ve turbo update

#41

Many PepBoys locations have a PepBoys Speed Shop inside them now. My buddy manages one of the Speed Shops here in DFW. He varying shapes/sections of legit mandrel bends in both aluminized steel and stainless up to 3". He also has v band clamps and all sorts of other goodies. This is all stocked in-store and available off the shelf.

I don't believe any other chain auto parts places sell legit mandrel stuff.

Of course I can it cheaper online but it's nice to know that I can get that stuff locally in a pinch if I ever run out of material on a weekend or something.

I don't believe any other chain auto parts places sell legit mandrel stuff.

Of course I can it cheaper online but it's nice to know that I can get that stuff locally in a pinch if I ever run out of material on a weekend or something.

#42

Of course, on an exhaust they probably go totally unnoticed. It's a bigger deal on IC piping like what my pipe was in my picture.

Dan you have a TIG machine?

I just can't imagine ever wanting to spend the money for one. Although Eastwood has good sales on their TIG machines occasionally.

#43

Many PepBoys locations have a PepBoys Speed Shop inside them now. My buddy manages one of the Speed Shops here in DFW. He varying shapes/sections of legit mandrel bends in both aluminized steel and stainless up to 3". He also has v band clamps and all sorts of other goodies. This is all stocked in-store and available off the shelf.

I don't believe any other chain auto parts places sell legit mandrel stuff.

Of course I can it cheaper online but it's nice to know that I can get that stuff locally in a pinch if I ever run out of material on a weekend or something.

I don't believe any other chain auto parts places sell legit mandrel stuff.

Of course I can it cheaper online but it's nice to know that I can get that stuff locally in a pinch if I ever run out of material on a weekend or something.

I just did some checking around online and apparently lots of people have trouble getting air-tight seals on MIG butt welds.

Of course, on an exhaust they probably go totally unnoticed. It's a bigger deal on IC piping like what my pipe was in my picture.

Dan you have a TIG machine?

I just can't imagine ever wanting to spend the money for one. Although Eastwood has good sales on their TIG machines occasionally.

Of course, on an exhaust they probably go totally unnoticed. It's a bigger deal on IC piping like what my pipe was in my picture.

Dan you have a TIG machine?

I just can't imagine ever wanting to spend the money for one. Although Eastwood has good sales on their TIG machines occasionally.

it's not perfect but it's serviceable weld IMO...

once funding frees up a little i'll pick up the everlast AC/DC model.

#44

You mean arc, or wire fed arc? A true MIG, and certainly a TIG is out of the price range for someone who isn't welding for a living.

Please believe that building a catback exhaust without a lift and experience is NOT something you want to take on. I can almost guarantee that you will end up spending double on piping because creating the proper bends takes experience and some trial and error. You would be way better off buying a 3" catback from MES for $195 or $270 for SS where all the bends are created for you. Don't both tacking it up, just take the kit to a shop and have them do it for you. You will be much happier with the end product and won't feel it's nessesary to completely redo it. Several guys on this board alone have experienced this first hand. Besides, I don't think that any local auto store has 3" mandrel bends. Were you thinking of going 2.5"?

#45

#47

wow that's pretty insane. i doubt that stuff will move much. it's not like it's a quart of oil that gets used and used. once you build your set up it's good for a few years at least.

i was going to pick up the everlast (chinese made) one but i have full use of my buddy's miller TIG so at that point i just used his. was burning up a few tanks of gas before i got the hang of it but eventually i got better.

it's not perfect but it's serviceable weld IMO...

once funding frees up a little i'll pick up the everlast AC/DC model.

i was going to pick up the everlast (chinese made) one but i have full use of my buddy's miller TIG so at that point i just used his. was burning up a few tanks of gas before i got the hang of it but eventually i got better.

it's not perfect but it's serviceable weld IMO...

once funding frees up a little i'll pick up the everlast AC/DC model.

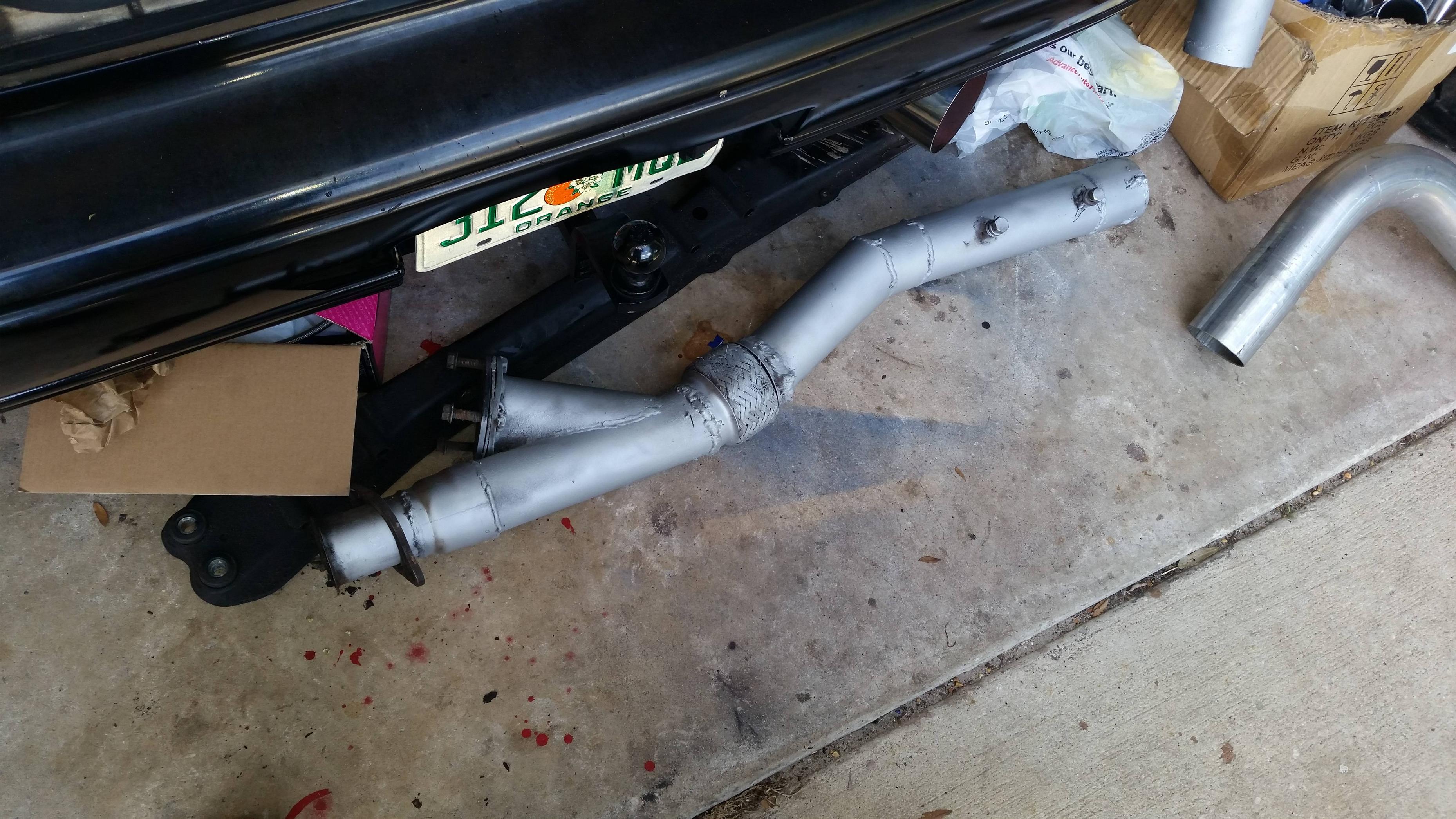

And Dan do I spy a 3 bolt flange that bolts up to the factory exhaust manifolds? Does that have the recess in it for a crush ring? I have been looking for those flanges off and on for years. Where'd you get it?

#48

Yeah I think he said he can't even remember selling any mandrel bends or v bands to date. They also fill nitrous bottles and stuff. Pretty cool by PepBoys IMO to do some of this stuff even though a lot of it is low volume stuff.

And Dan do I spy a 3 bolt flange that bolts up to the factory exhaust manifolds? Does that have the recess in it for a crush ring? I have been looking for those flanges off and on for years. Where'd you get it?

And Dan do I spy a 3 bolt flange that bolts up to the factory exhaust manifolds? Does that have the recess in it for a crush ring? I have been looking for those flanges off and on for years. Where'd you get it?

for the flanges that you're looking for there's no recess but i'm sure you can get like the 2.5" (or whatever pipe it's there) 3 bolt flange with the flat copper gaskets instead of the crush ring.

it's all a trial and error with flanges and very rare do you find the actual diagram/specs.

#49

You will need to add your own muffler.

I added my own V band clamps and did a bunch of work on it at the back to fit over my Addco swabar and also to make it not slant my muffler downwards which I hate and is a common problem on 3rd gens with universal mufflers.

They have an issue on the back that will kink one of the bends. I can't remember which one but I think it's the very rear most bend. This is a byproduct of the mandrel bending machines with large diameter pipe that make it difficult to bend two bends close together. The part that "grips" the pipe tends to then kink the second bend. They will send you a replacement matching bend for this section but you will need to weld it in yourself. Here is the kinked bend:

#50

ewww...the last bend is no bueno.

lucky you man...i had to stitch the entire exhaust out of a bunch of bends myself. i didn't know about this company or even any company that makes this for the 3rd gen when i was building my set up.

lucky you man...i had to stitch the entire exhaust out of a bunch of bends myself. i didn't know about this company or even any company that makes this for the 3rd gen when i was building my set up.

#51

I wouldn't be surprised if I'm the only person who has ever bought their 3" system for a 3rd gen. They also sell mandrel bends by themselves for pretty darn good prices. I actually just recently bought some bends on eBay which was the cheapest price I could find.

I forgot about MES selling bends. I just checked and they sell a 3" assortment bend pack with a straight section, a 180, two 90's and two 45's for about $85 shipped. That's a great deal. I paid more and got less bends on eBay.

#52

I'm guessing you mean a catback without a muffler? I pretty sure at that price it includes no cat, and muffler or resonator. I have ideal (IMO) recommendations for both muffler and resonator, but that's if you want maximum performance and a quiet exhaust which you clearly care nothing about.

#53

#54

Tony, my exhaust is the MES 3" catback. Yes it is piping only but they will add in a resonator for you if you want. I opted to get the resonator.

You will need to add your own muffler.

I added my own V band clamps and did a bunch of work on it at the back to fit over my Addco swabar and also to make it not slant my muffler downwards which I hate and is a common problem on 3rd gens with universal mufflers.

They have an issue on the back that will kink one of the bends. I can't remember which one but I think it's the very rear most bend. This is a byproduct of the mandrel bending machines with large diameter pipe that make it difficult to bend two bends close together. The part that "grips" the pipe tends to then kink the second bend. They will send you a replacement matching bend for this section but you will need to weld it in yourself. Here is the kinked bend:

#55

Catback without an exhaust?

I'm guessing you mean a catback without a muffler? I pretty sure at that price it includes no cat, and muffler or resonator. I have ideal (IMO) recommendations for both muffler and resonator, but that's if you want maximum performance and a quiet exhaust which you clearly care nothing about.

#56

It goes all the way to just prior to my sway bar and is in two pieces so will either need to be welded together or will need to be clamped with exhaust clamps. I can't remember where the joint is, I want to say behind the resonator. From just prior to the sway bar area I had to really cut it up and angle it up higher and then back down to clear the bar.

The 2.5" will fit over your stock bar for sure. I don't know about the 3". I suspect it might be close but worst case a couple of cuts and welds and should be no problem. Mine only has so many welds back in that area because I ran out of mandrel bends and had to start doing pie cuts from straight pipe.

#57

#60

I guess a better way to describe what I mean would be the "center point" of the penetration. Imagine a 1/2" wide weld bead around a pipe butt joint. Assuming being an amateur like me, if the exact "center point" of the penetration (bead) doesn't happen to fall directly in line with the joint, the outside edges of the bead are subject to leak and what I found was happening to me with leaks appearing to come up around the bead.

I guess more succinctly, your joint can leak if your bead is still covering the joint but not necessarily perfectly centered ON the joint. Which is what was happening to me.

wow that's pretty insane. i doubt that stuff will move much. it's not like it's a quart of oil that gets used and used. once you build your set up it's good for a few years at least.

i was going to pick up the everlast (chinese made) one but i have full use of my buddy's miller TIG so at that point i just used his. was burning up a few tanks of gas before i got the hang of it but eventually i got better.

it's not perfect but it's serviceable weld IMO...

once funding frees up a little i'll pick up the everlast AC/DC model.

i was going to pick up the everlast (chinese made) one but i have full use of my buddy's miller TIG so at that point i just used his. was burning up a few tanks of gas before i got the hang of it but eventually i got better.

it's not perfect but it's serviceable weld IMO...

once funding frees up a little i'll pick up the everlast AC/DC model.

Danny less heat and feed filler faster. Youll get it just practice practice.

#61

Is Everlast a "budget" unit? What do you think of AHP? I have been contemplating a "cheap" ($700-$800) TIG for a few years now to learn on and then use going forward for stuff just like in this thread

#64

yeah it's just really practice...the miller i was on had the foot pedal so it was weird to step on the pedal and modulate that while controlling the torch along with the filler.

it's like total hand/eye/foot coordination....but i don't do it for a living so i just need to find more time to practice on it.

james...the AHP and the other lower priced ones are pretty much the same aside from the name they are all made in china. i've heard good reviews things about everlast that's why i'm considering it. also i'm working with 115v so i need to have the flexibility to switch back and forth depending on where i am.

one thing is that you go through A LOT of gas with TIG. with MIG the tank lasts a good while with TIG it'll last a few hours (if that) before it's done. also the torch i was using was water cooled so i heard it's a lot smaller than an air cooled one. back purging and etc is important too but i only ran pre and post since i was already running out of gas quickly.

i dipped the tungsten so much times i was sharpening it like crazy..LOL

it's like total hand/eye/foot coordination....but i don't do it for a living so i just need to find more time to practice on it.

james...the AHP and the other lower priced ones are pretty much the same aside from the name they are all made in china. i've heard good reviews things about everlast that's why i'm considering it. also i'm working with 115v so i need to have the flexibility to switch back and forth depending on where i am.

one thing is that you go through A LOT of gas with TIG. with MIG the tank lasts a good while with TIG it'll last a few hours (if that) before it's done. also the torch i was using was water cooled so i heard it's a lot smaller than an air cooled one. back purging and etc is important too but i only ran pre and post since i was already running out of gas quickly.

i dipped the tungsten so much times i was sharpening it like crazy..LOL

#66

Thats about right if the quality is there for a reverse y pipe, downpipe with dump tube. Also are they back purging? Very critical when welding stainless. If thats a full manifold price to cheap and I would stay away. For v6-v8 full manifolds in stainless steel with a downpipe I charge $1200-1700 price varys.

Is what your referring to is lack of fusion on toe of the weld. Can be caused by various things. Fitment of parts being welded, Parameters machine set at usually to little heat or to much wire speed. Welder can also be the cause wrong technique etc. Also simply any kind mill scale oil grease can cause this. Good practice to wire wheel every joint before welding.

Ive been running everlast for few years now and no issues and I use it 3-4 times a week. Currently I have the Micro tig 180. Mainly do stainless and aluminum as I prefer to not build manifolds out of steel these days. I have run many millers lincoln etc and its very comparable low amperage to welding razor blades together up to thich 1/2 inch welds great. All these pics were done with my everlast. (11years welding what I do for living)

Is what your referring to is lack of fusion on toe of the weld. Can be caused by various things. Fitment of parts being welded, Parameters machine set at usually to little heat or to much wire speed. Welder can also be the cause wrong technique etc. Also simply any kind mill scale oil grease can cause this. Good practice to wire wheel every joint before welding.

Ive been running everlast for few years now and no issues and I use it 3-4 times a week. Currently I have the Micro tig 180. Mainly do stainless and aluminum as I prefer to not build manifolds out of steel these days. I have run many millers lincoln etc and its very comparable low amperage to welding razor blades together up to thich 1/2 inch welds great. All these pics were done with my everlast. (11years welding what I do for living)

I know what I'm getting next. 😈

I know what I'm getting next. 😈

#74

I just finished putting my engine back together yesterday. Going to try to drop it in this week and do my engine break-in next weekend.

Boy, the VE timing chain is annoying in that the two idler sprocket marks for the upper timing chains are not visible once the front timing cover is installed. And even less access/sight-line with the heads on. In fact, the timing marks face downwards when the engine is at TDC so you can't even remotely see them. Obviously this isn't a problem in and of itself as you line your chains up prior to putting the timing cover on, but then if you rotate the engine after the timing cover is installed you're screwed. I made that mistake. I wanted to make sure the lower chain/engine still turned over smooth with the cover and whatnot installed. Then after that I realized whoops my upper chains don't line back up.

Thankfully I marked in yellow paint the actual tooth on the idler sprockets which corresponded to the timing marks. So as I turned the engine over some more I was able to locate the yellow mark as it would pass by. Once I located that yellow mark, I counted out the exact halfway point of the other side of the sprocket from the timing mark, which was the 9th tooth. So I painted that tooth blue.

With the blue tooth sprocket facing "up" at TDC, and knowing the blue tooth sprocket was the 9th tooth, I also then knew that the roller just above the 9th tooth would be the 10th roller from the timing mark. So then I just had to count 11th, 12th, and so on upwards until I got my 28 rollers (or whatever it was, can't remember off the top of my head but think it was 28) to the VTC assembly or cam sprocket depending on which side you're working on. And then of course from there, I could count over the 12 rollers to the other cam. Whew.

#76

Was it by design to put the rebuild on the front in case you have to do it again in the future?