4th Gen Adjustable Front Sway Bar End Links

#1

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

4th Gen Adjustable Front Sway Bar End Links

These were done to see if it was possible to make a stock style end link that was adjustable. I've found the front sway bar to have a bit of preload meaning the sway bar is binding on one side of the car while cornering. The right side of the sway bar seems worse than the left side. This imparts a much greater roll stiffness than what the bar was designed for and this can lead to more understeer. The right side sway bar bushing has already torn and got pushed out of the bracket by what I believe to be caused by this binding. I've replaced the sway bar bushings but I would like to eliminate this problem.

I read a tip in GRM that if you put a washer in between the saddle bracket and the subframe this should help eliminate some bind at the extremes. I will try this method first with stock end links to see what happens. Ideally you would want to eliminate any preload on the sway bar with adjustable links.

The problem with the 4th gen design is the sway bar sits right on top of the end link and the link is very short. The adjuster is only 25 mm long and the spherical thread and the bolt that holds the bushings to the sway bar both need about 10 mm of the adjuster's thread length. This only gives +/- 2.5 mm of safe adjustment range over the stock end links, which is not alot. The adjuster cannot be any longer than 25 mm or the end link will be higher than the stock end link.

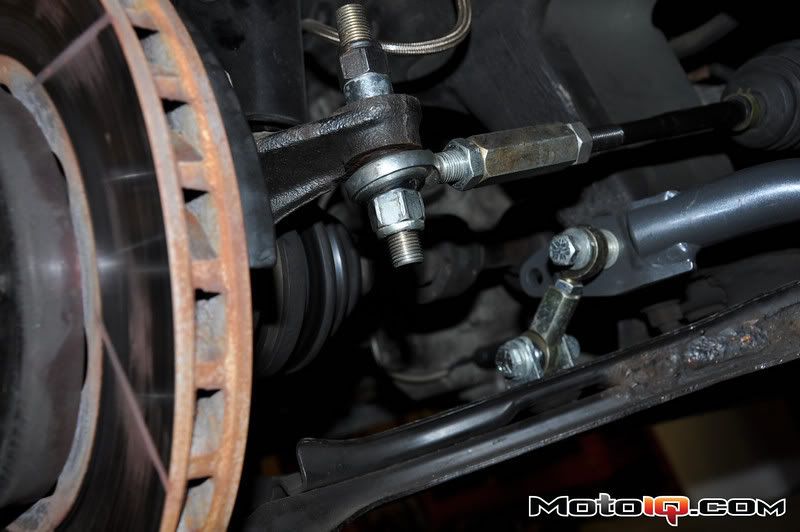

This would be the ideal solution to the problem. This was done on MotoIQ's 200SX project car, which has a similar suspension design to the 4th gen.

Convert the sway bar by welding on adjustment tabs, mount the end link on the other side of the tab on the control arm, and create an end link with two spherical bearings. The end link would be longer and allow for much greater adjustment range, it would also make the front sway bar adjustable as well.

Oh as an added bonus for those who like to drag race you can do the opposite with a preloaded sway bar. You can use the adjustable end link to push down on a control arm, this would help if one wheel is always spinning off the line. You can make the link push down on the control arm of the spinning wheel and get more traction. I talked to some people that drag race FWD cars and this is how I learned about this method.

Last edited by 98SEBlackMax; 07-11-2010 at 10:09 PM.

#2

Supporting Maxima.org Member

iTrader: (60)

Join Date: Aug 2003

Location: Southern California

Posts: 2,036

The endlinks need to be a lot shorter than stock to work well when lowered. Some of us have had custom made ones for several years.

The squishy bushings are a big problem. They move a lot before the bar really starts working. That's why the 5g uses balljoint on each end, no bushings.

Can't raise the mounting points of the bar on the subframe due to a bunch of crap in the way. Look under there. And those mounts are squishy too, allowing the bar to move up and down and not allowing it to pivot smoothly because the rubber "grabs", hurting preformance. Some of us have had custom machined mounts for years that allow the bar to turn smoothly without deflection.

The squishy bushings are a big problem. They move a lot before the bar really starts working. That's why the 5g uses balljoint on each end, no bushings.

Can't raise the mounting points of the bar on the subframe due to a bunch of crap in the way. Look under there. And those mounts are squishy too, allowing the bar to move up and down and not allowing it to pivot smoothly because the rubber "grabs", hurting preformance. Some of us have had custom machined mounts for years that allow the bar to turn smoothly without deflection.

#3

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

5th gen end links are much easier to convert to spherical as they have two ball joints. You could take some measurements and buy a set of generic adjustable spherical end links from Whiteline or several other companies.

As it stands the 4th gen end link design is crap.

I actually thought about using a 5th gen sway bar so it would be easier to convert to spherical end links.

I am thinking of cutting off the ends of a 4th gen bar and welding adjustable ends onto it. Then use two spherical bearings as to allow for proper end link adjustment.

Your also right about the chassis mounts, when lowered or using really sticky tires they don't work right under cornering. This causes sway bar binding which leads to a crazy high front roll resistance and terminal understeer.

For this season I ground down the bushings a little bit and put washers in between the saddle mounts and subframe to see if that helps, but will have to come up with something more creative to solve the problem.

As it stands the 4th gen end link design is crap.

I actually thought about using a 5th gen sway bar so it would be easier to convert to spherical end links.

I am thinking of cutting off the ends of a 4th gen bar and welding adjustable ends onto it. Then use two spherical bearings as to allow for proper end link adjustment.

Your also right about the chassis mounts, when lowered or using really sticky tires they don't work right under cornering. This causes sway bar binding which leads to a crazy high front roll resistance and terminal understeer.

For this season I ground down the bushings a little bit and put washers in between the saddle mounts and subframe to see if that helps, but will have to come up with something more creative to solve the problem.

Last edited by 98SEBlackMax; 07-28-2010 at 10:44 AM.

#4

Are these going to be for sale any time soon? Any idea on price? What's the word on maintenance for these things?

Thanks for putting in all this work for our cars, it's much appreciated!

Thanks for putting in all this work for our cars, it's much appreciated!

#5

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

Id like to convert a sway bar to adjustable and use a link with two bearings they would be C shaped instead of the L shape of the current design.

Last edited by 98SEBlackMax; 08-10-2010 at 01:20 PM.

#6

Can't wait to hear about the new end link design.

#7

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

The end links are skewed when the car sits on level ground.

I might try those adjustable end lnks that I built because the links need to be a bitter shorter on lowered cars to work properly. I will just try to make them 5 ~ 10 mm shorter than the stock ones I have.

#8

I put one high strength 10 mm washer between the saddle bracket and the subframe on all four of the bolts. Not enough to correct the 1.5" drop the car has now. Haven't cornered the car very hard but I'm sure it will still bind up with the R-compounds on the road course.

The end links are skewed when the car sits on level ground.

I might try those adjustable end lnks that I built because the links need to be a bitter shorter on lowered cars to work properly. I will just try to make them 5 ~ 10 mm shorter than the stock ones I have.

The end links are skewed when the car sits on level ground.

I might try those adjustable end lnks that I built because the links need to be a bitter shorter on lowered cars to work properly. I will just try to make them 5 ~ 10 mm shorter than the stock ones I have.

Do you think those bolts for the saddle bracket are long enough for 2 washers? I'm on Tokico/Custom Maxima springs which are pretty soft, less than ideal and lower around 1.6 or so, perhaps more.

Would shaving down the endlink lower bushing help at all? I cranked down on them pretty hard but they're only supposed to be 12-16 ft/lbs per fsm. the poly seems stiff enough that shaving off a couple of mm wouldn't kill them...

edit: brain fart. I subconsciously absorbed all of the above from what you said earlier in the thread and then thought i was saying something new. wow.

how much did you take off the end link bushings?

Last edited by tvrds; 08-24-2010 at 09:35 PM.

#9

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

Yup I need those washers. I just did ES SB bushings 2 weekends ago and within a few days the passenger side bushing had squished out and torn. I put it back in this weekend but it's already starting to squeak again so I ordered a new set.

Do you think those bolts for the saddle bracket are long enough for 2 washers? I'm on Tokico/Custom Maxima springs which are pretty soft, less than ideal and lower around 1.6 or so, perhaps more.

Would shaving down the endlink lower bushing help at all? I cranked down on them pretty hard but they're only supposed to be 12-16 ft/lbs per fsm. the poly seems stiff enough that shaving off a couple of mm wouldn't kill them...

edit: brain fart. I subconsciously absorbed all of the above from what you said earlier in the thread and then thought i was saying something new. wow.

how much did you take off the end link bushings?

Do you think those bolts for the saddle bracket are long enough for 2 washers? I'm on Tokico/Custom Maxima springs which are pretty soft, less than ideal and lower around 1.6 or so, perhaps more.

Would shaving down the endlink lower bushing help at all? I cranked down on them pretty hard but they're only supposed to be 12-16 ft/lbs per fsm. the poly seems stiff enough that shaving off a couple of mm wouldn't kill them...

edit: brain fart. I subconsciously absorbed all of the above from what you said earlier in the thread and then thought i was saying something new. wow.

how much did you take off the end link bushings?

I kill end link & saddle bushings but only on the road courses with R-compound tires.

Anyways I had 3 washers under the saddle brackets but only drove around the block, so 2 washers might be a little to much; keep in mind this only helps keep the saddle bracket bushing from binding with the sway bar. I settled on one washer for each bolt. Will play around with 2 washers later on this year. I am only 0.5" lower than stock on GC/Konis anyways.

Also you can grind down the bottom end link bushing a little, I took off 2~3 mm of material grinding them down. Ideal solution would be shorter adjustable end links, to be honest with all the other stuff going on with my car and this track day coming up I haven't had time to play with the end links much.

#12

Dr J

#13

Is there room to rotate the bar up some? i.e. remove both links and raise the bar up as far as it can go. then compress the suspension to the bump stops. see how much room you have then. Is there enough room to make a longer link and stick in there, and will the angles work with a longer link?

There's no rule that the new links have to be identical in length to the old ones, as long as they will fit in place and work.

there's also no rule saying you have to use the existing mounting configuration or bolt holes. move stuff around and see what works. weld or bolt a u-bracket onto the control arm in a better location for you. you're going through a lot of work in other areas on the control arm, so this should be a minor inconvenience vs. a major pain.

There's no rule that the new links have to be identical in length to the old ones, as long as they will fit in place and work.

there's also no rule saying you have to use the existing mounting configuration or bolt holes. move stuff around and see what works. weld or bolt a u-bracket onto the control arm in a better location for you. you're going through a lot of work in other areas on the control arm, so this should be a minor inconvenience vs. a major pain.

#15

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

Ordered some cheapo end links to try an idea out. I am just going to carefully grind off the existing bosses and thread the stud with a metric die. Then use a locking nut and washer to make a new lower seat for the bushings to sit and use wicking locktite once I make my sway bar adjustments. As far as I can tell the end link bushings need to be a few mm shorter, nothing more than that. Not perfect but it will help get some of the bind out of the end links and allow them to be adjusted slightly.

For the sway bar I came across another trick where they use two piece locking clamps on one or both sides of the sway bar bushing. These prevent the bar from sliding around and forces it to rotate around the bushing as it should. Mcmaster Carr has these for like 10 bucks each with a 20 mm inner diameter which is the size of the 4th gen sway bar. But before that wrap the area of the bar that sits on the saddle bushings with Teflon tape to help with the bind.

As far as changing the sway bar most shops won't take the risk of welding different ends on a sway bar. The bar is made from spring steel and welding a sway bar is very tricky. It requires a special filler rod and even then if its not done right the weld/sway bar area will be brittle from different heat exposures from the welding. The bar has to be heated first to and the weld has to be done carefully, no one in this area will do this for me. Best bet would be to get a custom sway bar bent, but again no one specializes in this around here.

Ideally I would make a 20 mm bar with blade type ends with different holes so that the sway bar's effect can be adjusted and allow a traditional C shaped spherical end link to be used. We need less bar up front, but not eliminate the bar completely along with a larger bar on the rear suspension IMO.

For the sway bar I came across another trick where they use two piece locking clamps on one or both sides of the sway bar bushing. These prevent the bar from sliding around and forces it to rotate around the bushing as it should. Mcmaster Carr has these for like 10 bucks each with a 20 mm inner diameter which is the size of the 4th gen sway bar. But before that wrap the area of the bar that sits on the saddle bushings with Teflon tape to help with the bind.

As far as changing the sway bar most shops won't take the risk of welding different ends on a sway bar. The bar is made from spring steel and welding a sway bar is very tricky. It requires a special filler rod and even then if its not done right the weld/sway bar area will be brittle from different heat exposures from the welding. The bar has to be heated first to and the weld has to be done carefully, no one in this area will do this for me. Best bet would be to get a custom sway bar bent, but again no one specializes in this around here.

Ideally I would make a 20 mm bar with blade type ends with different holes so that the sway bar's effect can be adjusted and allow a traditional C shaped spherical end link to be used. We need less bar up front, but not eliminate the bar completely along with a larger bar on the rear suspension IMO.

#16

Maxima.org Insomniac

Thread Starter

iTrader: (9)

Join Date: May 2002

Location: Shrewsbury, MA

Posts: 1,879

Got around to messing with the end links today. The first pic shows the end link with the seat ground off. Second pic is a comparison with an unmodified end link with one of the end links I threaded.

There was much less angular bind when I re-installed the suspension and put the car back on the ground. However I need to thread the end links even lower because there is still some bind. So it is more than a few MM to fix this end link problem and I am only lowered an 1" or so.

The collar locks proved to be a bigger problem. The sway bar might be 20 mm diameter but it changes shape quite a bit around the area where the bushing is located. So a 20 mm inner diameter collar lock isn't going to fit, I need to try a 22 mm and make it fit. I had to machine away a bit of the collar lock to get them to not rub against the subframe only to find I can't clamp around the sway bar.

Thread

Thread Starter

Forum

Replies

Last Post

kingw323

4th Generation Maxima (1995-1999)

20

10-21-2015 08:36 AM