speedo/RPM gauge cluster

#1

speedo/RPM gauge cluster

Hey all, I just picked up a silver-face instrument panel cluster from a 2002 SE, for my 2003 GLE. I got a pretty good deal at the pick-n-pull too. I wanted to know if there's a way to install the gauge face overlays without having to reprogram the new one for correct mileage...... I thought I saw a write up on it, but I can't be sure. Can someone help out?

Last edited by Jagalag; 01-07-2018 at 03:33 PM.

#3

Indeed, that's exactly what I thought, after taking the front bezel and circular gauge frame cutouts off the SE cluster last night. From what I can tell, I don't even need to worry about the cutout frame silver outline on the speedo and RPM gauges, as they're also silver in the GLE. Does the "clock" positioning matter on the needles when you reattach them onto the shaft? You don't have to mark it as if you're changing a timing belt, right? It didn't seem like that, because when it's unplugged, the needle flips to the complete opposite side of the dial after moving it past a certain point, suggesting that it is controlled by an electrical motor, and not an analog spring tension mechanism. What say you?

Last edited by Jagalag; 01-07-2018 at 03:34 PM.

#4

Does the "clock" positioning matter on the needles when you reattach them onto the shaft? You don't have to mark it as if you're changing a timing belt, right? It didn't seem like that, because when it's unplugged, the needle flips to the complete opposite side of the dial after moving it past a certain point, suggesting that it is controlled by an electrical motor, and not an analog spring tension mechanism. What say you?

Make sure the overlay sits flush to the cluster, not bubbling anywhere as the needles can stick. Also, I found that I needed to pull up slightly on the needles after getting them to point where I wanted to avoid them sticking.

Also, while you're in there if you're handy with a soldering iron you may want to give the 4 fuel gauge resistors a massaging so you never have to tear it apart again. I've got a post in another thread on how to go about that.

#5

Oh it matters, and you will probably want to leave the clear front off while you take the car for a drive. I used my Torque app for RPM, and GPS to correlate speed. The tach will probably be off by a couple hundred RPM here and there so choose where you want it accurate. Mine is pretty close at idle and 3000-4000 but off in the 2000-2500 range. You can get real close by aligning them as per the FSM but I found mine sat slightly different than the FSM.

Make sure the overlay sits flush to the cluster, not bubbling anywhere as the needles can stick. Also, I found that I needed to pull up slightly on the needles after getting them to point where I wanted to avoid them sticking.

Also, while you're in there if you're handy with a soldering iron you may want to give the 4 fuel gauge resistors a massaging so you never have to tear it apart again. I've got a post in another thread on how to go about that.

Make sure the overlay sits flush to the cluster, not bubbling anywhere as the needles can stick. Also, I found that I needed to pull up slightly on the needles after getting them to point where I wanted to avoid them sticking.

Also, while you're in there if you're handy with a soldering iron you may want to give the 4 fuel gauge resistors a massaging so you never have to tear it apart again. I've got a post in another thread on how to go about that.

#6

You gotta do all that to access the chip anyways  The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

If you are in there already, would you mind taking some close up pics of the traces going to the LEDs in the bottom right corner? Cruise/Service engine soon/etc. I'd like to see if I can figure out how to repair my SES ghost light. No codes but partially illuminated. It's really hard to make out the traces underneath the black silkscreen in the pics I took and don't want to tear mine apart at the moment

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.If you are in there already, would you mind taking some close up pics of the traces going to the LEDs in the bottom right corner? Cruise/Service engine soon/etc. I'd like to see if I can figure out how to repair my SES ghost light. No codes but partially illuminated. It's really hard to make out the traces underneath the black silkscreen in the pics I took and don't want to tear mine apart at the moment

#8

You gotta do all that to access the chip anyways  The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

If you are in there already, would you mind taking some close up pics of the traces going to the LEDs in the bottom right corner? Cruise/Service engine soon/etc. I'd like to see if I can figure out how to repair my SES ghost light. No codes but partially illuminated. It's really hard to make out the traces underneath the black silkscreen in the pics I took and don't want to tear mine apart at the moment

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.

The EEPROM is circled in the pic I attached, as are the 4 fuel gauge resistors.If you are in there already, would you mind taking some close up pics of the traces going to the LEDs in the bottom right corner? Cruise/Service engine soon/etc. I'd like to see if I can figure out how to repair my SES ghost light. No codes but partially illuminated. It's really hard to make out the traces underneath the black silkscreen in the pics I took and don't want to tear mine apart at the moment

#9

Oh it matters, and you will probably want to leave the clear front off while you take the car for a drive. I used my Torque app for RPM, and GPS to correlate speed. The tach will probably be off by a couple hundred RPM here and there so choose where you want it accurate. Mine is pretty close at idle and 3000-4000 but off in the 2000-2500 range. You can get real close by aligning them as per the FSM but I found mine sat slightly different than the FSM.

Make sure the overlay sits flush to the cluster, not bubbling anywhere as the needles can stick. Also, I found that I needed to pull up slightly on the needles after getting them to point where I wanted to avoid them sticking.

Also, while you're in there if you're handy with a soldering iron you may want to give the 4 fuel gauge resistors a massaging so you never have to tear it apart again. I've got a post in another thread on how to go about that.

Make sure the overlay sits flush to the cluster, not bubbling anywhere as the needles can stick. Also, I found that I needed to pull up slightly on the needles after getting them to point where I wanted to avoid them sticking.

Also, while you're in there if you're handy with a soldering iron you may want to give the 4 fuel gauge resistors a massaging so you never have to tear it apart again. I've got a post in another thread on how to go about that.

#11

looks like you did a pretty good job of getting the speedo needle and RPM needle aligned right in the diagnosis mode, and you just carefully moved the needles with your fingers? Did the fuel needle just refuse to co-operate?

#12

The needles suck, you have to pull them off, and then try to push them back on without causing the motor shaft to turn unintentionally. It can be done in diagnosis mode though so you can get pretty darn close.

I decided to disregard the FSM pic for the fuel and temp gauges. They didn't match before I opened up my cluster so I consider the picture an approximation. Where the temp needle sits in diagnosis mode is where my normal operating temp is. That gauge is all relative anyways so that's where I chose. If you're used to it being higher, put it where you like.

The fuel gauge I set once my fuel light came on (post repair) and that is where mine sits when in diagnosis mode. I think I had the needle sitting just below the last small tick before E. I've run through several tanks since and I'm satisfied with the accuracy. The DTE display and fuel gauge match up pretty well. I definitely wouldn't want to put it where the FSM indicates (which would make it read 1/4 tank higher).

I decided to disregard the FSM pic for the fuel and temp gauges. They didn't match before I opened up my cluster so I consider the picture an approximation. Where the temp needle sits in diagnosis mode is where my normal operating temp is. That gauge is all relative anyways so that's where I chose. If you're used to it being higher, put it where you like.

The fuel gauge I set once my fuel light came on (post repair) and that is where mine sits when in diagnosis mode. I think I had the needle sitting just below the last small tick before E. I've run through several tanks since and I'm satisfied with the accuracy. The DTE display and fuel gauge match up pretty well. I definitely wouldn't want to put it where the FSM indicates (which would make it read 1/4 tank higher).

Last edited by freezer; 01-09-2018 at 09:04 PM.

#14

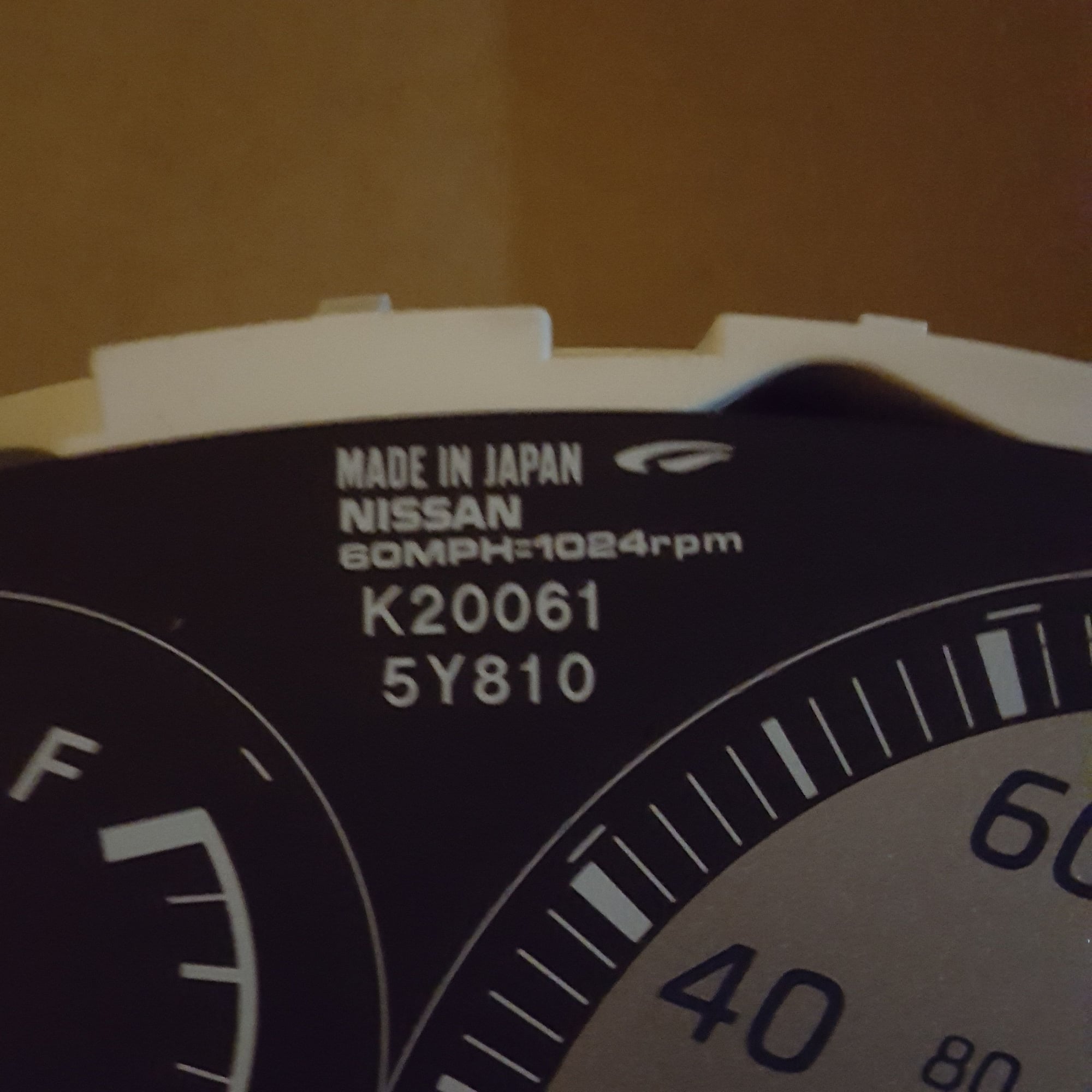

I noticed a similar number on mine. It's gotta be the calibration of the speedo (either input to cluster or output to ECU) which could be different in trims which had different tire sizes. I didn't grab a picture of mine though. Won't have anything to do with setting the needles though.

Thread

Thread Starter

Forum

Replies

Last Post

bellis

5th Generation Classifieds (2000-2003)

7

06-17-2012 06:29 PM

maxfever1987

4th Generation Classifieds (1995-1999)

25

05-01-2011 09:28 AM

2001i30

Audio and Electronics

12

09-21-2010 10:15 AM

MrMaximaGLE

5th Generation Classifieds (2000-2003)

11

10-08-2007 04:22 AM