Slamrod's RomRaider Adventure

#42

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Ok, lets start getting to the juicy meat of all these efforts. Here is a preliminary list of items I will be addressing, in order, to get a tune that is basic enough for me to drive around safely and make further adjustments. PLEASE PLEASE PLEASE correct me if you see something that is wrong, or missing, or out of correct order - or anything of that nature.

1) Remove 2" timing across my Main Ignition Map to have a safety net. Remove another 2" from my knock map, so that the ignition retardation that occurs on the knock map is significant enough to instantly notice a loss of power. [I am strongly considering skipping this step, since the "HR" motor I am using already can tolerate more timing advance than the stock DE motor. Since my ECU is still for the stock DE motor, step 1 should essentially be done already, as the "safety net" condition of having a timing advance slightly lower than what the motor can tolerate is already present. Thoughts on this?]

2) Adjust Target AFR map by changing all the cells that are not 14.7 (im assuming these are closed loop cells?) to [target AFR] - Not sure what that should be, ive seen countless opinions such as 12.2, 12.5, 12.8-13.1 ... For now, Ill go with 12.5, but if anyone has suggestions for what AFR these motors prefer, thatd be great, since I wont be having a dyno to work with to confirm for myself.

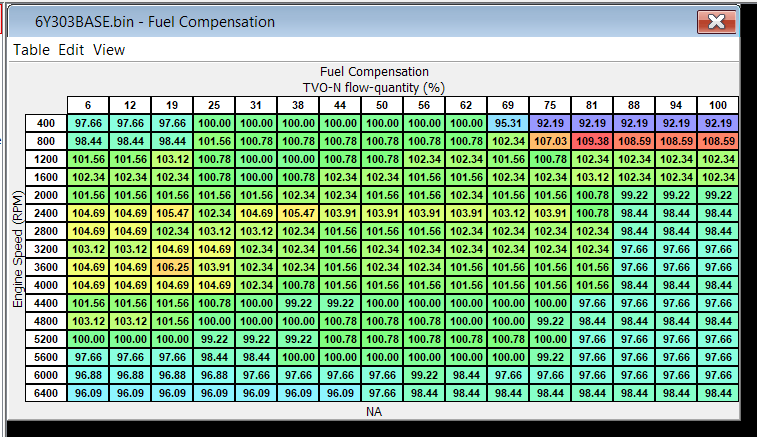

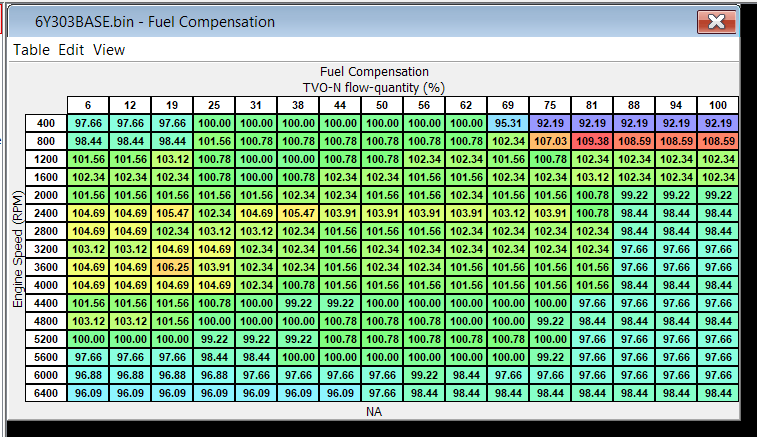

3) Set Fuel Corrections to "100" across the entire map (AKA no adjustments). Once I am data logging further on, I should be able to see via Long Term Fuel Trims where the ECU is trying to add/remove fuel. Using that data, I can re-adjust the Fuel Corrections cell by cell accordingly, with the goal being to have the Fuel Correction map set up in such a way that the ECU no longer wants to make any LTFT adjustments.

4) Adjust the K value, as I am using larger injectors and MAF. [PLEASE check if my math formulas for determining K value are correct - they are based off of random forum posts I found, not official guides - so if anyone can confirm that they are correct, I will be very grateful] The stock K value for the 6Y303 ECU is 27592.

- (Old Injector cc / New Injector cc) x (K value) = New K value. (315/560) x (27592) = 15,520.5

-(New MAF area / Old MAF area) x (K value) = (2^2[[i]the radius of new 4'' MAF] x π) ) / ( (1.375^2[[i]the radius of old 2.75'' MAF] x π) x (K value) = (12.57) / (5.94) x (15,520.5) = 32,679 as the final new K value.

*** [Again, I am VERY unsure about these formulas. Do I have them correct? Earlier in the thread I had different math (using MAF diameter rather than MAF area) and got a very different final result. Really need guidance in this area!!] ***

5) Adjust Fuel Scalar (Injector Pulse Width) to account for the larger injectors. Using the math (560cc - 315cc) = 245 difference, (315cc/245) = 0.77, I have determined that the 560cc injectors have a 77% increase in flow over the 315cc injectors. [Again, I SUCK at math. Is this calc correct?] The stock Injector Pulse Width is 19.37ms.

(Injector Pulse Width x % of change) = New IPW (19.37 x 0.77) = 14.91ms as the new IPW.

Or is this incorrect? Is it the inverse instead, aka (19.37 x 0.23) = 4.46ms as the new IPW?

6) From here, I should be have a basic enough tune to continue forward and data log fuel corrections.

Did I miss anything? What comes next? Most importantly, are my formulas correct? If they arent correct, than the calculations are wrong, and I blow my motor - so before I can continue, Im gonna need one of you fine folks to step in and steer me in the right direction. Thanks guys.

1) Remove 2" timing across my Main Ignition Map to have a safety net. Remove another 2" from my knock map, so that the ignition retardation that occurs on the knock map is significant enough to instantly notice a loss of power. [I am strongly considering skipping this step, since the "HR" motor I am using already can tolerate more timing advance than the stock DE motor. Since my ECU is still for the stock DE motor, step 1 should essentially be done already, as the "safety net" condition of having a timing advance slightly lower than what the motor can tolerate is already present. Thoughts on this?]

2) Adjust Target AFR map by changing all the cells that are not 14.7 (im assuming these are closed loop cells?) to [target AFR] - Not sure what that should be, ive seen countless opinions such as 12.2, 12.5, 12.8-13.1 ... For now, Ill go with 12.5, but if anyone has suggestions for what AFR these motors prefer, thatd be great, since I wont be having a dyno to work with to confirm for myself.

3) Set Fuel Corrections to "100" across the entire map (AKA no adjustments). Once I am data logging further on, I should be able to see via Long Term Fuel Trims where the ECU is trying to add/remove fuel. Using that data, I can re-adjust the Fuel Corrections cell by cell accordingly, with the goal being to have the Fuel Correction map set up in such a way that the ECU no longer wants to make any LTFT adjustments.

4) Adjust the K value, as I am using larger injectors and MAF. [PLEASE check if my math formulas for determining K value are correct - they are based off of random forum posts I found, not official guides - so if anyone can confirm that they are correct, I will be very grateful] The stock K value for the 6Y303 ECU is 27592.

- (Old Injector cc / New Injector cc) x (K value) = New K value. (315/560) x (27592) = 15,520.5

-(New MAF area / Old MAF area) x (K value) = (2^2[[i]the radius of new 4'' MAF] x π) ) / ( (1.375^2[[i]the radius of old 2.75'' MAF] x π) x (K value) = (12.57) / (5.94) x (15,520.5) = 32,679 as the final new K value.

*** [Again, I am VERY unsure about these formulas. Do I have them correct? Earlier in the thread I had different math (using MAF diameter rather than MAF area) and got a very different final result. Really need guidance in this area!!] ***

5) Adjust Fuel Scalar (Injector Pulse Width) to account for the larger injectors. Using the math (560cc - 315cc) = 245 difference, (315cc/245) = 0.77, I have determined that the 560cc injectors have a 77% increase in flow over the 315cc injectors. [Again, I SUCK at math. Is this calc correct?] The stock Injector Pulse Width is 19.37ms.

(Injector Pulse Width x % of change) = New IPW (19.37 x 0.77) = 14.91ms as the new IPW.

Or is this incorrect? Is it the inverse instead, aka (19.37 x 0.23) = 4.46ms as the new IPW?

6) From here, I should be have a basic enough tune to continue forward and data log fuel corrections.

Did I miss anything? What comes next? Most importantly, are my formulas correct? If they arent correct, than the calculations are wrong, and I blow my motor - so before I can continue, Im gonna need one of you fine folks to step in and steer me in the right direction. Thanks guys.

Last edited by Slamrod; 03-28-2020 at 10:55 AM.

#43

1) Remove 2" timing across my Main Ignition Map to have a safety net. Remove another 2" from my knock map, so that the ignition retardation that occurs on the knock map is significant enough to instantly notice a loss of power. [[i]I am strongly considering skipping this step, since the "HR" motor I am using already can tolerate more timing advance than the stock DE motor. Since my ECU is still for the stock DE motor, step 1 should essentially be done already, as the "safety net" condition of having a timing advance slightly lower than what the motor can tolerate is already present. Thoughts on this?]

3) Set Fuel Corrections to "100" across the entire map (AKA no adjustments). Once I am data logging further on, I should be able to see via Long Term Fuel Trims where the ECU is trying to add/remove fuel. Using that data, I can re-adjust the Fuel Corrections cell by cell accordingly, with the goal being to have the Fuel Correction map set up in such a way that the ECU no longer wants to make any LTFT adjustments.

4) Adjust the K value, as I am using larger injectors and MAF. [[i]PLEASE check if my math formulas for determining K value are correct - they are based off of random forum posts I found, not official guides - so if anyone can confirm that they are correct, I will be very grateful] The stock K value for the 6Y303 ECU is 27592.

- (Old Injector cc / New Injector cc) x (K value) = New K value. (315/560) x (27592) = 15,520.5

- (Old Injector cc / New Injector cc) x (K value) = New K value. (315/560) x (27592) = 15,520.5

5) Adjust Fuel Scalar (Injector Pulse Width) to account for the larger injectors. Using the math (560cc - 315cc) = 245 difference, (315cc/245) = 0.77, I have determined that the 560cc injectors have a 77% increase in flow over the 315cc injectors. [[i]Again, I SUCK at math. Is this calc correct?]

Or is this incorrect? Is it the inverse instead, aka (19.37 x 0.23) = 4.46ms as the new IPW?

This value is how long the injector needs to fire to fill the cylinder @ 100% volumetric efficiency. It's inversely proportional to injector size. 270/560 * 19.37 = 9.34ms

#44

This has got me snagged right now. So I suppose I dont technically need to convert all timing values like i did on that excel sheet - I can adjust in degrees with the timing map as-is. However, I still want to know what those values actually are. How do I determine that?

Like what timing measurement am I looking at that the map is displaying adjustments of? Im just not understanding where/how I find the ‘base timing’ (is this even the correct term??) if its not 17” like i thought it was. Is my excel sheet at all accurate or is it simply the right concept but wrong numbers? Is this something where I would essentially need to use RR logger to see the cells the ECU is accessing in real time, and correlate that with a datalog to see what timing is displayed - thus connecting the map valued to a BTDC degree value?

Another issue just popped into my head. I know in NY state when they plug your car in for inspection, they can see a bunch of information off of the ECU. Im concerned that if I flash to 6Y303, the inspection station will read my ECU as being from a 2003, and fail me, since it doesnt match my car which is a 2002. Do 5.5gen ECUs report VIN or model year? I know on 4th gens the ECU didnt report it as that feature wasnt built in yet - anyone know what year that started? IIRC, its this gen or 6th gen.

#45

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Stock injectors are around 270cc I believe, but otherwise this is fine.

I recommend to use the MAF scalar for this, and also not to use such an enormous intake. With a 4" you'll probably have to adjust K. Don't need to bother with pi in the calcs; 4^2/2.75^2 = 2.11 2.11 * old maf scalar = new maf scalar.

I recommend to use the MAF scalar for this, and also not to use such an enormous intake. With a 4" you'll probably have to adjust K. Don't need to bother with pi in the calcs; 4^2/2.75^2 = 2.11 2.11 * old maf scalar = new maf scalar.

As far as the MAF scalar goes, do I do that in addition to modifying the K value? Or does modifying the MAF scalar negate the need to adjust K value for larger diameter MAF? Also, wouldnt using the area of the piping be more accurate that using the diameter? The area inside a 4'' pipe is about double of that of a 2.75'' pipe, but 4'' is not anywhere close to being double of 2.75''? In hindsight, knowing what I know now, I probably would have opted for a 3.5'' intake and perhaps 440cc injectors. Unfortunately Im not in a financial position to buy more parts at the moment, with this whole pandemic thing putting me out of work. Maybe in the future, but as of now, the 4'' + 560cc setup is what I will be using.

NO!!! The stock Injector Pulse Width is 19.37ms.

(Injector Pulse Width x % of change) = New IPW (19.37 x 0.77) = 14.91ms as the new IPW.

Or is this incorrect? Is it the inverse instead, aka (19.37 x 0.23) = 4.46ms as the new IPW?

This value is how long the injector needs to fire to fill the cylinder @ 100% volumetric efficiency. It's inversely proportional to injector size. 270/560 * 19.37 = 9.34ms

Or is this incorrect? Is it the inverse instead, aka (19.37 x 0.23) = 4.46ms as the new IPW?

This value is how long the injector needs to fire to fill the cylinder @ 100% volumetric efficiency. It's inversely proportional to injector size. 270/560 * 19.37 = 9.34ms

Im finally understanding the whole timing map thing. I know youre probably feeling blue in the face trying to hammer it into my skull, but it took until now for it to click for me. Basically the timing map shows how long until the mixture combustion produces the maximum amount of torque at the ideal degree of timing (in other words, at what degree of timing the mixture combustion is 100% complete, typically after TDC since thats where maximum leverage pushing on the crankshaft is). Since that ideal degree of timing for making maximum possible torque varies based on many various motor + environment conditions, we can never know exactly where it is without data logging, and therefore, we cant read the timing map in terms of BTDC, since that would require knowing the 'best torque angle' or whatever its called to convert it to those terms. Once data logging of timing is conducted, we can correlate that information and find BTDC-based timing values (which probably isnt actually necessary unless one just cant live without knowing the BTDC values). Im probably not explaining this in the proper technical terms - looking back, the explanations you gave are crystal clear, but not knowing the terms and acronyms made it very difficult for me to grasp. Anyways, cant thank you enough for all your patience with helping me out on this, I quite literally could not have made it this far without your guidance.

Beyond that, hows my initial tune workflow look? I know theres a ton of other things I need to modify, but in terms of just getting the car up and running safely and being able to do real world data logging, how am I looking?

Last edited by Slamrod; 03-28-2020 at 03:17 PM.

#47

3.0DE injectors are rumored to be 270cc. Here is a link to a number of VQ injectors I personally flow tested at 3bar. Convert to 3.5 bar for your usage. https://maxima.org/forums/all-motor/...omparison.html

#48

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Made some changes, reflashed the ECU. Car is idling with a very high AFR (17.xx) and giving any throttle results in the car bogging and rpms basically going nowhere. Obviously a fueling issue. However... I am trying to use RomRaider Logger and I am not able to connect to the ECU. Or, rather, my laptop is not seeing my openport 2.0 cable correctly. It is not giving me a COM port for the cable - instead, under device manager, it appears under "Vehicle PassThru Interface". I am unable to assign a COM port inside of RR logger because of this. Any suggestions? I read I think under the subi RR subforum that assigning com is not needed for this logger, but the logger just stays on "connecting" and goes nowhere.

How do I assign my cable a COM port? Or, how do I get RR logger to see my taxtrix cable without a COM port? Im trying to see where on the map my idle is, but without the logger's map tracing ability, I dont know how to go about doing that.

edit: figured i should mention that its probably not the cable (bought directly from Tactrix, lights up/changes colors when powered, etc). Just cant get RR logger to connect to my ECU!!

edit2: how long does the logger take to connect anyways? Maybe Im not giving it enough time?

Edit3: Managed to get the logger to run. Going to be toying with stuff for the rest of today (4/1/20) and see what happens. Will report back later or tomorrow with how things went.

How do I assign my cable a COM port? Or, how do I get RR logger to see my taxtrix cable without a COM port? Im trying to see where on the map my idle is, but without the logger's map tracing ability, I dont know how to go about doing that.

edit: figured i should mention that its probably not the cable (bought directly from Tactrix, lights up/changes colors when powered, etc). Just cant get RR logger to connect to my ECU!!

edit2: how long does the logger take to connect anyways? Maybe Im not giving it enough time?

Edit3: Managed to get the logger to run. Going to be toying with stuff for the rest of today (4/1/20) and see what happens. Will report back later or tomorrow with how things went.

Last edited by Slamrod; 04-01-2020 at 01:53 PM.

#50

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

So unfortunately I have not made any real progress on this over the last day or two. Car is still idling super lean and is otherwise acting like a 3000lb paperweight in the driveway. No worries, its only a matter of time before I get it ironed out. As of now though, I figured Ill use the phone-a-friend option and see if anyone can point me in the right direct.

I adjusted the K value for the larger injectors (15520 K value), and scaled the Injector Pulse Width to account for that change. I also lowered the Min Pulse Width in the same proportion (from 19.37 to 10.98ms), as well as lowered the Minimum Pulse Width limit. I tried to adjust for the 4'' MAF tube under the Airflow tab, but I ran into a snag here. Freezer suggested using these settings to account for MAF changes rather than using the K value, but I dont understand how to exactly do that. The MAF Factor/multiplier (stock value is 149) has a limit of 255. My new intake is 2.12 times larger than the stock intake - wouldnt this mean I need to multiply my MAF Factor by 2.12? Which in turn exceeds the 255 limit - because of this, I applied the 2.12 to the K value, as all of these different values get combined in the end to form Theoretical PulseWidth/Load. This brought my K value up to 33,000 and some change. This is more or less where I am out, with a super lean idle and no power - I am obviously missing a step, or applying calculations wrong.

Some ideas:

-I need to deal with the MAF voltage table. Im not really sure how to handle this. The MAF sensor reacts to airflow by generating a voltage signal between 0.9V-5v, or something similar to that, with low flow generating low voltage, and maximum flow generating 5 volts. Since my 4'' intake is 2.12 times larger in area, this means that the values the ECU is reading from the MAF are roughly 2.12 smaller, since the sensor is interacting with much less airflow, even though in reality, the same flow is entering the motor. Because the ECU thinks it is getting roughly half the air it is in reality getting, it supplies roughly half the fuel that it normally would under stock conditions, as less air means less fuel needed. And because there is less fuel/more air in the motor than what the ECU thinks there is, the AFR leans out. Ok - so my train of logic says I should simply multiply all of my MAF values by 2.12, so that they reflect that the sensor is getting 2.12 times less airflow across is that it is able to detect. Here I run into the snag that my max/5V value is around 61k, where the maximum allowed value is around 65k. Since doubling 61k would put it way over the max allowed value, I dont know how to proceed here. I either need to get the ECU to allow that max airflow value to be exceeded (unlikely), or, I need to modify something, somewhere, that would basically change the ECU's math so those values are being scaled correctly, even though they arent on the actual MAF table. I thought this is what multiplying the K-value by 2.12 (proportion of MAF area change) was doing, but it appears that is not the case...

-Im also not understanding exactly how this are intertwines with the K value. I mentioned earlier that I tried out multiplying the K value by 2.12 to account for the larger MAF (several tuning guides mention using K value to account for MAF changes, with larger K = bigger MAF). Since the change is accounted for there, wouldnt that mean I dont need to change my MAF voltage values? Or, does that get changed in addition? And if thats the case, it goes back to my previous issue - how am I supposed to double my MAF voltage values if doing so would cause me to exceed the maximum values that the ECU allows? Just not wrapping my head around the different interactions between values and the math involved, how changing one multiplier affects the need/lack of need to change other multipliers/tables, etc...

Basically right now all of this stuff is just a big rats nest in my brain, to the point where I am having trouble even articulating what is supposed to be occurring. Im pretty certain I am doing the math wrong somewhere. Going to keep fiddling with stuff for now, but really could use some assistance. I know its something really dumb that Im snagged on but I just cant nail down what exactly I am doing wrong and how to remedy it. As always, thanks for reading.

Edit: Another question about the K-value. What exactly is the "goal" when changing it? I think in essence, you want a K-value that requires minimum changes to fuel corrections and such. Is that correct? Kinda an offshoot of that question - should my idle be 'good' with the correct K-value? Or should I expect my ideal K-value to require me to make significant changes to the idle cells of my fuel correction map?

Edit2: Something just occurred to me - changing the K-value for injector resizing means I also need to change the IPW, right? Since Im also changing the K-value for the MAF (since the MAF multiplier doesnt go high enough for me to edit it to where it needs to be), I would again be applying the same proportion of change to the IPW? For example, larger injectors dropped it from 19.37ms to 10.98ms - I presume if it must be altered to account for MAF changes as well, a larger MAF will bring this number back up. And if multiplied by the proportion of MAF area change (2.12), it comes back up to approximately 23.27ms. Several guides mention pairing injectors with MAFs (for example, 50% more airflow MAF should be paired with 50% bigger injectors) so that the load scales dont need to be changed much - is THIS what those guides are referring to? It would make sense, especially if you consider that Bigger Injectors = Lower IPW, Bigger MAF = Larger IPW, and that the proportion of change is larger with my MAF than it is with my injectors, thus why my end resulting IPW would be higher than stock rather than lower... it also seems like it would line up with the K value being a bit higher than stock. Idk, does this make sense? Im at the point where Im kinda just tossing theories around why I cant get this to work, but Im afraid to experiment and test those theories since failure would be catastrophic. Is it even possible to break something at low load or while idling when messing with AFR factors, or will screwing up just mean the motor runs like crap and stalls? I really think this is the step i missed - but I dont want to mess with anything until I can get a little reassurance Im not doing something completely pant-on-head retarded.

I adjusted the K value for the larger injectors (15520 K value), and scaled the Injector Pulse Width to account for that change. I also lowered the Min Pulse Width in the same proportion (from 19.37 to 10.98ms), as well as lowered the Minimum Pulse Width limit. I tried to adjust for the 4'' MAF tube under the Airflow tab, but I ran into a snag here. Freezer suggested using these settings to account for MAF changes rather than using the K value, but I dont understand how to exactly do that. The MAF Factor/multiplier (stock value is 149) has a limit of 255. My new intake is 2.12 times larger than the stock intake - wouldnt this mean I need to multiply my MAF Factor by 2.12? Which in turn exceeds the 255 limit - because of this, I applied the 2.12 to the K value, as all of these different values get combined in the end to form Theoretical PulseWidth/Load. This brought my K value up to 33,000 and some change. This is more or less where I am out, with a super lean idle and no power - I am obviously missing a step, or applying calculations wrong.

Some ideas:

-I need to deal with the MAF voltage table. Im not really sure how to handle this. The MAF sensor reacts to airflow by generating a voltage signal between 0.9V-5v, or something similar to that, with low flow generating low voltage, and maximum flow generating 5 volts. Since my 4'' intake is 2.12 times larger in area, this means that the values the ECU is reading from the MAF are roughly 2.12 smaller, since the sensor is interacting with much less airflow, even though in reality, the same flow is entering the motor. Because the ECU thinks it is getting roughly half the air it is in reality getting, it supplies roughly half the fuel that it normally would under stock conditions, as less air means less fuel needed. And because there is less fuel/more air in the motor than what the ECU thinks there is, the AFR leans out. Ok - so my train of logic says I should simply multiply all of my MAF values by 2.12, so that they reflect that the sensor is getting 2.12 times less airflow across is that it is able to detect. Here I run into the snag that my max/5V value is around 61k, where the maximum allowed value is around 65k. Since doubling 61k would put it way over the max allowed value, I dont know how to proceed here. I either need to get the ECU to allow that max airflow value to be exceeded (unlikely), or, I need to modify something, somewhere, that would basically change the ECU's math so those values are being scaled correctly, even though they arent on the actual MAF table. I thought this is what multiplying the K-value by 2.12 (proportion of MAF area change) was doing, but it appears that is not the case...

-Im also not understanding exactly how this are intertwines with the K value. I mentioned earlier that I tried out multiplying the K value by 2.12 to account for the larger MAF (several tuning guides mention using K value to account for MAF changes, with larger K = bigger MAF). Since the change is accounted for there, wouldnt that mean I dont need to change my MAF voltage values? Or, does that get changed in addition? And if thats the case, it goes back to my previous issue - how am I supposed to double my MAF voltage values if doing so would cause me to exceed the maximum values that the ECU allows? Just not wrapping my head around the different interactions between values and the math involved, how changing one multiplier affects the need/lack of need to change other multipliers/tables, etc...

Basically right now all of this stuff is just a big rats nest in my brain, to the point where I am having trouble even articulating what is supposed to be occurring. Im pretty certain I am doing the math wrong somewhere. Going to keep fiddling with stuff for now, but really could use some assistance. I know its something really dumb that Im snagged on but I just cant nail down what exactly I am doing wrong and how to remedy it. As always, thanks for reading.

Edit: Another question about the K-value. What exactly is the "goal" when changing it? I think in essence, you want a K-value that requires minimum changes to fuel corrections and such. Is that correct? Kinda an offshoot of that question - should my idle be 'good' with the correct K-value? Or should I expect my ideal K-value to require me to make significant changes to the idle cells of my fuel correction map?

Edit2: Something just occurred to me - changing the K-value for injector resizing means I also need to change the IPW, right? Since Im also changing the K-value for the MAF (since the MAF multiplier doesnt go high enough for me to edit it to where it needs to be), I would again be applying the same proportion of change to the IPW? For example, larger injectors dropped it from 19.37ms to 10.98ms - I presume if it must be altered to account for MAF changes as well, a larger MAF will bring this number back up. And if multiplied by the proportion of MAF area change (2.12), it comes back up to approximately 23.27ms. Several guides mention pairing injectors with MAFs (for example, 50% more airflow MAF should be paired with 50% bigger injectors) so that the load scales dont need to be changed much - is THIS what those guides are referring to? It would make sense, especially if you consider that Bigger Injectors = Lower IPW, Bigger MAF = Larger IPW, and that the proportion of change is larger with my MAF than it is with my injectors, thus why my end resulting IPW would be higher than stock rather than lower... it also seems like it would line up with the K value being a bit higher than stock. Idk, does this make sense? Im at the point where Im kinda just tossing theories around why I cant get this to work, but Im afraid to experiment and test those theories since failure would be catastrophic. Is it even possible to break something at low load or while idling when messing with AFR factors, or will screwing up just mean the motor runs like crap and stalls? I really think this is the step i missed - but I dont want to mess with anything until I can get a little reassurance Im not doing something completely pant-on-head retarded.

Last edited by Slamrod; 04-02-2020 at 02:10 PM.

#51

What's your Idle pulse width?

What is your idle MAF voltage?

5.5 gen MAFs aren't great, they're really going to struggle on the bottom of the flow range.

Trial and error isn't going to kill you, just change one thing at a time. You're lean so you need more fuel; raise K by 10% and see if your AFR improves accordingly.

What is your idle MAF voltage?

5.5 gen MAFs aren't great, they're really going to struggle on the bottom of the flow range.

Trial and error isn't going to kill you, just change one thing at a time. You're lean so you need more fuel; raise K by 10% and see if your AFR improves accordingly.

#52

#53

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Alrighty, so it seems I got really mixed up earlier. The lean issue was with the base tune... no surprises it idles like total crap, its not tuned, DUH! My REAL problem is that I cant get past cranking when I reflash using the settings I mentioned above. I must have gotten confused with what flash I was running, since I was trying different things to get the logger to work - one suggestion was to have the car actually running before attempting to get the logger to communicate, which is why I went back to the stock tune just to see if I could get it to work. Must have forgot to reflash it back to a tune after that experiment. Sorry for wasting your time guys. Going forward, I am keeping a notebook handy with the details of every tune file and what got edited in each, along with results of that tune, to stay better organized.

Anyways, back to issue.. Any suggestions on what to change for cranking? She just cranks and goes nowhere. Right now I am trying to edit Fuel Corrections for cranking, but Im not entirely sure what cells those are (which is why I was trying to use the logger for map tracing, thus why I got mixed up). I think they are the last five cells in 400 + 800 RPM, basically the full volume % ones on the top right of the map. Is this correct? Right now I am trying different things, like adding/removing fuel in these cells, and so far I have not had success. Again, sorry for the run-around and confusion. Gotta go one step at a time, and right now Im still stuck on step 1 trying to get the motor running. Thanks guys.

Edit1: So far I have tried adding/removing 30% fuel in those cells. I feel like thats excessive already, and something else seems to be the issue if it requires such drastic corrections.

Current settings:

K - 32,902

IPW - 10.89ms

MPW - 0.54ms

Tried using stock corrections map, stock with cranking edited, everything set to 100, everything @ 100 except cranking... etc etc. No luck! Any ideas on whats keeping it from turning over?

I would again like to thank everyone who has been helping me, and for being so very patient. I would also like to remind anyone reading that I really dont know wtf I am doing - and that this is a very involved learning process I am trying to tackle here. Right now it seems to be kicking my ***, but I will say I am still very determined to figure this out. I expected it to be very difficult and frustrating, and it absolutely has stood up tall to those expectations. I will get to the bottom of it all though! And hopefully in doing so, I will then be knowledgeable enough myself to know wtf I am talking about, and be able to assist others who want to take advantage of this software.

Anyways, back to issue.. Any suggestions on what to change for cranking? She just cranks and goes nowhere. Right now I am trying to edit Fuel Corrections for cranking, but Im not entirely sure what cells those are (which is why I was trying to use the logger for map tracing, thus why I got mixed up). I think they are the last five cells in 400 + 800 RPM, basically the full volume % ones on the top right of the map. Is this correct? Right now I am trying different things, like adding/removing fuel in these cells, and so far I have not had success. Again, sorry for the run-around and confusion. Gotta go one step at a time, and right now Im still stuck on step 1 trying to get the motor running. Thanks guys.

Edit1: So far I have tried adding/removing 30% fuel in those cells. I feel like thats excessive already, and something else seems to be the issue if it requires such drastic corrections.

Current settings:

K - 32,902

IPW - 10.89ms

MPW - 0.54ms

Tried using stock corrections map, stock with cranking edited, everything set to 100, everything @ 100 except cranking... etc etc. No luck! Any ideas on whats keeping it from turning over?

I would again like to thank everyone who has been helping me, and for being so very patient. I would also like to remind anyone reading that I really dont know wtf I am doing - and that this is a very involved learning process I am trying to tackle here. Right now it seems to be kicking my ***, but I will say I am still very determined to figure this out. I expected it to be very difficult and frustrating, and it absolutely has stood up tall to those expectations. I will get to the bottom of it all though! And hopefully in doing so, I will then be knowledgeable enough myself to know wtf I am talking about, and be able to assist others who want to take advantage of this software.

Last edited by Slamrod; 04-03-2020 at 03:09 PM.

#55

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Thats the plan, somewhat. Im going to see if I can get away with going back to the stock intake, and tuning for the larger injectors, that way im not dealing with as many variables at the same time. At least one guide said doing both at once is beneficial and easier, but that has definitely not been my experience so far lol

#56

Looking forward to taking advantage of you, I mean, your assistance, in getting me a 300/300 file.

Just kidding. I'll trade you though, by the time you have this dialed in, I'll have the recipe for a ginormous 6 pot Brembo, 14" rotor, SS line front brake system for less than six hundred bux.

Just kidding. I'll trade you though, by the time you have this dialed in, I'll have the recipe for a ginormous 6 pot Brembo, 14" rotor, SS line front brake system for less than six hundred bux.

#57

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Still stuck... Can someone point out what cells deal with cranking? I mentioned earlier that I think it is the top right corner of the fuel corrections map, but idk. I switched back to the stock MAF and adjusted fuel only for injectors, and still cant get this thing to start. Went through basically the whole process I went through yesterday, adding fuel, pulling fuel... still wont start. Can someone confirm Im even dealing with the correct cells for cranking? Does cranking usually require a richer or leaner mixture? Is there a setting that deals with cranking that Im missing? I cant find any useful information on the topic.

I would just go back to stock injectors, but I dont see the point. My problem right now is that I cant get the car to start. If I go back to stock, then the car should obviously start - I can toy with all sorts of settings and tweak things to get a feel for tuning, but that wont help me solve the problem I am dealing with now - starting. What I need is to figure out what cells handle cranking, whether cranking on these motors requires a richer or leaner mixture, etc. Really frustrated right now because I feel like im just stumbling around blindly and getting nowhere. Going to keep experimenting in the meantime. Thanks.

Edit: Heres a pic of the stock fuel corrections map:

I presume the cells in the top right are cranking (low RPM, full cylinder %), where idle would be the top left (low RPM, low cylinder %). Is this correct? Also, what should I make of fuel being pulled across 400rpm, and being added at 800rpm? Ive tried leaving it as is, changing them to 100, adding, removing... im hitting a brick wall on this one and Im not seeing any way over or around.

I would just go back to stock injectors, but I dont see the point. My problem right now is that I cant get the car to start. If I go back to stock, then the car should obviously start - I can toy with all sorts of settings and tweak things to get a feel for tuning, but that wont help me solve the problem I am dealing with now - starting. What I need is to figure out what cells handle cranking, whether cranking on these motors requires a richer or leaner mixture, etc. Really frustrated right now because I feel like im just stumbling around blindly and getting nowhere. Going to keep experimenting in the meantime. Thanks.

Edit: Heres a pic of the stock fuel corrections map:

I presume the cells in the top right are cranking (low RPM, full cylinder %), where idle would be the top left (low RPM, low cylinder %). Is this correct? Also, what should I make of fuel being pulled across 400rpm, and being added at 800rpm? Ive tried leaving it as is, changing them to 100, adding, removing... im hitting a brick wall on this one and Im not seeing any way over or around.

Last edited by Slamrod; 04-04-2020 at 11:16 AM.

#58

Good on you for hanging onto Win7. I'm doing the same on a couple of my machines.

If I were a gambling man, I'd say engine is rich at startup and leans out as temp increases. This based on my smelling fuel in the exhaust and during warm up on every car I've ever ever had whether carburated or fuel injected. (think, choke).

If you have full control to edit the cells, can you zero them all out, test, max them all out, test, and work towards the middle from there? I've been following but haven't had a chance to read your walls of text from beginning to end. I'll get caught up tonight.

I would think starting would be the easy part, just dump a bunch of fuel and work from there. The fine tuning is where I would think the big time investment would come from.

Are you pulling codes as you go along to make sure all other systems are operating wnl? Do you have spark? lol

If I were a gambling man, I'd say engine is rich at startup and leans out as temp increases. This based on my smelling fuel in the exhaust and during warm up on every car I've ever ever had whether carburated or fuel injected. (think, choke).

If you have full control to edit the cells, can you zero them all out, test, max them all out, test, and work towards the middle from there? I've been following but haven't had a chance to read your walls of text from beginning to end. I'll get caught up tonight.

I would think starting would be the easy part, just dump a bunch of fuel and work from there. The fine tuning is where I would think the big time investment would come from.

Are you pulling codes as you go along to make sure all other systems are operating wnl? Do you have spark? lol

#59

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Good on you for hanging onto Win7. I'm doing the same on a couple of my machines.

If I were a gambling man, I'd say engine is rich at startup and leans out as temp increases. This based on my smelling fuel in the exhaust and during warm up on every car I've ever ever had whether carburated or fuel injected. (think, choke).

If you have full control to edit the cells, can you zero them all out, test, max them all out, test, and work towards the middle from there? I've been following but haven't had a chance to read your walls of text from beginning to end. I'll get caught up tonight.

I would think starting would be the easy part, just dump a bunch of fuel and work from there. The fine tuning is where I would think the big time investment would come from.

Are you pulling codes as you go along to make sure all other systems are operating wnl? Do you have spark? lol

If I were a gambling man, I'd say engine is rich at startup and leans out as temp increases. This based on my smelling fuel in the exhaust and during warm up on every car I've ever ever had whether carburated or fuel injected. (think, choke).

If you have full control to edit the cells, can you zero them all out, test, max them all out, test, and work towards the middle from there? I've been following but haven't had a chance to read your walls of text from beginning to end. I'll get caught up tonight.

I would think starting would be the easy part, just dump a bunch of fuel and work from there. The fine tuning is where I would think the big time investment would come from.

Are you pulling codes as you go along to make sure all other systems are operating wnl? Do you have spark? lol

Anyways, idk whats going on. The motor seems to stumble the most when I am pulling fuel from what I believe to be the cranking cells. Like its just on the verge of starting but just cant tip over the edge. Definitely getting spark, just not getting the correct mixtures. Really lost on what else I can adjust. I dont feel that my experimenting at this point is gaining me any ground, im basically throwing darts at the board and none of them are leading me in the right direction it seems.

#61

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

315cc -> 560cc Injectors:

Stock K = 27592

New K = (315/560)*27592 = 15520.

Stock Injector Pulse Width [aka mTP100] = 19.37ms

New IPW = (315/560)*(19.37) = 10.89ms

I also lowered Min IPW proportionally, from 0.96ms to 0.54ms. Based on everything Im reading, this should account for the larger injectors. Unfortunately that does not appear to be the case, at least not for getting the car to start.

Thanks Freezer. Im gonna owe you a whole damn keg of beer by the time this fiasco is over.

Last edited by Slamrod; 04-04-2020 at 02:01 PM.

#63

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

As far as I am aware it should be the latest version, I got it off the download page of the romraider website. Ill try a fresh install just to see if that changes anything. As far as checksums, is that something I need to do manually, or some setting I need to modify? I was under the assumption it was something either RR or nisprog did automatically. Anything I need to do other than verify my RR is the latest V? Also, how would I be able to tell that the checksums are off? Is that something intuitive or something I would need an understanding of programming to make sense of?

#64

http://www.romraider.com/forum/viewt...p?f=65&t=13994

Don't need to re-install RR. Just replace the .jar in your installation folder with the one in this thread, post #6. RR will take care of the checksum automatically upon save.

Don't need to re-install RR. Just replace the .jar in your installation folder with the one in this thread, post #6. RR will take care of the checksum automatically upon save.

#65

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

http://www.romraider.com/forum/viewt...p?f=65&t=13994

Don't need to re-install RR. Just replace the .jar in your installation folder with the one in this thread, post #6. RR will take care of the checksum automatically upon save.

Don't need to re-install RR. Just replace the .jar in your installation folder with the one in this thread, post #6. RR will take care of the checksum automatically upon save.

Once again, and I know Im laying it on pretty thick - thank you Freezer! Couldnt have done it without you.

#66

Freezer is the man. I feel bad for having forgotten to take the EVT signal wheel measurements he asked me for when I had my valve covers off during my 2nd gen swap. He would have had EVT working with our swaps and we would have had both.

#67

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Not really much to report right this moment. Car runs and drives well enough. Im still using NDS2 for logging because thats what Im familiar with, but Im going to make an effort to better understand RR's logger since it has slightly more utility. Couple of things to note as of now:

-Putting all corrections @ 100 led to the car idling like **** and having no power, and running very lean. I suspect part of the issue may be the Injector Latency value - still waiting to get replies from the shop I bought them from, as well as Bosch, to see if they can fill me in on what the Latency is for these injectors. Supposedly it has a significant role in low pulse width operations, which of course includes idling, so perhaps getting the correct value here will fix this issue. For now, Im not touching the corrections table.

-Even without touching the corrections map, idle seems a little unsteady, randomly getting lean before calming back down. Again, I think this is a latency issue. Unless, I need to make changes to the idle voltage range?

-Overall, it seems that the tune is on the leaner side. My LTFTs seem to stay at around 110 more or less across the board. I need to dissect my logs a bit more but Im assuming that if I see an overarching trend of richness/leanness, it means I should slightly lower my K rather than changing all the correction cells.

-I did a short WOT run to see what would come up. Noticed a drastic AFR spike around 4400RPM or so, which to my knowledge is around where the VIAS activates. This same pattern was occuring while using the Apexi NEO for tuning - should be much easier to smooth out now that I have total control over the variables in play.

-Potting around, the pedal just doesnt feel as responsive. Not really sure what to chalk this up to, but its noticeable, im missing a lot of low end torque. My best theory as of now is that its because its using the stock 15 degree timing, rather than the 17" timing advance, or at least I dont remember advancing the timing after reflashing. Not really sure, honestly.

-Im still having this annoying stall issue when coming to a stop! It will stall basically every single time unless I keep it in gear until I am at or below idle speed, or else the RPMs just drop to the floor and the motor stalls. Right now, Im theorizing it might have to do with the Latency issue mentioned above. Not really sure what settings I can adjust for this one, but Im sure theres something in RR I can change to fix this problem. Ideas?

Thats about it off the top of my head. Any thoughts, ideas, criticisms, or any other form of discussion is more than welcome!

-Putting all corrections @ 100 led to the car idling like **** and having no power, and running very lean. I suspect part of the issue may be the Injector Latency value - still waiting to get replies from the shop I bought them from, as well as Bosch, to see if they can fill me in on what the Latency is for these injectors. Supposedly it has a significant role in low pulse width operations, which of course includes idling, so perhaps getting the correct value here will fix this issue. For now, Im not touching the corrections table.

-Even without touching the corrections map, idle seems a little unsteady, randomly getting lean before calming back down. Again, I think this is a latency issue. Unless, I need to make changes to the idle voltage range?

-Overall, it seems that the tune is on the leaner side. My LTFTs seem to stay at around 110 more or less across the board. I need to dissect my logs a bit more but Im assuming that if I see an overarching trend of richness/leanness, it means I should slightly lower my K rather than changing all the correction cells.

-I did a short WOT run to see what would come up. Noticed a drastic AFR spike around 4400RPM or so, which to my knowledge is around where the VIAS activates. This same pattern was occuring while using the Apexi NEO for tuning - should be much easier to smooth out now that I have total control over the variables in play.

-Potting around, the pedal just doesnt feel as responsive. Not really sure what to chalk this up to, but its noticeable, im missing a lot of low end torque. My best theory as of now is that its because its using the stock 15 degree timing, rather than the 17" timing advance, or at least I dont remember advancing the timing after reflashing. Not really sure, honestly.

-Im still having this annoying stall issue when coming to a stop! It will stall basically every single time unless I keep it in gear until I am at or below idle speed, or else the RPMs just drop to the floor and the motor stalls. Right now, Im theorizing it might have to do with the Latency issue mentioned above. Not really sure what settings I can adjust for this one, but Im sure theres something in RR I can change to fix this problem. Ideas?

Thats about it off the top of my head. Any thoughts, ideas, criticisms, or any other form of discussion is more than welcome!

Last edited by Slamrod; 04-05-2020 at 03:05 PM.

#68

#70

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

In any case, theres definitely a massive spike of air in the low 4k RPMs, that much is absolutely certain. Today I added 10% to the K value since things seemed slightly lean, which definitely has the motor idling much better. Still gotta do some driving and logging to see how it is overall, but I think my K is pretty close to where it should be. Fuel alphas dont seem to be exceeding +/- 10%. I tried to do a WOT run, but soon as I hit 4000RPM, the AFRs spike from mid 12's to 16-17. Up until that point the AFR is actually quite nice and flat, but like clockwork, AFR shoots through the roof to dangerous levels almost precisely the same time that I cross the 4k threshold. Not really sure what is causing it - perhaps im accessing a part of the corrections table that is pulling fuel still? Still stock corrections on this tune - though I doubt this is the cause, since there are no cells anywhere in or near the 4k RPM range on the corrections table that are removing more than 2% fuel. I was also thinking maybe I had set my Fuel Target table up incorrectly, but this behavior was also occurring when I was using the NEO for tuning - all of my RPM points had me removing fuel, except for the low 4k's, where I had to add tons of fuel to try and stamp things back down to safe levels.

Another question, perhaps a silly one. Does the motor ever reach 100% load? Under what conditions? I was under the impression that load is somewhat correlated to throttle position, in the sense that more air = higher % of cylinder volume = more load, with 100% load being where the cylinder is being filled to 100% possible volume with fuel/air mixture to produce maximum energy. Say I were to do a WOT run in 4th gear on a flat road, mild climate conditions, no accessories running, starting at 2k rpm... around where should my load be? This most recent WOT run has it at around 60% load from when I put the pedal to the floor, to when I let off. I imagine that the ECU leaves some headroom for temperature differences, accessories running, going up inclines, etc.. but 60% seems low to me. Wouldnt this imply my Injector Pulse Width scaling needs to be adjusted further, since Im not accessing most of the right half of my fuel map? ((Also - IPW gets scaled in proportion to injector changes, that much I know... but does it also get scaled with MAF changes? I only scaled it for injectors, although K was scaled for both)).

Anyways, if my IPW scaling is indeed off, this would probably explain why I am getting the spike - the ECU is operating under a fuel target (based on calculated load) where it thinks it is cruising and needs 14.7AFR, when in reality it is under high load and needs somewhere around 12.5. I dont know that changing MAF size would require IPW to be rescaled though, so maybe this theory is total crud. It makes sense to me though. Hypothetically suppose I only installed a larger MAF and didnt change injectors, wouldnt that mean that I would require a higher IPW to account for the increase in air? In other words, is it more accurate to say that mTP100 should be scaled in proportion to the change in K value, rather than just the change in injectors?

Last edited by Slamrod; 04-06-2020 at 04:44 PM.

#71

Hi I had some experience with romraider and my 03 maxima mt. I had the 6Y310 stock flash but couldn't find any definitions to read it. I tried to edit the provided 314 thinking it would be the same but couldn't figure it out. I played with the 314 flash and the 303 flash on my ecu. I also was able to flash the 303 rom onto a automatic trans ecu I got off ebay successfully. One thing I noticed was the 6y314 rom was like my stock flash in performance. I compared the 314 rom with the 303 in RR and there were some differences. MAF voltage limits, idle BFS limits, idle targets, fuel cut JECS and fuel restore JECS. Knock values were different and so was the torque value map. I don't know much about the values or how to edit them successfully. Anyway it seems to me that the 303 rom is better in performance than the 314 or my stock 310 flash and its the rom that I run today. Also my AF meter shows richer conditions on WOT with the 303 rom than with the stock and 314 flash. The idle is kind of rough but I think that could be my MAF. I suspect the 303 was a tune someone had or did and uploaded but I can't find anything about it in the RR forums. I had a strong interest in trying to figure out how to scale my maf but couldn't locate any resources that could help me figure it out in RR. I also tried things like swapping timing maps from the 350z rom to the 303 and 314 roms. It kind of worked but performance was worse. I didn't really know what I was doing with it and it served my purpose so far. If you have a mt you can use it to flash any 5th gen cpu to your car. I hope you figure it out especially the maf scaling part. If you do maybe you can put it into laymens terms for us or let me pay you to do mine.

Thanks

Thanks

#72

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Hi I had some experience with romraider and my 03 maxima mt. I had the 6Y310 stock flash but couldn't find any definitions to read it. I tried to edit the provided 314 thinking it would be the same but couldn't figure it out. I played with the 314 flash and the 303 flash on my ecu. I also was able to flash the 303 rom onto a automatic trans ecu I got off ebay successfully. One thing I noticed was the 6y314 rom was like my stock flash in performance. I compared the 314 rom with the 303 in RR and there were some differences. MAF voltage limits, idle BFS limits, idle targets, fuel cut JECS and fuel restore JECS. Knock values were different and so was the torque value map. I don't know much about the values or how to edit them successfully. Anyway it seems to me that the 303 rom is better in performance than the 314 or my stock 310 flash and its the rom that I run today. Also my AF meter shows richer conditions on WOT with the 303 rom than with the stock and 314 flash. The idle is kind of rough but I think that could be my MAF. I suspect the 303 was a tune someone had or did and uploaded but I can't find anything about it in the RR forums. I had a strong interest in trying to figure out how to scale my maf but couldn't locate any resources that could help me figure it out in RR. I also tried things like swapping timing maps from the 350z rom to the 303 and 314 roms. It kind of worked but performance was worse. I didn't really know what I was doing with it and it served my purpose so far. If you have a mt you can use it to flash any 5th gen cpu to your car. I hope you figure it out especially the maf scaling part. If you do maybe you can put it into laymens terms for us or let me pay you to do mine.

Thanks

Thanks

#73

I definitely have plans to make another thread once I get where I want to be with tuning. Basically a How-To on how to get started with RomRaider, some of the tuning concepts, what different terms mean, how the different values interact, etc... Literally all of this is freely available on the internet already, but in my experience it requires lots of searching and sifting and the info provided is not straight forward at all. I hope to be able to provide a guide at some point that has everything you need in one place in a format thats understandable by someone with zero knowledge of tuning. This thread has loads of info but its format is far from ideal for other readers to learn from. I dont think I want to make it easy for people to just copy everything I do though - if thats the case, theyre not going to learn anything. I still would like people to go through their own process of experimentation because thats how you really connect the dots with this stuff. Anyways, this isnt gonna happen for a while lol, so stay tuned..

#74

Edited for lousy advice, see posts below. You should see close to 100% during a WOT pull from fairly low RPMs, then falling off as RPMs get too high and VE decreases.

Have you replaced the stock fuel pump?

Have you replaced the stock fuel pump?

Last edited by freezer; 04-08-2020 at 06:08 PM.

#75

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Yes, Yes, and Yes, you need to scale it for MAF also, you'll have a hard time achieving proper AFR targets if you aren't getting over 60% load. You should see close to 100% during a WOT pull from fairly low RPMs, then falling off as RPMs get too high and VE decreases.

Have you replaced the stock fuel pump?

Have you replaced the stock fuel pump?

So larger injectors mean smaller mTP100, yes? For example, injectors double the size of stock means you need to cut mTP100 in half. Youre saying that I would have to raise that number back up again for the MAF change? I tried this yesterday (mTP100 went from stock 19.37 to around 10.97 for injector scaling, then back up to around 23.xx for the MAF). This didnt work - car was unable to produce any power and stalled when trying to move. Am i misinterpreting what you mean by scaling load?

Im experimenting with trying to get load to 100 but its not working. If I lower mTP100, it seems to in turn make my motor run leaner, which in turn requires me to raise K to compensate. Which, apparently, seems to affect my load again, unless theres other variables at play that I am overlooking. I feel like Im just going in circles right now. I cant seem to get over mid 60’s in load no matter what I do, at least not with a tune that is at all usable.

Im going to swap the stock intake back on again tomorrow to see if I can get everything nailed down for just the injectors (im tempted to swap injectors back and leave the 4” MAF, but im really nervous about overworking the inejctors). Hopefully the math will make sense that way because right now it isnt.

Last edited by Slamrod; 04-08-2020 at 03:27 PM.

#76

Sorry, I get my head in a twist when using K to adjust for MAF.

mTP100 should be scaled for injector size only. Just cuz K gets bastardized doesn't mean mTP100 should be.

Have you flattened your fuel compensation map?

The most important issue at play here is that you might not be logging the correct parameter. The ECU has several "load" type measurements it uses internally. The value on the load axis should be scaling correctly, but you won't know based on the parameter your'e logging. Fun huh!?

mTP100 should be scaled for injector size only. Just cuz K gets bastardized doesn't mean mTP100 should be.

Have you flattened your fuel compensation map?

The most important issue at play here is that you might not be logging the correct parameter. The ECU has several "load" type measurements it uses internally. The value on the load axis should be scaling correctly, but you won't know based on the parameter your'e logging. Fun huh!?

Last edited by freezer; 04-08-2020 at 05:59 PM.

#77

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Sorry, I get my head in a twist when using K to adjust for MAF.

mTP100 should be scaled for injector size only. Just cuz K gets bastardized doesn't mean mTP100 should be.

Have you flattened your fuel compensation map?

The most important issue at play here is that you might not be logging the correct parameter. The ECU has several "load" type measurements it uses internally. The value on the load axis should be scaling correctly, but you won't know based on the parameter your'e logging. Fun huh!?

mTP100 should be scaled for injector size only. Just cuz K gets bastardized doesn't mean mTP100 should be.

Have you flattened your fuel compensation map?

The most important issue at play here is that you might not be logging the correct parameter. The ECU has several "load" type measurements it uses internally. The value on the load axis should be scaling correctly, but you won't know based on the parameter your'e logging. Fun huh!?

#78

So, in order to correct the standard calculated load value you are reading with NDS2, scale the entire "Load Base Fuel Schedule" table the same amount that you scaled mTP100. Then you'll see more accurate data.

Have you read through the RR thread on datalogging Nissan? I've been using it pretty reliably for a while. All the info you should need to get that functioning is there.

Have you read through the RR thread on datalogging Nissan? I've been using it pretty reliably for a while. All the info you should need to get that functioning is there.

#79

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

So, in order to correct the standard calculated load value you are reading with NDS2, scale the entire "Load Base Fuel Schedule" table the same amount that you scaled mTP100. Then you'll see more accurate data.

Have you read through the RR thread on datalogging Nissan? I've been using it pretty reliably for a while. All the info you should need to get that functioning is there.

Have you read through the RR thread on datalogging Nissan? I've been using it pretty reliably for a while. All the info you should need to get that functioning is there.

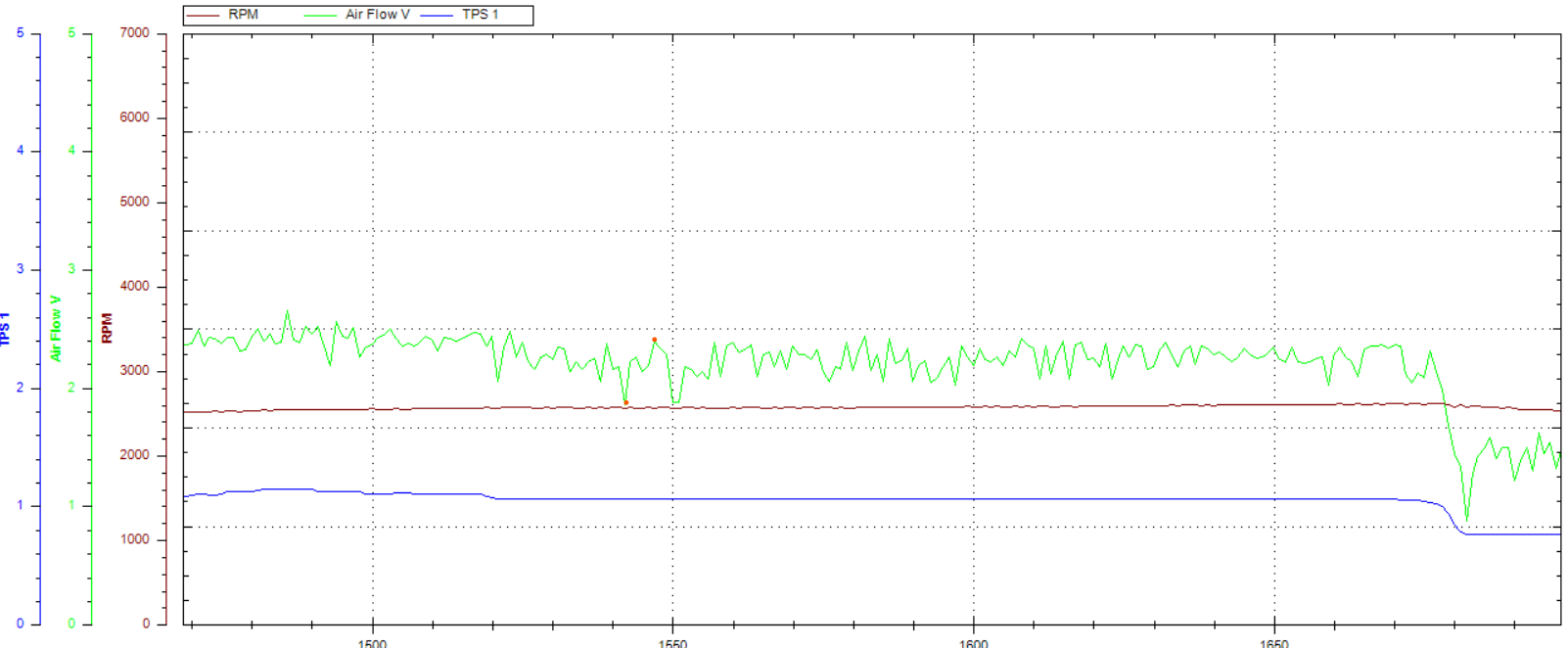

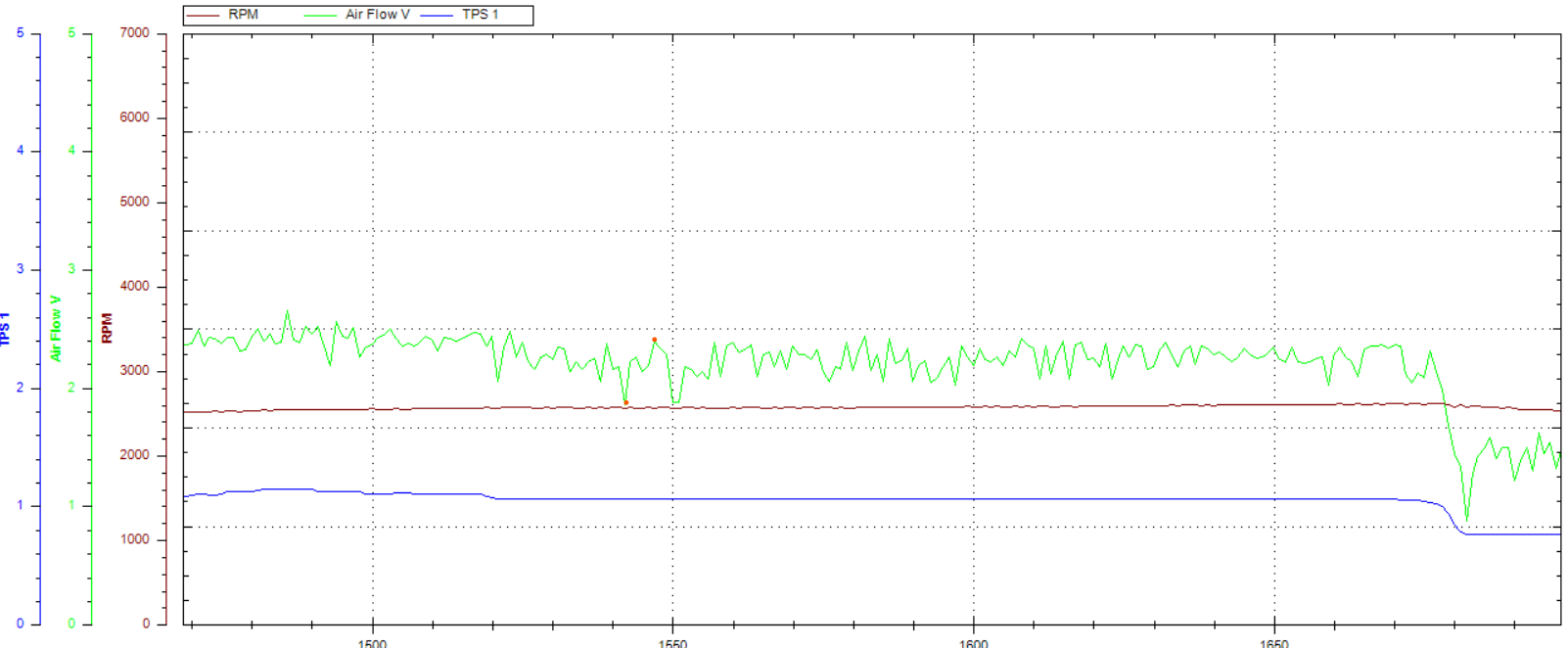

I have RR logger working, its more of an issue of learning how to use its features. Or rather, how to do map tracing. I couldnt really find any info on how to use the logger, just info on how to get it to work.

Still having this massive AFR spike issue at 4k rpms. Happens with stock corrections, and when set to 100. AFR rises at 4k so drastically that the car loses tons of power if I stay on the throttle. I suppose I could just add a bunch of fuel in those cells, but I feel like this spike shouldnt be happening to begin with. I can see the AFR dropping when I begin a WOT run, which seems to imply its accessing the correct fuel targets. Any ideas? Is this just a quirk im going to have to live with and tune around? Or do I have a legitimate reason to be concerned?

Couple of theories:

1) Vacuum leak. I find this extremely unlikely, as I checked multiple times for one. Not to mention that this would cause issues across the board, not just at 4krpm, and that something like that could be fixed extremely easily by adjusting K.

2) Fueling issue. Also unlikely, 255lph pump and 560cc injectors are already massive overkill. Wouldnt a problem of this nature appear at higher rpms rather than midrange?

3) MAF issue. Maybe my sensor is tired after nearly 2 decades of work? I think this might be a probable cause. I have absolutely no idea what a graph of MAF voltage should ideally look like - i would assume that given MAF voltage has such an important role in how the motor runs, that voltage should be relatively smooth. Im looking at some logs, and it appears that my MAF voltage has some fluctuations in it. Id imagine things like temp, turbulence, environmental factors etc etc, would cause that, and I shouldnt expect my voltage graphs to be perfectly smooth. However, im seeing that the magnitude of the fluctuations in MAF voltage are doubling or even tripling from their average fluctuations... right as my AFRs are spiking at 4k rpm.

Could it be that my MAF is simply crapping out, and that my troubles are a hardware issue rather than me failing to understand the software? Or are fluctuations with MAF voltage normal? Can anyone upload a random log of a healthy tune so I can compare what MAF voltage should look like when graphed?

Last edited by Slamrod; 04-10-2020 at 02:23 PM.

#80

Newbie - Just Registered

Thread Starter

iTrader: (11)

Join Date: Apr 2013

Location: Long Island, NY

Posts: 1,171

Ok, so I am humbly asking those of you who are more knowledgeable than I am to weigh in on this. But right now I am VERY convinced that my MAF sensor is faulty. As stated earlier, some minor fluctuations should be expected with MAF voltages. Variables like temperature, humidity, air turbulence, oxygen density... all sorts of sht - mean that you will never get a completely flat/linear MAF voltage. However...

-It should correlate directly to throttle position and RPMs. A jump in throttle position will result in a jump in MAF voltage, because you are suddenly introducing more air to the system. As for RPMS, MAF voltage will generally climb at roughly the same rate RPMs climb - as the motor sucks in more air, that increased consumption is measured by the MAF. Pretty straight forward stuff.

-Fluctuations/oscillations in voltage should be minimal if throttle position and RPMs are constant. While the environmental variables mentioned above can introduce small fluctuations, they should be very small, maybe 0.1-0.2 volts, at least according to what I found on google.

Im seeing fluctuations of 0.2 volts, minimum. Average seems to be a fluctuation of around 0.3-0.4 volts or so, but I am seeing fluctuations in spots where the difference is as high as 0.6 volts! With the MAF voltage going up to about roughly 5 volts at max measurable airflow, it seems to me that a fluctuation of half a volt where throttle input and RPMs are constant is massive.

Green represents MAF voltage, blue is throttle, red is RPMs. You can see I am cruising here, with throttle and RPMs pretty much constant and unchanging. However, look at how much the MAF voltage is jumping around. If you look closely you can see where I added two orange dots on the green graph, where there is a low and a high point in fluctuation - 1.86v to 2.40v, for a total of 0.54 volts of change. With WOT pulls (not shown in this pic, lol), I am seeing this same relative type of fluctuations, but right as I start getting around 4k rpm, my MAF voltage starts to fluctuate with greater intensity.

So - Am I on to something here? Is my MAF on its way out and giving inaccurate readings, possibly explaining why I am having AFR issues? Or is this type of oscillation with MAF voltage normal? Can someone take a peak at their own logs to see how their MAF voltage looks compared to mine?

-It should correlate directly to throttle position and RPMs. A jump in throttle position will result in a jump in MAF voltage, because you are suddenly introducing more air to the system. As for RPMS, MAF voltage will generally climb at roughly the same rate RPMs climb - as the motor sucks in more air, that increased consumption is measured by the MAF. Pretty straight forward stuff.

-Fluctuations/oscillations in voltage should be minimal if throttle position and RPMs are constant. While the environmental variables mentioned above can introduce small fluctuations, they should be very small, maybe 0.1-0.2 volts, at least according to what I found on google.

Im seeing fluctuations of 0.2 volts, minimum. Average seems to be a fluctuation of around 0.3-0.4 volts or so, but I am seeing fluctuations in spots where the difference is as high as 0.6 volts! With the MAF voltage going up to about roughly 5 volts at max measurable airflow, it seems to me that a fluctuation of half a volt where throttle input and RPMs are constant is massive.

Green represents MAF voltage, blue is throttle, red is RPMs. You can see I am cruising here, with throttle and RPMs pretty much constant and unchanging. However, look at how much the MAF voltage is jumping around. If you look closely you can see where I added two orange dots on the green graph, where there is a low and a high point in fluctuation - 1.86v to 2.40v, for a total of 0.54 volts of change. With WOT pulls (not shown in this pic, lol), I am seeing this same relative type of fluctuations, but right as I start getting around 4k rpm, my MAF voltage starts to fluctuate with greater intensity.

So - Am I on to something here? Is my MAF on its way out and giving inaccurate readings, possibly explaining why I am having AFR issues? Or is this type of oscillation with MAF voltage normal? Can someone take a peak at their own logs to see how their MAF voltage looks compared to mine?

Last edited by Slamrod; 04-11-2020 at 12:27 AM.