HELP PLEASE 2k1 surging, bucking, help

#1

HELP PLEASE 2k1 surging, bucking, help

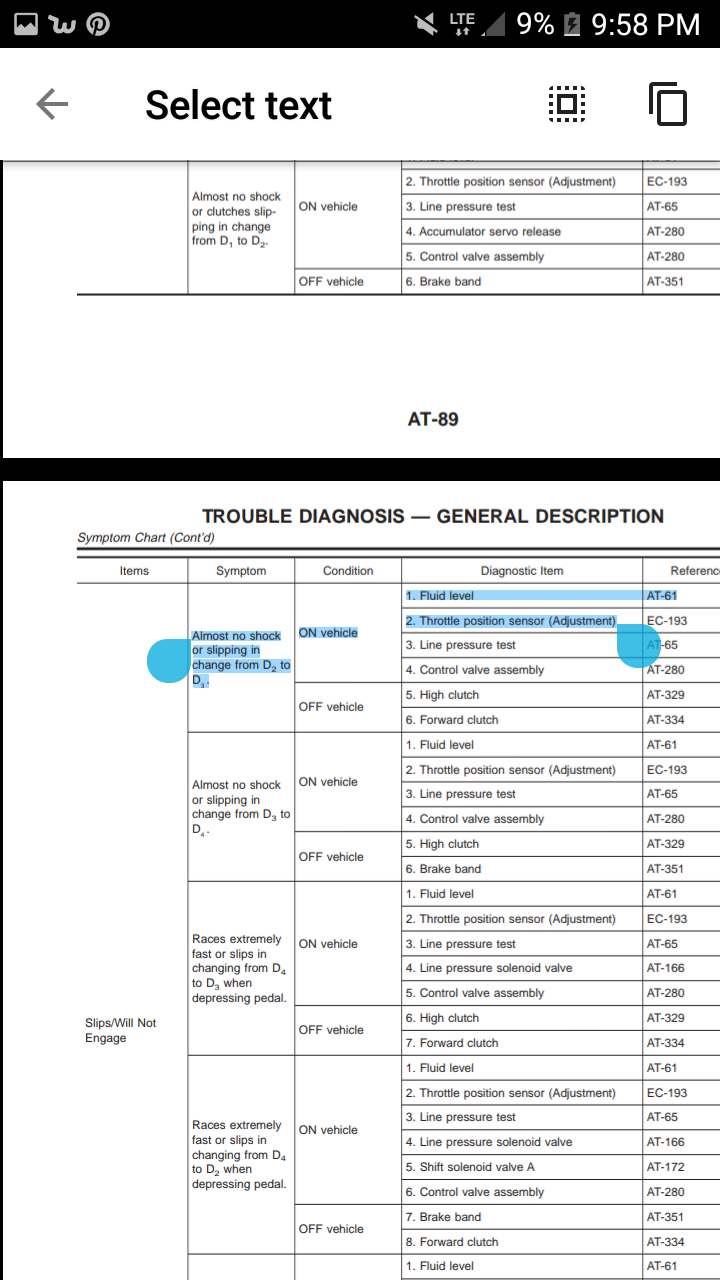

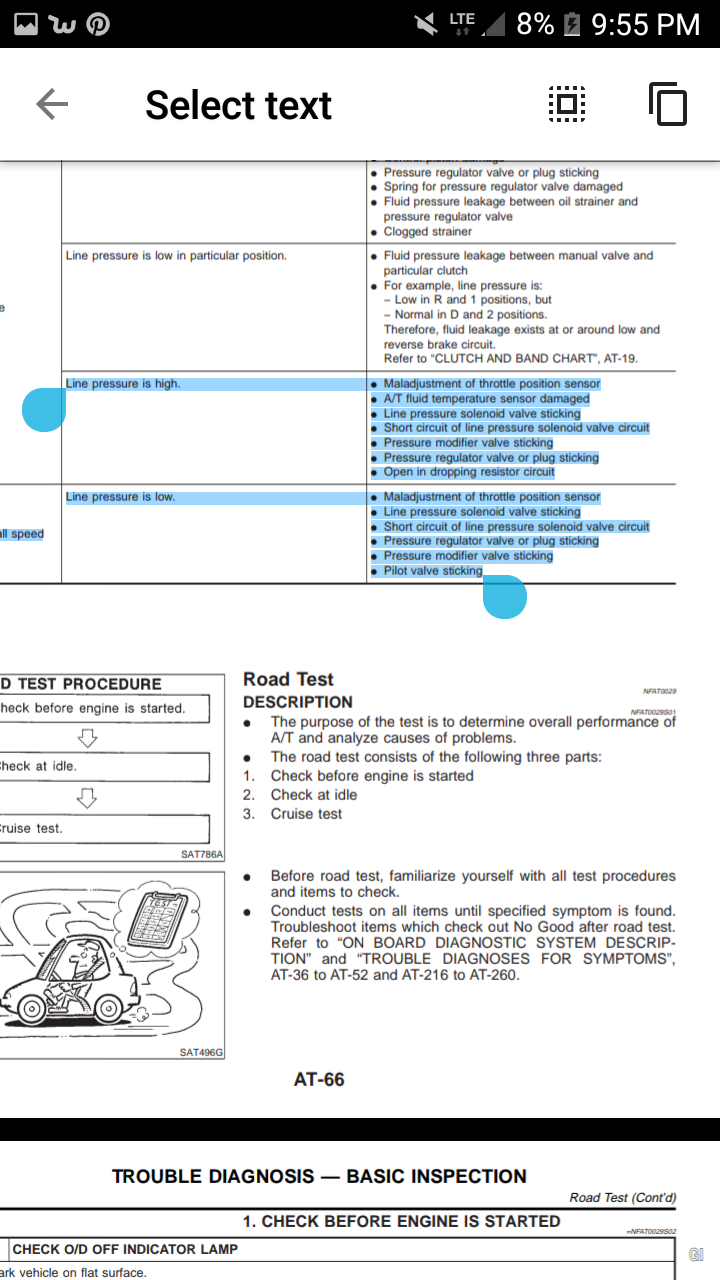

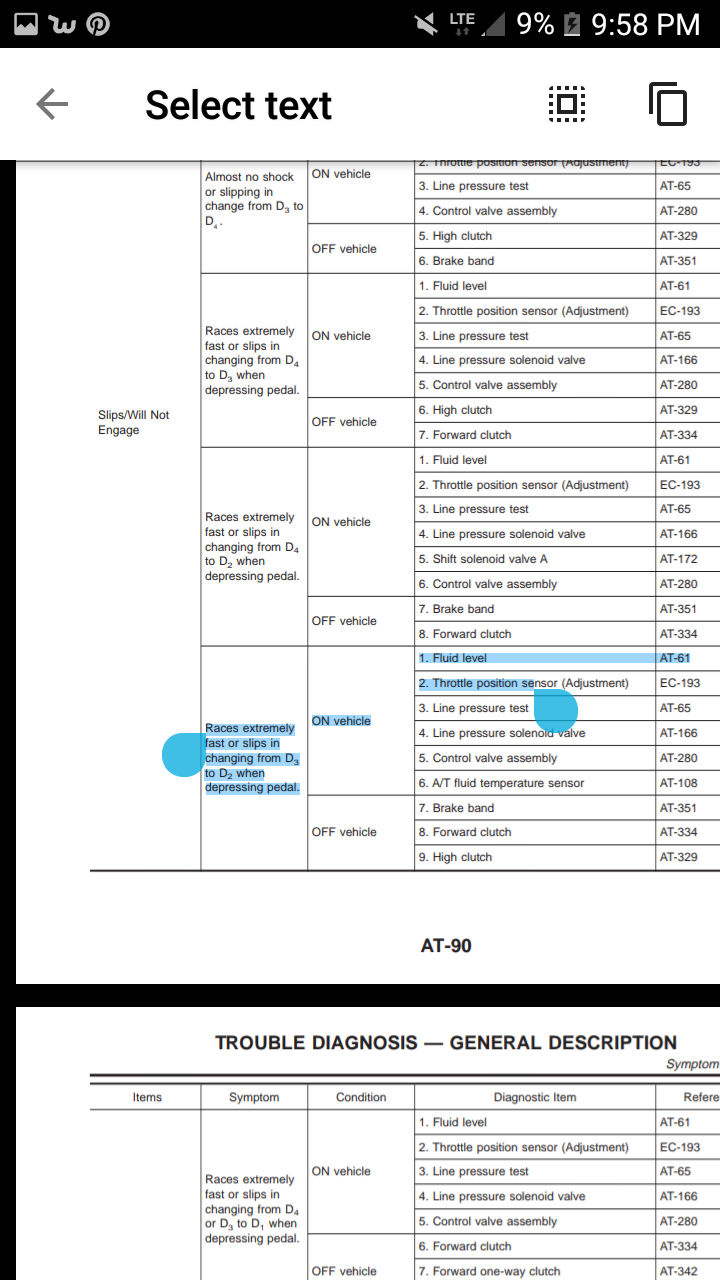

Heads up this will be a long one. My 2k 5speed project car has been set aside for a tranny rebuild due to the input shaft bearing. My 2k1 gle has been parked because of erratic behavior following me gutting the lim buterflies. Had a nasty head on collision where someone was in more of a hurry than myself and failed to yield. Trucks totaled and I have to get to work and back. I've put too much money and work into glee at this point to turn around so needing a car I ordered a bunch of parts and had them shipped to where it sat. When all had arrived I went to throw her together... After the lim job glee started slipping shifts 1to2 and 2to3. I had cleaned the tb and had the tps off of course. Threw a closed throttle switch tranny code a couple of times and got frustrated with it. That's why it was parked. Borrowed some parts from her for the 5 speed who had p0505 and knew better than to chance reinstalling any of it on glee. So the parts I ordered were pen iacv, oem tps, pcv valve, valve cover gaskets, spark plug tube seals, new connectors for tps, injectors, coils, new gram ultra synthetic dry filter, removed k&n, fuel filter, fuel pump screen, lim gasket, tb gasket, egr gasket, and vias gasket. I brought with me datascan 2, some extra key blanks I had cut to program, maf, tb, brake cleaners, extra tps, relays, maf, coils, wiring supplies, connectors, loom, solder tools, heat shrinks, tools, and the fsm. Got her together bypassed iacv (car has never had iacv issue due to preventative maintenance), adjusted tps, and she fired right up. No codes other than 02 for headers. A day later the slip returned, the surge in rpm when throttle is barely applied in park/neutral, the bucking in first gear low throttle, and the drop resistor unplugged only helped so much with the slip. At this point I have all the above time and money invested right? Eel shortly before she was parked I went for an alignment and was told couldn't be done due to lca bushings destroyed. So I know better than to do and steering/suspension repair and leaving weak links so I ordered and installed new lca bushings (pressed myself), sway bar links, axles, ball joints, inner/outer tie rod ends, fsm complete struts all 4 corners, wheel bearings (also self pressed), axle shaft seals, rack and pinion bezels, and front abs sensors. Shortly before that my family had car sent to nissan for alternator, bracket, and battery as a gift. I insisted to let me and they insisted on laying nissan $900 for those 3 things. Ebay headers (for pre cat elimination not hp), test pipe, custom cut and fabbed the factory cat back tool out the bottle necks and kinks, stock own muffler (straight piped to factory muffler sounds great, performs amazing, and keeps low end torque due to muffler design. Radiator fan assembly, new tires, 5 year alignment, plugs, stereo add ons, religious 3k full synthetic oil change with gram ultra synthetic filter every time, and even have a special gas station I use that carries no ethanol supreme and I could tell they weren't lying upon first fill up. Needless to say I love my cars and have learned so much. Made mistakes too. But it's easy to see why giving up isn't an option. I have an infant daughter, I work, and am mechanically inclined but self taught mostly. The problems I'm having are cordless the only codes I show are my 02 and it's lean codes. I only have primaries, grey connectors hooked into exhaust atm, secondaries dangling freely away from hazards and hooked up, and not even the closed throttle switch code will come back. I have adjusted, readjusted, feeler gauge style datascan2 style, reset ecu, and I either end up with way high idle that won't relearn, successful relearn with light throttle surging, bucking in first, and slipping shifts. Because I couldn't get it to stop and have to drive to work which is a short drive and I had a week to either get fixed or at least figure out... my weeks up Wednesday night... I drained atf and I know it's not all of it but replaced with 1 quart lucas stop slip, and the rest valvoline full synthetic. Started checking wiring after some tests with multimeter, ended up adding ground to tps, cleaning all grounds with Drexel wire brush, crc electric cleaning all connectors, and wiring, repairing all frayed wiring, and assuming I have an open/short for closed tps traced wiring back to ecu... When I popped the connector off i found motor oil all over the end of the connector and inside ecu connector port... it was motor oil, and must have been from valve cover gasket in the past because no more leak now. I think when I did Kim job what little was in the ecu harness ran it's way to ecu... I cry cleaned it, dielectric greased ecu connector and every other one under the hood. Still same problem. Maf is the only not new part. I have Hitachi own in route from rock auto as we speak. I did for now clean mine with mad cleaner and it does appear to be working. Data Scan 2 and it's sensor monitoring is a godsend. Please help me out with advice. Trans never slipped before this. Tps adjustment is killing me. Haven't touch iacv adjustment and won't. Same goes for tb idle screw, haven't touched it and wont. 206,000 miles and compression Test from a year ago I did showed all 6 cylinders above what nissan standards were new. Oil comes out like it went in and I other than lucas trans crap and the occasional straight octane booster I don't do snake oils.

#3

Maf shipped today...

Hey you've helped me before and I just thought I'd say thanks again. I have tried a couple of the ones I have. They both lived behind over oiled k&n filters though. I can unplug them and the car dies. Datascan2 shows them reading but not sure if they're in spec. I don't trust them and went ahead and ordered new. I'm hoping but not counting on it. I have had the strangest luck with these cars. What about the tps circuit code I had thrown. When I did and continuity test on the brown tps connector before I discovered the oil buildup at the ecm connector the ground showed no resistance of course but the other outside wire 5v I believe is what it's supposed to be it had a glitch but .7xx resistance to ground which I'm assuming means a short to ground? Didn't get a chance for a retest after cleaning oil mess because it started pouring rain. Also there is a buzzing from the tranny that seems to be in conjunction with the throttle and changes pitch as the throttle is applied and let go. I noticed if the tps is I guess way out of adjustment but still within fsm allowed tolerance it will be constant even if no throttle applied.i had already planned on maf. But in the meantime while I wait I thought I'd post some of the symptoms, what's been done, and ask what else I could check. It's sucks how smooth it idles, cranks, all the money, work, and yet I'm terrified of that it's going to find a way to die. So far every overwhelming thing I've had to reach out for help, info, and advice for these 2 cars ends up being a unique problem and symptoms seem to always be bits and pieces of several different directions. That's why I'm so worried about getting this maf. I wish I'd never done the lim, took throttle body restriction out, did headers instead of replacing cats, and the k&n filters. Not to mention hitting a deer in glee was a big set back as well.

#4

Conflict resolved before new maf arrives

Granted what few mafs I do have seem to work... they are very decrepit looking, have been inline with over oiled k&n filters, and rolled around separate from their housings in parts bind I'm still keeping and installing the new own one in route. However that didn't seem to be the answer to the problem at hand. Adjusting these (2k and 2k1) tps sensors according to protocol must be done strictly and in my case working, a beautiful 11 month old, and the chaotic unpredictable schedule that comes with warming the vehicle was tedious, attempting to make adjustments cold was uneventful, and of the billions of times i had the thing adjusted but couldn't get the idle to fall within specs was confusing to say the least. Datascan 2 which has been there with me since the beginning gets a big shout out. The data display settings allowing me to view the closed throttle switch, tps voltage, and wide open tps activities made the multimeter obsolete. In the end though using both methods with the feeler gauge was starting to make me feel discouraged. I kept reading threads of people mentioning .4v and .6v being the target voltages. I kept ending up with either .4v, .6v, and high idle. On the flip side I could nail target idle, get idle relearn to successfully complete, and was technically in specs at .18v. The drawback was my trans slipping like 300,000 mile teenage driven civics, bucking in first gear like it wanted to face plant, and hesitation in park and neutral with light throttle. What seemed to be The big fix all was adjust tps without feeler gauge in pursuit of the target .4v-.6v range via datascan 2 as my gauge, after it was in spec removing the brown cable, ignoring completely the 5 second rule, I'm not sure if I went over or not but I noticed that if you didn't hurry and plug it back in the tps voltage would slowly rise to 5v. When achieved the idle would fall within spec. Now heres the last step I discovered I had been missing right after idle falls within spec, cable still disconnected, the closed throttle switch indicator in the bottom tray of datascan 2 turned red, on, or closed. When.l quit worrying about the 5 second rule, it didn't take me an hour to accidentally stumble upon this, and I didn't even use a feeler gauge to set it. I did however go back and double check the results with the feeler gauge and it was on point. The more I involve datascan 2, it's massive availability of live sensor monitoring, the more it helps me fix, prevent, and even in cases like this work around the atrocious workflow the fsm is so famous for. Datascan 2 people. It's cheap, it does keys, clears codes, timing, and most of all saves money.

#5

Granted what few mafs I do have seem to work... they are very decrepit looking, have been inline with over oiled k&n filters, and rolled around separate from their housings in parts bind I'm still keeping and installing the new own one in route. However that didn't seem to be the answer to the problem at hand. Adjusting these (2k and 2k1) tps sensors according to protocol must be done strictly and in my case working, a beautiful 11 month old, and the chaotic unpredictable schedule that comes with warming the vehicle was tedious, attempting to make adjustments cold was uneventful, and of the billions of times i had the thing adjusted but couldn't get the idle to fall within specs was confusing to say the least. Datascan 2 which has been there with me since the beginning gets a big shout out. The data display settings allowing me to view the closed throttle switch, tps voltage, and wide open tps activities made the multimeter obsolete. In the end though using both methods with the feeler gauge was starting to make me feel discouraged. I kept reading threads of people mentioning .4v and .6v being the target voltages. I kept ending up with either .4v, .6v, and high idle. On the flip side I could nail target idle, get idle relearn to successfully complete, and was technically in specs at .18v. The drawback was my trans slipping like 300,000 mile teenage driven civics, bucking in first gear like it wanted to face plant, and hesitation in park and neutral with light throttle. What seemed to be The big fix all was adjust tps without feeler gauge in pursuit of the target .4v-.6v range via datascan 2 as my gauge, after it was in spec removing the brown cable, ignoring completely the 5 second rule, I'm not sure if I went over or not but I noticed that if you didn't hurry and plug it back in the tps voltage would slowly rise to 5v. When achieved the idle would fall within spec. Now heres the last step I discovered I had been missing right after idle falls within spec, cable still disconnected, the closed throttle switch indicator in the bottom tray of datascan 2 turned red, on, or closed. When.l quit worrying about the 5 second rule, it didn't take me an hour to accidentally stumble upon this, and I didn't even use a feeler gauge to set it. I did however go back and double check the results with the feeler gauge and it was on point. The more I involve datascan 2, it's massive availability of live sensor monitoring, the more it helps me fix, prevent, and even in cases like this work around the atrocious workflow the fsm is so famous for. Datascan 2 people. It's cheap, it does keys, clears codes, timing, and most of all saves money.

And it can log wideband, so people can ghetto tune :P

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

#6

Wow at the difference...

And it can log wideband, so people can ghetto tune :P

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

#9

You mentioned wide bands il

And it can log wideband, so people can ghetto tune :P

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

edit: Oops, missed what you said. I was gonna say I'd just keep adjusting it down till it worked (which you did). I have no idea why that would cause driveability problems, though.

Are you sure maf isn't bad? lol. Anytime I've had bucking and very low throttle issues it was maf. It would run fine otherwise. TPS isn't usually that picky, given the wide range of spec.

Thread

Thread Starter

Forum

Replies

Last Post

the_3d_man

4th Generation Maxima (1995-1999)

13

05-03-2006 05:52 PM