Crankshaft Position/Oil Pressure Harness Rework

#1

Crankshaft Position/Oil Pressure Harness Rework

Here are some recent pictures from Phase I of the Maxima II enhancement project listed below. No doubt I've spent way too much time refurbishing the Front Crankshaft Position and Oil sensor wiring harness. I think I finally worked out a solution that may be easier to keep the wiring harness from getting oil soaked when the filter is changed.

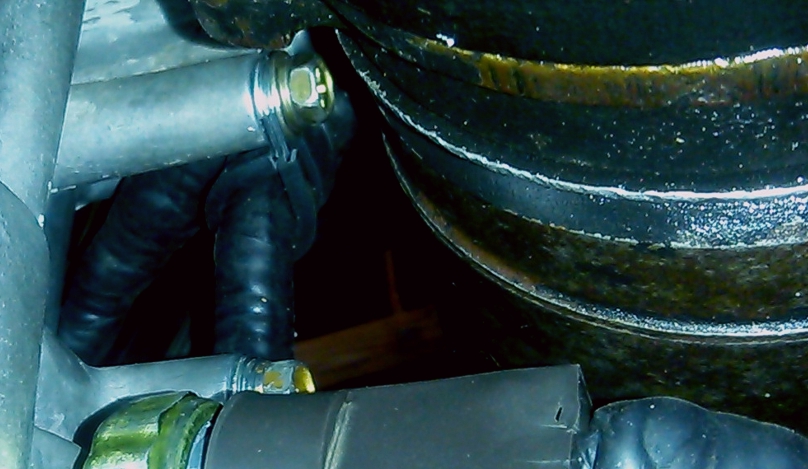

The Problem - We all know how the Front Crankshaft Position /Oil Pressure Sensor gets soaked with oil from filter changes and other engine compartment oil leaks. Also it is common for the CKPS and Oil Sensor wiring harness to pick up dirt, salt, and any other road grime while it is soaked in oil. Every CKPS and Oil Sensor harness that I have seen had at least one break in the harness conduit that exposed wires as shown in the picture below.

The Solution - The Front CKPS and Oil Pressure Sensor Switch Wiring harnesses have been refurbished (wrapped with F4 aviation or equivalent tape and surrounded in a new fire retardant conduit) and relocated to avoid oil from oil filter changes.

Step 1: Read about F4 Mil Spec Self Fusing tape at the following link.

http://www.f4tape.com/aviation-tape.html

Step 2: Look at aviation grade ADEL clamps at the following URL. I use a similar clamp that is available at automotive stores that withstands heat and engine oil.

http://www.aircraftspruce.com/catalo...es/0400920.php

Step 3: Remove the old oil soaked wiring conduit up to where the harness begins to runs behind the front timing cover and gently separate the CKPS (sub harness) and oil pressure switch wires from the old conduit. I pulled the wiring harness up from behind the firewall to have room to work by laying it across the engine.

Step 4: Wrap the existing CKPS wiring harness (as wrapped in the existing jacket) and Oil Pressure Sensor Switch wires with F4 or equivalent.

Step 5: Surround the newly F4 wrapped wires with 1/2 inch fire retardant automotive conduit for an additional layer of heat resistant insulation.

Step 6: Wrap the fireproof conduit in F4 or equivalent a final layer of silicone tape to seal and protect the outer harness conduit from oil, fuel, salt, and road grime.

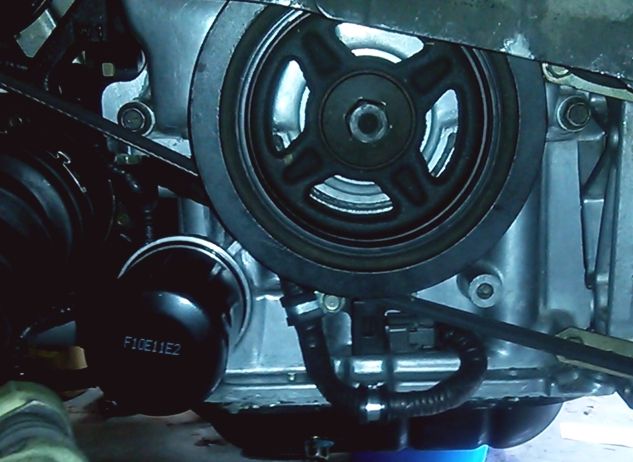

Step 7: The new enhanced wiring harness was positioned above the oil filter and bolted to the upper oil pan using automotive versions of the ADEL clamps shown in Step 2.

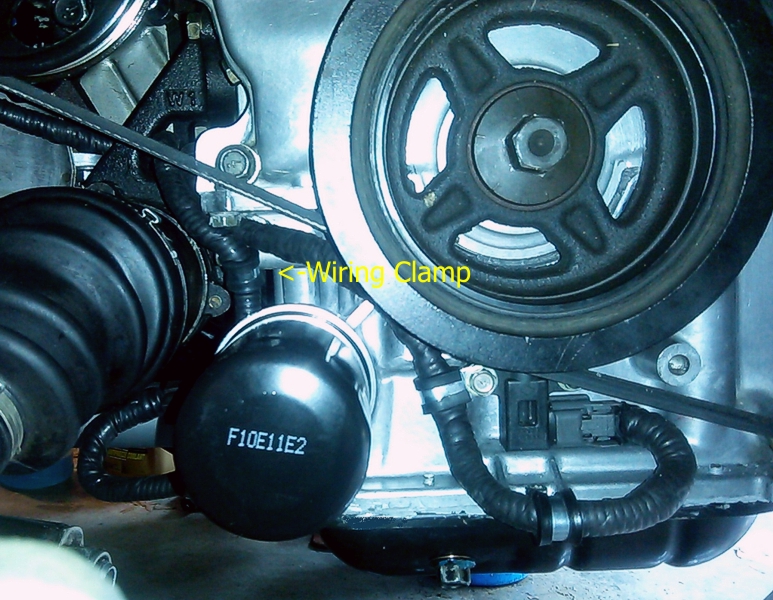

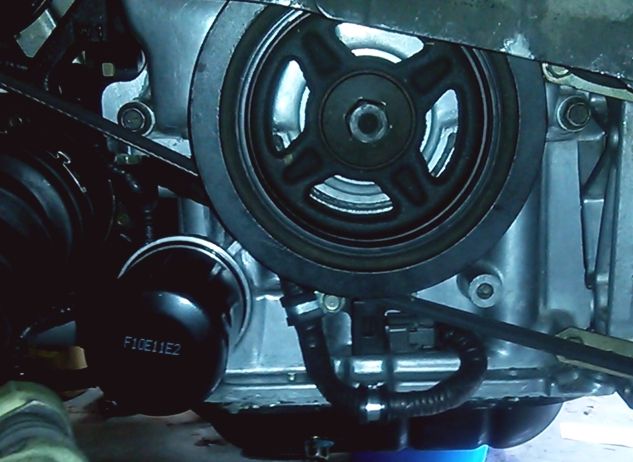

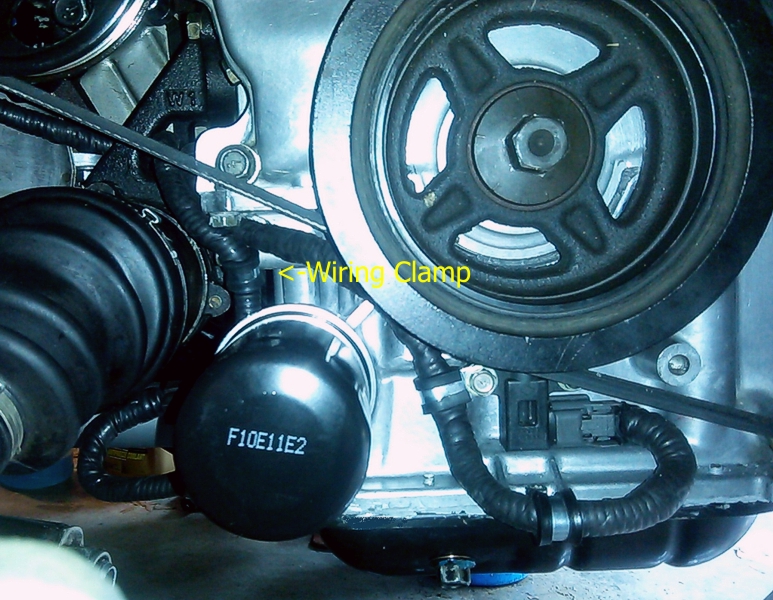

In this picture you can see the old wiring harness bracket has been replaced with automotive wiring conduit clamps. The smaller conduit clamps take up less space and allow for better harness routing to avoid oil spills that occur during filter changes.

[/URL]

[/URL]

The picture shows the Oil Pressure Sensor Switch (OPSS) harness routing and conduit clamp mounted in one of the original harness bracket mounting bolt locations.

Here's another picture of the conduit clamp bolted to the engine up and away from the CV axle mount.

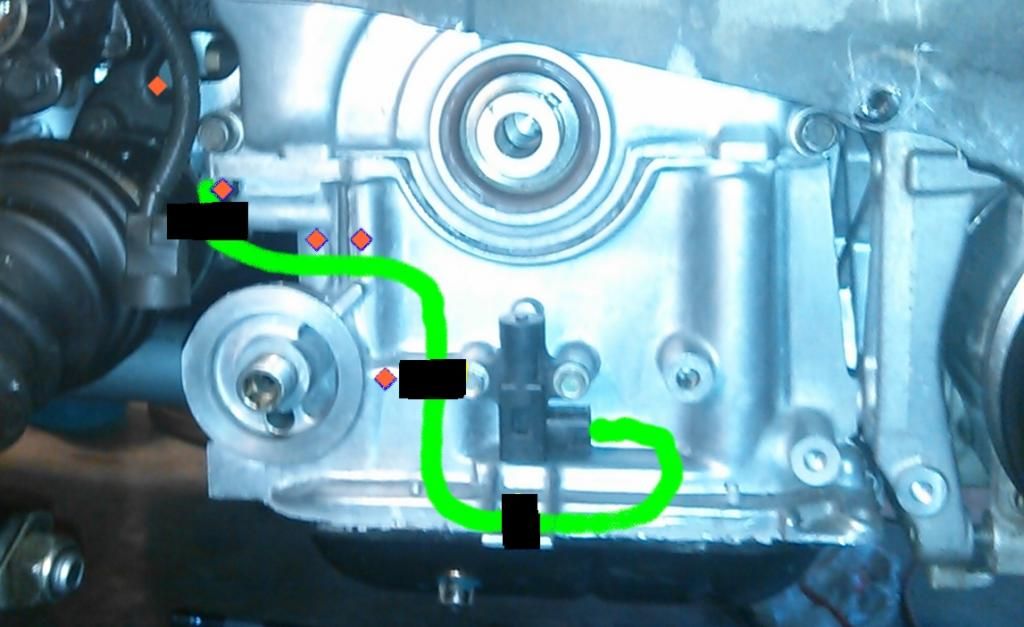

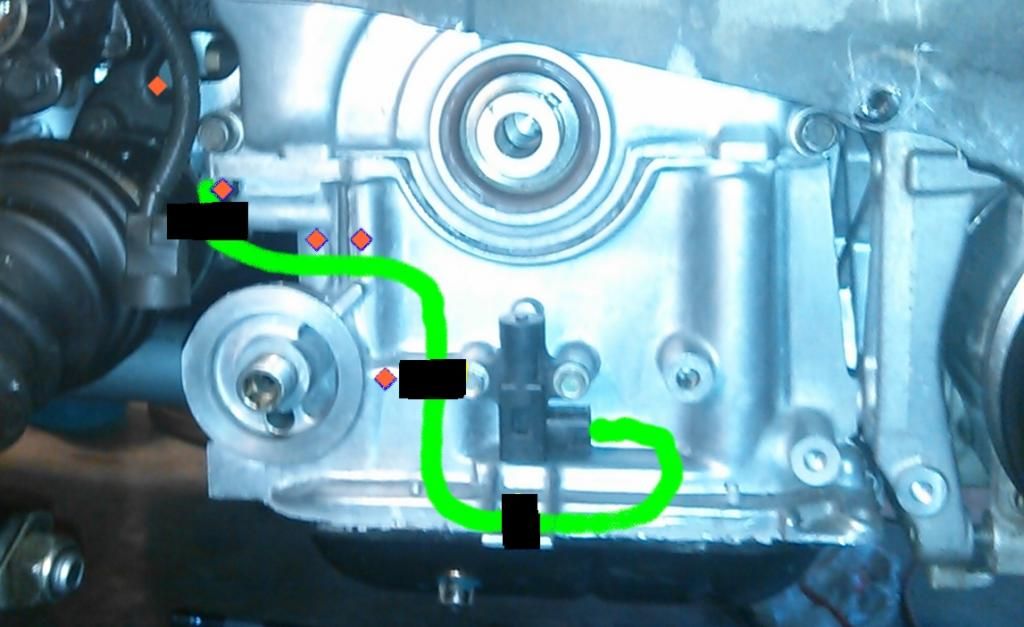

The conduit PATH is shown with the green line in the image below. The orange diamond shaped markers indicate points where the conduit starts to step down and in as it routes upward.

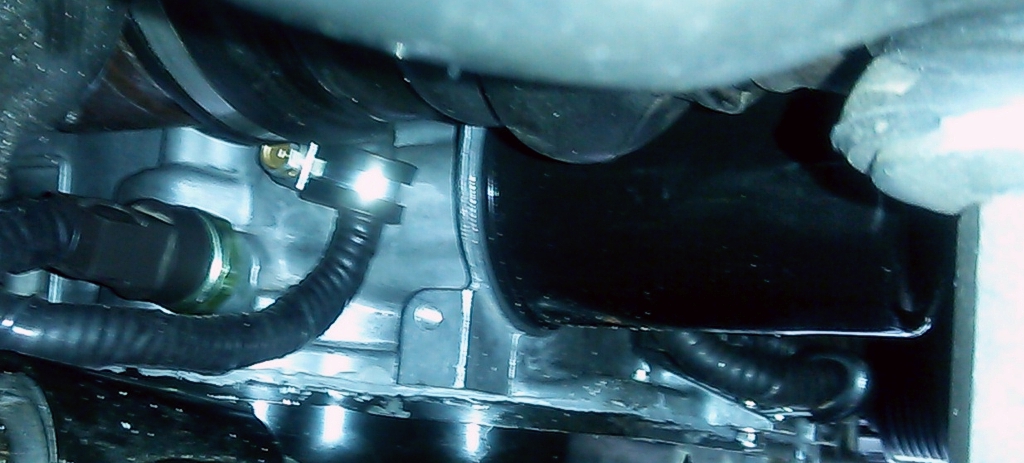

Here's a picture of the conduit PATH as it moves left along a track set by the conduit clamps and makes a left turn while bumping against a protrusion in the upper oil pan just to the right of the oil filter.

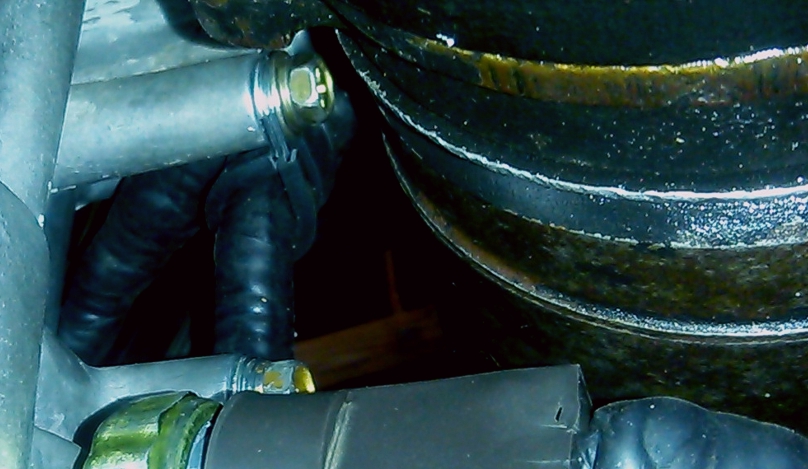

At the point where the conduit is closest to the power steering pulley, it rides at a slightly lower elevation than the crank sensor body.

As you can see in the picture, the Crankshaft Position Sensor rides closer to the inner power steering pulley than the conduit or the clamp. If (more like when) the outer crankshaft pulley separates from the inner pulley structure, it will bump up against the power steering belt and start squealing.

If the PS belt is destroyed in the process of crank pulley separation, it looks like the outer A/C-ALT pulley will bump against the protruding left sensor bolt, the conduit clamp, and the crank sensor before it will hit the wiring conduit.

Time will tell how well this will work out. I started using the silicone self fusing tape to wrap critical wiring on the Q45 four years ago. It has been used by the military for years instead of regular glue type electrical tape.

The tape fuses to itself after wrapping to form a heat shrink like seal around wiring and conduit. It protects up to 500 degrees Fahrenheit. I bought the tape at O'Reilly Auto Supply. I've found similar tapes at Advance Auto and Hardware Stores.

Updated: Sept 7, 2014 - First Oil Change Results

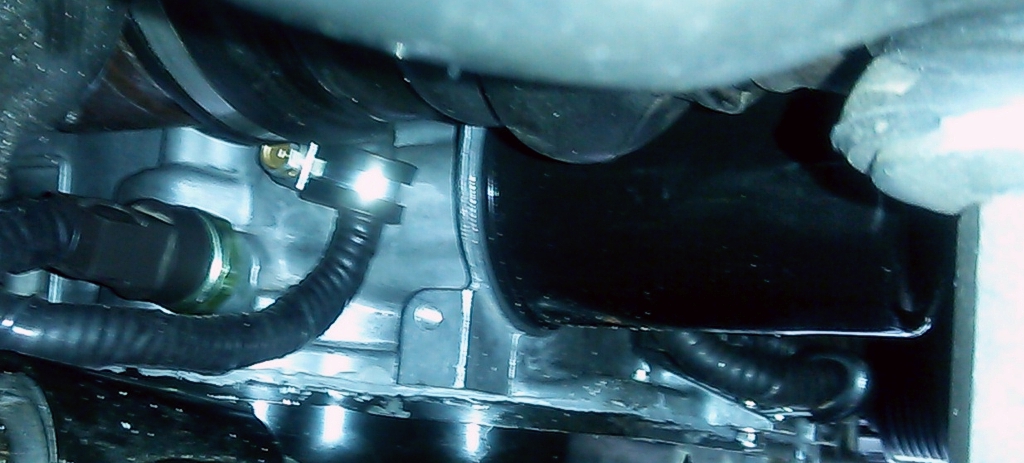

After the first oil filter change, I'm seeing the benefit in the picture below.

The was no oil soaked wiring harness after the first oil filter change.

The Problem - We all know how the Front Crankshaft Position /Oil Pressure Sensor gets soaked with oil from filter changes and other engine compartment oil leaks. Also it is common for the CKPS and Oil Sensor wiring harness to pick up dirt, salt, and any other road grime while it is soaked in oil. Every CKPS and Oil Sensor harness that I have seen had at least one break in the harness conduit that exposed wires as shown in the picture below.

The Solution - The Front CKPS and Oil Pressure Sensor Switch Wiring harnesses have been refurbished (wrapped with F4 aviation or equivalent tape and surrounded in a new fire retardant conduit) and relocated to avoid oil from oil filter changes.

Step 1: Read about F4 Mil Spec Self Fusing tape at the following link.

http://www.f4tape.com/aviation-tape.html

Step 2: Look at aviation grade ADEL clamps at the following URL. I use a similar clamp that is available at automotive stores that withstands heat and engine oil.

http://www.aircraftspruce.com/catalo...es/0400920.php

Step 3: Remove the old oil soaked wiring conduit up to where the harness begins to runs behind the front timing cover and gently separate the CKPS (sub harness) and oil pressure switch wires from the old conduit. I pulled the wiring harness up from behind the firewall to have room to work by laying it across the engine.

Step 4: Wrap the existing CKPS wiring harness (as wrapped in the existing jacket) and Oil Pressure Sensor Switch wires with F4 or equivalent.

Step 5: Surround the newly F4 wrapped wires with 1/2 inch fire retardant automotive conduit for an additional layer of heat resistant insulation.

Step 6: Wrap the fireproof conduit in F4 or equivalent a final layer of silicone tape to seal and protect the outer harness conduit from oil, fuel, salt, and road grime.

Step 7: The new enhanced wiring harness was positioned above the oil filter and bolted to the upper oil pan using automotive versions of the ADEL clamps shown in Step 2.

In this picture you can see the old wiring harness bracket has been replaced with automotive wiring conduit clamps. The smaller conduit clamps take up less space and allow for better harness routing to avoid oil spills that occur during filter changes.

[/URL]

[/URL]The picture shows the Oil Pressure Sensor Switch (OPSS) harness routing and conduit clamp mounted in one of the original harness bracket mounting bolt locations.

Here's another picture of the conduit clamp bolted to the engine up and away from the CV axle mount.

The conduit PATH is shown with the green line in the image below. The orange diamond shaped markers indicate points where the conduit starts to step down and in as it routes upward.

Here's a picture of the conduit PATH as it moves left along a track set by the conduit clamps and makes a left turn while bumping against a protrusion in the upper oil pan just to the right of the oil filter.

At the point where the conduit is closest to the power steering pulley, it rides at a slightly lower elevation than the crank sensor body.

As you can see in the picture, the Crankshaft Position Sensor rides closer to the inner power steering pulley than the conduit or the clamp. If (more like when) the outer crankshaft pulley separates from the inner pulley structure, it will bump up against the power steering belt and start squealing.

If the PS belt is destroyed in the process of crank pulley separation, it looks like the outer A/C-ALT pulley will bump against the protruding left sensor bolt, the conduit clamp, and the crank sensor before it will hit the wiring conduit.

Time will tell how well this will work out. I started using the silicone self fusing tape to wrap critical wiring on the Q45 four years ago. It has been used by the military for years instead of regular glue type electrical tape.

The tape fuses to itself after wrapping to form a heat shrink like seal around wiring and conduit. It protects up to 500 degrees Fahrenheit. I bought the tape at O'Reilly Auto Supply. I've found similar tapes at Advance Auto and Hardware Stores.

Updated: Sept 7, 2014 - First Oil Change Results

After the first oil filter change, I'm seeing the benefit in the picture below.

The was no oil soaked wiring harness after the first oil filter change.

Last edited by CS_AR; 09-07-2014 at 05:50 PM.

#3

I spent way too much time on this one..

#5

Great idea and modification!

My CKPS ref and it's harness is covered in dirt and oil due to changing the filter over the years. When I do an oil change in ~2 months I may also try that method.

I'm a little skeptic on how close the harness is to the PS belt. Keep us notified on how the relocated harness holds up over time.

My CKPS ref and it's harness is covered in dirt and oil due to changing the filter over the years. When I do an oil change in ~2 months I may also try that method.

I'm a little skeptic on how close the harness is to the PS belt. Keep us notified on how the relocated harness holds up over time.

#6

Thanks guys. I updated the O-P below the PATH picture with the following note and picture. When I was looking for a route to run the conduit, I could feel a smooth path along the upper oil pan and around the corner like it might have been part of an original design for something.

I guess you can tell that I'm not a big fan of securing wiring conduit with zip ties unless it is just for temporary or partial reinforcement while wrapping either wires or conduit with F4 Self Fusing Tape.

Here's a picture of the conduit PATH as it moves left along a track set by the conduit clamps and makes a left turn while bumping against a protrusion in the upper oil pan just to the right of the oil filter.

As you can see in the picture, the Crankshaft Position Sensor rides closer to the inner power steering pulley than the conduit or the clamp. If (more like when) the outer crankshaft pulley separates from the inner pulley structure, it will bump up against the power steering belt and start squealing.

At the point where the conduit is closest to the power steering pulley, it is actually riding at a lower elevation than the sensor body. If the PS belt is destroyed in the process of crank pulley separation, the outer A/C-ALT pulley will bump against the protruding left sensor bolt, the conduit clamp and the crank sensor before it will hit the conduit.

I guess you can tell that I'm not a big fan of securing wiring conduit with zip ties unless it is just for temporary or partial reinforcement while wrapping either wires or conduit with F4 Self Fusing Tape.

Here's a picture of the conduit PATH as it moves left along a track set by the conduit clamps and makes a left turn while bumping against a protrusion in the upper oil pan just to the right of the oil filter.

As you can see in the picture, the Crankshaft Position Sensor rides closer to the inner power steering pulley than the conduit or the clamp. If (more like when) the outer crankshaft pulley separates from the inner pulley structure, it will bump up against the power steering belt and start squealing.

At the point where the conduit is closest to the power steering pulley, it is actually riding at a lower elevation than the sensor body. If the PS belt is destroyed in the process of crank pulley separation, the outer A/C-ALT pulley will bump against the protruding left sensor bolt, the conduit clamp and the crank sensor before it will hit the conduit.

#7

The modification is indeed good I admit. With the whole crank pulley separation that is plaguing the 4th gens due to age of the rubber, I would have mine separate and rub against that harness.

#8

The harness dips lower then the outer CKPS housing edge. When the pulley separates, it starts rubbing against the power steering belt where you will get squealing belt nose. After losing the power steering belt, the pulley would crash into the CKPS housing before it would hit the harness.

Last edited by CS_AR; 09-07-2014 at 05:07 PM.

#9

Here's the benefit after the first oil filter change since making the wiring harness enhancement.

Oil can now drain from the filter without getting into the wiring harness.

Here's an oil soaked wiring harness picture to see how the original harness routing would pick up oil.

Here's a picture before today's oil filter change.

Oil can now drain from the filter without getting into the wiring harness.

Here's an oil soaked wiring harness picture to see how the original harness routing would pick up oil.

Here's a picture before today's oil filter change.

Last edited by CS_AR; 09-08-2014 at 07:41 AM.

Thread

Thread Starter

Forum

Replies

Last Post

My Coffee

New Member Introductions

15

06-06-2017 02:01 PM

magiconthetire

Audio and Electronics

2

10-26-2015 09:03 PM

hayne

6th Generation Maxima (2004-2008)

2

10-05-2015 11:53 AM