Wtf happen

#1

Wtf happen

All I did was lower my car with some intrax springs then I go for a test drive and my car barely moves. It's seem like my tranny is bad but it goes in gear n it moves but barely. It has a rough noise like the calipers are stuck. I took the tire out on driver side n notice the outer cv boot had tons of fresh grease. I spin the hub and I see the outer joint move but not the inner joint move please help.

#8

sounds like you snapped your CV joint. A feat I've never even heard of....... but if the outer part moves, and the shaft does not... then it's broken. Do you have the ability to take a clear well-lit video of what's going on when you spin the hub? From the inner joint of the axle @ the transmission, out to the wheel side?

#9

Open diff = both axles receive equal torque, with potentially unequal speed. Since both axles get an equal 50% of the torque, a broken axle that can receive 0tq means the good axle also receives 0tq because 0.5*0=0. So the car won't move. (Even if one tire spinning is in mud and the other is on solid ground, if the car is moving with an open diff, then both wheels are contributing to moving the car. The low torque limit of the muddy wheel means that the torque limit of the grippy wheel is equally low, hence why you can't accelerate very well with even one tire in the mud).

Locking diff is the opposite of open..

Lock diff = both axles receive equal speed, but with potentially unequal torque. A broken axle has no effect on the vehicle's ability to move, because the broken axle receives 0% and the good one receives 100%.

VLSD diff = both axles can get unequal speed and unequal torque at the same time, within limits. A broken axle will spin slightly faster than the unbroken axle, but the good axle will receive slightly more torque (the broken axle's torque is wasted through the VLSD coupler unit as heat, and can damage it).

#12

So in that video example you can how an open diff works. Imagine that if one of the wheels had a broken axle, then the small gears in the middle would just rotate around the other axle, freewheeling, without actually giving any power, because you have to have a load on both axles in order to get motion.

A locked diff would be like the rigid crossbar (4:30ish).

My friend's car (which happened to be a 3rd gen but in reality doesn't matter what it was) had a very similar thing happen... he was driving, then all the sudden he heard a clunk and the engine and speedometer revved, but the car slowed down to a stop. Once stopped, the car wouldn't move. All that had happened was the axle popped out of the transmission because the axle bracket-to-bearing bolts were too loose, and jiggled their way out, releasing the axle.

A locked diff would be like the rigid crossbar (4:30ish).

My friend's car (which happened to be a 3rd gen but in reality doesn't matter what it was) had a very similar thing happen... he was driving, then all the sudden he heard a clunk and the engine and speedometer revved, but the car slowed down to a stop. Once stopped, the car wouldn't move. All that had happened was the axle popped out of the transmission because the axle bracket-to-bearing bolts were too loose, and jiggled their way out, releasing the axle.

Last edited by CapedCadaver; 04-26-2013 at 08:56 PM.

#13

i spin the passanger hub and it turns freely. i see the outer cv joint move as i spin the hub. but there was grease on top of the boot which was weird because i didnt see any rip boot. im 80% sure its the bearing that went bad on the passenger side hub.. it grind really bad like metal spinning on dry metal. maybe the grease i saw on top of the cv boot was from the bearing from the hub... the boot looks like in good shape.

if it is the bearing on the passenger side, would a bad bearing cause the car to barely move?

and no i didnt take out the axle or even touch it. only remove the struts.

if it is the bearing on the passenger side, would a bad bearing cause the car to barely move?

and no i didnt take out the axle or even touch it. only remove the struts.

#14

#15

So in that video example you can how an open diff works. Imagine that if one of the wheels had a broken axle, then the small gears in the middle would just rotate around the other axle, freewheeling, without actually giving any power, because you have to have a load on both axles in order to get motion.

A locked diff would be like the rigid crossbar (4:30ish).

My friend's car (which happened to be a 3rd gen but in reality doesn't matter what it was) had a very similar thing happen... he was driving, then all the sudden he heard a clunk and the engine and speedometer revved, but the car slowed down to a stop. Once stopped, the car wouldn't move. All that had happened was the axle popped out of the transmission because the axle bracket-to-bearing bolts were too loose, and jiggled their way out, releasing the axle.

A locked diff would be like the rigid crossbar (4:30ish).

My friend's car (which happened to be a 3rd gen but in reality doesn't matter what it was) had a very similar thing happen... he was driving, then all the sudden he heard a clunk and the engine and speedometer revved, but the car slowed down to a stop. Once stopped, the car wouldn't move. All that had happened was the axle popped out of the transmission because the axle bracket-to-bearing bolts were too loose, and jiggled their way out, releasing the axle.

#16

When I push the car from behind in neutral it doesn't make the grinding noise but when in gear it does make the grinding sound.

So doesnt that mean its not the bearings because if its the bearing it should grind in gear or neutral right?

So doesnt that mean its not the bearings because if its the bearing it should grind in gear or neutral right?

#17

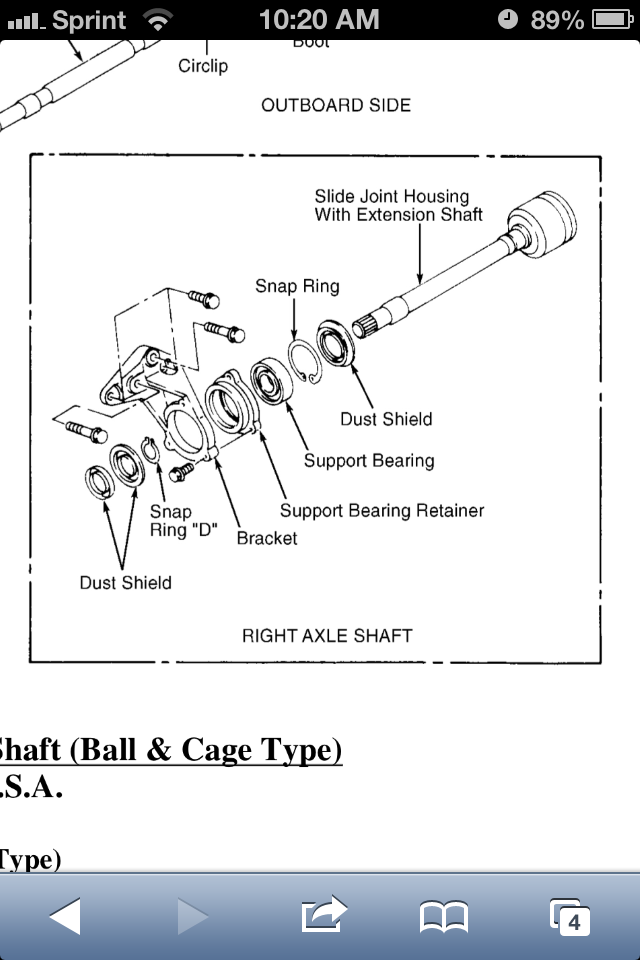

after doing some research online and the haynes manual aka the bible of nissan lol. i starting to think its the support bearing on the axle. the support bearing is located in the middle of the passenger side axle.

#19

Axle ABS ring touching your ball joint? That was my first thought when reading your first sentence. Although that doesn't seem to match your other symptoms later on in your thread. But if you didn't touch your axles I can't see them suddenly going bad. It has to be a clearance related issue directly related to the suspension orientation change from lowering (assuming you did the install properly).

It's happened to me several times lowering 3rd gens on Intrax. With the exact same symptoms you describe. I had to about burn up my clutch to get my car to move 2 feet and it did so in a cacophony of grinding and screeching. Had to remove the knuckle and cut a little bit off the ball joint studs.

It's happened to me several times lowering 3rd gens on Intrax. With the exact same symptoms you describe. I had to about burn up my clutch to get my car to move 2 feet and it did so in a cacophony of grinding and screeching. Had to remove the knuckle and cut a little bit off the ball joint studs.

#20

i spin the passanger hub and it turns freely. i see the outer cv joint move as i spin the hub. but there was grease on top of the boot which was weird because i didnt see any rip boot. im 80% sure its the bearing that went bad on the passenger side hub.. it grind really bad like metal spinning on dry metal. maybe the grease i saw on top of the cv boot was from the bearing from the hub... the boot looks like in good shape.

if it is the bearing on the passenger side, would a bad bearing cause the car to barely move?

and no i didnt take out the axle or even touch it. only remove the struts.

if it is the bearing on the passenger side, would a bad bearing cause the car to barely move?

and no i didnt take out the axle or even touch it. only remove the struts.

If you can turn the hub by hand, then SURELY the engine can turn it with all of its torque plus the torque multiplication of 1st gear + final drive. If you have the front of the car jacked up with the wheels removed, and you have the engine running and put the car in 1st gear and let it idle, do both hubs turn? or only one? If both spin, do they seem to be turning at the same speed? What about a higher gear, like 5th? Same or different outcome?

Also are your brake rotors installed while you are trying this test with the wheels off? Remember that they float loosely unless they are clamped down, so that might be part of the noise you hear if you hear it on both wheels.

Last edited by CapedCadaver; 04-27-2013 at 09:25 AM.

#21

#22

Thing is if you can turn the wheel freely, then you can turn the WHOLE axle from #5 all the way into the differential. The bearing #3 sits still and the axle turns through it.

That's why i asked for a video, so we can see what's moving, and what isn't, and maybe you can even get the camera close to the source of the grinding noise.

That's why i asked for a video, so we can see what's moving, and what isn't, and maybe you can even get the camera close to the source of the grinding noise.

#24

I high doubt the differential is the problem but if it were the problem it would depend what broke and whether anything else was damaged by it breaking. All i was getting at by showing you the function of the differential is how when one wheel cannot deliver any torque to the road due to a problem, then the "good" one cannot either, hence no motion. That's the differential working as designed, if it's an open type diff.

Another way to test the diff is that when you have the engine off, transmission in gear, spinning one hub forward should result in the opposite hub spinning backwards, at the same speed. Like this:

Another way to test the diff is that when you have the engine off, transmission in gear, spinning one hub forward should result in the opposite hub spinning backwards, at the same speed. Like this:

Last edited by CapedCadaver; 04-27-2013 at 11:06 AM.

#29

sounds like you snapped your CV joint. A feat I've never even heard of....... but if the outer part moves, and the shaft does not... then it's broken. Do you have the ability to take a clear well-lit video of what's going on when you spin the hub? From the inner joint of the axle @ the transmission, out to the wheel side?

A low frame-rate 240p video under the car with no lighting? Can't see a damn thing. Do you have a "real" camera, and a worklight, or a friend with a new-ish smartphone?

This is what my Z31's CV axle looks like @ 480p w/ onboard flash on my Galaxy S2:

This is what my Z31's CV axle looks like @ 1080p w/ a fluorescent worklight on my Canon point-n-shoot

Last edited by CapedCadaver; 04-27-2013 at 09:30 PM.

#30

You can see his axle is spinning almost in an oval type motion instead of a tight stationary rotation. It's almost like he somehow kinked the joint at an angle making it rotate in that oval motion. I know the inner joints on the axles can be somewhat pulled apart and get "stuck" in that position. The picture of the boot he took looks stretched too.

Did you somehow do that TonyJr? You didn't touch your axles at all during this spring swap? Did you move the hubs or let them stretch over and "hang" at all? That could pull the axle.

Did you somehow do that TonyJr? You didn't touch your axles at all during this spring swap? Did you move the hubs or let them stretch over and "hang" at all? That could pull the axle.

#31

You can see his axle is spinning almost in an oval type motion instead of a tight stationary rotation. It's almost like he somehow kinked the joint at an angle making it rotate in that oval motion. I know the inner joints on the axles can be somewhat pulled apart and get "stuck" in that position. The picture of the boot he took looks stretched too.

Did you somehow do that TonyJr? You didn't touch your axles at all during this spring swap? Did you move the hubs or let them stretch over and "hang" at all? That could pull the axle.

Did you somehow do that TonyJr? You didn't touch your axles at all during this spring swap? Did you move the hubs or let them stretch over and "hang" at all? That could pull the axle.

Inner joint is a double-offset joint (straight ball races on outer shell) like this, and it telescopes.

the other common type is a tripod, but I don't think any 3rd gen maxima used those. Z31's used them though.

#32

Nice pics of the joint. But I know it's a bad video but its clear enough to see the axle is not right. So I'm replacing it tomorrow. I didn't pull on it, but I did lower the hub by hand to pull out the structs.

#36

VE transmissions MUST use VE axles. VG must use VG. The reason is b/c your hubs are bored out larger than a VG's hubs are, so the VG axle wouldn't fit into the splines, it would just spin loosely.

#37

ie separated #1 from #2&3

Last edited by CapedCadaver; 04-28-2013 at 08:38 AM.

#38

Yep it spin perfect in mid air but with weight on it it grinds n barely move. I'm about to buy an axle now or should I attempt to pop it back in?

#39

Do you have the tools to replace the axle? 36mm axle nut socket, a 1/2" drive torque wrench (to approximate the tightening torque for the 36mm nut assuming that a 150lb/ft click plus an extra shove = 230lb/ft that it requires), a big-**** breaker bar to loosen the nut, a screwdriver to jam into the rotor vent thru the hole in the caliper while loosening, etc.

If you already have all that, then might as well try and get the axle nut loose now, and get your current axle free from the hub. Then disconnect the strut bolts from the knuckle, turn the steering wheel all the way to the left and lock it there, and you should then be able to get the axle out of the hub and the hub out of your way.

After that it will be easier to manipulate the axle and joint so that you can try and get them lined up again, and see if it will just push itself back on. Or at least line up good enough to get a hammer on the end (with a wooden block to protect the threads... or maybe the axle nut threaded on to protect the threads) and drive it back on.

If that fails, then you're already gonna be most of the way home in terms of removing the axle, which you'll have to do to install a new one.

Either way, you have to get new cotter pin for the nut retainer.

If you already have all that, then might as well try and get the axle nut loose now, and get your current axle free from the hub. Then disconnect the strut bolts from the knuckle, turn the steering wheel all the way to the left and lock it there, and you should then be able to get the axle out of the hub and the hub out of your way.

After that it will be easier to manipulate the axle and joint so that you can try and get them lined up again, and see if it will just push itself back on. Or at least line up good enough to get a hammer on the end (with a wooden block to protect the threads... or maybe the axle nut threaded on to protect the threads) and drive it back on.

If that fails, then you're already gonna be most of the way home in terms of removing the axle, which you'll have to do to install a new one.

Either way, you have to get new cotter pin for the nut retainer.

#40

Tony - pull that axle and see if the outer joint is "locked". It should be able to turn/bend freely in all directions. But I bet yours doesn't. If not, fool with it to see if you can get the joint moving properly. You'll have to pull the axle anyway to replace it so you're not out anything.

Last edited by James92SE; 04-28-2013 at 11:43 AM.

i saw that vid back in mechanic school, even all the instructors said thats about the best vid to get the basics on how a diff works

i saw that vid back in mechanic school, even all the instructors said thats about the best vid to get the basics on how a diff works