How to: Build you own Poly Motor Mounts

#1

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

How to: Build your own Poly Motor Mounts

This is a project that has been on my slate for a while, and I'm finally getting around to it. I have seen several people ask what the advantages of stiffer motor mounts are. The answer it simple, the more you reduce the amount the motor moves by rotational force, the more power you put to the pavement, and reduce wheel hop. They do not increase power, but allow you to harness the power you already have.

The down side is that engine vibration is greatly increased inside the cabin. There are trade off in every project you take on.

Here we go:

Step 1.

Jack up the car and support with jack stands. Remove the lower engine cradle. This can be done by supporting the weight of the motor with your floor jack to slowly lower it down. The tranny and timing cover mounts will support the motor while the lower support is out of the car. I've been turbo'd for 5 years, and I cannot recall if removal of the Y pipe is necessary. Use your own judgment.

Step 2.

Once the mounts are out of the car, evaluate the condition of your mounts. You will want to remove a lot of the factory material; however you do not want to change location of the center bushing. Make sure you have a way to keep it in its factory location. I made sure I had plenty of rubber on both ends to keep it in place during curing.

Step 3.

Remove as much factory material as you fell comfortable with. The more Poly you have in there the stronger it will be. To do so, I used an electric drill and several sized drill bits, and a set of needle nosed pliers. There is considerable metal reinforcement on the inside of the mount, so don't be too afraid to explore. Just remember to keep the center bushing centered.

Step 4.

Cleanliness is next to Godliness! Get a bucket of hot soapy water and scrub away. The cleaner the inside of the mounts are the better the poly will stick to it. Depending on the funkiness, you might want to hit them with some degreaser first. Dawn dish washing detergent works wonders. If your mom wonít get too upset, put them in the toaster oven at 200 degrees to for an hour or so, to make sure they are good and dry.

The down side is that engine vibration is greatly increased inside the cabin. There are trade off in every project you take on.

Here we go:

Step 1.

Jack up the car and support with jack stands. Remove the lower engine cradle. This can be done by supporting the weight of the motor with your floor jack to slowly lower it down. The tranny and timing cover mounts will support the motor while the lower support is out of the car. I've been turbo'd for 5 years, and I cannot recall if removal of the Y pipe is necessary. Use your own judgment.

Step 2.

Once the mounts are out of the car, evaluate the condition of your mounts. You will want to remove a lot of the factory material; however you do not want to change location of the center bushing. Make sure you have a way to keep it in its factory location. I made sure I had plenty of rubber on both ends to keep it in place during curing.

Step 3.

Remove as much factory material as you fell comfortable with. The more Poly you have in there the stronger it will be. To do so, I used an electric drill and several sized drill bits, and a set of needle nosed pliers. There is considerable metal reinforcement on the inside of the mount, so don't be too afraid to explore. Just remember to keep the center bushing centered.

Step 4.

Cleanliness is next to Godliness! Get a bucket of hot soapy water and scrub away. The cleaner the inside of the mounts are the better the poly will stick to it. Depending on the funkiness, you might want to hit them with some degreaser first. Dawn dish washing detergent works wonders. If your mom wonít get too upset, put them in the toaster oven at 200 degrees to for an hour or so, to make sure they are good and dry.

Last edited by choray911; 04-02-2008 at 10:17 AM.

#2

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

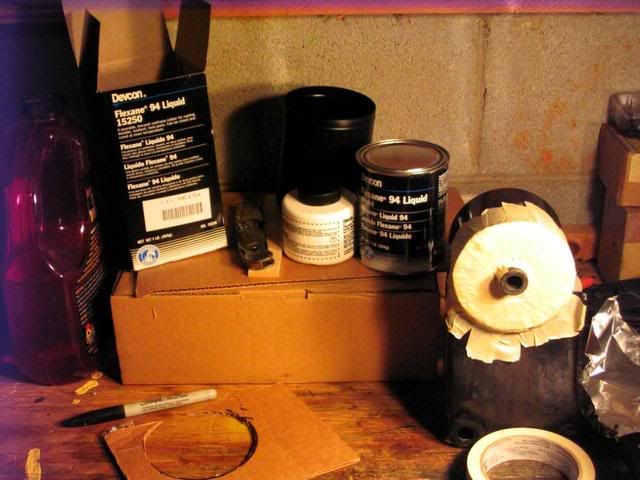

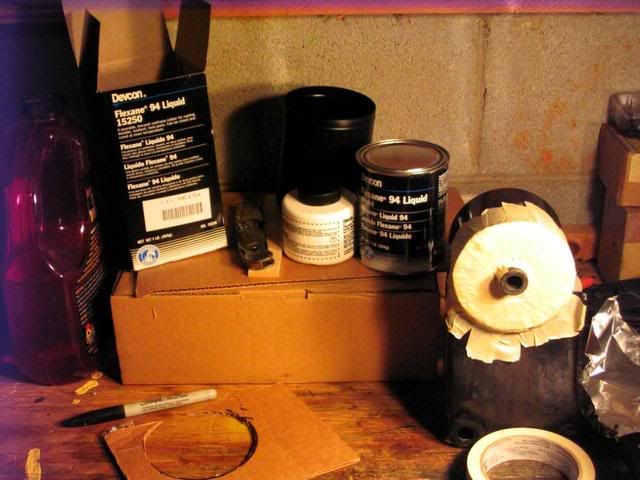

Step 5.

Seal one side of the motor mount. Trace out the outer boundary of the mount on cardboard and cut it out. Lay the mount on its side and center the circle cardboard piece on the center bushing. Lightly tap the center of the cardboard to make an impression of the center bushing. Cut out the center impression a little small, and then force it onto the center bushing. This will stop the resin from poring out the bottom. Cover the cardboard piece with aluminum foil, and pull it tight with out tearing. Spray some sort of release agent (PAM, Olive oil, WD-40) only on the side that will make contact with the motor mount. Tape it into place using masking tape. Masking tape will not leave residue like duct tape, but this is your project. Tape the ring securely to the mount. The more tape the better. There will be leaks that show up; this will just keep them at a minimum. Donít forget to tape around the center hole really good. The resin pours in like warm molasses, and if it has a place to go, it WILL LEAK OUT. Then you have to start over.

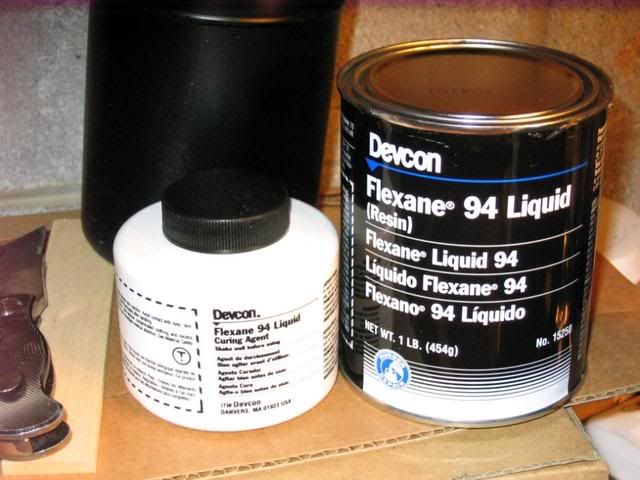

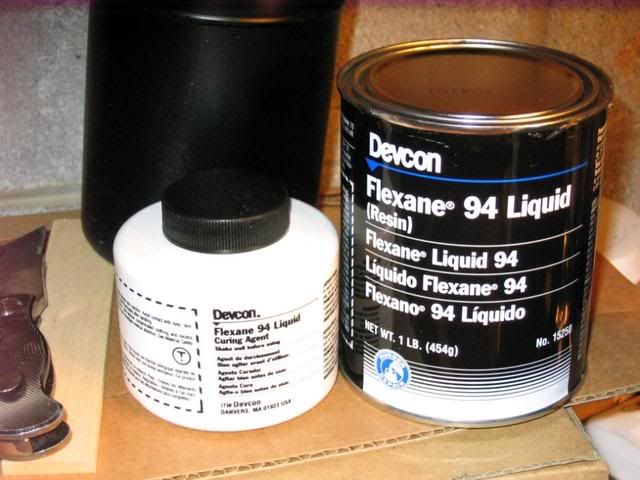

Step 6.

The Pour. The poly resin I used was Devcon, Flexane 94. It dries the hardest of their line; however they do have Flexane 60 that is more flexable. It can be picked up ant any industrial supply store, like Granger, for around $36. The kit comes with the resin, curing agent, plastic cup to mix it in, and a stir stick. One ďkitĒ will build two mounts with some left over if you remove a considerable amount of material from the factory mount. Place the mounts on their sides, and make them level. Rolls of duct tape or masking tape work. Combine the resin and activator according to the enclosed directions and stir for a good 7 to 10 minutes. The mixture has a work time of a good ten to fifteen minutes depending on temp and humidity. The warmer it is the faster it cures. You only have one shot at this, so make sure the mounts are ready to be filled. Pour slowly and try to keep from developing bubbles in the mount. Fill one half full; fill the next one half full, and then top off the first. This gives the resin a change to seep into all the nooks and crannies, and allowing the air to escape. If small leaks appear, donít freak out. The resin will thicken up and stop leaking. If a big leak shows up, get creative, you didnít follow the directions.

Seal one side of the motor mount. Trace out the outer boundary of the mount on cardboard and cut it out. Lay the mount on its side and center the circle cardboard piece on the center bushing. Lightly tap the center of the cardboard to make an impression of the center bushing. Cut out the center impression a little small, and then force it onto the center bushing. This will stop the resin from poring out the bottom. Cover the cardboard piece with aluminum foil, and pull it tight with out tearing. Spray some sort of release agent (PAM, Olive oil, WD-40) only on the side that will make contact with the motor mount. Tape it into place using masking tape. Masking tape will not leave residue like duct tape, but this is your project. Tape the ring securely to the mount. The more tape the better. There will be leaks that show up; this will just keep them at a minimum. Donít forget to tape around the center hole really good. The resin pours in like warm molasses, and if it has a place to go, it WILL LEAK OUT. Then you have to start over.

Step 6.

The Pour. The poly resin I used was Devcon, Flexane 94. It dries the hardest of their line; however they do have Flexane 60 that is more flexable. It can be picked up ant any industrial supply store, like Granger, for around $36. The kit comes with the resin, curing agent, plastic cup to mix it in, and a stir stick. One ďkitĒ will build two mounts with some left over if you remove a considerable amount of material from the factory mount. Place the mounts on their sides, and make them level. Rolls of duct tape or masking tape work. Combine the resin and activator according to the enclosed directions and stir for a good 7 to 10 minutes. The mixture has a work time of a good ten to fifteen minutes depending on temp and humidity. The warmer it is the faster it cures. You only have one shot at this, so make sure the mounts are ready to be filled. Pour slowly and try to keep from developing bubbles in the mount. Fill one half full; fill the next one half full, and then top off the first. This gives the resin a change to seep into all the nooks and crannies, and allowing the air to escape. If small leaks appear, donít freak out. The resin will thicken up and stop leaking. If a big leak shows up, get creative, you didnít follow the directions.

#3

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

Step 7.

The Cure. The mixture will harden so that it can be handled with in 30 to 45 minutes. To speed up this time, place them under a heat lamp. I have a torch lamp in my living room that has 3 adjustable lights that works perfectly. Remove the cardboard end and foil. They are hard in 24 hours and reach full stiffness with in 7 days. If this is a two day project then you can put them in the oven again at 200 degrees for 24 hours to speed up the cure.

Step 8.

Reinstall.

The Cure. The mixture will harden so that it can be handled with in 30 to 45 minutes. To speed up this time, place them under a heat lamp. I have a torch lamp in my living room that has 3 adjustable lights that works perfectly. Remove the cardboard end and foil. They are hard in 24 hours and reach full stiffness with in 7 days. If this is a two day project then you can put them in the oven again at 200 degrees for 24 hours to speed up the cure.

Step 8.

Reinstall.

#5

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

Right now am in the middle of changing several things, so the car has not hit the floor yet. I did the two top mounts a four years ago, and thay made a tremendous difference.

I also did this for a buddies turbo hatch honda, and it feels great.

I also did this for a buddies turbo hatch honda, and it feels great.

#6

#11

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

The whloe point of this procedure is to make them more stiff, hence vibration. To my knowledge there is no happy medium.

#14

I had them on my old Honda... the whole car would buzz at idle. Shifts were so crisp though, it was just like bang-chirrrrrrrrp, bang, bang... car seemed to handle a little better too as the engine stayed put in the twisties.

I am thinking of doing this on the Max too.

I am thinking of doing this on the Max too.

#15

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

There is a little more vibration than stock, but it is still less vibration than when they were completely busted.

#17

Project has been finished for a couple of months, and they perform wonderfully. I took part in a track day at the Nashville Superspeedway on the in field road course, and they worked perfectly. They showed no signs of push out, and almost all wheel hop was eliminated. Once I get the Quafe diff in she might actually be trackworthy.

There is a little more vibration than stock, but it is still less vibration than when they were completely busted.

There is a little more vibration than stock, but it is still less vibration than when they were completely busted.

Reason I ask is because I had some mounts made for my 3rd gen auto 2 years ago by a fellow org(er) and they were full solid poly without the original rubber left in like you did and what happened was that the hole where the sleeve/metal was in started to sag in the bottom causing the hole to expand. Once mount was removed I could remove the metal part with no effort. I'd like to attemp to poly my old mounts which were replaced recently and have them handy for either a rainy day or as backup. thanks in advance

#18

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

Well, you said this 1 year and almost 3 months ago PLUS whatever those couple of months prior to the post...how have the mounts been holding up? Are you still using the same ones shown above?

Reason I ask is because I had some mounts made for my 3rd gen auto 2 years ago by a fellow org(er) and they were full solid poly without the original rubber left in like you did and what happened was that the hole where the sleeve/metal was in started to sag in the bottom causing the hole to expand. Once mount was removed I could remove the metal part with no effort. I'd like to attemp to poly my old mounts which were replaced recently and have them handy for either a rainy day or as backup. thanks in advance

Reason I ask is because I had some mounts made for my 3rd gen auto 2 years ago by a fellow org(er) and they were full solid poly without the original rubber left in like you did and what happened was that the hole where the sleeve/metal was in started to sag in the bottom causing the hole to expand. Once mount was removed I could remove the metal part with no effort. I'd like to attemp to poly my old mounts which were replaced recently and have them handy for either a rainy day or as backup. thanks in advance

#20

#21

Here is another write up if you scroll down a bit on the page. And you can buy different mixtures of urethane, which cure harder the higher the number.

http://www.energysuspensionparts.com...%20Inserts.asp

http://www.energysuspensionparts.com...%20Inserts.asp

#22

Here you go guys, for those that wanna know what its like to have Poly mounts. This is a 7 minute video I took back in July of 2007 in my 3rd gen. Notice the "slight" vibration

Automatic transmission and stock everything except for suspension stuff listed in my sig

http://www.youtube.com/watch?v=PxPfhyrsPFE

Automatic transmission and stock everything except for suspension stuff listed in my sig

http://www.youtube.com/watch?v=PxPfhyrsPFE

#24

Sweet, I'd hate to relive the days I had during the video... I dont like super vibration or rattling so yea I guess 80 is good. 80 is still a bit stiffer than OEM right?

#25

wow, great right up. i saw a vid in another thread of a 5thgen on the dyno and the motor was just hoping around everywhere. i was wondering if anyone made poly mounts for maximas but this write up is perfect. i think i'll get same mounts from the junk yard and try this. i think i found a way to take out 95% of the rubber by looking at some of these pics. thanks again for this info...

#26

The Crazy Azz Cracka

Thread Starter

iTrader: (1)

Join Date: Aug 2003

Location: Chattanooga, TN

Posts: 3,035

wow, great right up. i saw a vid in another thread of a 5thgen on the dyno and the motor was just hoping around everywhere. i was wondering if anyone made poly mounts for maximas but this write up is perfect. i think i'll get same mounts from the junk yard and try this. i think i found a way to take out 95% of the rubber by looking at some of these pics. thanks again for this info...

#27

#29

#30

The only compaines I can think of is Cattman that has mounts pre poly'd

#33

#34

And whats so hard about "ripping" out the old crap and pressing in ES inserts? There is far less down time and far more reliability with ES.

#35

You will want to remove a lot of the factory material; however you do not want to change location of the center bushing. Make sure you have a way to keep it in its factory location. I made sure I had plenty of rubber on both ends to keep it in place during curing.

Step 3.

Remove as much factory material as you fell comfortable with. The more Poly you have in there the stronger it will be. To do so, I used an electric drill and several sized drill bits, and a set of needle nosed pliers. There is considerable metal reinforcement on the inside of the mount, so don't be too afraid to explore. Just remember to keep the center bushing centered.

Step 3.

Remove as much factory material as you fell comfortable with. The more Poly you have in there the stronger it will be. To do so, I used an electric drill and several sized drill bits, and a set of needle nosed pliers. There is considerable metal reinforcement on the inside of the mount, so don't be too afraid to explore. Just remember to keep the center bushing centered.

Sorry to resurrect this old thread, but where is this center bushing you speak of? I am not seeing it in the pics.

#37

Its there. Look in the background of the pic in step 2 and its still in pic 3, and several other ones. Its just a hollow cylindrical rod, that the mounting bolts insert into, to secure the engine to the mounts.

Thread

Thread Starter

Forum

Replies

Last Post

AaronL

5th Generation Maxima (2000-2003)

15

08-08-2020 10:31 AM

Unclejunebug

5th Generation Maxima (2000-2003)

10

04-02-2016 05:42 AM

CAN-Toronto FS: Basement cleaning

knight_yyz

5th Generation Classifieds (2000-2003)

12

11-01-2015 01:34 PM