grey99max building another 3.5

#121

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Boost it? Naw, that's too much work to boost this one - but the next one, hummmm, there might be a surprise coming. Gotta do something with the old 3.5, you know.

Cryoing parts is a whole new world for me - and I find a group of professional car builders doing it in my back yard! I'll share anything I find out on the subject.

#122

#123

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

I don't claim to be an expert on anything, but I do have experience on some things - those I share, because that's what this forum is very good at doing.

"I love you, man".

#124

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Tranny busted...

Friday night, I was getting the LandShark ready for a trip to KCIR on Saturday, and Reverse gear just quit working! I had opened up the headers and installed the larger M&H slicks, and when I wanted to back the car off the Rhino ramps, it wouldn't move. I pushed the car off the ramps then drove it around the block - all the forward gears still work fine, but no reverse. If I can't back off the trailer, I'm staying home. After three years of constant abuse, the tranny finally broke something.

I have a spare '01 AE VLSD sitting in the garage, so I'm waiting until I get the VLSD cryoed axles from 520whpNashville then I'll get the longer NISMO wheels studs, axles and spare tranny and TC installed at the same time. It's really too bad I don't have the new engine done - still waiting on some parts - but Oh Well, the tracks are opening up now and I hate to waste a track day.

I have a spare '01 AE VLSD sitting in the garage, so I'm waiting until I get the VLSD cryoed axles from 520whpNashville then I'll get the longer NISMO wheels studs, axles and spare tranny and TC installed at the same time. It's really too bad I don't have the new engine done - still waiting on some parts - but Oh Well, the tracks are opening up now and I hate to waste a track day.

#126

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

I mounted the '01 tranny up to the new short block last night, just to see about the bolt holes matching - everything seemed fine there.

#127

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

ARP not shipping

I've ordered the ARP 57mm stainless-steel exhaust studs from Jegs on 3/18/2009 and they haven't arrived yet. Just got off the phone with Jegs and they called ARP - ARP says they don't have the SS nuts for those studs and they can't ship any until May 1 2009. ( ARP P/N is 400-8035 for 16 pieces of stud/washer/nut).

Is China on strike now?

Is China on strike now?

#129

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

It's the heat. Heat steel in the presence of oxygen and it begins to oxidize. Heat steel a LOT and it rusts away quickly. Do the same thing to stainless steel and nothing much happens.

Build an engine with lots more HP than the original design planned for, and all sorts of things happen because of the additional stress - such as too much heat on the header flanges because of tons of nitrous going through the motor. Pretty soon, the nuts are rusting away, along with the studs. That's what my present motor is doing.

Stainless steel is much more forgiving in extreme temps - both in exhaust studs and in exhaust valves - so I have (or soon will have) both things on my new engine.

Build an engine with lots more HP than the original design planned for, and all sorts of things happen because of the additional stress - such as too much heat on the header flanges because of tons of nitrous going through the motor. Pretty soon, the nuts are rusting away, along with the studs. That's what my present motor is doing.

Stainless steel is much more forgiving in extreme temps - both in exhaust studs and in exhaust valves - so I have (or soon will have) both things on my new engine.

#130

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Cryo-in-a-can update.

I talked to my machinist this AM - his valve/head guy still hasn't gotten to my Cosworth heads for measuring for valve lifters - but I asked him again about the cryo-in-a-can treatment being done to transmissions. He steered me to the guy that does it around this end of the state.

http://performancecryogenics.org

He said the trick on doing a complete transmission was that he takes the entire unit down to -300*F and raises it to +300*F, which really reforms the crystal structure of the metals but does not exceed the temperature ratings of seals, which are usually rated to +350*F.

No guarantees, but he's doing it for serious racers.

http://performancecryogenics.org

He said the trick on doing a complete transmission was that he takes the entire unit down to -300*F and raises it to +300*F, which really reforms the crystal structure of the metals but does not exceed the temperature ratings of seals, which are usually rated to +350*F.

No guarantees, but he's doing it for serious racers.

#131

I talked to my machinist this AM - his valve/head guy still hasn't gotten to my Cosworth heads for measuring for valve lifters - but I asked him again about the cryo-in-a-can treatment being done to transmissions. He steered me to the guy that does it around this end of the state.

http://performancecryogenics.org

He said the trick on doing a complete transmission was that he takes the entire unit down to -300*F and raises it to +300*F, which really reforms the crystal structure of the metals but does not exceed the temperature ratings of seals, which are usually rated to +350*F.

No guarantees, but he's doing it for serious racers.

http://performancecryogenics.org

He said the trick on doing a complete transmission was that he takes the entire unit down to -300*F and raises it to +300*F, which really reforms the crystal structure of the metals but does not exceed the temperature ratings of seals, which are usually rated to +350*F.

No guarantees, but he's doing it for serious racers.

#133

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Some parts are arriving.

The cryoed VLSD axles arrived last night - they look good.

The Jegs stainless steel exhaust studs just shipped, so in a few days they should be in their new home.

The spark plug tubes for the new heads showed up over the weekend.

Still waiting for timing gears and measurements on the HR valve lifters so I can order a bunch of them and finish the heads.

EDIT This PM -got all the valve lash measurements back from the machinist - all the machined valve heights were very close to the required clearances when the four Cosworth cams were installed in the heads. I need to order 22 more HR valve lifters now, so the heads can be completely assembled. Yeah!

.

The Jegs stainless steel exhaust studs just shipped, so in a few days they should be in their new home.

The spark plug tubes for the new heads showed up over the weekend.

Still waiting for timing gears and measurements on the HR valve lifters so I can order a bunch of them and finish the heads.

EDIT This PM -got all the valve lash measurements back from the machinist - all the machined valve heights were very close to the required clearances when the four Cosworth cams were installed in the heads. I need to order 22 more HR valve lifters now, so the heads can be completely assembled. Yeah!

.

Last edited by grey99max; 04-16-2009 at 12:09 PM.

#134

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

2001 VLSD automatic installed in my '99

The gurus at Automotion in Topeka finished installing the 2001 VLSD tranny, the cryoed axles, new Edge 2800-stall TC, and the 50mm Nismo wheel studs. I picked up the car Wednesday and drove it home, then went back to family issues. Wife's parents need to move closer to civilization, so we're it! There house is sold, their new apartment is ready, and my wife and her sister are picking them up this weekend (605 miles away, in far western Nebraska). Sigh.

We figured out how to adapt the 2001 box with shifter parts from the '99 and chopped off the 2001 wiring cable and spliced in the '99 cable (since the valve bodies function identically) and I took it out for a nitrous run tonight. It works just like the '99 - pressure boost make shifts hard, and the Shift_Fast shifter performs exactly the same.

I took some photos of before and after the 2001 tranny was installed - it's not complicated. This should give the 4th gens another source of low-mileage VLSD automatics, since they were put in Maximas in 2001 and Infiniti in 2000 and 2001. Look for the RE4F04W model number.

Photos will follow.... now I gotta chop off the Nismo studs so the M/T shank nuts will tighten down.

We figured out how to adapt the 2001 box with shifter parts from the '99 and chopped off the 2001 wiring cable and spliced in the '99 cable (since the valve bodies function identically) and I took it out for a nitrous run tonight. It works just like the '99 - pressure boost make shifts hard, and the Shift_Fast shifter performs exactly the same.

I took some photos of before and after the 2001 tranny was installed - it's not complicated. This should give the 4th gens another source of low-mileage VLSD automatics, since they were put in Maximas in 2001 and Infiniti in 2000 and 2001. Look for the RE4F04W model number.

Photos will follow.... now I gotta chop off the Nismo studs so the M/T shank nuts will tighten down.

#135

The gurus at Automotion in Topeka finished installing the 2001 VLSD tranny, the cryoed axles, new Edge 2800-stall TC, and the 50mm Nismo wheel studs. I picked up the car Wednesday and drove it home, then went back to family issues. Wife's parents need to move closer to civilization, so we're it! There house is sold, their new apartment is ready, and my wife and her sister are picking them up this weekend (605 miles away, in far western Nebraska). Sigh.

We figured out how to adapt the 2001 box with shifter parts from the '99 and chopped off the 2001 wiring cable and spliced in the '99 cable (since the valve bodies function identically) and I took it out for a nitrous run tonight. It works just like the '99 - pressure boost make shifts hard, and the Shift_Fast shifter performs exactly the same.

I took some photos of before and after the 2001 tranny was installed - it's not complicated. This should give the 4th gens another source of low-mileage VLSD automatics, since they were put in Maximas in 2001 and Infiniti in 2000 and 2001. Look for the RE4F04W model number.

Photos will follow.... now I gotta chop off the Nismo studs so the M/T shank nuts will tighten down.

We figured out how to adapt the 2001 box with shifter parts from the '99 and chopped off the 2001 wiring cable and spliced in the '99 cable (since the valve bodies function identically) and I took it out for a nitrous run tonight. It works just like the '99 - pressure boost make shifts hard, and the Shift_Fast shifter performs exactly the same.

I took some photos of before and after the 2001 tranny was installed - it's not complicated. This should give the 4th gens another source of low-mileage VLSD automatics, since they were put in Maximas in 2001 and Infiniti in 2000 and 2001. Look for the RE4F04W model number.

Photos will follow.... now I gotta chop off the Nismo studs so the M/T shank nuts will tighten down.

#136

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Very nice, the 01 tranny shouldn't have been an issue to install for them, its basically the same thing, had been done here locally as well. Good to know ur making some progress. I got my block back today after being balanced, turns out Wiseco had given me one set of different rings, so now im going to wait to get those. once that is in, im going to give it to the guy to file fit, and im done. ready to assemble.

Yup, details, details, details - "it's always something". My order for HR valve lifters had to be assembled from supply depots all over the country - my supplier says he'll have the final size in from New York on the 28th - then he can ship. I also have to locate some long 6mm stainless pins for Stephen Max's cam gear set... sigh...

#137

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

HR valve lifters arrived, 6mm pins have shipped

The remaining 22 HR valve lifters arrived last night, and were delivered to my machinist to complete the Cosworth head assembly.

The long 6mm cam pins I had ordered have shipped, and should arrive May 4. These are needed for the new Stephen Max machined gear set I now have.

Hummm.. guess I need to check with the Post Office to see what has happened to my Lost Contents claim for the gear set I bought from Josh..

I think that this is all the stuff I need to begin assembling the engine.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

.

The long 6mm cam pins I had ordered have shipped, and should arrive May 4. These are needed for the new Stephen Max machined gear set I now have.

Hummm.. guess I need to check with the Post Office to see what has happened to my Lost Contents claim for the gear set I bought from Josh..

I think that this is all the stuff I need to begin assembling the engine.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood. .

#138

The remaining 22 HR valve lifters arrived last night, and were delivered to my machinist to complete the Cosworth head assembly.

The long 6mm cam pins I had ordered have shipped, and should arrive May 4. These are needed for the new Stephen Max machined gear set I now have.

Hummm.. guess I need to check with the Post Office to see what has happened to my Lost Contents claim for the gear set I bought from Josh..

I think that this is all the stuff I need to begin assembling the engine.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

.

The long 6mm cam pins I had ordered have shipped, and should arrive May 4. These are needed for the new Stephen Max machined gear set I now have.

Hummm.. guess I need to check with the Post Office to see what has happened to my Lost Contents claim for the gear set I bought from Josh..

I think that this is all the stuff I need to begin assembling the engine.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood.

I also ordered from eBay a LIM for a 350Z so I can assess the fitment for a Cosworth intake manifold, if things go that far. It's kinda big, so to use it I might have to bubble my spare hood. .

About"bubbling" your spare hood, you could perhaps go my route when I added the Z33 and MD spacer; drop the whole powertrain. It seems a bit on orthodox, but it works. The biggest concern is axle triangularlity issues. But in reality, the lowered power train reduced axle trainagluarlity since the transmission output and spindles now sit almost on the same plane (on my car).

Posts 1 and 10 of my very old Intake Manifold thread have more details. LINK

Either way, good luck.

#139

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

About"bubbling" your spare hood, you could perhaps go my route when I added the Z33 and MD spacer; drop the whole powertrain. It seems a bit on orthodox, but it works. The biggest concern is axle triangularlity issues. But in reality, the lowered power train reduced axle trainagluarlity since the transmission output and spindles now sit almost on the same plane (on my car).

Posts 1 and 10 of my very old Intake Manifold thread have more details. LINK

Posts 1 and 10 of my very old Intake Manifold thread have more details. LINK

.

. With the Cosworth heads and cams set up for deep-breathing, I'm concerned about how to pull 20% more air through the intake manifold - a SSIM, in my case. It will be a while before I can test or measure anything, after the new build is installed. I'll review your earlier work for inspirations.

.

#140

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Cosworth heads issue

The Cosworth heads are ready to be picked, along with some more glass-bead-blasted water pipes, but there was a problem with installing the HR valve lifters correctly.

Long story - short version: when Cosworth installed the inconel and stainless valves in those heads, they did cut the valve stems to OEM specs. However, the machinist assigned to this job was getting inconsistent valve lash readings, and discovered that Cosworth had not ground the valve faces to be concentric, but installed them as-is, so that if the valve was rotated in place, the valve lash might vary 1 or 2 thousands.

The machinist ran every valve through their Sunnen (?) valve grinder, which uses the valve stem as the center, and ground all valve faces correctly. Then the valve lash was consistent and did not change with valve rotation.

A good machinist is critical to a good build.

Long story - short version: when Cosworth installed the inconel and stainless valves in those heads, they did cut the valve stems to OEM specs. However, the machinist assigned to this job was getting inconsistent valve lash readings, and discovered that Cosworth had not ground the valve faces to be concentric, but installed them as-is, so that if the valve was rotated in place, the valve lash might vary 1 or 2 thousands.

The machinist ran every valve through their Sunnen (?) valve grinder, which uses the valve stem as the center, and ground all valve faces correctly. Then the valve lash was consistent and did not change with valve rotation.

A good machinist is critical to a good build.

#142

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

I got people. Absolute Automotive Machine shop in Topeka builds race engines for all sorts of cars - even Honduhs. Steve Day knows what he's doing, and his staff are good.

Doing this one right has involved a ton of small details, but they've been resolved as they come up. The non-finished valves issue was a surprise, but Absolute took it in stride - they "see that a lot" with new heads.

It's really kinda funny to see one of my heads standing next to a built BBC head. Man, those valves are BIG.

I'll pick up my heads tonight.

.

#147

Yea, a build is not as straight forward as one expects at least i didnt. this one being my first has been tough. I messed up one of the oil rings while putting in the pistons, so im waiting on that. So anxious to finish my build!!! looks like we all have delays on our projects one way or another.

#149

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Yea, a build is not as straight forward as one expects at least i didnt. this one being my first has been tough. I messed up one of the oil rings while putting in the pistons, so im waiting on that. So anxious to finish my build!!! looks like we all have delays on our projects one way or another.

#150

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Since I just picked up the Cosworth heads, pix ??

I picked up my completed set of Cosworth CNCed heads, so I took some pictures of the left head, since I'll probably never see the combustion chambers again. I thought some of these shots would be of interest to those whose are porting their heads.

These cams have the Cosworth ZK2 cams and HR valve lifters fitted to exact clearances. All valves are 1mm larger - intakes are stainless steel, exhaust valves are inconel, and titanium retainers are installed... Some shots show the intake and exhaust valve completely open, showing the 3-angle cuts behind the valves, and one shot of the stock 3.5 cam lobes compared to the ZK2 lobes. Definitely meatier.

http://i48.photobucket.com/albums/f2...9/DSCN0883.jpg

Notice I haven't installed the spark plug tubes yet...

http://i48.photobucket.com/albums/f2...9/DSCN0884.jpg

exhaust valves fully open...

http://i48.photobucket.com/albums/f2...9/DSCN0885.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0886.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0887.jpg

The intake valves - fully open..

http://i48.photobucket.com/albums/f2...9/DSCN0888.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0889.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0890.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0891.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0892.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0893.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0894.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0895.jpg

pretty long Harbor Freight 24mm wrench, eh?

http://i48.photobucket.com/albums/f2...9/DSCN0896.jpg

These cams have the Cosworth ZK2 cams and HR valve lifters fitted to exact clearances. All valves are 1mm larger - intakes are stainless steel, exhaust valves are inconel, and titanium retainers are installed... Some shots show the intake and exhaust valve completely open, showing the 3-angle cuts behind the valves, and one shot of the stock 3.5 cam lobes compared to the ZK2 lobes. Definitely meatier.

http://i48.photobucket.com/albums/f2...9/DSCN0883.jpg

Notice I haven't installed the spark plug tubes yet...

http://i48.photobucket.com/albums/f2...9/DSCN0884.jpg

exhaust valves fully open...

http://i48.photobucket.com/albums/f2...9/DSCN0885.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0886.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0887.jpg

The intake valves - fully open..

http://i48.photobucket.com/albums/f2...9/DSCN0888.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0889.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0890.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0891.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0892.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0893.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0894.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0895.jpg

pretty long Harbor Freight 24mm wrench, eh?

http://i48.photobucket.com/albums/f2...9/DSCN0896.jpg

#152

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

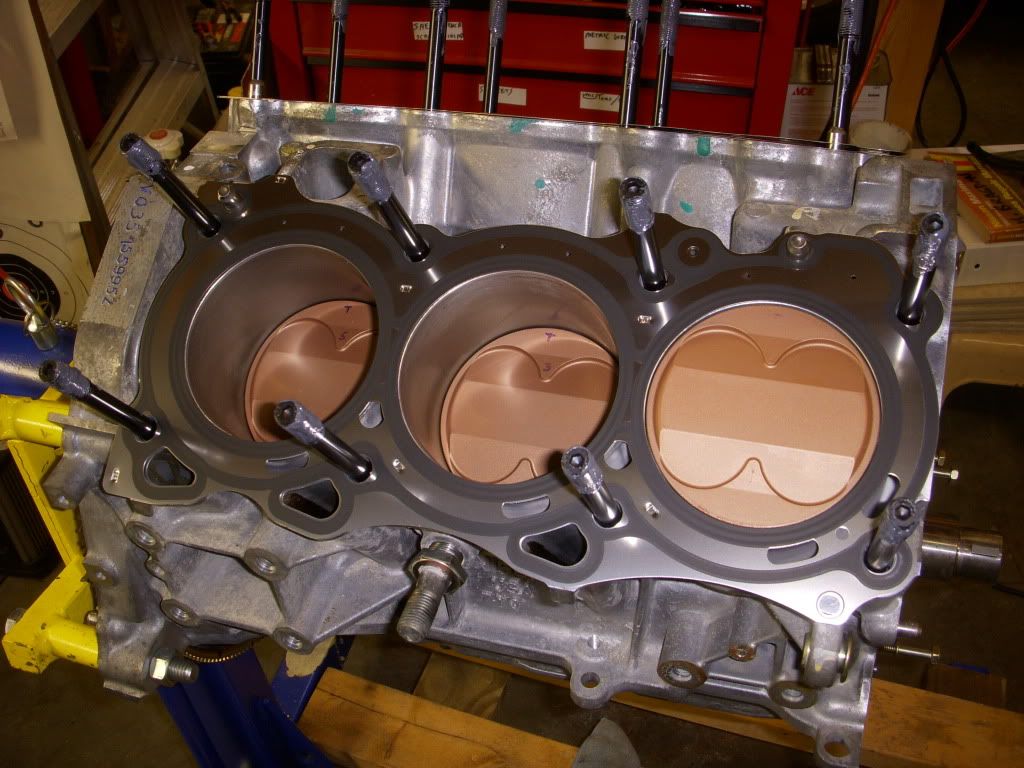

I mounted both heads on the short block last night - I've gotten all the head studs installed and "anti-seized" them with the copper Permatex stuff. The final torque-down will wait until I port-match the LIM to the heads, since the intake ports are 2mm larger than stock. I got the six spark plug tubes installed after a conversation with Cosworth to verify the correct part. I froze the tubes, put some ARP moly on the tube ends and the head openings and tapped in with a rubber mallet. Never a dull moment.....

The white insulated eBay intake gaskets seem too thick for this setup - the thicker gasket causes an upwards movement of the LIM ports so they don't align with the head ports. I'll probably use the OEM intake gaskets instead.

I'm taking pix of all this as I progress, so at some point I'll post new pix. I still need to decide on a color scheme for the engine - I'm leaning towards a blue ceramic engine paint for the timing covers, water piping, and LIM-UIM.

The 2005 Maxima valve covers I was going to use are covered with "fried" oil that even acetone won't take off, so I ordered a new pair from Peoria Nissan.

The white insulated eBay intake gaskets seem too thick for this setup - the thicker gasket causes an upwards movement of the LIM ports so they don't align with the head ports. I'll probably use the OEM intake gaskets instead.

I'm taking pix of all this as I progress, so at some point I'll post new pix. I still need to decide on a color scheme for the engine - I'm leaning towards a blue ceramic engine paint for the timing covers, water piping, and LIM-UIM.

The 2005 Maxima valve covers I was going to use are covered with "fried" oil that even acetone won't take off, so I ordered a new pair from Peoria Nissan.

#153

The NWP Engineering LIM Thermal Intake Spacers are 1/16" thick. The 2 white gaskets from ebay are made of a Nylon or Teflon, which will not hold up very long. I tested these materials long before NWP Engineering was started and after 6 months, the spacers lost their shape and softened preventing you from being able to reuse them. Plus, knowing that they softened and misshaped in such a short amount of time, I wouldn't trust this material at all.

But since the two NWP LIM spacers are 1/16" thick, in order to perfectly match them to my custom heads, I had to do port work on the heads and LIM intake ports after taking accurate measurements to make sure everything matches once installed. So for you since you don't plan to port the Cosworth heads, you'll have to use the stock gaskets.

Also, the ebay gaskets are just copies of OEM gaskets and are of course thicker. So once installed, nothing will line up properly. The NWP Engineering gaskets are port matched to the stock LIM ports. So once installed there is no change in how the air flows since there is already a mismatch from the factory. It's better to have the spacer port matched to one side rather than none at all. But if anybody decided to do massive headwork and port match the lower intake manifold to the heads, then the spacers will need to be matched as well, which is very easy to do.

So the heads are installed, just not yet torqued? It's nice to finally see the heads on the block after staring at the bare block all winter long. It was for me.

It was for me.

But since the two NWP LIM spacers are 1/16" thick, in order to perfectly match them to my custom heads, I had to do port work on the heads and LIM intake ports after taking accurate measurements to make sure everything matches once installed. So for you since you don't plan to port the Cosworth heads, you'll have to use the stock gaskets.

Also, the ebay gaskets are just copies of OEM gaskets and are of course thicker. So once installed, nothing will line up properly. The NWP Engineering gaskets are port matched to the stock LIM ports. So once installed there is no change in how the air flows since there is already a mismatch from the factory. It's better to have the spacer port matched to one side rather than none at all. But if anybody decided to do massive headwork and port match the lower intake manifold to the heads, then the spacers will need to be matched as well, which is very easy to do.

So the heads are installed, just not yet torqued? It's nice to finally see the heads on the block after staring at the bare block all winter long.

It was for me.

It was for me.

#154

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

The NWP Engineering LIM Thermal Intake Spacers are 1/16" thick. The 2 white gaskets from ebay are made of a Nylon or Teflon, which will not hold up very long. I tested these materials long before NWP Engineering was started and after 6 months, the spacers lost their shape and softened preventing you from being able to reuse them. Plus, knowing that they softened and misshaped in such a short amount of time, I wouldn't trust this material at all.

But since the two NWP LIM spacers are 1/16" thick, in order to perfectly match them to my custom heads, I had to do port work on the heads and LIM intake ports after taking accurate measurements to make sure everything matches once installed. So for you since you don't plan to port the Cosworth heads, you'll have to use the stock gaskets.

Also, the ebay gaskets are just copies of OEM gaskets and are of course thicker. So once installed, nothing will line up properly. The NWP Engineering gaskets are port matched to the stock LIM ports. So once installed there is no change in how the air flows since there is already a mismatch from the factory. It's better to have the spacer port matched to one side rather than none at all. But if anybody decided to do massive headwork and port match the lower intake manifold to the heads, then the spacers will need to be matched as well, which is very easy to do.

So the heads are installed, just not yet torqued? It's nice to finally see the heads on the block after staring at the bare block all winter long. It was for me.

It was for me.

But since the two NWP LIM spacers are 1/16" thick, in order to perfectly match them to my custom heads, I had to do port work on the heads and LIM intake ports after taking accurate measurements to make sure everything matches once installed. So for you since you don't plan to port the Cosworth heads, you'll have to use the stock gaskets.

Also, the ebay gaskets are just copies of OEM gaskets and are of course thicker. So once installed, nothing will line up properly. The NWP Engineering gaskets are port matched to the stock LIM ports. So once installed there is no change in how the air flows since there is already a mismatch from the factory. It's better to have the spacer port matched to one side rather than none at all. But if anybody decided to do massive headwork and port match the lower intake manifold to the heads, then the spacers will need to be matched as well, which is very easy to do.

So the heads are installed, just not yet torqued? It's nice to finally see the heads on the block after staring at the bare block all winter long.

It was for me.

It was for me.? The Cosworth heads are already fully ported and flow-benched ? I'm just concerned about still porting the LIM to match - and OEM gaskets make the most sense to me. Since I finished the short-block in March '09, this project has been going on for about 2 1/2 more months, and yes, it's good to see the heads assembled. I've had to gather a lot of small parts because the Cosworth heads were new castings.

It continues.....

#155

Your comments match my feelings about the eBay gaskets - they're not very rugged, and testing under heat would probably show deformation quickly. I like to have products in hand to test them.

? The Cosworth heads are already fully ported and flow-benched ? I'm just concerned about still porting the LIM to match - and OEM gaskets make the most sense to me. Since I finished the short-block in March '09, this project has been going on for about 2 1/2 more months, and yes, it's good to see the heads assembled. I've had to gather a lot of small parts because the Cosworth heads were new castings.

It continues.....

? The Cosworth heads are already fully ported and flow-benched ? I'm just concerned about still porting the LIM to match - and OEM gaskets make the most sense to me. Since I finished the short-block in March '09, this project has been going on for about 2 1/2 more months, and yes, it's good to see the heads assembled. I've had to gather a lot of small parts because the Cosworth heads were new castings.

It continues.....

Every part of my intake is perfectly port matched from the MAF adapter, TB, Elbow, UIM, LIM, and heads. All with the NWP Spacers installed of course.

But for you, if you wanted to use Thermal Intake Spacers in between the heads and LIM, you just have to match the spacers to your Cosworth heads and port a lot of material from the LIM since the ports on the bottom of the LIM is drastically undersized. If you want to go this route, I can give you a couple tips on how I set everything up in order to make my scribe marks with the 1/16" spacer installed.

And if you are interested in getting a set of NWP Spacers, the price has been reduced for the Pre-MAXUS 09 sale.

#156

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

The Cosworth heads aren't ported with a 1/16" spacer in mind. What I did was put masking tape around the studs on the head to keep the LIM centered. Then I took all my measurements and made my scribe marks with the 1/16" spacer. Some material needed to be removed from the intake port on the head in one direction, and the LIM needed material removed on the other side of the intake port. I had to port both the heads and the LIM in order to meet the spacers half way. I hope you know what I mean. Everything was gasket matched using the OEM gasket as a template.

Every part of my intake is perfectly port matched from the MAF adapter, TB, Elbow, UIM, LIM, and heads. All with the NWP Spacers installed of course.

But for you, if you wanted to use Thermal Intake Spacers in between the heads and LIM, you just have to match the spacers to your Cosworth heads and port a lot of material from the LIM since the ports on the bottom of the LIM is drastically undersized. If you want to go this route, I can give you a couple tips on how I set everything up in order to make my scribe marks with the 1/16" spacer installed.

And if you are interested in getting a set of NWP Spacers, the price has been reduced for the Pre-MAXUS 09 sale.

Every part of my intake is perfectly port matched from the MAF adapter, TB, Elbow, UIM, LIM, and heads. All with the NWP Spacers installed of course.

But for you, if you wanted to use Thermal Intake Spacers in between the heads and LIM, you just have to match the spacers to your Cosworth heads and port a lot of material from the LIM since the ports on the bottom of the LIM is drastically undersized. If you want to go this route, I can give you a couple tips on how I set everything up in order to make my scribe marks with the 1/16" spacer installed.

And if you are interested in getting a set of NWP Spacers, the price has been reduced for the Pre-MAXUS 09 sale.

It was the one thing I didn't photograph because I promptly taped it up for some Duplicolor hi-temp ceramic primer. I'm going to try a medium blue paint on the 350Z LIM to see how that looks, before doing the rest of the parts.

I've been porting heads a while - first time was a set of Ford Y-block Thunderbird heads with Pontiac valves in about 1963 - and that was done on cast iron heads with carbide cutting stones and a drill. Funny how some things don't change, eh?

Some more photos:

Note the HR head gaskets..

http://i48.photobucket.com/albums/f2...9/DSCN0902.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0906.jpg

350Z LIM:

http://i48.photobucket.com/albums/f2...9/DSCN0907.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0908.jpg

ARP studs peeking up:

http://i48.photobucket.com/albums/f2...9/DSCN0910.jpg

Got the spark plug tubes in:

http://i48.photobucket.com/albums/f2...9/DSCN0911.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0912.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0913.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0914.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0915.jpg

Heads on the block:

http://i48.photobucket.com/albums/f2...9/DSCN0916.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0919.jpg

Peekin down a hole:

http://i48.photobucket.com/albums/f2...9/DSCN0921.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0924.jpg

http://i48.photobucket.com/albums/f2...9/DSCN0925.jpg

Haven't torqued down anything yet...

#158

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

It's interesting to watch the development of the LS-series engines in Engine Masters, Car Craft, and Hot Rod magazines... maybe for Xmas....

#159

Very nice!

With all my port work and headwork, I use a series of different bits. If I have to remove a lot of material, I'll start with a carbide cutting burr and switch to a 40 grit sand paper cartridge roll. I like the cartridge rolls much better since they last quite a while. Then I switch to a new 80 grit. Once it wears down slightly, it makes a smoother surface. And then depending what part of the intake tract I'm porting, I'll switch to the series of crossbuffs to put a polish on it. But for the intake ports on the heads, I stopped at 80 grit since it's after the fuel injector spray. Everything else gets polished.

Standard Abrasives makes a pretty good starter kit. I order all my parts through Summitracing in individual bulk boxes when the stock of a certain bit starts getting low. I do port work through NWP for different customers. So I go through quite a lot of bits when I'm doing a lot of work.

Thanks for all those pics.

With all my port work and headwork, I use a series of different bits. If I have to remove a lot of material, I'll start with a carbide cutting burr and switch to a 40 grit sand paper cartridge roll. I like the cartridge rolls much better since they last quite a while. Then I switch to a new 80 grit. Once it wears down slightly, it makes a smoother surface. And then depending what part of the intake tract I'm porting, I'll switch to the series of crossbuffs to put a polish on it. But for the intake ports on the heads, I stopped at 80 grit since it's after the fuel injector spray. Everything else gets polished.

Standard Abrasives makes a pretty good starter kit. I order all my parts through Summitracing in individual bulk boxes when the stock of a certain bit starts getting low. I do port work through NWP for different customers. So I go through quite a lot of bits when I'm doing a lot of work.

Thanks for all those pics.

#160

LandShark has Cosworth

Thread Starter

iTrader: (12)

Join Date: Jan 2004

Location: Topeka, KS

Posts: 4,327

Very nice!

With all my port work and headwork, I use a series of different bits. If I have to remove a lot of material, I'll start with a carbide cutting burr and switch to a 40 grit sand paper cartridge roll. I like the cartridge rolls much better since they last quite a while. Then I switch to a new 80 grit. Once it wears down slightly, it makes a smoother surface. And then depending what part of the intake tract I'm porting, I'll switch to the series of crossbuffs to put a polish on it. But for the intake ports on the heads, I stopped at 80 grit since it's after the fuel injector spray. Everything else gets polished.

Standard Abrasives makes a pretty good starter kit. I order all my parts through Summitracing in individual bulk boxes when the stock of a certain bit starts getting low. I do port work through NWP for different customers. So I go through quite a lot of bits when I'm doing a lot of work.

Thanks for all those pics.

With all my port work and headwork, I use a series of different bits. If I have to remove a lot of material, I'll start with a carbide cutting burr and switch to a 40 grit sand paper cartridge roll. I like the cartridge rolls much better since they last quite a while. Then I switch to a new 80 grit. Once it wears down slightly, it makes a smoother surface. And then depending what part of the intake tract I'm porting, I'll switch to the series of crossbuffs to put a polish on it. But for the intake ports on the heads, I stopped at 80 grit since it's after the fuel injector spray. Everything else gets polished.

Standard Abrasives makes a pretty good starter kit. I order all my parts through Summitracing in individual bulk boxes when the stock of a certain bit starts getting low. I do port work through NWP for different customers. So I go through quite a lot of bits when I'm doing a lot of work.

Thanks for all those pics.

I've already checked the exhaust ports and they matched the header plates pretty well, so no real work needed there. Cosworth did not open up the exhaust ports beyond the stock opening, so the present 1-5/8" OD tubes will be fine for the new engine.

I will start off with the present SSIM manifold, but if the new engine performs well, I'll look at going to something with less restrictions in the intake path. The Jenvey ITB packages look awfully good.... maybe the Xmas after next...

.