Cluster Issues

#1

Cluster Issues

My cluster is acting up and I was wondering if i could replace the cluster while keeping my mileage the same? I seen a write up in the How-To section but the link was dead.

#2

nop my cluster had a broken gas gauge and burnt out led's. either you buy a used one and have it reprogrammed to your current mileage. funny today i just received my brand new cluster original from nissan came with my current m ileage and its all good now. decided to buy it new because i dint have any luck with the used ones i had purchased. i bought mine from nissanparts.cc give them a call and talk to cliff hes the one that helped me out.

#4

So I just read my CEL... And it was a P0500 which is wheel speed sensor A. Now, my car has 16" 4th Gen SE wheels. I think my cluster problem is caused by a misreading of the speed sensor because of the undersized wheels. The cluster just dies like it has no power at all. Im not sure if the issues are related.

#5

So I just read my CEL... And it was a P0500 which is wheel speed sensor A. Now, my car has 16" 4th Gen SE wheels. I think my cluster problem is caused by a misreading of the speed sensor because of the undersized wheels. The cluster just dies like it has no power at all. Im not sure if the issues are related.

#6

In either case, you're absolutely correct it won't make any difference except the speedometer won't read accurately if the Outside diameter of the tire is different from stock.

On another note, I would suspect this problem is NOT the gauge cluster itself, but rather the power supplyto the cluster. Check the METER fuse in your fuse panel, I suggest replacing it with a new fuse just in case youhave a bad connection.

#7

Last edited by nelledge; 08-27-2011 at 05:31 PM.

#8

So I just read my CEL... And it was a P0500 which is wheel speed sensor

We are so semantical, no matter which sensor it is, it obviously has nothing to do with his problem

We are so semantical, no matter which sensor it is, it obviously has nothing to do with his problem

#10

Lol haha. Well now that we got all that sorted out, weird thing about the cluster is that it totally resets, meaning trip mileage and everything. I dont go to my automotive classes this semester so I dont have access to wiring diagrams anymore :/ Could anyone find me which fuses power the cluster?

#11

Lol haha. Well now that we got all that sorted out, weird thing about the cluster is that it totally resets, meaning trip mileage and everything. I dont go to my automotive classes this semester so I dont have access to wiring diagrams anymore :/ Could anyone find me which fuses power the cluster?

Start at EL-123.

#13

The FSM that is currently listed as the 2000 FSM is for the Maxima QV that is sold in Europe. If you read the bottom left corner of FWD-1, it states that it is printed in Amsterdam. At the top of page 2 it says this is for the Maxima QV. I don't know exactly how similiar or different the QV is from the USA early 2000, but it does seem to be based on the early production model we have here in the USA. However there are differences in the electrical section (EL). The US FSM has 370 pages while the QV EL section has 376 pages.

If you go to pmohr's website for the manuals, he has the correct ones. His website is:

http://boredmder.com/FSMs/NISSAN/

#14

nicoclub is playing games with the FSMs. They used to list this as the 2000.5 FSM. What they used to list as the 2000 FSM is now properly labeled as the 2000.5....

If you go to pmohr's website for the manuals, he has the correct ones. His website is:

http://boredmder.com/FSMs/NISSAN/

If you go to pmohr's website for the manuals, he has the correct ones. His website is:

http://boredmder.com/FSMs/NISSAN/

Last edited by nelledge; 08-28-2011 at 09:33 PM.

#15

Good to know for future reference. You'll need a slight adjustment, though. The link you posted in not currently active. You'll have to use the cached link for now. Slight modification. Just don't use all caps in Nissan to use it. http://boredmder.com/FSMs/Nissan/

Last edited by DennisMik; 08-28-2011 at 09:47 PM.

#17

FYI, there are 2 versions of the 2002 FSM. I have them both but I don't have any info as to how you figure out which version is for a specific car. For the 2000 model, I have VIN number divisions.

#19

#21

#24

Sorry to hijack the post, but where on the transaxle is the VSS located? My wife's car is throwing P0500 but the instrument cluster appears to be working. Car's about 11 years old, so it could just be the sensor going bad. I'm gonna follow the diagnostic procedures in the FSM but if I have to replace the VSS I'd like to know where I should be looking.

Thanks in advance.

Thanks in advance.

#25

#26

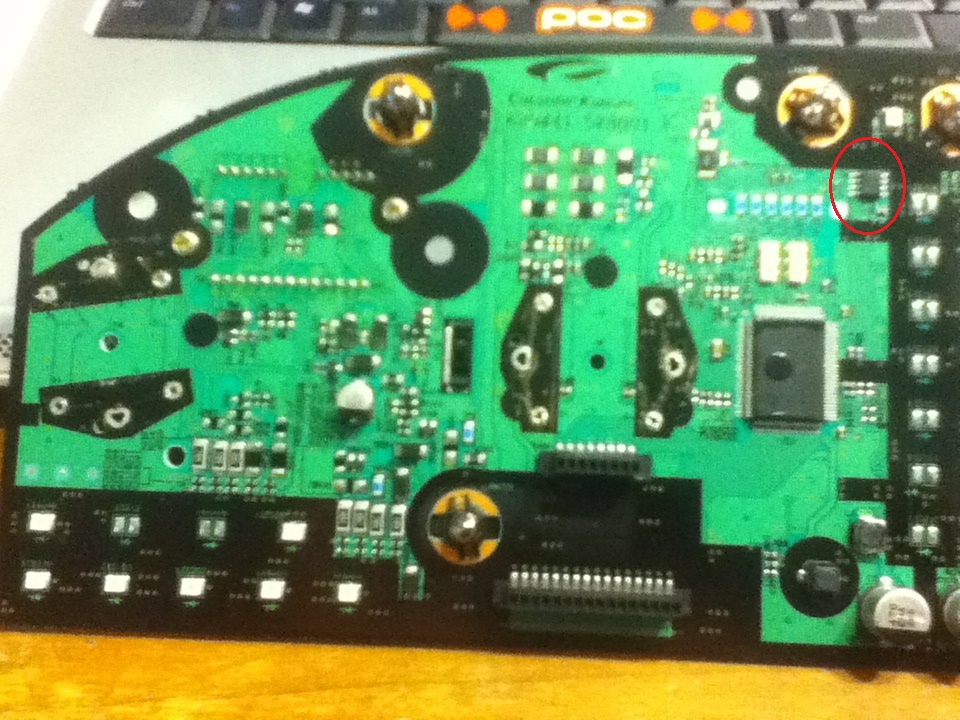

hey guys i need some help i have a 5.5 gen and im trying to transplant the mileage chip into my newer cluster from my old one and my cluster looks completely different than the 2 clusters that tunermax posted up. i have an idea of which chip it could be but im not certain, heres the pictures of my cluster from a 2003, btw i have like 4 of these clusters lying around and they're all 02-03 and look the same

i know the picture quality sucks, its the best the ipod 4 could do!!!

i know the picture quality sucks, its the best the ipod 4 could do!!!

#27

I thik the chip is in the first picture, near the top right corner. It looks to be down maybe an inch from the top and in maybe 3/4 of an inch from the right in a small green "finger". The chip should have a number on it, 93C56EN.

#28

#31

Don't remember if there are holes and soldered from the back. If you want to wait I can take a picture of it and check that.

Otherwise you need to post a better picture so we can see the chip.

Otherwise you need to post a better picture so we can see the chip.

#33

FLUX. Don't try heating it without flux.

You' should also use electrical cleaner spray for when you are finished soldering back on to clean off all the solder. Most electrical supply shops carry it.

Flux one side then heat all 4 contacts at the same time with a precision flathead under the center of the chip, twist the flathead so that it lifts on the portion you're heating, do this VERY gently until it moves, just moves.

Once it does go to the other side and do the same. Work back and forth, allowing the contacts to cool completely in between so you don't overheat the chip.

And make sure to apply flux before each heating session. When you do get it off clean it thoroughly.

Another technique to use alongside this is to heat the one side up and use solder wick/Sucker to remove as much solder from the contacts as possible, do the same for the other side, then attempt the screwdriver method above.

You' should also use electrical cleaner spray for when you are finished soldering back on to clean off all the solder. Most electrical supply shops carry it.

Flux one side then heat all 4 contacts at the same time with a precision flathead under the center of the chip, twist the flathead so that it lifts on the portion you're heating, do this VERY gently until it moves, just moves.

Once it does go to the other side and do the same. Work back and forth, allowing the contacts to cool completely in between so you don't overheat the chip.

And make sure to apply flux before each heating session. When you do get it off clean it thoroughly.

Another technique to use alongside this is to heat the one side up and use solder wick/Sucker to remove as much solder from the contacts as possible, do the same for the other side, then attempt the screwdriver method above.

#34

ok i think i understand the flux part, i checked this video on youtube which was amazing, im going out to buy a new tip for my soldering iron and will try your method and the flux is supposed to be inside the soldering material right?

youtube soldering video for reference

youtube soldering video for reference

#35

That is a brilliant video, thanks for posting it!!!!

The Flux I'm talking about using is brush-on, just the flux alone.

But yes most solder comes with it in the center. You want to apply additional flux to heat it all up because you are not using solder to take them off. You just want them clean so the solder melts quick and you don't overheat things.

This is the method to use a solder sucker as mentioned earlier

The Flux I'm talking about using is brush-on, just the flux alone.

But yes most solder comes with it in the center. You want to apply additional flux to heat it all up because you are not using solder to take them off. You just want them clean so the solder melts quick and you don't overheat things.

This is the method to use a solder sucker as mentioned earlier

Last edited by TunerMaxima3000; 11-11-2012 at 07:22 PM.

#37

It's a guess based off the picture you posted. Without a better picture I can't tell you 100%, sorry dude.

But you can see it, if it's the same as the one I pictured then yes. Does the circuit board say IC2 on it next to the chip like in my picture?

But you can see it, if it's the same as the one I pictured then yes. Does the circuit board say IC2 on it next to the chip like in my picture?

#38

It looks like the op's cluster uses surface mount components, including the odometer chip. The designation of IC2 may or may not be the same and really doesn't matter. All that matters is that it is the 93C56 chip, which is a 2K eprom.

#39

Originally Posted by DjHackStyle

The circled chip has the following numbers on it, its not exact but similar so i juss wanna confirm with you guys and ill go ahead and transplant it

S93c5

6dv21

3985

S93c5

6dv21

3985

#40

FLUX. Don't try heating it without flux.

You' should also use electrical cleaner spray for when you are finished soldering back on to clean off all the solder. Most electrical supply shops carry it.

Flux one side then heat all 4 contacts at the same time with a precision flathead under the center of the chip, twist the flathead so that it lifts on the portion you're heating, do this VERY gently until it moves, just moves.

Once it does go to the other side and do the same. Work back and forth, allowing the contacts to cool completely in between so you don't overheat the chip.

And make sure to apply flux before each heating session. When you do get it off clean it thoroughly.

Another technique to use alongside this is to heat the one side up and use solder wick/Sucker to remove as much solder from the contacts as possible, do the same for the other side, then attempt the screwdriver method above.

You' should also use electrical cleaner spray for when you are finished soldering back on to clean off all the solder. Most electrical supply shops carry it.

Flux one side then heat all 4 contacts at the same time with a precision flathead under the center of the chip, twist the flathead so that it lifts on the portion you're heating, do this VERY gently until it moves, just moves.

Once it does go to the other side and do the same. Work back and forth, allowing the contacts to cool completely in between so you don't overheat the chip.

And make sure to apply flux before each heating session. When you do get it off clean it thoroughly.

Another technique to use alongside this is to heat the one side up and use solder wick/Sucker to remove as much solder from the contacts as possible, do the same for the other side, then attempt the screwdriver method above.

Its all good though, thanks man very much appreciated!

Its all good though, thanks man very much appreciated!