Wideband Bargain? PLX R-300

#1

Wideband Bargain? PLX R-300

I just ordered this wideband, and thought I would share the price here.

http://shop.edoperformance.com/plx-r...er-p-9157.html

Seems pretty reasonable - $336.75 - and has enough features for me.

http://shop.edoperformance.com/plx-r...er-p-9157.html

Seems pretty reasonable - $336.75 - and has enough features for me.

#8

I noticed that the O2 sensor for this unit is compatible with leaded fuels - kinda unusual.

In their specs:

"The R-300 can be fully customized to select the specific fuel setting for your application. Fuels with lead are compatible with the Bosch and NTK sensors."

Last edited by grey99max; 02-08-2008 at 10:59 AM.

#9

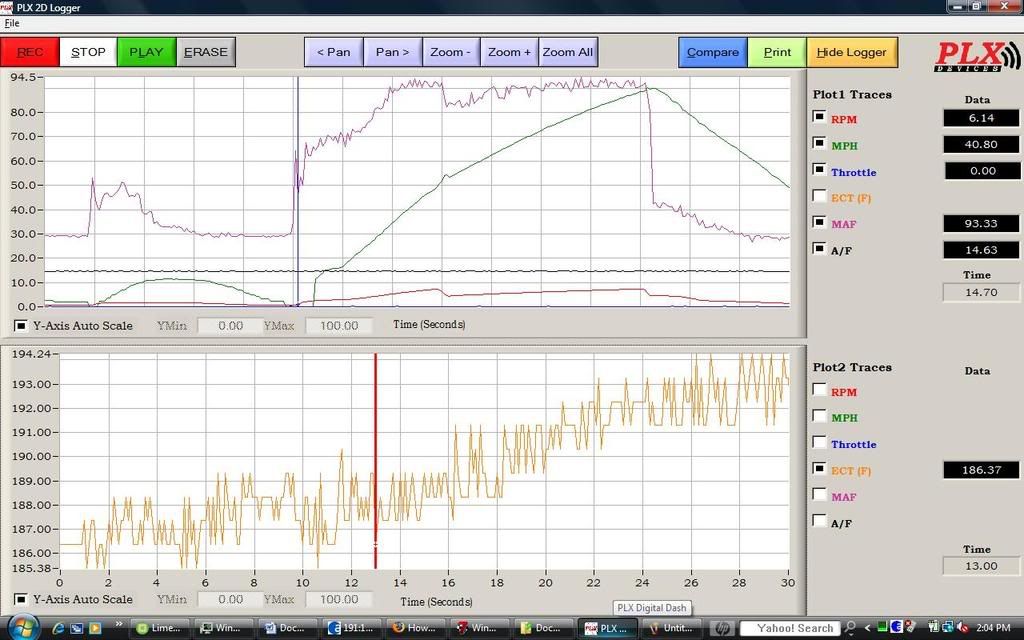

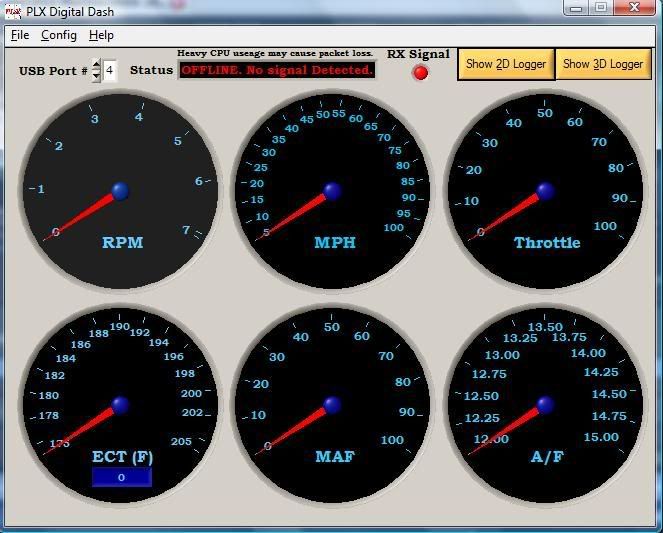

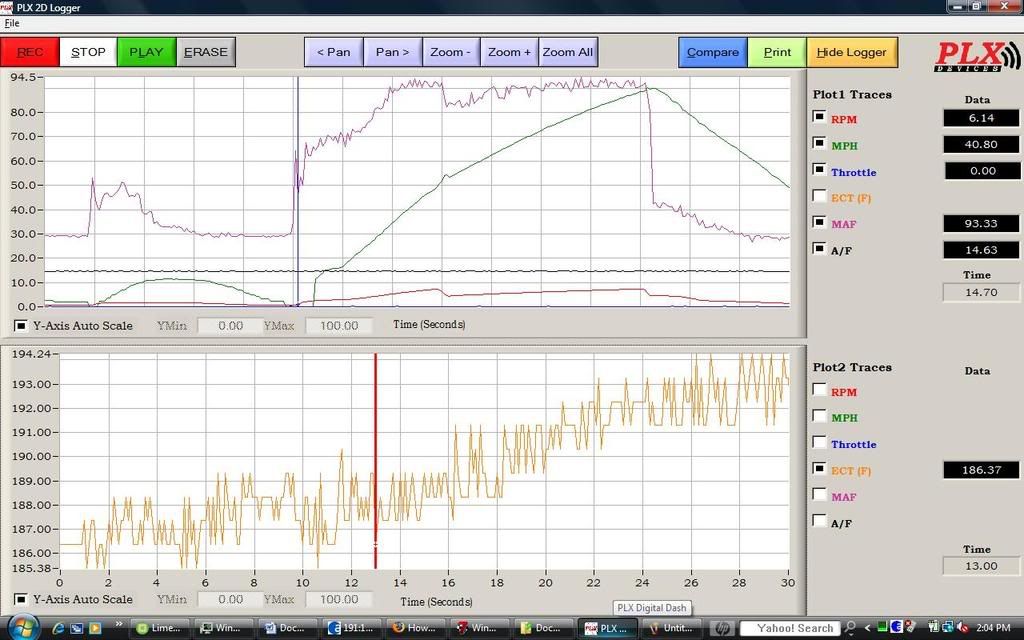

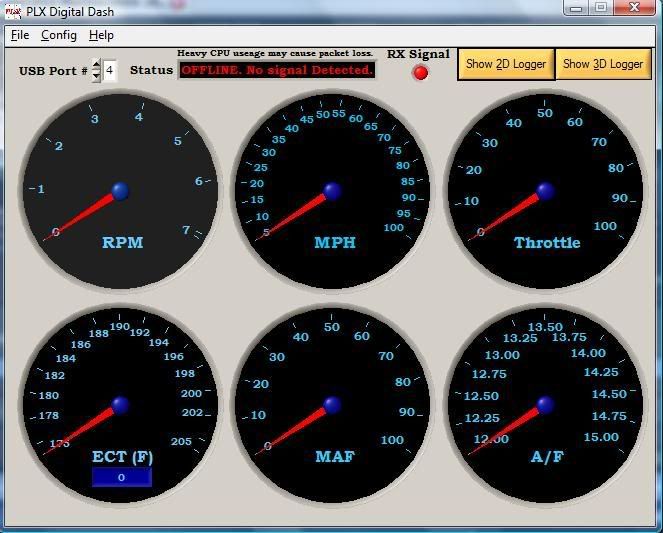

I monitor my MAF/TPS/MPH/RPM/ECT/AFR with this unit. I like it. I got mine for about 100$ more.

f you have access to an old laptop that you can bring with you, you could even get a live readout like this, all colors/graphics are customizable. Not too functional but definitely high on the cool factor.

You can select between different fuels (diesel, gasoline etc). But ahh, I typically only use gasoline in mine

f you have access to an old laptop that you can bring with you, you could even get a live readout like this, all colors/graphics are customizable. Not too functional but definitely high on the cool factor.

You can select between different fuels (diesel, gasoline etc). But ahh, I typically only use gasoline in mine

#13

depends on what you need from a wideband. if you have EU or something similar that can datalog a bunch of different parameters and a wideband input then you wouldn't necessarily need a wideband that can datalog as well.

#14

After a whole lot of reading I went with the Innovate unit. You may ask why? They all (mostly) use the same Bosch LSU4 sensor.

The main thing to understand is that a sensor that calibrates and gives a 14.7 reading in "free air" is not necessarily accurate at 12:1.

Here is an explanation from a guy that has been "an instrumentation engineer in the aerospace industry for over 20 years. I have a Ph.D. in applied mathematics and a M.S. in mechanical engineering. I take words like "calibration", "standard", and "characterized" very seriously ( even if I don't always spell them right ). They used to be life and death things for me. Literally. Annecdotal things like "this guy has XXX meter and he is happy" mean nothing to me. Calibrated standards, NBS certificates, chains of tracebility, and test procedures do."

The analog based wideband meters (AEM, PLX, et al ) may not be able to detect a damaged sensor and just go on giving bad data. How would they know ??? Any meter that uses the standard Bosch WB controller chipset does not analyze the sensor in real-time. They just go by the factory calibration resistor that comes on the sensor.

Which gives rise to...

Quote:

Why does the sensor have to calibrate for air and heat? No other widebands have to do that?

No other widebands can do that. If you don't calibrate the system, you are relying on the calibration resistor on the sensor that was set to match the sensor output at the factory. The sensors change over time ( especially when run rich ); often as little as a 3 or 4 hours. And then, the calibration is off. But how will you know ???? It will still always be accurate right at 14.7AFR so you can't check it that way.... But now 13.0 is really 11.9 ? 12.3 is really 14.0 ? How will you check it ? In OEM applications the sensor is almost always run at 14.7AFR; so it does not drift nearly as quickly as on a tuner car running 12.0AFR or richer.

Every time you do a re-calibrate of a sensor on an LM-1, it adjusts for any changes in the sensor over time. As long as it's not damaged, it is accurate like a new sensor again. And, in the process, it can detect damaged sensors, etc.

I wonder what would happen if you put a sensor with a damaged ( but not open or shorted ) or just aged pump-cell on an AEM meter ? It can't analyze the pump resistance... so it would assume all is well and give bogus data thinking that the calibration resistor info is still valid ????

I don't really know the answer to that. Maybe I should do an experiment

But if it does, and it shows 12.5 when the real AFR is 14.1, at WOT... Bad things are going to happen. Could be game over.

I'd rather get an error code.

Most wideband manufacturers guarantee .1AFR. How do they expect you to check up on them? Klaus is the only guy I know with 3 welders bottles full of calibrated lab gases for various AFRs. When you check serveral WB meters against the known constant gasses, they often give different readings. Which one is right ? The one that matches the certificate on the gas bottle. done deal.

As for "self calibrated sensors", you are probably refering to the calibration resistor that is on each sensor. They are trimmed at the factory to nomalize the output of the sensors to a standardized value. This works great in an OEM application. In the tuner world, where sensors are run rich all the time, the sensor outputs drift. But the calibration resistor stays the same... If you re-trimmed the calibration resistor, everything would work great. But nobody does.

So, out of the box, a new sensor works great.

But...

If you were to take a well used sensor and AEM/PLX meter and bring them into Klaus's office and run them on the calibration gasses. Do you really think you would be within the "guaranteed" 0.1AFR ? I wouldn't bet on it. And they are betting you wont do it. And this would probably happen long before you noticed the sensor "slowing down". How slow is slow anyway ?

Without a known standard of measurement, it does not mater how many satisfied customers there are. All they can do is assume that the readings are correct. And since it's ALWAYS right when reading 14.7.... that's exactly what they do. Which is understandable.

Generally, the cars you mentioned are all set up to run pig rich. It does not really matter so much if they are running 9.7 or 10.6, etc. I tune Ferrari racing V12's. Thats 12 barrels of Weber carburettors. To get best power I have to tend twords the lean side of 13.0 That is a dangerous place to play. A rebuild of a 365TB/4 Daytona V12 will run about $30,000-$40,000. Just a gasket set is $1500. If an AEM, PLX, or Dynojet worked even a TINY BIT better than an LM-1, then I would use them. Brand loyalty doesn't count for allot when you are looking at shelling out $6000 just for a new V12 crankshaft or $2500 for new pistons and so on. Do you really think I would take the word of a sales guy on this ?

I don't trust any aftermarket wideband controller that relys on the sensor's calibration resistor. I know the chemistry, physics, electronics and the math that makes these things work. Right down to the Nernst equations. The sensors drift. The calibration resistors stay the same.

I also know what the circuitry in the Bosch controller chip is. I could make one from scratch out of parts from radioshack ( or at least digikey ). That ALL ANALOG circuit was designed for OEM applications. It was never meant to be run in an engine that spends allot of time at 12.0AFR or richer.

I bet if you asked Bosch to guarantee .1AFR under those conditions, they wouldn't do it. And if they won't, why would you believe it from someone using their parts?

Maybe some nice magazine will do a "wideband shoot-out" where we run the hell out of some sensors on the dyno, then test the meters against a calibrated gas standard. Maybe slip some lead fouled sensors in the mix

The main thing to understand is that a sensor that calibrates and gives a 14.7 reading in "free air" is not necessarily accurate at 12:1.

Here is an explanation from a guy that has been "an instrumentation engineer in the aerospace industry for over 20 years. I have a Ph.D. in applied mathematics and a M.S. in mechanical engineering. I take words like "calibration", "standard", and "characterized" very seriously ( even if I don't always spell them right ). They used to be life and death things for me. Literally. Annecdotal things like "this guy has XXX meter and he is happy" mean nothing to me. Calibrated standards, NBS certificates, chains of tracebility, and test procedures do."

The analog based wideband meters (AEM, PLX, et al ) may not be able to detect a damaged sensor and just go on giving bad data. How would they know ??? Any meter that uses the standard Bosch WB controller chipset does not analyze the sensor in real-time. They just go by the factory calibration resistor that comes on the sensor.

Which gives rise to...

Quote:

Why does the sensor have to calibrate for air and heat? No other widebands have to do that?

No other widebands can do that. If you don't calibrate the system, you are relying on the calibration resistor on the sensor that was set to match the sensor output at the factory. The sensors change over time ( especially when run rich ); often as little as a 3 or 4 hours. And then, the calibration is off. But how will you know ???? It will still always be accurate right at 14.7AFR so you can't check it that way.... But now 13.0 is really 11.9 ? 12.3 is really 14.0 ? How will you check it ? In OEM applications the sensor is almost always run at 14.7AFR; so it does not drift nearly as quickly as on a tuner car running 12.0AFR or richer.

Every time you do a re-calibrate of a sensor on an LM-1, it adjusts for any changes in the sensor over time. As long as it's not damaged, it is accurate like a new sensor again. And, in the process, it can detect damaged sensors, etc.

I wonder what would happen if you put a sensor with a damaged ( but not open or shorted ) or just aged pump-cell on an AEM meter ? It can't analyze the pump resistance... so it would assume all is well and give bogus data thinking that the calibration resistor info is still valid ????

I don't really know the answer to that. Maybe I should do an experiment

But if it does, and it shows 12.5 when the real AFR is 14.1, at WOT... Bad things are going to happen. Could be game over.

I'd rather get an error code.

Most wideband manufacturers guarantee .1AFR. How do they expect you to check up on them? Klaus is the only guy I know with 3 welders bottles full of calibrated lab gases for various AFRs. When you check serveral WB meters against the known constant gasses, they often give different readings. Which one is right ? The one that matches the certificate on the gas bottle. done deal.

As for "self calibrated sensors", you are probably refering to the calibration resistor that is on each sensor. They are trimmed at the factory to nomalize the output of the sensors to a standardized value. This works great in an OEM application. In the tuner world, where sensors are run rich all the time, the sensor outputs drift. But the calibration resistor stays the same... If you re-trimmed the calibration resistor, everything would work great. But nobody does.

So, out of the box, a new sensor works great.

But...

If you were to take a well used sensor and AEM/PLX meter and bring them into Klaus's office and run them on the calibration gasses. Do you really think you would be within the "guaranteed" 0.1AFR ? I wouldn't bet on it. And they are betting you wont do it. And this would probably happen long before you noticed the sensor "slowing down". How slow is slow anyway ?

Without a known standard of measurement, it does not mater how many satisfied customers there are. All they can do is assume that the readings are correct. And since it's ALWAYS right when reading 14.7.... that's exactly what they do. Which is understandable.

Generally, the cars you mentioned are all set up to run pig rich. It does not really matter so much if they are running 9.7 or 10.6, etc. I tune Ferrari racing V12's. Thats 12 barrels of Weber carburettors. To get best power I have to tend twords the lean side of 13.0 That is a dangerous place to play. A rebuild of a 365TB/4 Daytona V12 will run about $30,000-$40,000. Just a gasket set is $1500. If an AEM, PLX, or Dynojet worked even a TINY BIT better than an LM-1, then I would use them. Brand loyalty doesn't count for allot when you are looking at shelling out $6000 just for a new V12 crankshaft or $2500 for new pistons and so on. Do you really think I would take the word of a sales guy on this ?

I don't trust any aftermarket wideband controller that relys on the sensor's calibration resistor. I know the chemistry, physics, electronics and the math that makes these things work. Right down to the Nernst equations. The sensors drift. The calibration resistors stay the same.

I also know what the circuitry in the Bosch controller chip is. I could make one from scratch out of parts from radioshack ( or at least digikey ). That ALL ANALOG circuit was designed for OEM applications. It was never meant to be run in an engine that spends allot of time at 12.0AFR or richer.

I bet if you asked Bosch to guarantee .1AFR under those conditions, they wouldn't do it. And if they won't, why would you believe it from someone using their parts?

Maybe some nice magazine will do a "wideband shoot-out" where we run the hell out of some sensors on the dyno, then test the meters against a calibrated gas standard. Maybe slip some lead fouled sensors in the mix

#15

After a whole lot of reading I went with the Innovate unit. You may ask why? They all (mostly) use the same Bosch LSU4 sensor.

The main thing to understand is that a sensor that calibrates and gives a 14.7 reading in "free air" is not necessarily accurate at 12:1.

---etc---

The main thing to understand is that a sensor that calibrates and gives a 14.7 reading in "free air" is not necessarily accurate at 12:1.

---etc---

1. No wideband other than an Innovate can be trusted.

2. 9x % of drag racers made the wrong choice of widebands.

3. If not using Innovate products, you should calibrate often - perhaps on a dyno with their wideband?

This also leads to implying that all analog circuits reading A/F sensors are bogus, and can't be trusted - so most racers are in immediate danger of misreading their A/F ratios - except for Innovate products. ???

My opinion of the PLX R-300 is the same as before - it will work as designed and intended, within the limits of the sensor technology used. I should not trust this sensor any more than I do any other sensors in my car - trust, but verify.

I should change my motor oil, transmission oil, wideband sensor, and OEM O2 sensors on a scheduled basis - oh, I already do that.

A bargain is a bargain - and should be brought to the attention of forum members as a matter of obligation to the group. I can afford any instrumentation made for racing - I don't choose to spend my money that way, however.

Jime brought some expert advice to the table - and we always appreciate it - but I don't choose to take others' opinions as gospel. I reserve the right to blow up my engine in any way I see fit - and I've done that a time or three.

.

#16

#19

a little misleading in their description then dont you think?

"Introduction:

The R-300 is a compact, dash mountable, easy to use wideband air/fuel controller with powerful data logging capabilities. Wideband air/fuel ratio can be monitored in numeric, gauge or graphical form. Data logger inputs can be fully customized to display virtually ANY type of data. It's like combining 6 gauges into one! The R-300 can store up to 90 minutes of logged data and 99 individual sessions for later PC download and analysis with PLX Logger PC software. "

"Introduction:

The R-300 is a compact, dash mountable, easy to use wideband air/fuel controller with powerful data logging capabilities. Wideband air/fuel ratio can be monitored in numeric, gauge or graphical form. Data logger inputs can be fully customized to display virtually ANY type of data. It's like combining 6 gauges into one! The R-300 can store up to 90 minutes of logged data and 99 individual sessions for later PC download and analysis with PLX Logger PC software. "

#21

WOW - this long treatise on widebands is - interesting - but leads me to some conclusions.

1. No wideband other than an Innovate can be trusted.

2. 9x % of drag racers made the wrong choice of widebands.

3. If not using Innovate products, you should calibrate often - perhaps on a dyno with their wideband?

This also leads to implying that all analog circuits reading A/F sensors are bogus, and can't be trusted - so most racers are in immediate danger of misreading their A/F ratios - except for Innovate products. ???

My opinion of the PLX R-300 is the same as before - it will work as designed and intended, within the limits of the sensor technology used. I should not trust this sensor any more than I do any other sensors in my car - trust, but verify.

I should change my motor oil, transmission oil, wideband sensor, and OEM O2 sensors on a scheduled basis - oh, I already do that.

A bargain is a bargain - and should be brought to the attention of forum members as a matter of obligation to the group. I can afford any instrumentation made for racing - I don't choose to spend my money that way, however.

Jime brought some expert advice to the table - and we always appreciate it - but I don't choose to take others' opinions as gospel. I reserve the right to blow up my engine in any way I see fit - and I've done that a time or three.

.

1. No wideband other than an Innovate can be trusted.

2. 9x % of drag racers made the wrong choice of widebands.

3. If not using Innovate products, you should calibrate often - perhaps on a dyno with their wideband?

This also leads to implying that all analog circuits reading A/F sensors are bogus, and can't be trusted - so most racers are in immediate danger of misreading their A/F ratios - except for Innovate products. ???

My opinion of the PLX R-300 is the same as before - it will work as designed and intended, within the limits of the sensor technology used. I should not trust this sensor any more than I do any other sensors in my car - trust, but verify.

I should change my motor oil, transmission oil, wideband sensor, and OEM O2 sensors on a scheduled basis - oh, I already do that.

A bargain is a bargain - and should be brought to the attention of forum members as a matter of obligation to the group. I can afford any instrumentation made for racing - I don't choose to spend my money that way, however.

Jime brought some expert advice to the table - and we always appreciate it - but I don't choose to take others' opinions as gospel. I reserve the right to blow up my engine in any way I see fit - and I've done that a time or three.

.

The R-300 and R-500 are also being phased out so they are on sale.

I'm not asking you to believe any opinions, just facts.

Not trying to ruffle your feathers Harold, but you might give it a second look.

#23

I'll second Jime's comments.

I've seen the side-by-side testing done in multiple magazines (SCC, MotoIQ, and others), and almost all of them point to the same thing. even though they all use the same Bosch sensor, the response time and calibration can very greatly between one unit and another. there's more to it than just the sensor itself.

the Innovate stuff seems to have the best repeatability and long-term reliable readings of all of them. It's the only one I'd recommend using.

I've seen the side-by-side testing done in multiple magazines (SCC, MotoIQ, and others), and almost all of them point to the same thing. even though they all use the same Bosch sensor, the response time and calibration can very greatly between one unit and another. there's more to it than just the sensor itself.

the Innovate stuff seems to have the best repeatability and long-term reliable readings of all of them. It's the only one I'd recommend using.

#24

Oh yeah, and what Jime said...

#25

Btw, I don't think anyone is bashing you for this, I for one, am thankful for your posting of the good deal (although, I didn't buy it). The main thing being debated is the relative accuracy of PLX's (and other's) technology. And of course, everyone is entitled to an opinion.

#26

Like I said earlier:

"WOW - this long treatise on widebands is - interesting - but leads me to some conclusions.

1. No wideband other than an Innovate can be trusted.

2. 9x % of drag racers made the wrong choice of widebands."

Unless 9x % of drag racers use an Innovate wideband, of course....

"WOW - this long treatise on widebands is - interesting - but leads me to some conclusions.

1. No wideband other than an Innovate can be trusted.

2. 9x % of drag racers made the wrong choice of widebands."

Unless 9x % of drag racers use an Innovate wideband, of course....

#27

yeah thanks to grey99, no need to feel like we're comin down on you. its not like its YOUR product.

also, I know alot of you guys are picky, so I just want to make sure that the problem with this widebands accuracy is not just something tiny. I dont want to make a bad purchase but I also dont have an unlimited budget to where I can buy top notch parts all day long. definitely dont want to skimp on something important though.

also, I know alot of you guys are picky, so I just want to make sure that the problem with this widebands accuracy is not just something tiny. I dont want to make a bad purchase but I also dont have an unlimited budget to where I can buy top notch parts all day long. definitely dont want to skimp on something important though.

#33

IMHO...

If you're just doing the typical N/A setup with bolt ons and want to tune your AFR reasonably, then most of the popular WB's such as PLX, Zeitronix etc are fine.

If you are running a high-boost, highly tuned (or agressive tune) car that sees a lot of racing use, or if you're running a standalone then my choice is without question the LC-1.

If you're just doing the typical N/A setup with bolt ons and want to tune your AFR reasonably, then most of the popular WB's such as PLX, Zeitronix etc are fine.

If you are running a high-boost, highly tuned (or agressive tune) car that sees a lot of racing use, or if you're running a standalone then my choice is without question the LC-1.

#34

Originally Posted by PLXSupport_PL

All M-300, SM-AFR, R-500, R-300 essentially have the same technology. They're all identical in accuracy and performance.

Ony difference is that they're in a different form factor.

Ony difference is that they're in a different form factor.

#35

IMHO...

If you're just doing the typical N/A setup with bolt ons and want to tune your AFR reasonably, then most of the popular WB's such as PLX, Zeitronix etc are fine.

If you are running a high-boost, highly tuned (or agressive tune) car that sees a lot of racing use, or if you're running a standalone then my choice is without question the LC-1.

If you're just doing the typical N/A setup with bolt ons and want to tune your AFR reasonably, then most of the popular WB's such as PLX, Zeitronix etc are fine.

If you are running a high-boost, highly tuned (or agressive tune) car that sees a lot of racing use, or if you're running a standalone then my choice is without question the LC-1.

#38

Considering the LC-1 with sensor is $199 its a no brainer. Why pay more money for a wideband that can be off as much as 1.0. When its reading 13.0 it could be either 14.0 or 12.0. I don't care what you use your car for, even a DD thats just not good sense.

#39

what!!! where are you seeing that price?!

. . . .

. . . .

^^ It's not an AFC.

^^ It's not an AFC.