rear main seal replacement / oil pan removal

#1

rear main seal replacement / oil pan removal

for those who have done a rear main seal on a 3.5

what is the easy way?? i see the new rear main comes with the whole bracket. using that the oil pan has to be removed, and from what im reading from the FSM its a pain.

anyone remove the just the seal???? i think i might give it a shot. considering i dont want to remove the oil pan realllly bad.

removing the oil pan will add hours and hours to the clutch replacement job im about to do, but i feel i should do the rear main while im there.

any ideas???

what is the easy way?? i see the new rear main comes with the whole bracket. using that the oil pan has to be removed, and from what im reading from the FSM its a pain.

anyone remove the just the seal???? i think i might give it a shot. considering i dont want to remove the oil pan realllly bad.

removing the oil pan will add hours and hours to the clutch replacement job im about to do, but i feel i should do the rear main while im there.

any ideas???

#2

its the oil pan gasket thats leaking not the rear main seal, but if you gonna split the engine and tranny, you might as well do the rear main seal. I have done this before without removing the oil pan, but it is a pain in the *** and you'll have to remove the alighnment pins and even then it very difficult. Just drop the oil pan, will also give you a chance to see and clean the oil pan of any gunk or any of such things.

#3

well im not sure anything is even leaking, just sence im there i was going to change the rear main just cuz, i do have 166,000 miles and just my luck if i did not change it a week later it would be leaking.

i guess ima order some oil pan gaskets and take the long route.

i guess ima order some oil pan gaskets and take the long route.

#4

No oil pan gaskets (beyond the two half-moons), it's all RTV. There are a few o-rings, but if they're not torn or damaged in any way they can be reused.

4 (IIRC) 12mm head bolts you have to get with the lower oil pan off, then 4 on the right side and 3 on the left (by memory, but I just tore down another core motor today so it should be about that). After that, just get a rubber mallet and go to town.

3x10mm head bolts hold in the RMS retainer (and no, you never want to try to just replace the seal. I can almost guarantee that it will end up failing prematurely. Hell, I don't think you can even buy the seal seperately from Nissan), then it pulls straight off of the two alignment dowels in the block.

Be sure to lube up the seal and the end of the crank, and test fit a few times to make sure you don't pop the spring out of the seal during installation.

...something like that.

#6

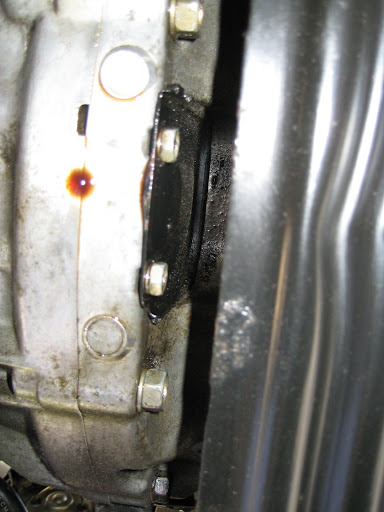

Rear Oil Pan Gasket

Hi, Is it (in the picture below) the Moon gasket that you guys were talking about? My 95 max GLE is having a minor leak around the area. I think it was the problem - my leak is likely between the black metal bracket and the oil pan. I just had my RMS replaced at the dealer last year. In fact, one of the two bolts was not tightened at all. I am not sure that the dealer forgot it or had overtightened and messed the threads. So I tightened it a little bit (not too tight as I don't know the torque, plus if the threads are gone, I certainly don't want to make it worse.) Hopefully, it fixed the problem!

Regardless I don't want to spend another $1600 for it again. I am wondering whether I can just order a gasket from Nissan, and remove the two bolts and attach the gasket on the plate (with some sealant of course) and tighten the two bolts back. (or it doesn't go this way)?

Advice appreciated!

Regardless I don't want to spend another $1600 for it again. I am wondering whether I can just order a gasket from Nissan, and remove the two bolts and attach the gasket on the plate (with some sealant of course) and tighten the two bolts back. (or it doesn't go this way)?

Advice appreciated!

#7

That black cover does absolutely nothing but allow you access to the clutch, or TC bolts.

The seal is between the oil pan and RMS retainer.

See this pic:

The half moon seal goes at the bottom of that picture (where mine is actually weeping a bit, now that I look at it...).

Requires removal of the upper oil pan to replace...

The seal is between the oil pan and RMS retainer.

See this pic:

The half moon seal goes at the bottom of that picture (where mine is actually weeping a bit, now that I look at it...).

Requires removal of the upper oil pan to replace...

#8

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

Thank god, because when I read the 1st post I was like "Oh no, I hope I caught this one in time" Because myself, as well as a few other members that I know of replaced the RMS with a new 1/2 moon (yes, they must be ordered seperate) come to find out the 1/2 moon (which is ALWAYS the only one that leaks anyways) now leaked bad enough to drip and would have possibly gotten on the clutch (it takes alot) if it didn't have to be done again, well sorta done again, see below.

Method 1: use an engine hoist and work between it's legs, you WILL pull tons of back muscles and be really sore, it is a god-damn uncomfortable mothertruckin NIGHTMARE.

Method 2: install the new rms without the 1/2 moon, reinstall tranny (minus the smaller bottom bolts that go into upper pan) install tranny mount, than do the 1/2 moons/oil-pan.

Method no-no: Wedge the 1/2 moon in without pulling the pan. Like I said, I'm part of the retard club.

Best method: Don't do anything, it has to leak REALLY REALLY bad to contaminate clutch, plus it's the 1/2 moon that leaks anyways (pmohr, you see alot more vq bellhousings than me these days, take notes of mileage) I;ve found that by 40k the 1/2 moon is already weeping and causing wetness, and I've seen plenty with 200k+ that covered the block side of the bellhousing in oil-grime, were starting to drip, but still NO-WHERE near clutch contamination. Also, keep in mind since it's almost always the 1/2 moon and rarely ever the RMS, you can do the 1/2 moon properly at a later point in time.

#9

I recently manufactured myself a perfect procharger tool, 8mm allen key cut to the perfect length such that it bottoms out fully in a 5/16" 1/4" drive socket and is exposed enough to fully engage the bolts for a procharger main bracket...all held together with JB Weld. Of course it's only for taking them out, so extremely low-torque use...so bah.

Best method: Don't do anything, it has to leak REALLY REALLY bad to contaminate clutch, plus it's the 1/2 moon that leaks anyways (pmohr, you see alot more vq bellhousings than me these days, take notes of mileage) I;ve found that by 40k the 1/2 moon is already weeping and causing wetness, and I've seen plenty with 200k+ that covered the block side of the bellhousing in oil-grime, were starting to drip, but still NO-WHERE near clutch contamination. Also, keep in mind since it's almost always the 1/2 moon and rarely ever the RMS, you can do the 1/2 moon properly at a later point in time.

Mine is barely weeping at ~120k, but there have definitely been a bunch of ~60kers recently I've done clutches/flywheels on that have had a fair amount of grime built up back there. Seems to be relatively random at best (around here, anyway)

#10

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

Heh, yea. Not the way I'd do it, personally, but it can be done if it has to.

I recently manufactured myself a perfect procharger tool, 8mm allen key cut to the perfect length such that it bottoms out fully in a 5/16" 1/4" drive socket and is exposed enough to fully engage the bolts for a procharger main bracket...all held together with JB Weld. Of course it's only for taking them out, so extremely low-torque use...so bah.

Mine is barely weeping at ~120k, but there have definitely been a bunch of ~60kers recently I've done clutches/flywheels on that have had a fair amount of grime built up back there. Seems to be relatively random at best (around here, anyway)

I recently manufactured myself a perfect procharger tool, 8mm allen key cut to the perfect length such that it bottoms out fully in a 5/16" 1/4" drive socket and is exposed enough to fully engage the bolts for a procharger main bracket...all held together with JB Weld. Of course it's only for taking them out, so extremely low-torque use...so bah.

Mine is barely weeping at ~120k, but there have definitely been a bunch of ~60kers recently I've done clutches/flywheels on that have had a fair amount of grime built up back there. Seems to be relatively random at best (around here, anyway)

#13

I have my tranny off and need to replace the upper oil pan gasket. What is the best way to hang the engine if I have to take the front and rear engine mounts off. There is no good place to bolt anything to. I can use two bolts from the tranny holes but the chain is tight among stuff on the top of the engine and I am afraid it will tilt and break something.

Or is the best way to put the RMS on and rebolt the upper half of the tranny and remount it on the drivers side and then take the front/rear motor mounts off with the big bar on the bottom. Half the exhaust and the AC to get the upper oil pan off? Help please. JS

Or is the best way to put the RMS on and rebolt the upper half of the tranny and remount it on the drivers side and then take the front/rear motor mounts off with the big bar on the bottom. Half the exhaust and the AC to get the upper oil pan off? Help please. JS

#16

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

Lowers are cake, just pull all the 10mm bolts, and iirc there is some rusty bracket near the y-pipe that needs to bent out of the way I think. You'll get a little messy, but it's all really easy.

#17

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

I have my tranny off and need to replace the upper oil pan gasket. What is the best way to hang the engine if I have to take the front and rear engine mounts off. There is no good place to bolt anything to. I can use two bolts from the tranny holes but the chain is tight among stuff on the top of the engine and I am afraid it will tilt and break something.

Or is the best way to put the RMS on and rebolt the upper half of the tranny and remount it on the drivers side and then take the front/rear motor mounts off with the big bar on the bottom. Half the exhaust and the AC to get the upper oil pan off? Help please. JS

Or is the best way to put the RMS on and rebolt the upper half of the tranny and remount it on the drivers side and then take the front/rear motor mounts off with the big bar on the bottom. Half the exhaust and the AC to get the upper oil pan off? Help please. JS

Re-bolting the tranny is the best imho, refer a couple posts up as to why. If you need to hoist an engine, I prefer to use romex (house electrical wire) to fish it under the lower intake, than use the romex to pull the chain through. Start the romex through the timing cover side. It will take some practice, your first time you might cuss alot, but I've gotten it down to a science and can get the chain under there in less than 2-minutes, I use long pliers to grab the romex once it is near the knock sensor, and than intertwine the romex through several links of the chain while keeping the links normal (ie not sideways/bunched up or they won't clear the timing cover.)

But seriously, re-bolt the tranny, it's safer AND EASIER for several reasons, you have to do it anyways, and don't forget to sand your bellhousing surfaces

Last edited by KRRZ350; 08-07-2008 at 08:56 AM.

#18

It's done. I bought one of the hoist dollys that will level the two hangers. Managed to pull the chains beside the front vent pipe in between the water pipes and the block. The other one went just in front of the fuel rail. Both were a tight squeeze and then two bolts into the block.

Sure is a lot of crap to take off for one lousy seal. Tranny is back on and most of the stuff is bolted back up. I will have to find a special tool for the two bolts that go into the shifter bracket. Another poor design by Nissan. Can't get a wrench in to tighten it up. I have to find a very short 14 mm socket, perhaps a 1/4" drive so that I can tighten them. JS

Sure is a lot of crap to take off for one lousy seal. Tranny is back on and most of the stuff is bolted back up. I will have to find a special tool for the two bolts that go into the shifter bracket. Another poor design by Nissan. Can't get a wrench in to tighten it up. I have to find a very short 14 mm socket, perhaps a 1/4" drive so that I can tighten them. JS

#19

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

It's done. I bought one of the hoist dollys that will level the two hangers. Managed to pull the chains beside the front vent pipe in between the water pipes and the block. The other one went just in front of the fuel rail. Both were a tight squeeze and then two bolts into the block.

Sure is a lot of crap to take off for one lousy seal. Tranny is back on and most of the stuff is bolted back up. I will have to find a special tool for the two bolts that go into the shifter bracket. Another poor design by Nissan. Can't get a wrench in to tighten it up. I have to find a very short 14 mm socket, perhaps a 1/4" drive so that I can tighten them. JS

Sure is a lot of crap to take off for one lousy seal. Tranny is back on and most of the stuff is bolted back up. I will have to find a special tool for the two bolts that go into the shifter bracket. Another poor design by Nissan. Can't get a wrench in to tighten it up. I have to find a very short 14 mm socket, perhaps a 1/4" drive so that I can tighten them. JS

#20

Thanks. Turns out you can't buy a 14 mm socket for a 1/4" drive. I bought a special offset 14 mm wrench. It kind of has 2 ninety degree turns on it. It was good for the rear bolt. The front bolt gave me some grief but I used a dremel and a burr of sorts to grind away some of the bracket material. Just enough so the wrench would pass over it enough to tighten the bolt.

If it would not have worked I was going to weld a flat bar onto a 14 mm socket as I think that would clear everything to tighten. Luckily I didn't have to go that route.

As far as the oil pans go it was the metal one that took a bit more work to get off. The upper one has a nice pry bar hole on each side and if you are gentle it comes away quite nicely. Just had to wiggle it a bit to get it off the pins.

Didn't have any bolts on the timing cover area at all. The upper pan has 12 bolts. Seven on the outside and five inside where the metal pan covers up. I had wondered why the manual said you had to remove the oil pick up. Just a bit messy as some oil stays in the pan.

Nothing seems to be leaking after a quick drive around the area. Will check again tomorrow. I just have to fix a squeaky belt pulley. It may be too loose or too tight. I will adjust it in the morning.

FWIW I came up with an easy way to fill the tranny. Someone probably did this before. Took the speedo head out before mounting the tranny back in. I just happened to have some 3/4" clear plastic tubing I once used for another project and used that to funnel in the gear oil from 1 liter containers. I left the fill hole on the front open until I could just see the oil dribble out. JS

If it would not have worked I was going to weld a flat bar onto a 14 mm socket as I think that would clear everything to tighten. Luckily I didn't have to go that route.

As far as the oil pans go it was the metal one that took a bit more work to get off. The upper one has a nice pry bar hole on each side and if you are gentle it comes away quite nicely. Just had to wiggle it a bit to get it off the pins.

Didn't have any bolts on the timing cover area at all. The upper pan has 12 bolts. Seven on the outside and five inside where the metal pan covers up. I had wondered why the manual said you had to remove the oil pick up. Just a bit messy as some oil stays in the pan.

Nothing seems to be leaking after a quick drive around the area. Will check again tomorrow. I just have to fix a squeaky belt pulley. It may be too loose or too tight. I will adjust it in the morning.

FWIW I came up with an easy way to fill the tranny. Someone probably did this before. Took the speedo head out before mounting the tranny back in. I just happened to have some 3/4" clear plastic tubing I once used for another project and used that to funnel in the gear oil from 1 liter containers. I left the fill hole on the front open until I could just see the oil dribble out. JS

#21

Who misinformed you of such? I have at least 3 or 4 sitting in my box at work, along with a bunch of other 1/4" drive sockets up to ~19mm.

Just for future reference:

http://www.autozone.com/R,231656/sto...ductDetail.htm

http://www.autozone.com/R,1392085/st...ductDetail.htm

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

http://www.sears.com/shc/s/p_10153_1...0P?vName=Tools

...and so on.

#22

Thanks for the input. I tried 3 different supply shops and they all did not have any and said they weren't available. Dufus clerks sometimes give dufus information and this dufus believed them. I got it done so point is now moot. JS

#23

Supporting Maxima.org Member

iTrader: (29)

Join Date: Oct 2005

Location: Middleboro/Carver, Ma

Posts: 4,572

FWIW I came up with an easy way to fill the tranny. Someone probably did this before. Took the speedo head out before mounting the tranny back in. I just happened to have some 3/4" clear plastic tubing I once used for another project and used that to funnel in the gear oil from 1 liter containers. I left the fill hole on the front open until I could just see the oil dribble out. JS

Thread

Thread Starter

Forum

Replies

Last Post

jskirwin

7th Generation Maxima (2009-2015)

7

06-08-2016 08:49 AM

vingodine

5th Generation Classifieds (2000-2003)

45

05-21-2016 12:46 PM

Huttig2009

5th Generation Classifieds (2000-2003)

8

09-25-2015 03:31 PM

kirkhilles

5th Generation Maxima (2000-2003)

2

08-08-2015 10:53 AM