a 3.0, we all know when that boost hits the motor wants to jump out of the engine bay. Probably fit 4th gens as well.

Are you using steel? I wouldn't mind welding the bracket to the frame for a firmer hold instead of using the bolts.

I will take one also. Looks like I should be able to fit it on a 3.0 with zero issues, if all fails one of my 5.5 gen buddies can buy it from me.

Last edited by secondtonone317; 06-05-2009 at 10:45 AM.

#36

Thread Starter

NWP Engineering.com

iTrader: (128)

Joined: Jul 2001

Posts: 14,066

From: Walstonburg, NC

what is preventing this from being used on a 5th gen with a 3.0?

It looks like it may work on a 3.0, we all know when that boost hits the motor wants to jump out of the engine bay. Probably fit 4th gens as well.

Are you using steel? I wouldn't mind welding the bracket to the frame for a firmer hold instead of using the bolts.

I will take one also. Looks like I should be able to fit it on a 3.0 with zero issues, if all fails one of my 5.5 gen buddies can buy it from me.

It looks like it may work on a 3.0, we all know when that boost hits the motor wants to jump out of the engine bay. Probably fit 4th gens as well.

Are you using steel? I wouldn't mind welding the bracket to the frame for a firmer hold instead of using the bolts.

I will take one also. Looks like I should be able to fit it on a 3.0 with zero issues, if all fails one of my 5.5 gen buddies can buy it from me.

I'm not sure what is preventing it from working the 5th gen 3.0L. But I will need to test fitment to make sure. I will do that during MAXUS 09 I'm sure.

#37

Yes, it is zinc plated steel. So it will weld nicely. But so far, I have not had ANY issues with the bolts holding the power. And the brackets themselves are WAY over engineered. But I love sturdy brackets.

I'm not sure what is preventing it from working the 5th gen 3.0L. But I will need to test fitment to make sure. I will do that during MAXUS 09 I'm sure.

I'm not sure what is preventing it from working the 5th gen 3.0L. But I will need to test fitment to make sure. I will do that during MAXUS 09 I'm sure.

If you want to send me a pic of the bolt locations you're using, I can get you some measurements for the A32.

#38

I'm still not completely convinced. What mods does the test car have? Like I said, the idea is a good one and of course the bar works but I'm still sure there must be a con side to this.

I would like to see this on a 5.5 gen making 240+whp, and putting down at least low 13 second times. I wanna know the condition of the frame/chassis after 1-2 years, or like 50-100 passes. Instead of an engine tie down, I'd much prefer an engine damper that still allows for some movement or has a shock to absorb the movement.

I would like to see this on a 5.5 gen making 240+whp, and putting down at least low 13 second times. I wanna know the condition of the frame/chassis after 1-2 years, or like 50-100 passes. Instead of an engine tie down, I'd much prefer an engine damper that still allows for some movement or has a shock to absorb the movement.

#39

I'm still not completely convinced. What mods does the test car have? Like I said, the idea is a good one and of course the bar works but I'm still sure there must be a con side to this.

I would like to see this on a 5.5 gen making 240+whp, and putting down at least low 13 second times. I wanna know the condition of the frame/chassis after 1-2 years, or like 50-100 passes. Instead of an engine tie down, I'd much prefer an engine damper that still allows for some movement or has a shock to absorb the movement.

I would like to see this on a 5.5 gen making 240+whp, and putting down at least low 13 second times. I wanna know the condition of the frame/chassis after 1-2 years, or like 50-100 passes. Instead of an engine tie down, I'd much prefer an engine damper that still allows for some movement or has a shock to absorb the movement.

This thing will not do any damage to the chassi. How can you justify asking a question like that after seeing the pictures of how its mounted?

Last edited by secondtonone317; 06-05-2009 at 11:28 AM.

#40

Hmm i am certainly liking it more after seeing where is attaches. One more question Aaron92SE. The old car I was speaking of was a 00-05 Celica btw, and the other problem the rod caused was while it wouldn't let the engine move forward or backward it would actually cause the engine and tranny to twist sideways in the engine bay. Is there a hint of this at all when installed on 5.5 gens?? Your right about the solid mounting point though, that area on the car is beefy.