cold valve lash adjustment

#1

cold valve lash adjustment

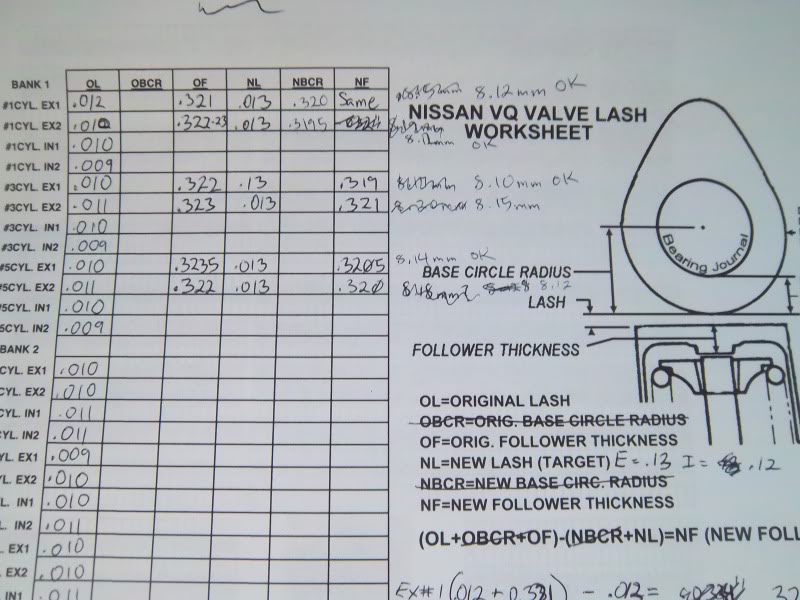

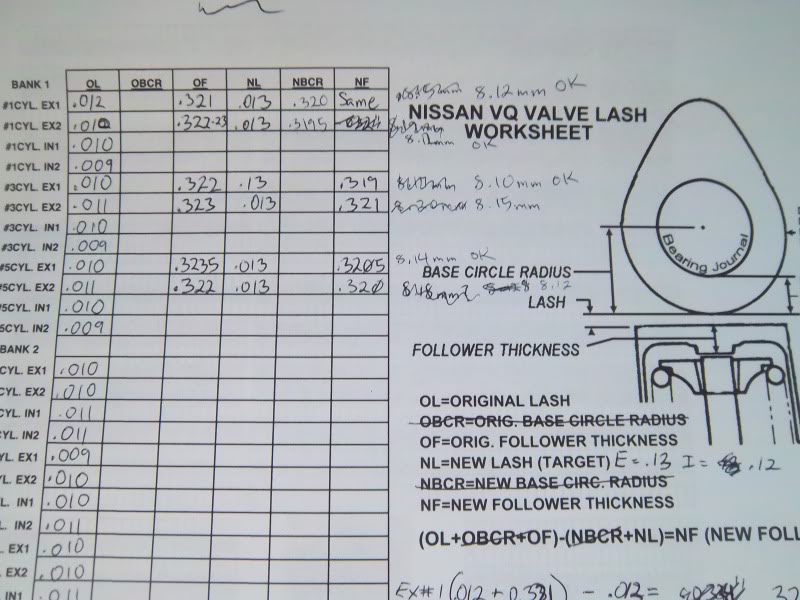

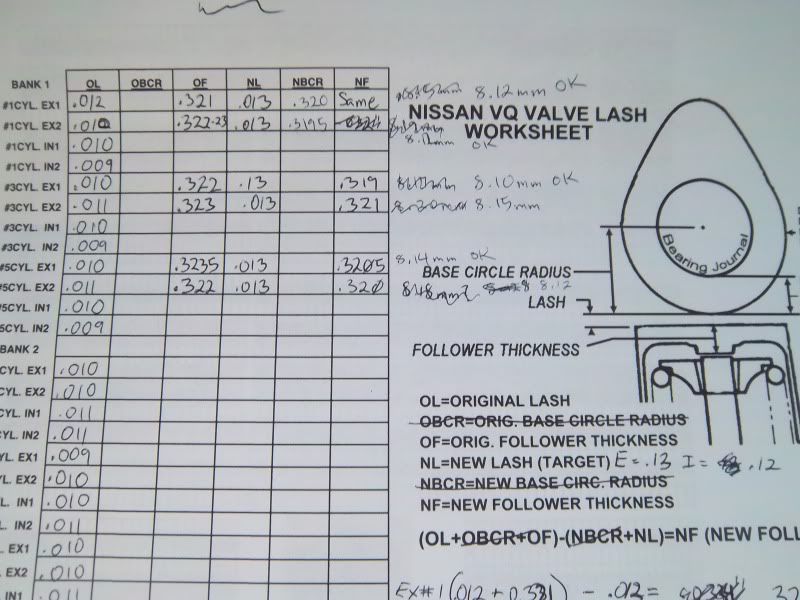

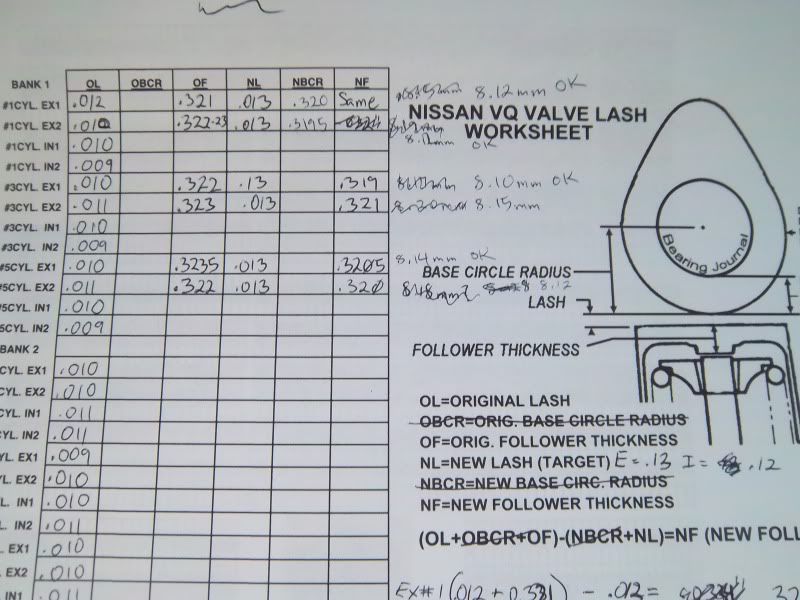

Hello. I just got my heads back from the machinist(needed a valve job) and since the valve job I think may have minimized my valve lash, I decided to measure them, and they are all on the low side of FSM spec, or just below spec.

I printed out a chart on jim wolf website, and I set my target lashes for Intake =.012", and Exhaust = .013".

I have been getting readings on Intake averaging around 0.010" and averages on exhaust to be 0.011"...with various out of specs here and there. So am I ok with just leaving them alone at the minimal specs and just replacing the few bad ones? O should I go all out and order 24 new buckets? Here's a shot of a few measurements I took on the exhaust side:

And anyone have the good deals on these?

I printed out a chart on jim wolf website, and I set my target lashes for Intake =.012", and Exhaust = .013".

I have been getting readings on Intake averaging around 0.010" and averages on exhaust to be 0.011"...with various out of specs here and there. So am I ok with just leaving them alone at the minimal specs and just replacing the few bad ones? O should I go all out and order 24 new buckets? Here's a shot of a few measurements I took on the exhaust side:

And anyone have the good deals on these?

#2

Hello. I just got my heads back from the machinist(needed a valve job) and since the valve job I think may have minimized my valve lash, I decided to measure them, and they are all on the low side of FSM spec, or just below spec.

I printed out a chart on jim wolf website, and I set my target lashes for Intake =.012", and Exhaust = .013".

I have been getting readings on Intake averaging around 0.010" and averages on exhaust to be 0.011"...with various out of specs here and there. So am I ok with just leaving them alone at the minimal specs and just replacing the few bad ones? O should I go all out and order 24 new buckets? Here's a shot of a few measurements I took on the exhaust side:

And anyone have the good deals on these?

I printed out a chart on jim wolf website, and I set my target lashes for Intake =.012", and Exhaust = .013".

I have been getting readings on Intake averaging around 0.010" and averages on exhaust to be 0.011"...with various out of specs here and there. So am I ok with just leaving them alone at the minimal specs and just replacing the few bad ones? O should I go all out and order 24 new buckets? Here's a shot of a few measurements I took on the exhaust side:

And anyone have the good deals on these?

I assume you've looked at the underneath of the buckets - see that little nub sticking up in the middle? That's what actually establishes the valve lash. If you use a Dremel small grinding tool with a flat side you can grind down the nub - stem - a bit and that will increase the valve lash spacing. If you can set up a micrometer to measure the "before" height of the stem measured from the top of the lifter and get a reference height then you can measure progress as you grind down the stem.

Courtesy Nissan On-Line parts have good prices on the buckets of lifters.

#3

thank you-Yes I tried grinding down a bucket. They have a mirror-like finish on those nubs and after grinding the nub it was all scratched up making me question the structural integrity of the nub, making it fail after a while, but it should be ok to to this?

#4

I did it on my current engine - using a real fine rotary stone works good.

#6

Yup - I had to install two sets of Cosworth cams, 'cause the first set developed cracks in the front of the cams where the locator pins are installed. I figured out the technique, then my machinist came up with a grinding method that allowed a measurement while grinding. It was time-consuming, but DLC buckets are over $18 each - even from Courtesy Nissan. That adds up quick. I had to buy a few, but we swapped them around first, ground down the few that were too tight, then I purchased the rest. Maybe half a dozen...

#7

Yup - I had to install two sets of Cosworth cams, 'cause the first set developed cracks in the front of the cams where the locator pins are installed. I figured out the technique, then my machinist came up with a grinding method that allowed a measurement while grinding. It was time-consuming, but DLC buckets are over $18 each - even from Courtesy Nissan. That adds up quick. I had to buy a few, but we swapped them around first, ground down the few that were too tight, then I purchased the rest. Maybe half a dozen...

#8

ok I tried with one bucket-the new in-spec nub that I ground down seems a little uneven. As these push on the valves at a high rpm, don't they need to be ground perfectly square or is a bit of unevenness ok? I figured they need to be ground perfectly square to meet the top of the valve stem, right?

#9

ok, but I'm just probably going to try to reuse the mirror-like stock ones. I measured up to one thousandth of difference after grinding it, so the nub has high and low surfaces...I used a drill press to grind it btw with a pink rotary grinding stone meant for a dremel. I'm going to keep at it. Thanks for all of your help bro I appreciate!!

#10

ok, but I'm just probably going to try to reuse the mirror-like stock ones. I measured up to one thousandth of difference after grinding it, so the nub has high and low surfaces...I used a drill press to grind it btw with a pink rotary grinding stone meant for a dremel. I'm going to keep at it. Thanks for all of your help bro I appreciate!!

#11

Did you write you numbers down that are on the bottom of the "lifters"? If so you may be able to swap a few of them around to get them with in spec, that's what I did with my engine, and I still needed to order two from Nissan. Once you know what number lifters you have you will be able to figure out which p/n's you need. It time consuming but it is just simple math in the end.

#12

after getting the heads back, they replaced some of the lifters, and the replacements didn't have the numbers of the mm heights. So I micd them. I suppose they figured that some of the original lifters were too far out of spec? so when I got the heads back they were for the most part in spec, though near the bottom measurements. There were about eight out of spec by about a thousandth or so. My garage is pretty cold, so maybe that played a role in the borderline measurements, and in the shop where I assume is temp-controlled, they were more in spec? Maybe I'll try some DLC ones... Anyways thanks!

#13

Crankshaft Followers

Did you write you numbers down that are on the bottom of the "lifters"? If so you may be able to swap a few of them around to get them with in spec, that's what I did with my engine, and I still needed to order two from Nissan. Once you know what number lifters you have you will be able to figure out which p/n's you need. It time consuming but it is just simple math in the end.

Here's my problem hopefully someone can help. I got my crankshaft followers swapped and out of order. Can anyone tell me how to get them in order please? My 95 Maxima won't start. I was only getting 125 psi engine compression (min 143 psi to start). I took off the camkshaft, and the psi jumped to at least 165.

Thread

Thread Starter

Forum

Replies

Last Post

tarun900

4th Generation Maxima (1995-1999)

19

12-20-2021 06:57 PM

TKHanson

5th Generation Maxima (2000-2003)

6

11-24-2018 01:39 AM