My Massive I30 Revival and Build Thread

#561

In other news, I replaced a blown out motor mount! Some guy here made these mounts something like 8 years ago....xyz_123 or something? I saw some poly dust around the mount over the winter, and knew it was on its way out. Sometime around May I found a decent chunk of poly in my driveway and knew I had to pretty much park the car. The mount was real bad, and made tons of noise. This was my PS mount by the PS fluid reservoir. I think a very slow PS fluid leak over the years killed the old mount.

Turns out krismax was getting ready to make a batch of poly mounts, so I paid him for an already made poly side mount. It looks nicely done! He kept most of the old stock rubber in the mount and poured poly around it, which I think is a good strategy. It looks like my current mounts are 100% poly....

This is what was left of the old one:

So I bolted the mount to the motor, but it was too low for the long through bolt to get started:

So I grabbed one of my 1" thick super rubber jack pads and my transmission jack and gently raised the engine up. The jack pad happened to be almost the exact size of the oil pan. When I started the top bolt, I could tell it wasn't grabbing right, so I took it back out and it brought with it some stripped out aluminum:

Or is that a heli-coil? Who knows. So I grabbed my tap/die kit, chased the threads, grabbed a longer bolt (the shiny silver one below) and it seemed to torque down fine, so I'm calling it fixed.

However, with the mount bolted to the motor, it was off to the DS a little bit, and I didn't see a way of bringing the whole engine over that much. Do I ratchet strap the intake manifold to my wheel and crank that thing down? What if I....pull the IM towards me? Oh, it moved! So I grabbed my wife and gave her a hammer, and told her to tap the long through bolt while I pull the IM over to the PS. It worked! It helped that my PS fender is off the car, so I could really lean on the frame to pull it.

See the nut in the bottom center in the picture above? It's pointing down, and it on the long stud. How do most people get that off? I couldn't get any of my wrenches or sockets in there with enough room to break it loose. The belt tensioner adjuster prevented me from much rotation. I had to get access from the bottom with a combination of extensions and wobbles to get it, and it was very tight, Certainly, there must be a better way?

Of course, with the old mount out, I had access to areas that hadn't been cleaned in a very long time, so I did a fair amount of cleaning around the mount. It's much nicer now! And with that, the repair was complete. I haven't driven the car yet since I'm still trying to figure out what I'm going to do about this water leak, but I'm excited to have a properly mounted engine for the first time in a long time! Thanks krismax for the mount!

Turns out krismax was getting ready to make a batch of poly mounts, so I paid him for an already made poly side mount. It looks nicely done! He kept most of the old stock rubber in the mount and poured poly around it, which I think is a good strategy. It looks like my current mounts are 100% poly....

This is what was left of the old one:

So I bolted the mount to the motor, but it was too low for the long through bolt to get started:

So I grabbed one of my 1" thick super rubber jack pads and my transmission jack and gently raised the engine up. The jack pad happened to be almost the exact size of the oil pan. When I started the top bolt, I could tell it wasn't grabbing right, so I took it back out and it brought with it some stripped out aluminum:

Or is that a heli-coil? Who knows. So I grabbed my tap/die kit, chased the threads, grabbed a longer bolt (the shiny silver one below) and it seemed to torque down fine, so I'm calling it fixed.

However, with the mount bolted to the motor, it was off to the DS a little bit, and I didn't see a way of bringing the whole engine over that much. Do I ratchet strap the intake manifold to my wheel and crank that thing down? What if I....pull the IM towards me? Oh, it moved! So I grabbed my wife and gave her a hammer, and told her to tap the long through bolt while I pull the IM over to the PS. It worked! It helped that my PS fender is off the car, so I could really lean on the frame to pull it.

See the nut in the bottom center in the picture above? It's pointing down, and it on the long stud. How do most people get that off? I couldn't get any of my wrenches or sockets in there with enough room to break it loose. The belt tensioner adjuster prevented me from much rotation. I had to get access from the bottom with a combination of extensions and wobbles to get it, and it was very tight, Certainly, there must be a better way?

Of course, with the old mount out, I had access to areas that hadn't been cleaned in a very long time, so I did a fair amount of cleaning around the mount. It's much nicer now! And with that, the repair was complete. I haven't driven the car yet since I'm still trying to figure out what I'm going to do about this water leak, but I'm excited to have a properly mounted engine for the first time in a long time! Thanks krismax for the mount!

Last edited by 95maxrider; 07-23-2019 at 06:16 PM.

#562

Turns out krismax was getting ready to make a batch of poly mounts, so I paid him for an already made poly side mount. It looks nicely done! He kept most of the old stock rubber in the mount and poured poly around it, which I think is a good strategy. It looks like my current mounts are 100% poly....

Norm

#563

See the nut in the bottom center in the picture above? It's pointing down, and it on the long stud. How do most people get that off? I couldn't get any of my wrenches or sockets in there with enough room to break it loose. The belt tensioner adjuster prevented me from much rotation. I had to get access from the bottom with a combination of extensions and wobbles to get it, and it was very tight, Certainly, there must be a better way?

Of course, with the old mount out, I had access to areas that hadn't been cleaned in a very long time, so I did a fair amount of cleaning around the mount. It's much nicer now! And with that, the repair was complete. I haven't driven the car yet since I'm still trying to figure out what I'm going to do about this water leak, but I'm excited to have a properly mounted engine for the first time in a long time! Thanks krismax for the mount!

#564

wow man !! i thought poly lasted for ever? so confused ! and yea i see krismax's mounts they look super nice ! i want to do mine but....am intimidated in the can of worms it would be even with the help of krismax doing them in adavnce (theory)

get that thing on the road ! i wanna hear your impression on the mounts =)

get that thing on the road ! i wanna hear your impression on the mounts =)

#565

Originally Posted by Norm Peterson

Thanks . . . there's got to be some way I can use this approach. Somewhere, sometime, on some car.

Originally Posted by schmellyfart

I will usually get that nut from the bottom with a few extensions or in the engine bay with a ratcheting box end wrench.

wow man !! i thought poly lasted for ever? so confused ! and yea i see krismax's mounts they look super nice ! i want to do mine but....am intimidated in the can of worms it would be even with the help of krismax doing them in adavnce (theory)

get that thing on the road ! i wanna hear your impression on the mounts =)

get that thing on the road ! i wanna hear your impression on the mounts =)

I've gone through numerous ES poly control arm bushings due to oil dripping on them.

I've gone through numerous ES poly control arm bushings due to oil dripping on them.In addition to trying to figure out what's up with this water leak, I've got MD emissions to deal with. 2 years just flies by! I put the stock ECU back in, and I now have to wait and see if those damn EGR and cat codes come back. I REALLY wish we had been able to install the Nistune on my stock ECU instead of a Maxima ECU, but the guy in Australia who got the ECU ready wasn't sure he could get the I30 ECU to work, so we went with a Maxima ECU. However, the Maxima ECU never finishes the readiness monitors for EGR and cats, plus one other that I forget, so I can't go through emissions with my Nistune/Maxima ECU. Arg!

I anticipate the car will feel just like it did before the mount failed, which is to say, pretty great! I suppose having some of the stock rubber left in the bushing could make it slightly softer than the old pure poly mount, but I don't think I'll be able to tell the difference.

#566

Ok, so I've pulled the dash, and I'm looking at the heater core and blower motor assembly:

I'm really hoping I can remove the blower motor (the white thing on the right) without removing the whole heater core (black part on the left). I'm really not trying to drain all my coolant and my AC lines. Does anyone know if it can be done? Without removing the blower motor, I can't get to any of the seams on the firewall. So close, but so far!

I would also like to remove the PS air bag, as I don't have one on the DS, which disables the PS one, so I might as well get rid of it. Except it seems to be "one piece" with the outer cover:

There are a bunch of bolts and four rivet things, but without the air bag's brackets, there's no way to properly reinstall just the cover. Does anyone know if this can be done, or if I just need to keep the air bag?

I'm really hoping I can remove the blower motor (the white thing on the right) without removing the whole heater core (black part on the left). I'm really not trying to drain all my coolant and my AC lines. Does anyone know if it can be done? Without removing the blower motor, I can't get to any of the seams on the firewall. So close, but so far!

I would also like to remove the PS air bag, as I don't have one on the DS, which disables the PS one, so I might as well get rid of it. Except it seems to be "one piece" with the outer cover:

There are a bunch of bolts and four rivet things, but without the air bag's brackets, there's no way to properly reinstall just the cover. Does anyone know if this can be done, or if I just need to keep the air bag?

#568

Well I got the blower motor out without removing the AC evaporator in the black box to its left! I was under the impression that the black box housed both AC and heater stuff, but upon looking at the lines from the engine bay, it became clear that the black box only held AC stuff. The main blower assembly in the center is what houses the heater stuff I guess. I do have the ability to recharge the AC, but it's not something I'm very good at, and I didn't feel great about venting my whole system to the atmosphere. So I hoped and prayed that I would find a quick and simple way to get out the blower by itself. I went back into the garage this morning pretty worried about what the day had in store. I had the idea that I might want to trim off some plastic from the black box to give me enough room to slide out the blower. I was in there looking at it, and noticed that one of the sides for the black AC box was pretty flimsy. With almost no effort, I was able to snap off a good piece of it. I then followed up with my snips, and with that little bit of plastic out of the way, I could get the blower out! It was a joyous moment to be sure. Here's what I did:

That little bit of plastic was all that was keeping me from getting the blower out!

As this out of focus picture shows, there was a good amount of debris in the evaporator housing:

So I spent some time with different picks and my shop vac and cleaned it all out:

The blower was actually very clean:

So I was then left with this:

But there was still the factory insulation in the way. I ended up just cutting off a piece so I could get easy access to where I thought the leak was (I'll reinstall properly when I'm all done). And with that, I was FINALLY able to see the source of my water leak:

It's not in the exact same spot as the pics from schmellyfart, but it's not far, maybe 2" away. It's clear that this area has a few body panels coming together, and it's also right next to the drain for the cowl, so being sealed properly is crucial. If you have a water leak in a 4th gen, I wouldn't be surprised to find it's in this area! You can see three water trails coming down from that area, so I'm very confident this was my problem.

I spent quite a bit of time with different wire wheels, both on my big gun and little ones on my dremel, trying to peel back the old seam sealer so I could get a better look at exactly where the water is coming in.

It doesn't really come through in the picture, but the horizontal area just right of center is actually completely open now. I had to scrape the old seam sealer out of it with a screwdriver, because I didn't want any of that old cracked stuff getting in the way of my fresh seam sealer. Now I'll be able to completely refill the gap with new sealer. Access into this area was pretty awkward, and my back was aching after a few hours in there, but I think I'm happy with how clean I was able to get it. When I finally couldn't get it any cleaner, it was time to prep the surface for the seam sealer:

This stuff is SUPER strong, and has tons of warnings all over it. I go full-hazmat when I use this stuff, but professional painters swear by it, so I grit my teeth and bear it. I was considering applying the seam sealer today, but then I thought about it more and realized I would feel much better about it if I bought a new tube of it. My current tube is a few years old, and since I couldn't get a firm answer on its shelf life, I decided I would rather spend another $20 on new sealer than to have my current sealer fail because it was too old and didn't adhere properly. It should be here on Tuesday, so I'll continue after that. But for now I'm feeling pretty damn good that I was able to get the blower out by itself without ruining anything!

I'm left with this to look at, and ponder how many things I'm going to forget to reinstall, or reinstall in the wrong order. I'm not out of the woods yet!

That little bit of plastic was all that was keeping me from getting the blower out!

As this out of focus picture shows, there was a good amount of debris in the evaporator housing:

So I spent some time with different picks and my shop vac and cleaned it all out:

The blower was actually very clean:

So I was then left with this:

But there was still the factory insulation in the way. I ended up just cutting off a piece so I could get easy access to where I thought the leak was (I'll reinstall properly when I'm all done). And with that, I was FINALLY able to see the source of my water leak:

It's not in the exact same spot as the pics from schmellyfart, but it's not far, maybe 2" away. It's clear that this area has a few body panels coming together, and it's also right next to the drain for the cowl, so being sealed properly is crucial. If you have a water leak in a 4th gen, I wouldn't be surprised to find it's in this area! You can see three water trails coming down from that area, so I'm very confident this was my problem.

I spent quite a bit of time with different wire wheels, both on my big gun and little ones on my dremel, trying to peel back the old seam sealer so I could get a better look at exactly where the water is coming in.

It doesn't really come through in the picture, but the horizontal area just right of center is actually completely open now. I had to scrape the old seam sealer out of it with a screwdriver, because I didn't want any of that old cracked stuff getting in the way of my fresh seam sealer. Now I'll be able to completely refill the gap with new sealer. Access into this area was pretty awkward, and my back was aching after a few hours in there, but I think I'm happy with how clean I was able to get it. When I finally couldn't get it any cleaner, it was time to prep the surface for the seam sealer:

This stuff is SUPER strong, and has tons of warnings all over it. I go full-hazmat when I use this stuff, but professional painters swear by it, so I grit my teeth and bear it. I was considering applying the seam sealer today, but then I thought about it more and realized I would feel much better about it if I bought a new tube of it. My current tube is a few years old, and since I couldn't get a firm answer on its shelf life, I decided I would rather spend another $20 on new sealer than to have my current sealer fail because it was too old and didn't adhere properly. It should be here on Tuesday, so I'll continue after that. But for now I'm feeling pretty damn good that I was able to get the blower out by itself without ruining anything!

I'm left with this to look at, and ponder how many things I'm going to forget to reinstall, or reinstall in the wrong order. I'm not out of the woods yet!

#569

It's fun stuff, the **** we go though to save an old friend.

What kind of seam sealer did you buy? I've used a few different brands, not sure if I've really noticed a difference. Last tube was cheap stuff from Auto Zone.

What kind of seam sealer did you buy? I've used a few different brands, not sure if I've really noticed a difference. Last tube was cheap stuff from Auto Zone.

#570

Heh, it sure keeps me busy! It's all worth it though. I bought some 3M Dynatron 550 Auto Seam Sealer Grey Caulk - 12 oz.

#573

#574

This stuff is meant to be applied once .

Cavity wax is petroleum based,with other things.

#575

#577

I watched an informative video last night about corrosion protection:

There's lots of good info in there, I'm glad I watched it. I'm also glad I didn't rush to apply seam sealer, I realized I should put down some primer or POR15 first. According to the video, around the 10 minute mark, they discuss the four different types of primers, and how normal rattle can primers (1K) and etch primers have pretty much no place in auto body repair. The two types of acceptable primers are 2K and weld through. The 3M Dynatron seam sealer can be applied over bare metal or on a painted surface, so I think some POR15 will help give me that little bit of extra protection.

Around 1 hour 3 minutes into the video, they discuss which types of seam sealers can be applied over various surfaces. Apparently you CAN NOT apply seam sealer over any etch, 1K, or weld through primers. The only type of primer you can apply seam sealer over is 2K. I think I have a can of 2K primer, but since it must be used within 24 hours of opening, and I'm only spraying a 3"x3" section, I'm not sure I want to waste a whole can of 2K primer on that. Hence, the cheaper and possible more effective POR15.

So here's what I'm thinking I'm going to do:

Prepare the bare metal with POR15 prep products.

Apply POR15 paint (3 coats) to bare metal on inside of car.

Let it cure for a few days, then scuff the surface. Use more of my Prep-All surface cleaner.

Apply seam sealer from the inside, trying to push as much through the seam as possible.

Spray 3M cavity wax into outside of area from the cowl area. This will be a day after the seam sealer so it can cure fully.

Am I missing anything?

There's lots of good info in there, I'm glad I watched it. I'm also glad I didn't rush to apply seam sealer, I realized I should put down some primer or POR15 first. According to the video, around the 10 minute mark, they discuss the four different types of primers, and how normal rattle can primers (1K) and etch primers have pretty much no place in auto body repair. The two types of acceptable primers are 2K and weld through. The 3M Dynatron seam sealer can be applied over bare metal or on a painted surface, so I think some POR15 will help give me that little bit of extra protection.

Around 1 hour 3 minutes into the video, they discuss which types of seam sealers can be applied over various surfaces. Apparently you CAN NOT apply seam sealer over any etch, 1K, or weld through primers. The only type of primer you can apply seam sealer over is 2K. I think I have a can of 2K primer, but since it must be used within 24 hours of opening, and I'm only spraying a 3"x3" section, I'm not sure I want to waste a whole can of 2K primer on that. Hence, the cheaper and possible more effective POR15.

So here's what I'm thinking I'm going to do:

Prepare the bare metal with POR15 prep products.

Apply POR15 paint (3 coats) to bare metal on inside of car.

Let it cure for a few days, then scuff the surface. Use more of my Prep-All surface cleaner.

Apply seam sealer from the inside, trying to push as much through the seam as possible.

Spray 3M cavity wax into outside of area from the cowl area. This will be a day after the seam sealer so it can cure fully.

Am I missing anything?

#579

I watched an informative video last night about corrosion protection:

https://www.youtube.com/watch?v=eceOg7ifmIs

There's lots of good info in there, I'm glad I watched it. I'm also glad I didn't rush to apply seam sealer, I realized I should put down some primer or POR15 first. According to the video, around the 10 minute mark, they discuss the four different types of primers, and how normal rattle can primers (1K) and etch primers have pretty much no place in auto body repair. The two types of acceptable primers are 2K and weld through. The 3M Dynatron seam sealer can be applied over bare metal or on a painted surface, so I think some POR15 will help give me that little bit of extra protection.

Around 1 hour 3 minutes into the video, they discuss which types of seam sealers can be applied over various surfaces. Apparently you CAN NOT apply seam sealer over any etch, 1K, or weld through primers. The only type of primer you can apply seam sealer over is 2K. I think I have a can of 2K primer, but since it must be used within 24 hours of opening, and I'm only spraying a 3"x3" section, I'm not sure I want to waste a whole can of 2K primer on that. Hence, the cheaper and possible more effective POR15.

So here's what I'm thinking I'm going to do:

Prepare the bare metal with POR15 prep products.

Apply POR15 paint (3 coats) to bare metal on inside of car.

Let it cure for a few days, then scuff the surface. Use more of my Prep-All surface cleaner.

Apply seam sealer from the inside, trying to push as much through the seam as possible.

Spray 3M cavity wax into outside of area from the cowl area. This will be a day after the seam sealer so it can cure fully.

Am I missing anything?

https://www.youtube.com/watch?v=eceOg7ifmIs

There's lots of good info in there, I'm glad I watched it. I'm also glad I didn't rush to apply seam sealer, I realized I should put down some primer or POR15 first. According to the video, around the 10 minute mark, they discuss the four different types of primers, and how normal rattle can primers (1K) and etch primers have pretty much no place in auto body repair. The two types of acceptable primers are 2K and weld through. The 3M Dynatron seam sealer can be applied over bare metal or on a painted surface, so I think some POR15 will help give me that little bit of extra protection.

Around 1 hour 3 minutes into the video, they discuss which types of seam sealers can be applied over various surfaces. Apparently you CAN NOT apply seam sealer over any etch, 1K, or weld through primers. The only type of primer you can apply seam sealer over is 2K. I think I have a can of 2K primer, but since it must be used within 24 hours of opening, and I'm only spraying a 3"x3" section, I'm not sure I want to waste a whole can of 2K primer on that. Hence, the cheaper and possible more effective POR15.

So here's what I'm thinking I'm going to do:

Prepare the bare metal with POR15 prep products.

Apply POR15 paint (3 coats) to bare metal on inside of car.

Let it cure for a few days, then scuff the surface. Use more of my Prep-All surface cleaner.

Apply seam sealer from the inside, trying to push as much through the seam as possible.

Spray 3M cavity wax into outside of area from the cowl area. This will be a day after the seam sealer so it can cure fully.

Am I missing anything?

Try not to make a pool with the resin.

Make sure its bone dry before using the resin. I would use a torch to dry the area.I think if you want to you can use primer before the resin.

If you like you can do this procedure with POR 15.Myself when i did it i used some POR 15 first then the resin.

I have pictures of my I30 getting a full cavity wax plus treatment ,with Pictures. I'll try to put it up in a day or two.In my thread i'll say the cheapest place to get it.

Last edited by krismax; 08-08-2019 at 10:20 PM.

#580

get some 3M fiberglass resin (it's waterproof) in through the back side try to get it to leak through. Using Daubers, then use some fiber glass mat on it. Clean a bigger area ,and soak the mat,100% with resin and attach to the bare clean metal,on the inside.

Try not to make a pool with the resin.

Make sure its bone dry before using the resin. I would use a torch to dry the area.I think if you want to you can use primer before the resin.

If you like you can do this procedure with POR 15.Myself when i did it i used some POR 15 first then the resin.

I have pictures of my I30 getting a full cavity wax plus treatment ,with Pictures. I'll try to put it up in a day or two.In my thread i'll say the cheapest place to get it.

Try not to make a pool with the resin.

Make sure its bone dry before using the resin. I would use a torch to dry the area.I think if you want to you can use primer before the resin.

If you like you can do this procedure with POR 15.Myself when i did it i used some POR 15 first then the resin.

I have pictures of my I30 getting a full cavity wax plus treatment ,with Pictures. I'll try to put it up in a day or two.In my thread i'll say the cheapest place to get it.

#581

Time for an update!

So as I was digging around the car, I noticed some rust on the DS floor that appeared to match some rust on the PS floor. Here's the PS, right where the leak dripped down to and pooled.

But when I saw very similar rust on the DS, I knew that I had to investigate further. There's no way I'm doing this job twice, so as badly as I didn't want to dig into the DS, I knew that I had to.

To reach the equivalent leaking area on the DS, I would have to remove all sorts of important and scary-looking wires. I tried to get some extra space by cutting out some of the factory rubber insulation like I did on the PS. Not good enough. I unbolted the wiring harnesses, but they barely moved. I knew that if I tried to remove them from the car, I would be stripping the car to the bare shell. I decided to attempt the repair with poor access.

In that last picture, you can kind of see a little bubble of something back there. Well, I spent a long time with my boroscope and my small mirrors/flashlights trying to figure out exactly what I was dealing with. It's a pretty cheap scope, but when I could get the damn thing to stay in focus in those tight conditions, it looked like there was some rust bubbling going on. But how could I access it? I ended up using my longest screwdriver and a hammer to knock the old seam sealer out. It was not pretty.

I did some more cleaning to the PS as well. You can see the holes between the panels where I knocked the old stuff out.

Time for POR15!

DS:

PS after being painted and scuffed up in prep for seam sealer:

I got some fresh seam sealer, and it came in new packaging:

DS:

PS:

I haven't water tested the car yet because I wanted to spray the 3M cavity wax plus in there first, and it took a while to get here. Then I started thinking about the DS of the car. Maybe I should take off the DS fender and see what's going on in there? So I pull the DS fender and find even more junk trapped up in the cowl/fender area on that side.

I want that area to be able to drain water real quick, and this old debris was surely slowing that down. So I brought out my old bendy metal wire and got to poking around and agitating the dirt while my shop vac sucked away from the other side.

There was a razor blade in there....

There was even debris down in the front of the fender that I vacuumed out:

So as I was digging around the car, I noticed some rust on the DS floor that appeared to match some rust on the PS floor. Here's the PS, right where the leak dripped down to and pooled.

But when I saw very similar rust on the DS, I knew that I had to investigate further. There's no way I'm doing this job twice, so as badly as I didn't want to dig into the DS, I knew that I had to.

To reach the equivalent leaking area on the DS, I would have to remove all sorts of important and scary-looking wires. I tried to get some extra space by cutting out some of the factory rubber insulation like I did on the PS. Not good enough. I unbolted the wiring harnesses, but they barely moved. I knew that if I tried to remove them from the car, I would be stripping the car to the bare shell. I decided to attempt the repair with poor access.

In that last picture, you can kind of see a little bubble of something back there. Well, I spent a long time with my boroscope and my small mirrors/flashlights trying to figure out exactly what I was dealing with. It's a pretty cheap scope, but when I could get the damn thing to stay in focus in those tight conditions, it looked like there was some rust bubbling going on. But how could I access it? I ended up using my longest screwdriver and a hammer to knock the old seam sealer out. It was not pretty.

I did some more cleaning to the PS as well. You can see the holes between the panels where I knocked the old stuff out.

Time for POR15!

DS:

PS after being painted and scuffed up in prep for seam sealer:

I got some fresh seam sealer, and it came in new packaging:

DS:

PS:

I haven't water tested the car yet because I wanted to spray the 3M cavity wax plus in there first, and it took a while to get here. Then I started thinking about the DS of the car. Maybe I should take off the DS fender and see what's going on in there? So I pull the DS fender and find even more junk trapped up in the cowl/fender area on that side.

I want that area to be able to drain water real quick, and this old debris was surely slowing that down. So I brought out my old bendy metal wire and got to poking around and agitating the dirt while my shop vac sucked away from the other side.

There was a razor blade in there....

There was even debris down in the front of the fender that I vacuumed out:

Last edited by 95maxrider; 08-21-2019 at 06:01 PM.

#582

Then we get to the DS fender brace:

It has more surface rust than the PS does. After watching the video (above) I now know that if you weld something that was once coated on the other side, that will burn off and you lose your rust protection, so the back of your welds will rust. I was just barely able to get a glace of the inside of my fender braces by looking into the fender from the front, and sure enough it was rusty. I think the only thing I can do is to spray the cavity wax all over it and hope it doesn't get any worse. As for the fender braces, I'm thinking they may need a coat of POR15. I'm looking to get any feedback from you guys to help me do all this stuff in the best way possible, so please say something if I'm doing it wrong or poorly.

It has more surface rust than the PS does. After watching the video (above) I now know that if you weld something that was once coated on the other side, that will burn off and you lose your rust protection, so the back of your welds will rust. I was just barely able to get a glace of the inside of my fender braces by looking into the fender from the front, and sure enough it was rusty. I think the only thing I can do is to spray the cavity wax all over it and hope it doesn't get any worse. As for the fender braces, I'm thinking they may need a coat of POR15. I'm looking to get any feedback from you guys to help me do all this stuff in the best way possible, so please say something if I'm doing it wrong or poorly.

#583

I took krismax's advice and bought some 3M Cavity Wax Plus.

I also bought the kit that comes with three different length spray wands/hoses. The two longer ones have a special tip at the end that allows them to spray 360*, which is very useful in tight/enclosed spaces.

Since the hoses had been bent up in their bag, I had to find a way to make them straight and usable, so I grabbed my trusty piece of bendy metal wire and taped it in place.

I taped off most holes, and then just started spraying this stuff in all over the place. From here:

And here:

Even here:

Until the car starts doing stuff like this:

The inside of the fender looked like this when I was done:

I tested out the properties of the CWP and it's pretty cool. It sprays out a little thin and seems watery at first, but it does cling to vertical painted surfaces (I used an old hood). You can wipe it away easily with your finger. However, if you wait something like 12-24 hours, it hardens up and really turns waxy. I ran my finger over it again and none came up, it was very much stuck to and coating the panel. You can get it to come up if you press a little harder, but that's to be expected. The following day when it was cured I sprayed it with the garden hose at high pressure and it didn't budge. I then hit it with my heat gun set to high from 8", and while it melted, it did not run down the vertical surface, it stayed in place. That's pretty cool! The application of the CWP was a breeze, and it sure looks like it will be effective at keeping moisture off a surface. I look forward to doing other parts of the car(s).

Unfortunately, the application of POR15 is not nearly as carefree, so I'll get to that in another post.

I also bought the kit that comes with three different length spray wands/hoses. The two longer ones have a special tip at the end that allows them to spray 360*, which is very useful in tight/enclosed spaces.

Since the hoses had been bent up in their bag, I had to find a way to make them straight and usable, so I grabbed my trusty piece of bendy metal wire and taped it in place.

I taped off most holes, and then just started spraying this stuff in all over the place. From here:

And here:

Even here:

Until the car starts doing stuff like this:

The inside of the fender looked like this when I was done:

I tested out the properties of the CWP and it's pretty cool. It sprays out a little thin and seems watery at first, but it does cling to vertical painted surfaces (I used an old hood). You can wipe it away easily with your finger. However, if you wait something like 12-24 hours, it hardens up and really turns waxy. I ran my finger over it again and none came up, it was very much stuck to and coating the panel. You can get it to come up if you press a little harder, but that's to be expected. The following day when it was cured I sprayed it with the garden hose at high pressure and it didn't budge. I then hit it with my heat gun set to high from 8", and while it melted, it did not run down the vertical surface, it stayed in place. That's pretty cool! The application of the CWP was a breeze, and it sure looks like it will be effective at keeping moisture off a surface. I look forward to doing other parts of the car(s).

Unfortunately, the application of POR15 is not nearly as carefree, so I'll get to that in another post.

#584

After taking the fenders off the car, I was forced to confront something that I didn't plan on doing with this job. My pinch welds have been in bad shape for a long time. They're not too rusty, but they were bent to hell and folded over in a few spots. When I got the fenders off I couldn't help but try to fix the newly exposed pinch welds that have been hidden behind the fender. But then I kept going further back on the car. And when I made them "straight" it took a lot of the paint off, and I'm not about to go driving around with bare metal pinch welds, so obviously I had to paint them. But I don't want to do half the pinch welds now, and the other half later, I want them all done together, and I want them done now! Crap. I just delayed this project another few weeks....I'll start with the driver's side.

The rear of the car wasn't bad at all:

But the front was another story.

It was very bent.

So I made it better.

There was also some surface rust on the body inside the pinch welds:

There was also a mysterious bump/buckle on both sides of the car in roughly the same place. I wonder if this is frame damage from the speedbump incident a few years back....to try and reduce the bump I gently used my jack to push it straight, and probably made it 50% better. This is the before shot.

To straighten everything else out, I used a few different vice grips, plus a hammer and a little 8" extension to tap with. Some parts really were folded flat and had to be pried open with a screwdriver since I couldn't get the vice grip in that non-existent space. I would set the vice grips as tight as possible, then make them clamp any place that the pinch welds weren't straight or touching. I would then follow up with the hammer and bit to do the finishing touches. I'm very pleased with how it came out!

And since I was gonna be right there, I just had to take care of the rusty bits inside the pinch welds. I used a combination of little wire cleaners on my Dremel to take care of the rust in tight areas. POR15 (paint over rust) says I don't have to get up the rust, but I think it's recommended for the most perfect results.

Once it was all good enough, it was time for the POR15. It's a PITA to do both of the prep products properly, but I only want to do this once, so I try to follow the instructions.

Nice and glossy! I did three coats of the stuff.

Phew! Now let's see how the passenger side turned out.

The rear of the car wasn't bad at all:

But the front was another story.

It was very bent.

So I made it better.

There was also some surface rust on the body inside the pinch welds:

There was also a mysterious bump/buckle on both sides of the car in roughly the same place. I wonder if this is frame damage from the speedbump incident a few years back....to try and reduce the bump I gently used my jack to push it straight, and probably made it 50% better. This is the before shot.

To straighten everything else out, I used a few different vice grips, plus a hammer and a little 8" extension to tap with. Some parts really were folded flat and had to be pried open with a screwdriver since I couldn't get the vice grip in that non-existent space. I would set the vice grips as tight as possible, then make them clamp any place that the pinch welds weren't straight or touching. I would then follow up with the hammer and bit to do the finishing touches. I'm very pleased with how it came out!

And since I was gonna be right there, I just had to take care of the rusty bits inside the pinch welds. I used a combination of little wire cleaners on my Dremel to take care of the rust in tight areas. POR15 (paint over rust) says I don't have to get up the rust, but I think it's recommended for the most perfect results.

Once it was all good enough, it was time for the POR15. It's a PITA to do both of the prep products properly, but I only want to do this once, so I try to follow the instructions.

Nice and glossy! I did three coats of the stuff.

Phew! Now let's see how the passenger side turned out.

#585

Less talking, more pictures! Here's the passenger's side.

I had to get the car off the lift to do this job! The front was pretty jacked up, and I had already done quite a bit to it:

Here's the rear:

Got things straight enough:

Had to clean up the fender braces:

Good as new!

I had to get the car off the lift to do this job! The front was pretty jacked up, and I had already done quite a bit to it:

Here's the rear:

Got things straight enough:

Had to clean up the fender braces:

Good as new!

#586

The fenders needed some help too. I saw how the fenders rusted on my 3rd gen, there's no way I'm gonna let that happen to my I30!

Cleaned them up:

Cleaned them up:

Last edited by 95maxrider; 09-04-2019 at 04:50 PM.

#587

This is great stuff. The wax is something we should have done 50 years ago. I just straightened my pinch welds too. My car looks similar underneath. My fenders look perfect inside though.

What brand SFCs do you have? What about your rear trailing arm bushings? This thread is too long to search through damn it.

What brand SFCs do you have? What about your rear trailing arm bushings? This thread is too long to search through damn it.

#588

This is great stuff. The wax is something we should have done 50 years ago. I just straightened my pinch welds too. My car looks similar underneath. My fenders look perfect inside though.

What brand SFCs do you have? What about your rear trailing arm bushings? This thread is too long to search through damn it.

What brand SFCs do you have? What about your rear trailing arm bushings? This thread is too long to search through damn it.

#589

Yeah, I don't know what the previous owner did to the rockers. I thought it was a bad tech putting it up on a lift wrong.

I have the same SFCs and bushings to be installed. I'm very much in the air on installing the connectors. You think it's worth it? I have a welder but I hate welding upside down.

I have the same SFCs and bushings to be installed. I'm very much in the air on installing the connectors. You think it's worth it? I have a welder but I hate welding upside down.

#590

Yeah, I don't know what the previous owner did to the rockers. I thought it was a bad tech putting it up on a lift wrong.

I have the same SFCs and bushings to be installed. I'm very much in the air on installing the connectors. You think it's worth it? I have a welder but I hate welding upside down.

I have the same SFCs and bushings to be installed. I'm very much in the air on installing the connectors. You think it's worth it? I have a welder but I hate welding upside down.

#591

Norm

#593

Not much to report, the car is still chugging along. I made some time for it and gave it a proper detail a few months ago and got some nice pictures of it. But before I post those up, I feel like posting up a complete mod list of the car, along with some of the maintenance history. I've owned this car since 2003, and a lot has happened since then. I usually took pretty good notes of maintenance projects, or posted up about them, but there were still some gaps. It took a while to piece this all back together, and I still think I'm missing info about at least one more failed transmission, but I can't find any documentation to back up my suspicions. With that said, I present to you my 2020 mod and maintenance list!

Engine/Trans

-2002/03 Maxima 3.5 motor, no SS IM mod

-K&N filter, velocity stack

-2001/02 Pathfinder 70mm TB

-Custom PFTB adapter and throttle cable bracket from sicivic89

-Custom PFTB IACV block off plate from sicivic89

-NWP thermal intake manifold spacers

-NWP Block off plate

-Oil catch can

-Nistune ECU, 7k RPM rev-limit

-Cattman headers

-OEM cat

-2.5” resonated b-pipe

-Cattman muffler

-Aeromotive adjustable fuel pressure regulator

-Quaife differential in rebuilt/refreshed transmission

-Spare Nissan re-manufactured VLSD transmission that had gears and shifting mechanisms deburred, shot peened, and cryo treated, roughly 15k miles from new

-2000/01 DE-K Maxima OEM clutch and flywheel

-Poly shifter bushing

-97-99 Maxima shifter with 1” cut out from center and welded back together

-Sola Luna weighted aluminum shift ****

-Custom aluminum radiator brackets

-Put down 210 whp on old DE-K motor, about 250 whp on 3.5

Suspension

-BC Racing coilovers 9k front, 8k rear and valved to match dampers

-2.5* camber front (maxed out camber bolts), custom 4.7* caster (up from 2.2* stock, drilled new holes in front strut towers, rotated coilovers 90*), 0.1* toe out

-Corner balanced, 60.0% F, 40.0% R, 50/50 left to right

-3,130 lbs w/full tank of gas, empty trunk, full interior

-2J Racing converted the Scott-Russel linkage to a panhard rod rear suspension

-New panhard rod from Speedway Motors with PTFE-lined rod ends

-Progress RSB at max stiff

-Energy Suspension poly bushings for sway bar frame mounts (7.5118G), sway bar end links (9.8106G), control arms (7.3111G), cross member (7.1116G), and F&R motor mounts (7.1114G)

-Poly side/trans mounts

-Delrin front subframe bushings/collars

-Super Pro poly rear trailing arm bushings

-Moog control arms (better welds than stock)

Current Alignment:

-2.4* camber

+4.7* caster

-0.10* toe out

Brakes

-Wilwood 4 piston front calipers with 12.9” 2-piece rotors w/Wilwood Polymatrix E pads

-Fastbrakes 12.3” rear BBK (redrilled Accord rotors) with stock calipers and Carbotech AX-6 pads

-Track pads are Carbotech XP-8

-SS lines

-ATE DOT-4 fluid

Chassis

-Warpspeed Stage 1+2 Subframe connectors (welded)

-Custom fender braces, welded to chassis

-Stillen RSTB (Stillen front won't fit over 3.5 IM)

-No sunroof (stock)

-97-99 Maxima SE steering rack, B15 SE-R rack on shelf

-NWP engine torque link (not currently in use)

-Aluminum steering column bushing

-Relocated battery to trunk, 0-gauge wire

-95 Maxima aluminum front bumper support (-30 lbs)

-Rolled front fenders, rolled and slightly pulled rear fenders

Cooling

-Mishimoto radiator w/19 psi cap, Toyota red coolant

-Racer Parts Wholesale 24 row oil cooler with -10 AN lines

-Derale power steering cooler

Other Fluids

-Motul 8100 X-cess 5w-40 engine oil

-Amsoil 75w-90 MT fluid

Exterior

-The Retrofit Source FX-R 3” V3 projectors w/ 4.3k HID bulbs in Cefiro headlights with E55 shrouds

-TRS Blazer fog light projectors, 3k HID bulbs, independent fog light rewire mod

-All front lighting housings blacked out

-Painted grille vertical slats black

-Removed three vertical bars from lower bumper grille, filled, sanded, painted

-350Z horns

-Garage door front lip

-Nissan Murano windshield washer nozzles

-Black OEM mirrors

-35% tint

-All chrome window trim blacked out (temporarily removed)

-I30t spoiler

-Debadged trunk

-1998/99 I30 tail lights (heated up with heat gun, pressed center section together to fix common leak issue)

-All original paint (except spoiler and some touch up work on bumpers)

Interior

-Recaro Speed seat w/gray alcantara center section, CG Lock for seat belt

-Gunmetal aluminum dash trim from Shadow (old Org member), matching aluminum lower door panels

-Stock light gray leather (less than 5% of A32s?)

-Sparco L505 steering wheel

-350Z aluminum pedals, dead pedal

-Custom gray alcantara door panels

-Matching gray alcantara shift boots w/black stitching by Redline Goods

-Redline Goods black leather arm rest with some extra foam cushion inside

-Techtom MDM-100 (Set to display speed and water temp since the smaller steering wheel cuts off view of 20-120 mph)

-95/96 Maxima SE gauge cluster, gunmetal aluminum gauge rings

-Innovate Motorsports LC-2 Wideband O2 Sensor

-Innovate Motorsports MTX-D Oil Pressure & Oil Temperature Gauge

-99 I30 Limited aluminum door sill/scuff plates

-Most interior lights are white LEDs (Gauge cluster, door switches, HVAC display)

-97-99 Maxima center console with flip-over cup holder

-Fuzzy pillars (stock)

-Replaced cracking chrome interior door handles

Stereo

-Pioneer DEH-80PRS head unit (5V pre-out)

-Focal P165V15 6.5” component front speakers

-Hertz DCX 165 co-axial rear speakers

-Carstereoadapters.com PVC custom speaker adapters

-12” JL W6 subwoofer, Sonic Electronix 1.15 ft3 sealed box

-Boston Acoustics GT2 (125w RMS x 2 for front speakers) with 4 AWG OFC wire

-Alpine MRP-M500 (500w x 1 for sub) with 4 AWG OFC wire

-Clifford RS3.5 alarm with remote start

-MDF trunk floor with bracket to hold sub box in place

-14 AWG oxygen-free copper (OFC) speaker wire to speakers

-12 AWG oxygen-free copper (OFC) speaker wire to sub

-E-Dead sound deadening in the trunk, front doors and rear deck

-Frost King insulation in the front doors and other areas

-E-Dead sound deadening on front fender liners

Wheels/tires

-17x8 Enkei RPM2 +35 with 235/45/17 Michelin Pilot Sport 4S

-17x8.5 Enkei RPF1 +40 with 245/40/17 Hoosier A6

-ARP extended wheel studs

-2J Racing 10mm front, 15mm rear wheel spacers

Interesting Maintenance

-Replaced windshield

-Replaced radiator core support

-Touch up paint to bumpers

-DS front door hinges replaced due to door sagging

-Straightened and painted pinch welds

-Removed dash to repair cracked seam sealer at the base of the A pillar, fixing water leak into cabin

-3M Cavity Wax Plus inside the upper frame area behind the fenders and around the base of the windshield where water drains are located

-Replaced front door lock actuators, fixing haunted/wonky door lock action

-POR15 on pinch welds, fender braces, engine crossmember, and motor mount brackets

Old Interesting Parts

-Delrin CAB- too noisy, not enough benefit

-2JR bumpsteer kit- too noisy, not enough benefit

-Traction bars- didn't do much

-BlehmCo stage 2 lower tie bar- didn't clear headers

-Shortened Koni Yellows courtesy of JSutter

-Ben's rear strut mounts

-JWT ECU with nitrous daughterboard (65 shot)

-“Big 3” 0-gauge wire upgrade (partially removed at this point)

General timeline

Purchased- January 2003 with 82,000 miles

SFCs- Spring 2003

KYB AGX/H&Rs- Summer 2003

Original trans (#1) died, lost 1st and 2nd gear out of the blue, trans #2 installed (Phoenix Remanufactured Transmissions/PRT )- Summer 2003

Spec stage 2 clutch installed with resurfaced flywheel- Feb. 2005

Popped original motor with nitrous, jet hadn't been reinstalled- April 2005

DE-K installed- May 2005

SPEC clutch died, spring on the disk popped out, new SPEC stage 2 installed- September 2005

Q45/Cobra rotors BBK, Hawk HPS- Fall 2006

Trans #3 installed, input shaft bearing started to fail on trans #2- Oct. 2006

Konis/Eibachs- September 2007

Radiator core support replaced- Dec. 2009

#3 Trans? (open diff?) broke differential gear teeth due to hard launch on Nov. 10, 2010. It's possible that no trans was immediately reinstalled, no notes of that.

Trans #4: Nissan reman VLSD with 10k miles - Team RIP Engineering deburred, shot peened, and cryo treated the gears and some shifter parts which Dgeesaman reassembled with new bearings and seals. Reinstalled with a new clutch and resurfaced flywheel in March 2011.

Panhard rod- August 2011

Josh's old Wilwood BBK- Feb. 2012

Fender braces- March 2012

BC Coilovers- March 2012

Quaife trans from Crusher103 installed (#5)- May 2012

New Wilwood BBK, Carbotech AX-6 front and rear pads- July 2012

Quaife trans died (#5), reverse gear teeth broke for no reason- July 2012

Quaife (#5) removed, VLSD trans (#4) reinstalled along with new OEM 5th gen clutch and flywheel- August 2012

Quaife diff reinstalled in a junkyard trans (#6) which was rebuilt by Dgeesaman with new OEM bearings and seals but not installed in car- July 2013

New Wilwood Polymatrix E pads front pads and new rotors installed- Oct. 2013

3.5 installed with Quaife trans (#6)- Feb. 2014

3.5 up and running- August 2014

Nistune installed- April 2015

The chassis has about 175k on it as of Feb. 2020.

Thanks for reading, I promise some good pics and updates soon!

Engine/Trans

-2002/03 Maxima 3.5 motor, no SS IM mod

-K&N filter, velocity stack

-2001/02 Pathfinder 70mm TB

-Custom PFTB adapter and throttle cable bracket from sicivic89

-Custom PFTB IACV block off plate from sicivic89

-NWP thermal intake manifold spacers

-NWP Block off plate

-Oil catch can

-Nistune ECU, 7k RPM rev-limit

-Cattman headers

-OEM cat

-2.5” resonated b-pipe

-Cattman muffler

-Aeromotive adjustable fuel pressure regulator

-Quaife differential in rebuilt/refreshed transmission

-Spare Nissan re-manufactured VLSD transmission that had gears and shifting mechanisms deburred, shot peened, and cryo treated, roughly 15k miles from new

-2000/01 DE-K Maxima OEM clutch and flywheel

-Poly shifter bushing

-97-99 Maxima shifter with 1” cut out from center and welded back together

-Sola Luna weighted aluminum shift ****

-Custom aluminum radiator brackets

-Put down 210 whp on old DE-K motor, about 250 whp on 3.5

Suspension

-BC Racing coilovers 9k front, 8k rear and valved to match dampers

-2.5* camber front (maxed out camber bolts), custom 4.7* caster (up from 2.2* stock, drilled new holes in front strut towers, rotated coilovers 90*), 0.1* toe out

-Corner balanced, 60.0% F, 40.0% R, 50/50 left to right

-3,130 lbs w/full tank of gas, empty trunk, full interior

-2J Racing converted the Scott-Russel linkage to a panhard rod rear suspension

-New panhard rod from Speedway Motors with PTFE-lined rod ends

-Progress RSB at max stiff

-Energy Suspension poly bushings for sway bar frame mounts (7.5118G), sway bar end links (9.8106G), control arms (7.3111G), cross member (7.1116G), and F&R motor mounts (7.1114G)

-Poly side/trans mounts

-Delrin front subframe bushings/collars

-Super Pro poly rear trailing arm bushings

-Moog control arms (better welds than stock)

Current Alignment:

-2.4* camber

+4.7* caster

-0.10* toe out

Brakes

-Wilwood 4 piston front calipers with 12.9” 2-piece rotors w/Wilwood Polymatrix E pads

-Fastbrakes 12.3” rear BBK (redrilled Accord rotors) with stock calipers and Carbotech AX-6 pads

-Track pads are Carbotech XP-8

-SS lines

-ATE DOT-4 fluid

Chassis

-Warpspeed Stage 1+2 Subframe connectors (welded)

-Custom fender braces, welded to chassis

-Stillen RSTB (Stillen front won't fit over 3.5 IM)

-No sunroof (stock)

-97-99 Maxima SE steering rack, B15 SE-R rack on shelf

-NWP engine torque link (not currently in use)

-Aluminum steering column bushing

-Relocated battery to trunk, 0-gauge wire

-95 Maxima aluminum front bumper support (-30 lbs)

-Rolled front fenders, rolled and slightly pulled rear fenders

Cooling

-Mishimoto radiator w/19 psi cap, Toyota red coolant

-Racer Parts Wholesale 24 row oil cooler with -10 AN lines

-Derale power steering cooler

Other Fluids

-Motul 8100 X-cess 5w-40 engine oil

-Amsoil 75w-90 MT fluid

Exterior

-The Retrofit Source FX-R 3” V3 projectors w/ 4.3k HID bulbs in Cefiro headlights with E55 shrouds

-TRS Blazer fog light projectors, 3k HID bulbs, independent fog light rewire mod

-All front lighting housings blacked out

-Painted grille vertical slats black

-Removed three vertical bars from lower bumper grille, filled, sanded, painted

-350Z horns

-Garage door front lip

-Nissan Murano windshield washer nozzles

-Black OEM mirrors

-35% tint

-All chrome window trim blacked out (temporarily removed)

-I30t spoiler

-Debadged trunk

-1998/99 I30 tail lights (heated up with heat gun, pressed center section together to fix common leak issue)

-All original paint (except spoiler and some touch up work on bumpers)

Interior

-Recaro Speed seat w/gray alcantara center section, CG Lock for seat belt

-Gunmetal aluminum dash trim from Shadow (old Org member), matching aluminum lower door panels

-Stock light gray leather (less than 5% of A32s?)

-Sparco L505 steering wheel

-350Z aluminum pedals, dead pedal

-Custom gray alcantara door panels

-Matching gray alcantara shift boots w/black stitching by Redline Goods

-Redline Goods black leather arm rest with some extra foam cushion inside

-Techtom MDM-100 (Set to display speed and water temp since the smaller steering wheel cuts off view of 20-120 mph)

-95/96 Maxima SE gauge cluster, gunmetal aluminum gauge rings

-Innovate Motorsports LC-2 Wideband O2 Sensor

-Innovate Motorsports MTX-D Oil Pressure & Oil Temperature Gauge

-99 I30 Limited aluminum door sill/scuff plates

-Most interior lights are white LEDs (Gauge cluster, door switches, HVAC display)

-97-99 Maxima center console with flip-over cup holder

-Fuzzy pillars (stock)

-Replaced cracking chrome interior door handles

Stereo

-Pioneer DEH-80PRS head unit (5V pre-out)

-Focal P165V15 6.5” component front speakers

-Hertz DCX 165 co-axial rear speakers

-Carstereoadapters.com PVC custom speaker adapters

-12” JL W6 subwoofer, Sonic Electronix 1.15 ft3 sealed box

-Boston Acoustics GT2 (125w RMS x 2 for front speakers) with 4 AWG OFC wire

-Alpine MRP-M500 (500w x 1 for sub) with 4 AWG OFC wire

-Clifford RS3.5 alarm with remote start

-MDF trunk floor with bracket to hold sub box in place

-14 AWG oxygen-free copper (OFC) speaker wire to speakers

-12 AWG oxygen-free copper (OFC) speaker wire to sub

-E-Dead sound deadening in the trunk, front doors and rear deck

-Frost King insulation in the front doors and other areas

-E-Dead sound deadening on front fender liners

Wheels/tires

-17x8 Enkei RPM2 +35 with 235/45/17 Michelin Pilot Sport 4S

-17x8.5 Enkei RPF1 +40 with 245/40/17 Hoosier A6

-ARP extended wheel studs

-2J Racing 10mm front, 15mm rear wheel spacers

Interesting Maintenance

-Replaced windshield

-Replaced radiator core support

-Touch up paint to bumpers

-DS front door hinges replaced due to door sagging

-Straightened and painted pinch welds

-Removed dash to repair cracked seam sealer at the base of the A pillar, fixing water leak into cabin

-3M Cavity Wax Plus inside the upper frame area behind the fenders and around the base of the windshield where water drains are located

-Replaced front door lock actuators, fixing haunted/wonky door lock action

-POR15 on pinch welds, fender braces, engine crossmember, and motor mount brackets

Old Interesting Parts

-Delrin CAB- too noisy, not enough benefit

-2JR bumpsteer kit- too noisy, not enough benefit

-Traction bars- didn't do much

-BlehmCo stage 2 lower tie bar- didn't clear headers

-Shortened Koni Yellows courtesy of JSutter

-Ben's rear strut mounts

-JWT ECU with nitrous daughterboard (65 shot)

-“Big 3” 0-gauge wire upgrade (partially removed at this point)

General timeline

Purchased- January 2003 with 82,000 miles

SFCs- Spring 2003

KYB AGX/H&Rs- Summer 2003

Original trans (#1) died, lost 1st and 2nd gear out of the blue, trans #2 installed (Phoenix Remanufactured Transmissions/PRT )- Summer 2003

Spec stage 2 clutch installed with resurfaced flywheel- Feb. 2005

Popped original motor with nitrous, jet hadn't been reinstalled- April 2005

DE-K installed- May 2005

SPEC clutch died, spring on the disk popped out, new SPEC stage 2 installed- September 2005

Q45/Cobra rotors BBK, Hawk HPS- Fall 2006

Trans #3 installed, input shaft bearing started to fail on trans #2- Oct. 2006

Konis/Eibachs- September 2007

Radiator core support replaced- Dec. 2009

#3 Trans? (open diff?) broke differential gear teeth due to hard launch on Nov. 10, 2010. It's possible that no trans was immediately reinstalled, no notes of that.

Trans #4: Nissan reman VLSD with 10k miles - Team RIP Engineering deburred, shot peened, and cryo treated the gears and some shifter parts which Dgeesaman reassembled with new bearings and seals. Reinstalled with a new clutch and resurfaced flywheel in March 2011.

Panhard rod- August 2011

Josh's old Wilwood BBK- Feb. 2012

Fender braces- March 2012

BC Coilovers- March 2012

Quaife trans from Crusher103 installed (#5)- May 2012

New Wilwood BBK, Carbotech AX-6 front and rear pads- July 2012

Quaife trans died (#5), reverse gear teeth broke for no reason- July 2012

Quaife (#5) removed, VLSD trans (#4) reinstalled along with new OEM 5th gen clutch and flywheel- August 2012

Quaife diff reinstalled in a junkyard trans (#6) which was rebuilt by Dgeesaman with new OEM bearings and seals but not installed in car- July 2013

New Wilwood Polymatrix E pads front pads and new rotors installed- Oct. 2013

3.5 installed with Quaife trans (#6)- Feb. 2014

3.5 up and running- August 2014

Nistune installed- April 2015

The chassis has about 175k on it as of Feb. 2020.

Thanks for reading, I promise some good pics and updates soon!

Last edited by 95maxrider; 07-07-2020 at 09:54 AM.

#595

Ok, since you asked nicely

Here's my current detailing procedure. I got some new polishes since last time and also switched up my sealant.

1. Pressure wash the car (light pressure)

2. Wash

3. CarPro Iron-X spray to remove metal particles from paint

4. Wash

5. Clay bar

6. Wash

7. Griot's Fast Correcting Cream for deeper correction and Griot's Perfecting Cream as the final step with a Flex 3401 buffer

8. Finish Kare BWM Hi-Temp Paste Wax

I spent quite a bit of time removing the failing trim blackout tape I had around all my windows and its adhesive. I would really like to install the black trim from an SE Maxima onto the car, but when I tried to remove it from a car at the junkyard I couldn't figure out how to do it without bending it, so I gave up. So for now, I'm back to the stock chrome window trim. I don't hate it, but I don't love it. Maybe someday I'll do the blackout tape again, or figure out how to do proper vinyl. Hell, maybe I'll even paint it black.

I used to use Menzerna polishes, but I'm done with those after using these new Griot's polishes. The biggest change is that the Griot's puts off pretty much no dust, while the Menzerna used to cover the car with that stuff. The Griot's polishes also smell good, while the Menzerna had no smell. I also feel like they were simply more effective at cutting or finishing, and my final finish was shinier than I remember in the past. Pictures of washing and claying is pretty boring, but watching Iron-X do its thing is pretty entertaining. Just make sure you wear a respirator when you use this stuff, it reeks.

I then decided to go OCD on my gas cap cover area. I always try to clean it with my wash mitt or a toothbrush, but there were just too many areas I could never reach. So I finally just took the damn door off and went crazy on it.

Totally worth it!

A few years ago I finally bought a 3" (IIRC) buffing backing plate and pads, which allow me to work in much tighter areas more effectively. They're great! I put them to use around glass, on the A pillars, around the washer nozzles, on the bumpers, and the bump guards along the doors. For a while now I've noticed that when I polish plastic parts like the bumpers and door bump guards, the pads turn black way more quickly than I can explain. I really don't think those parts are that dirty after all my prep work. I can tell that the paint on my bumpers is getting thin, and I'll have to repaint them at some point, so maybe that has something to do with it.

Here's my current detailing procedure. I got some new polishes since last time and also switched up my sealant.

1. Pressure wash the car (light pressure)

2. Wash

3. CarPro Iron-X spray to remove metal particles from paint

4. Wash

5. Clay bar

6. Wash

7. Griot's Fast Correcting Cream for deeper correction and Griot's Perfecting Cream as the final step with a Flex 3401 buffer

8. Finish Kare BWM Hi-Temp Paste Wax

I spent quite a bit of time removing the failing trim blackout tape I had around all my windows and its adhesive. I would really like to install the black trim from an SE Maxima onto the car, but when I tried to remove it from a car at the junkyard I couldn't figure out how to do it without bending it, so I gave up. So for now, I'm back to the stock chrome window trim. I don't hate it, but I don't love it. Maybe someday I'll do the blackout tape again, or figure out how to do proper vinyl. Hell, maybe I'll even paint it black.

I used to use Menzerna polishes, but I'm done with those after using these new Griot's polishes. The biggest change is that the Griot's puts off pretty much no dust, while the Menzerna used to cover the car with that stuff. The Griot's polishes also smell good, while the Menzerna had no smell. I also feel like they were simply more effective at cutting or finishing, and my final finish was shinier than I remember in the past. Pictures of washing and claying is pretty boring, but watching Iron-X do its thing is pretty entertaining. Just make sure you wear a respirator when you use this stuff, it reeks.

I then decided to go OCD on my gas cap cover area. I always try to clean it with my wash mitt or a toothbrush, but there were just too many areas I could never reach. So I finally just took the damn door off and went crazy on it.

Totally worth it!

A few years ago I finally bought a 3" (IIRC) buffing backing plate and pads, which allow me to work in much tighter areas more effectively. They're great! I put them to use around glass, on the A pillars, around the washer nozzles, on the bumpers, and the bump guards along the doors. For a while now I've noticed that when I polish plastic parts like the bumpers and door bump guards, the pads turn black way more quickly than I can explain. I really don't think those parts are that dirty after all my prep work. I can tell that the paint on my bumpers is getting thin, and I'll have to repaint them at some point, so maybe that has something to do with it.

Last edited by 95maxrider; 03-01-2020 at 05:53 PM.

#596

I also went crazy with the 3" pads and polished the rocker panel for the first time ever. They're so shiny now!

After so many years of buffing this thing, I've basically smoothed out all of the orange peel in the paint, and some areas are just ridiculously smooth and perfect looking!

Can you tell what brand of light bulbs I use? Too bad I was using my old crappy camera for all this, I bought a new one recently that's all fancy and stuff. These pics are from like 2 months ago.

It's so hard to take good detail pics of silver paint.

After so many years of buffing this thing, I've basically smoothed out all of the orange peel in the paint, and some areas are just ridiculously smooth and perfect looking!

Can you tell what brand of light bulbs I use? Too bad I was using my old crappy camera for all this, I bought a new one recently that's all fancy and stuff. These pics are from like 2 months ago.

It's so hard to take good detail pics of silver paint.

Last edited by 95maxrider; 03-01-2020 at 06:35 PM.

#597

I really wish I had my new camera when I took these pics, they would look so much nicer. Oh well, guess I'll have to do this all again in the spring!

Yes, I got carried away.

So shiny....

My car was hanging out with some of its buddies from way back 90s reunion!

90s reunion!

Yes, I got carried away.

So shiny....

My car was hanging out with some of its buddies from way back

90s reunion!

90s reunion!

Last edited by 95maxrider; 03-01-2020 at 06:35 PM.

#598

Nice and flush.

Yes, these poor wheels need to be refinished....

And that's the state of my car in 2020. Here's my to do/wish list for the car.

-Install new Michelin PS4S tires, these old Super Sports are like 8 years old now and are starting to dry rot.

-Repair fender rot on rear fenders and do a good job with the paint. Since so much of the purple has faded out of the paint, getting it to match is going to be tricky.

-Remove exhaust, heat shields, and SFCs, and de-rustify the entire bottom of the car. It's not too bad underneath, but I want to get ahead of it while I still can. I let the rear fenders get away from me and I'm pissed. Then coat it all in POR15.

-Finally get PDR done.

-Refinish the wheels.

-Maybe repaint the bumpers and spoiler

Once the car is rust free and looking a little fresher, then I really want to do an 09+ Maxima engine swap and maybe a 6MT while I'm at it. Part of me really wants to do the full wiring swap and not have to worry about 3.0 timing gear, but I think that kind of work is out of my league. I'm already nervous about opening up a motor and doing the 3.0 timing conversion, I feel like I'm gonna break something....I need an adult!

More importantly, I want to get this thing back out there and do some racing. At a minimum I'll do some auto-x this year, and maybe one or two other things.

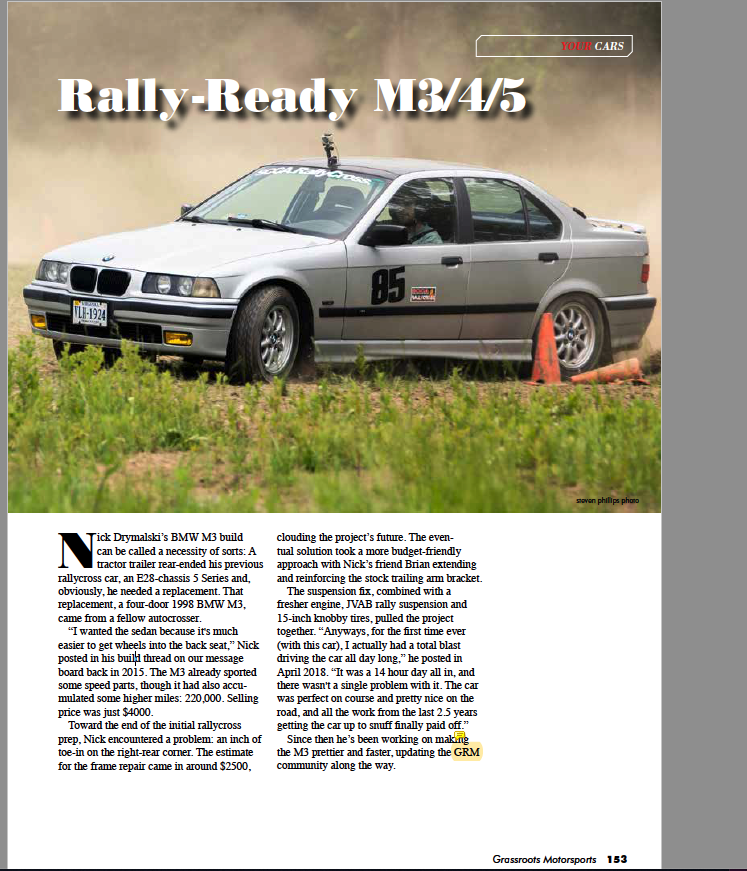

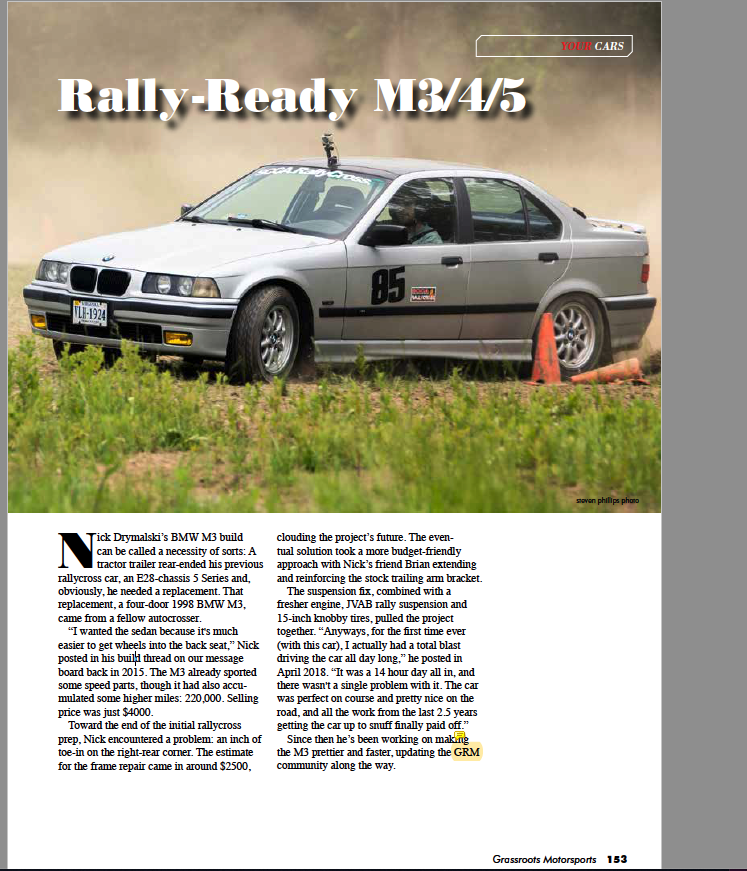

And hey, while you're here, you may get a kick out of my 1998 M3 that I use for rallycross. I've got a build thread for that too!

It even made it into Grassroots Motorsports!

And the wife even has a cool car now too! It's a 2007 FX35 AWD, and I adore it. For some reason, it also has a build thread.

Yes, these poor wheels need to be refinished....

And that's the state of my car in 2020. Here's my to do/wish list for the car.

-Install new Michelin PS4S tires, these old Super Sports are like 8 years old now and are starting to dry rot.

-Repair fender rot on rear fenders and do a good job with the paint. Since so much of the purple has faded out of the paint, getting it to match is going to be tricky.

-Remove exhaust, heat shields, and SFCs, and de-rustify the entire bottom of the car. It's not too bad underneath, but I want to get ahead of it while I still can. I let the rear fenders get away from me and I'm pissed. Then coat it all in POR15.

-Finally get PDR done.

-Refinish the wheels.

-Maybe repaint the bumpers and spoiler

Once the car is rust free and looking a little fresher, then I really want to do an 09+ Maxima engine swap and maybe a 6MT while I'm at it. Part of me really wants to do the full wiring swap and not have to worry about 3.0 timing gear, but I think that kind of work is out of my league. I'm already nervous about opening up a motor and doing the 3.0 timing conversion, I feel like I'm gonna break something....I need an adult!

More importantly, I want to get this thing back out there and do some racing. At a minimum I'll do some auto-x this year, and maybe one or two other things.

And hey, while you're here, you may get a kick out of my 1998 M3 that I use for rallycross. I've got a build thread for that too!

It even made it into Grassroots Motorsports!

And the wife even has a cool car now too! It's a 2007 FX35 AWD, and I adore it. For some reason, it also has a build thread.

#600

Car looks great!

Honestly, I understand the nervousness, I built my first motor ever from the ground up with the 9-5. Just take our time, be patient. Trust me there is always a way back or solution, you can figure it out. I'd say do the full harness.

Also, what happened to that Corolla?

Honestly, I understand the nervousness, I built my first motor ever from the ground up with the 9-5. Just take our time, be patient. Trust me there is always a way back or solution, you can figure it out. I'd say do the full harness.

Also, what happened to that Corolla?